The global automotive aftermarket parts industry is experiencing robust expansion, driven by rising vehicle ownership, increasing average vehicle age, and growing demand for cost-effective replacements. According to a report by Grand View Research, the global automotive aftermarket was valued at USD 641.6 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.7% from 2023 to 2030. This surge is further fueled by technological advancements, heightened focus on vehicle maintenance, and the proliferation of e-commerce platforms simplifying part distribution.

Within this dynamic landscape, Champion (Champ) auto parts has emerged as a trusted name, with several manufacturers specializing in high-performance ignition systems, filters, and engine components. As demand for reliable and durable aftermarket solutions continues to rise—particularly in regions like North America and Asia-Pacific—identifying the top manufacturers behind Champ products becomes critical for both consumers and industry professionals. Based on market presence, innovation, distribution strength, and customer reviews, the following five manufacturers stand out as the leading producers of Champ auto parts.

Top 5 Champ Auto Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

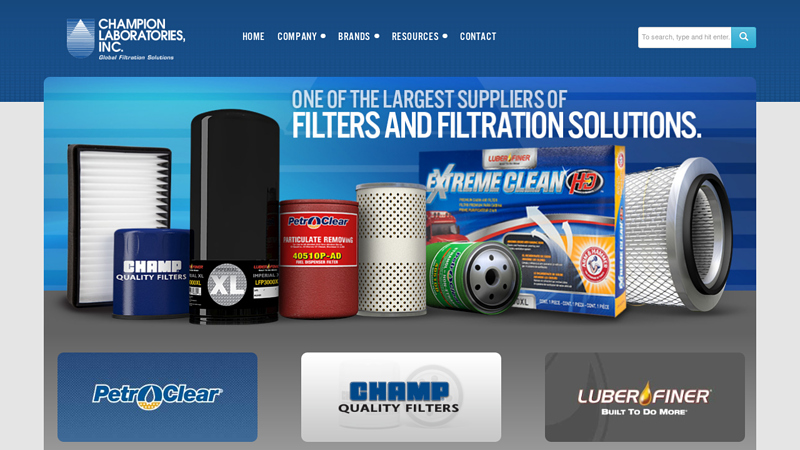

#1 Champion Laboratories Inc.

Domain Est. 1998

Website: champlabs.com

Key Highlights: At Champion Laboratories, Inc., we combine state-of-the-art filter technology with dedicated people to create an unbeatable customer experience….

#2 Champion Auto Parts

Domain Est. 2002

Website: championautoparts.com

Key Highlights: The legend of Champion auto parts lives in through our innovative, time-tested, and quality replacement parts. No matter what you drive, make it a Champion….

#3 DRiV: Elevating The Ride Experience

Domain Est. 2002

Website: driv.com

Key Highlights: DRiV is a leading global supplier of innovative light and commercial vehicle products and services, ready to serve you….

#4 Champion Power Equipment

Domain Est. 2003

Website: championpowerequipment.com

Key Highlights: From generators to log splitters, Champion Power Equipment delivers reliable power to make your life easier—at home, work, or play….

#5 Champ Automotive Products

Domain Est. 2021 | Founded: 1981

Website: champautomotiveproducts.com

Key Highlights: Champ was founded in 1981 and was the first company to offer a competitive post-based system for uni-body repair….

Expert Sourcing Insights for Champ Auto Parts

H2: Market Trends for Champ Auto Parts in 2026

As the automotive aftermarket industry evolves rapidly, Champ Auto Parts is positioned to navigate a dynamic landscape shaped by technological advancements, shifting consumer behaviors, and macroeconomic factors. The following analysis outlines key market trends expected to influence Champ Auto Parts in 2026:

1. Growth in Electric Vehicle (EV) Aftermarket Demand

By 2026, the global EV fleet is projected to surpass 70 million vehicles, driving demand for EV-specific components such as battery management systems, power electronics, and regenerative braking parts. While Champ Auto Parts has traditionally focused on internal combustion engine (ICE) vehicles, the company faces increasing pressure to expand its product portfolio to include EV-compatible parts. Strategic partnerships with EV component manufacturers and investment in R&D will be critical to capturing this emerging segment.

2. Expansion of E-Commerce and Digital Retail Channels

Online sales of auto parts are expected to account for over 30% of the aftermarket by 2026. Consumers increasingly prefer the convenience of digital platforms, mobile apps, and AI-driven part matching tools. Champ Auto Parts must enhance its e-commerce infrastructure, improve user experience, and integrate omnichannel capabilities—such as click-and-collect and real-time inventory tracking—to remain competitive against digital-first rivals like RockAuto and Amazon Automotive.

3. Increased Focus on Sustainability and Circular Economy

Environmental regulations and consumer preferences are pushing the auto industry toward sustainability. In 2026, demand for remanufactured, recycled, and eco-friendly parts is expected to rise. Champ Auto Parts can leverage this trend by promoting certified remanufactured components, reducing packaging waste, and launching take-back programs for used parts. Sustainability initiatives will not only improve brand image but may also lead to cost savings and regulatory compliance advantages.

4. Supply Chain Resilience and Localization

Ongoing geopolitical tensions and supply chain disruptions have highlighted the risks of global sourcing. By 2026, many auto parts suppliers are expected to adopt nearshoring or regional production models. Champ Auto Parts should evaluate its supply chain strategy to reduce dependency on single-source suppliers, increase inventory buffering for critical SKUs, and explore partnerships with North American manufacturers to improve delivery times and reduce logistics costs.

5. Labor Shortages and DIY Market Shifts

The automotive repair sector continues to face a shortage of skilled technicians, pushing more vehicle owners toward DIY repairs. This trend benefits retailers offering detailed installation guides, video tutorials, and user-friendly diagnostic tools. Champ Auto Parts can capitalize on this by enhancing its educational content, expanding its tool rental programs, and offering subscription-based maintenance kits tailored to popular vehicle models.

6. Data-Driven Inventory and Demand Forecasting

Advanced analytics and AI-powered forecasting tools will play a pivotal role in optimizing inventory in 2026. By leveraging real-time sales data, vehicle registration trends, and predictive maintenance algorithms, Champ Auto Parts can improve stock accuracy, reduce overstocking of obsolete parts, and increase inventory turnover. Integration with OEM recall data and telematics from connected cars will further refine demand planning.

Conclusion

In 2026, Champ Auto Parts must embrace digital transformation, sustainability, and product innovation to thrive in a competitive and rapidly changing market. By proactively addressing EV adoption, enhancing online customer experiences, and building a resilient supply chain, the company can strengthen its market position and drive long-term growth in the evolving automotive aftermarket.

Common Pitfalls When Sourcing Auto Parts from China (Quality, IP)

Sourcing auto parts from China can offer significant cost advantages, but it also comes with notable risks—particularly in the areas of quality control and intellectual property (IP) protection. Being aware of these pitfalls is crucial to ensuring a successful and secure supply chain.

Quality Inconsistencies and Substandard Materials

One of the most frequent challenges is inconsistent product quality. Suppliers may provide excellent samples but then deliver subpar production batches. This can stem from the use of inferior materials, lack of standardized manufacturing processes, or inadequate quality control systems. Parts that fail to meet safety or performance standards can lead to vehicle malfunctions, recalls, or legal liabilities, especially in regulated markets like North America or Europe.

Lack of Certification and Compliance

Many Chinese suppliers may not proactively comply with international automotive standards such as ISO/TS 16949 (now IATF 16949), ISO 9001, or region-specific requirements (e.g., DOT, ECE). Sourcing parts without proper certification increases the risk of non-compliance, customs delays, or rejection by end customers. Verifying compliance documentation and conducting third-party audits are essential but often overlooked steps.

Intellectual Property Infringement Risks

China’s IP enforcement has improved, but risks remain high. Suppliers may reverse-engineer your designs or use your specifications to produce and sell identical parts to competitors. Without robust legal safeguards—such as registered trademarks, patents, and well-drafted contracts with confidentiality and non-compete clauses—your proprietary designs can be easily copied or leaked.

Weak Contract Enforcement and Legal Recourse

Even with a contract in place, enforcing IP rights or quality clauses in China can be challenging. Local legal systems may favor domestic companies, and litigation can be time-consuming and costly. Dispute resolution mechanisms must be clearly defined in contracts, ideally with arbitration clauses specifying neutral venues like Hong Kong or Singapore.

Supply Chain Opacity and Tiered Subcontracting

Some suppliers outsource production to unauthorized subcontractors without disclosure, leading to loss of control over quality and IP. This lack of transparency makes it difficult to trace component origins, increasing exposure to counterfeit parts or unethical labor practices.

Language and Communication Barriers

Misunderstandings due to language differences or cultural nuances can result in incorrect specifications, delayed shipments, or unmet expectations. Relying solely on English translations of technical documents or contracts without local expertise increases the risk of errors.

Counterfeit and Grey Market Parts

The automotive aftermarket in China includes a significant volume of counterfeit or grey market parts. Unintentionally sourcing from these channels can damage brand reputation and lead to safety issues. Due diligence, including factory audits and supply chain mapping, is essential to avoid these pitfalls.

By recognizing these challenges early and implementing strong supplier vetting, quality assurance protocols, and IP protection strategies, businesses can mitigate risks and build reliable, long-term sourcing partnerships in China.

Logistics & Compliance Guide for Champ Auto Parts

This guide outlines the core logistics and compliance procedures for Champ Auto Parts to ensure efficient operations, regulatory adherence, and customer satisfaction. All employees involved in procurement, warehousing, transportation, and customer service must follow these standards.

1. Shipping & Receiving Procedures

All inbound and outbound shipments must be processed through the designated receiving and dispatch areas during operational hours. Receiving staff must verify purchase order numbers, count items, and inspect for damage upon arrival. Any discrepancies or damaged goods must be documented immediately using the Damage Report Form and reported to the Logistics Manager. Outbound shipments require double-checking against the sales order, proper labeling with tracking information, and confirmation in the inventory management system before dispatch.

2. Inventory Management & Warehousing

Champ Auto Parts maintains a centralized inventory tracking system (e.g., ERP/WMS) for real-time stock visibility. All inventory must be stored according to part type, size, and sensitivity, with high-turnover items placed in easily accessible locations. Stock rotation follows the First-In, First-Out (FIFO) principle to minimize obsolescence. Weekly cycle counts are conducted by warehouse staff, with full physical audits scheduled quarterly. Any inventory variances must be investigated and reported to the Inventory Controller.

3. Transportation & Carrier Management

Approved carriers must meet Champ Auto Parts’ safety, reliability, and insurance requirements. All shipments must be tendered with accurate weight, dimensions, and hazardous material declarations (if applicable). Expedited, ground, and freight shipments are selected based on cost, delivery timeline, and customer requirements. Tracking information must be shared with customers within one hour of shipment confirmation. Carrier performance is reviewed quarterly using metrics such as on-time delivery rate, damage rate, and claim resolution time.

4. Customs & International Compliance

For cross-border shipments, all documentation (commercial invoices, packing lists, certificates of origin) must be accurate and compliant with destination country regulations. The Compliance Officer is responsible for classifying parts under the correct HS codes and ensuring adherence to import/export laws, including ITAR, EAR, and local automotive regulations. Prohibited items (e.g., certain catalytic converters, unapproved emissions parts) must not be shipped without proper authorization. Records of international transactions must be retained for a minimum of five years.

5. Regulatory & Environmental Compliance

Champ Auto Parts complies with all applicable environmental regulations, particularly regarding the handling and disposal of hazardous automotive materials (e.g., batteries, oil filters, brake fluid). Used parts and packaging materials must be recycled or disposed of according to local, state, and federal laws. SDS (Safety Data Sheets) must be maintained for all hazardous substances in the warehouse. Employees handling such materials must complete annual safety training.

6. Documentation & Recordkeeping

All logistics and compliance-related documents—including bills of lading, customs forms, inspection reports, and training records—must be securely stored digitally with backup protocols. Hard copies, where required, must be filed in labeled binders accessible to authorized personnel only. The Document Control Manager oversees retention schedules and ensures audit readiness at all times.

7. Incident Response & Audits

In the event of a logistics failure (e.g., delayed shipment, lost goods, compliance violation), staff must escalate the issue immediately via the Incident Reporting Portal. A root cause analysis will be conducted, and corrective actions documented. Internal compliance audits occur semi-annually; external audits (including carrier and regulatory) are managed by the Compliance Department. All findings must be addressed within 30 days of reporting.

8. Employee Training & Responsibilities

All logistics and warehouse personnel must complete onboarding training covering safety protocols, WMS usage, and compliance standards. Refresher training is conducted annually. Each employee is responsible for reporting unsafe conditions, non-compliant practices, or process inefficiencies to their supervisor. Accountability ensures the integrity of Champ Auto Parts’ supply chain operations.

Conclusion on Sourcing Champ Auto Parts

Sourcing CHAMP auto parts presents a reliable and cost-effective solution for obtaining high-quality replacement components for various vehicle makes and models. As a trusted aftermarket brand, CHAMP offers a wide range of products—including sensors, ignition parts, and emission controls—that meet or exceed OEM specifications, ensuring compatibility, durability, and consistent performance.

One of the key advantages of sourcing CHAMP parts is the balance between affordability and quality. Their rigorous testing standards and ISO-certified manufacturing processes provide confidence in part reliability, helping reduce comebacks and customer complaints. Additionally, CHAMP’s extensive distribution network and availability through major auto parts retailers make these components easy to access for repair shops, mechanics, and DIY enthusiasts alike.

In conclusion, sourcing CHAMP auto parts is a smart choice for those seeking dependable performance and value without compromising on quality. By choosing CHAMP, automotive professionals and consumers can maintain vehicle efficiency and safety while managing repair costs effectively.