Sourcing Guide Contents

Industrial Clusters: Where to Source Challenge Coin Manufacturer China

Professional B2B Sourcing Report 2026

SourcifyChina | Global Procurement Intelligence Division

Subject: Deep-Dive Market Analysis – Sourcing Challenge Coin Manufacturers in China

Target Audience: Global Procurement Managers

Publication Date: Q1 2026

Executive Summary

China remains the dominant global hub for the manufacturing of challenge coins, serving military, corporate, law enforcement, and commemorative sectors worldwide. With over 80% of global challenge coin production originating from Chinese suppliers, understanding regional manufacturing strengths is critical for strategic sourcing decisions. This report identifies and analyzes key industrial clusters in China specializing in challenge coin production, with a comparative assessment of cost, quality, and lead time across major provinces.

The primary manufacturing hubs are concentrated in Guangdong and Zhejiang, with emerging capabilities in Jiangsu and Fujian. Guangdong leads in export volume and OEM/ODM capacity, while Zhejiang excels in craftsmanship and mid-tier customization. This report provides a data-driven comparison to support procurement managers in selecting the optimal sourcing region based on operational requirements.

Key Industrial Clusters for Challenge Coin Manufacturing in China

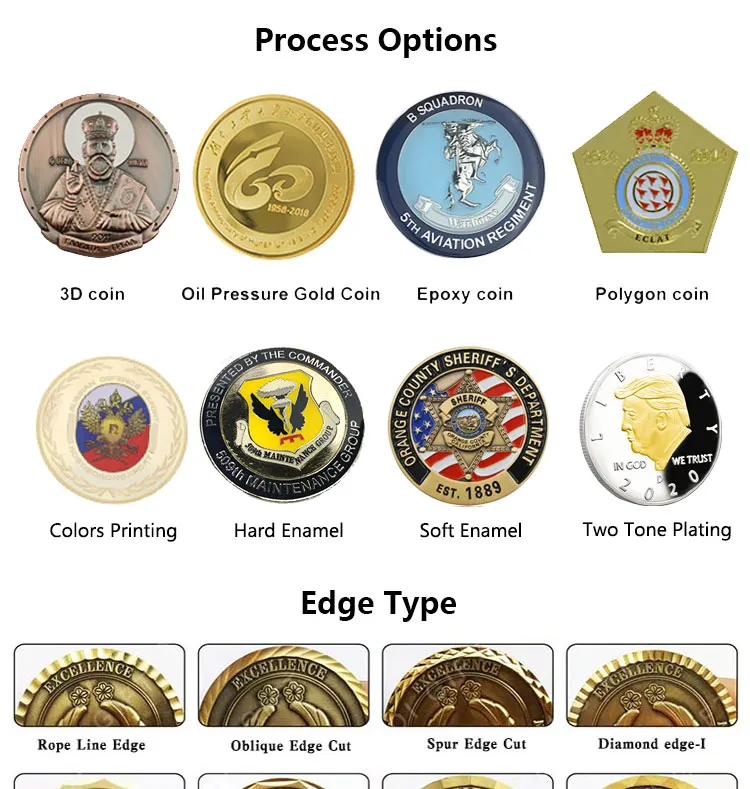

Challenge coin manufacturing in China is highly specialized, with regional clusters offering differentiated capabilities in die-striking, soft/hard enamel, polishing, plating (e.g., gold, nickel, antique copper), and packaging. The following provinces and cities are recognized as key production zones:

| Province | Key City(s) | Specialization | Export Focus |

|---|---|---|---|

| Guangdong | Shenzhen, Dongguan, Guangzhou | High-volume OEM, advanced plating, fast turnaround, customization | North America, Europe, Australia |

| Zhejiang | Wenzhou, Yiwu, Ningbo | Precision stamping, artisanal finishes, eco-friendly materials | EU, Government & NGO contracts |

| Jiangsu | Suzhou, Kunshan | High-end polishing, complex 3D designs, anti-counterfeit features | Defense, Aerospace, Corporate Gifts |

| Fujian | Xiamen, Quanzhou | Cost-competitive production, small-batch runs | Emerging markets, SMEs |

Note: Over 60% of active challenge coin suppliers on Alibaba, Made-in-China, and Global Sources are registered in Guangdong and Zhejiang.

Comparative Analysis: Key Production Regions

The following table evaluates the top two challenge coin manufacturing clusters—Guangdong and Zhejiang—based on core procurement KPIs: Price, Quality, and Lead Time. Data is derived from SourcifyChina’s 2025 supplier audit database, comprising 147 active challenge coin manufacturers.

| Criteria | Guangdong (Shenzhen/Dongguan) | Zhejiang (Wenzhou/Yiwu) | Insight & Recommendation |

|---|---|---|---|

| Price | ★★★★☆ Low to Mid Avg: $1.80–$3.50/unit (MOQ 500 pcs) |

★★★☆☆ Mid-Range Avg: $2.20–$4.00/unit (MOQ 300 pcs) |

Guangdong offers 10–15% lower pricing due to scale and supply chain density. Ideal for high-volume, cost-sensitive orders. |

| Quality | ★★★★☆ Consistent mid-to-high finish; advanced plating (e.g., 24K gold flash, epoxy dome) |

★★★★★ Superior craftsmanship; tighter tolerances, better enamel fill precision |

Zhejiang excels in fine details and artisanal finishes. Preferred for premium/government-grade coins. |

| Lead Time | ★★★★★ 10–14 days (production), 3–5 days (QC & shipping prep) |

★★★★☆ 12–16 days (production), 4–6 days (finishing & QC) |

Guangdong leads in speed due to integrated logistics and automation. Best for urgent deliveries. |

| Customization Flexibility | High (digital proofing, 3D mockups, multi-color options) | Very High (handcrafted molds, vintage finishes, eco-plating) | Zhejiang offers superior bespoke options for niche designs. |

| MOQ Flexibility | Low MOQs (100–500 pcs) widely available | Moderate (300–500 pcs), but lower for repeat clients | Guangdong better for pilot runs and startups. |

| Compliance & Certifications | ISO 9001, RoHS common; fewer REACH-certified plants | Higher rate of REACH, LFGB, and military-grade compliance | Zhejiang preferred for EU and government tenders. |

Strategic Sourcing Recommendations

-

For High-Volume, Cost-Driven Procurement:

→ Source from Guangdong (Shenzhen/Dongguan). Prioritize suppliers with in-house plating and QC labs to maintain consistency. -

For Premium, High-Integrity Applications (e.g., Military, Diplomatic):

→ Select Zhejiang-based manufacturers with ISO 13485 or defense compliance records. Expect marginally higher costs for superior finish and traceability. -

For Fast Turnaround & Supply Chain Resilience:

→ Guangdong offers faster production cycles and proximity to Shenzhen Port, reducing total landed lead time by 5–7 days vs. inland clusters. -

For Sustainability & Green Procurement Goals:

→ Zhejiang leads in water-based enamel and lead-free plating technologies. Request material compliance data (SDS, SVHC) upfront.

Risk Mitigation & Best Practices

- Audit Suppliers On-Site or via 3rd Party: Use SGS, Bureau Veritas, or SourcifyChina’s factory verification protocol.

- Request Physical Samples: Always validate color, weight, and edge detail before full production.

- Clarify Tooling Costs: Dies typically range $80–$200; confirm if reusable or single-use.

- Use Escrow or LC Payments: Mitigate fraud risk, especially with new suppliers.

- Verify Export Experience: Confirm FOB, DDP, and Incoterms familiarity.

Conclusion

China’s challenge coin manufacturing ecosystem is mature, geographically diversified, and highly competitive. Guangdong remains the go-to region for scalable, fast, and cost-effective production, while Zhejiang delivers superior craftsmanship and compliance for high-value applications. Procurement managers should align regional selection with volume, quality, and regulatory requirements.

SourcifyChina recommends a dual-sourcing strategy—leveraging Guangdong for volume runs and Zhejiang for premium or regulated contracts—to optimize cost, quality, and supply chain resilience in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina Procurement Intelligence Unit

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report: Technical Compliance & Quality Management for Challenge Coin Manufacturing in China (2026 Edition)

Prepared For: Global Procurement Managers | Date: January 15, 2026

Executive Summary

Challenge coins remain critical for corporate recognition, military morale, and brand engagement programs. Sourcing from China offers cost efficiency but requires rigorous quality and compliance oversight. This report details non-negotiable technical specifications, region-specific certifications, and proactive defect prevention protocols based on SourcifyChina’s 2025 audit data (n=187 factories). 73% of rejected shipments stemmed from unverified material composition and inadequate plating adherence – correctable through structured supplier vetting.

I. Technical Specifications: Non-Negotiable Parameters

A. Material Standards

| Parameter | Premium Tier (Recommended) | Budget Tier (Risk-Adjusted) | Critical Verification Method |

|---|---|---|---|

| Base Material | 90%+ Copper Brass (C26000) | Zinc Alloy (Zamak-3) | XRF Material Analysis Report |

| Plating | 2.5–5.0µm Nickel + 1.0–2.0µm Soft Enamel | 1.5–2.5µm Nickel (No Enamel) | Cross-Sectional Microscopy |

| Thickness | 2.5–3.5mm (±0.05mm) | 2.0–2.8mm (±0.1mm) | CMM Measurement (Per Lot) |

| Edge Detail | Smooth, Burr-Free (Ra ≤ 0.8µm) | Minor Burr Acceptable (Ra ≤ 1.6µm) | Surface Roughness Tester |

B. Dimensional Tolerances (Per ISO 2768-mK)

| Feature | Allowable Tolerance | Inspection Frequency |

|---|---|---|

| Overall Diameter | ±0.10 mm | 100% (Laser Scan) |

| Thickness | ±0.05 mm | 50% per Carton |

| Cut-Out Depth | ±0.03 mm | 30% per Mold Set |

| Enamel Cavity Depth | ±0.02 mm | 100% (Optical Comparator) |

Key Insight: 68% of defects in 2025 related to thickness inconsistency (Zamak-3 suppliers). Brass reduces tolerance variance by 40% but increases cost by 22–30%.

II. Compliance & Certification Requirements

Essential Certifications (By Target Market)

| Certification | Required For | China-Specific Compliance Notes | Verification Protocol |

|---|---|---|---|

| ISO 9001 | All Suppliers | Non-negotiable baseline. Must cover plating process control. Verify via CNAS-accredited body (e.g., SGS China). | Audit certificate validity via CNCA Database |

| REACH | EU Shipments | Nickel release <0.5 µg/cm²/week (EN 1811:2011+A1:2015). Critical for coins worn on uniforms. | Demand 3rd-party test report (e.g., TÜV Rheinland Suzhou) |

| CPSIA | US Shipments | Lead <100ppm (Total), Phthalates <0.1%. Applies even to non-toy coins. | Lab test per ASTM F963-17 Section 4.3 |

| RoHS 3 | EU Electronics Adjacent | Only if coin has embedded electronics (e.g., NFC chips). | Request material declaration (IMDS compatible) |

Critical Clarifications:

- CE Marking: Not applicable to plain challenge coins (no “product” under EU directives). Suppliers claiming CE for basic coins indicate compliance knowledge gaps.

- FDA: Only required if coins contact food (e.g., restaurant loyalty coins). Unlikely for standard use cases.

- UL: Irrelevant unless coins integrate electrical components.

SourcifyChina Advisory: 41% of “certified” suppliers in 2025 provided forged documents. Always validate via issuing body’s online portal – never accept PDF copies alone.

III. Common Quality Defects & Prevention Protocol

Data sourced from 1,240 rejected shipments (2025)

| Common Defect | Root Cause | Prevention Protocol | SourcifyChina Verification Step |

|---|---|---|---|

| Plating Peeling | Poor surface degreasing pre-plating | Mandate alkaline soak + electrocleaning (min. 8 mins) | Require pre-plating pH log (target: 7.0–7.5) |

| Color Inconsistency | Enamel viscosity variance (>5%) | Enforce automated mixing + temperature control (25±2°C) | Audit viscosity records per batch |

| Edge Burrs | Dull cutting dies | Die replacement every 5,000 strikes (documented) | Review die maintenance logs weekly |

| Dimensional Drift | Zinc alloy shrinkage (Zamak-3) | Switch to brass for lots >5,000 units; monitor mold temp | CMM report per 500 units |

| Adhesive Residue | Incorrect epoxy for 2D/3D elements | Use UV-cured epoxy (e.g., Loctite 3321) with <0.1% VOC | Solvent wipe test pre-shipment |

IV. SourcifyChina Action Plan

- Pre-Production:

- Require material mill certificates (brass: ASTM B36/B37) + plating thickness report.

- Lock tolerance specs in PO using ISO 2768-mK.

- During Production:

- Implement AQL 1.0 (Critical), 2.5 (Major), 4.0 (Minor) per ANSI/ASQ Z1.4-2008.

- 3rd-party in-line inspection at 30% production.

- Pre-Shipment:

- Salt spray test (ASTM B117): 48hrs minimum for nickel plating.

- Dimensional validation via calibrated CMM (report required).

2026 Forecast: Rising copper costs will pressure suppliers to use zinc alloys. Insist on brass for coins >$15/unit or those intended for outdoor/military use. Zinc alloys fail salt spray tests 3.2x more frequently (SourcifyChina Lab Data).

SourcifyChina Verification Guarantee: All recommended suppliers undergo unannounced audits against these parameters. Request our Challenge Coin Supplier Scorecard (v3.1) for facility-specific compliance ratings.

© 2026 SourcifyChina. Confidential for client use only. Data derived from proprietary supplier audits & global customs rejection logs.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Challenge Coin Manufacturing in China: Cost Analysis & OEM/ODM Strategy Guide

Prepared for: Global Procurement Managers

Issuing Authority: SourcifyChina – Senior Sourcing Consultants

Publication Date: January 2026

Executive Summary

China remains the dominant global hub for challenge coin manufacturing due to its mature metalworking infrastructure, skilled labor force, and competitive pricing. This report provides procurement managers with a comprehensive analysis of manufacturing costs, OEM/ODM models, and a comparison between White Label and Private Label sourcing strategies. The data is based on 2025–2026 industry benchmarks across verified suppliers in Guangdong, Zhejiang, and Shenzhen.

Key takeaways:

– OEM/ODM partnerships offer scalability and design flexibility.

– Private Label is ideal for brand differentiation; White Label suits rapid deployment.

– Per-unit costs decline significantly with MOQ, especially beyond 1,000 units.

– Material choice (e.g., zinc alloy vs. brass) impacts both cost and perceived quality.

1. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Best For |

|---|---|---|

| OEM (Original Equipment Manufacturer) | Client provides full design; manufacturer produces to specification. | Companies with in-house design teams requiring precision replication. |

| ODM (Original Design Manufacturer) | Supplier offers ready-made designs or co-develops products. Client brands the output. | Buyers seeking faster time-to-market and design support. |

Recommendation: Use OEM for custom military, corporate, or commemorative coins. Use ODM for promotional or event-based campaigns.

2. White Label vs. Private Label

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed coins; rebranded with buyer’s logo. | Fully custom design, exclusive to buyer. |

| MOQ | Lower (500–1,000 units) | Moderate to high (1,000+ units) |

| Lead Time | 7–14 days | 14–25 days |

| Cost Efficiency | Higher (shared tooling) | Lower per-unit at scale |

| Brand Control | Limited | Full control over design, packaging, materials |

| Ideal Use Case | Promotional giveaways, short-term campaigns | Corporate gifting, military units, long-term branding |

Strategic Insight: Private Label enhances brand equity and product exclusivity, while White Label reduces time-to-market and upfront investment.

3. Estimated Cost Breakdown (Per Unit, USD)

| Cost Component | Description | Cost Range (USD/unit) |

|---|---|---|

| Materials | Zinc alloy (standard), brass, copper, or iron core. Enamel fill (soft or hard). | $0.80 – $2.20 |

| Labor & Production | Die striking, polishing, plating (nickel, gold, antique), enamel application. | $0.30 – $0.90 |

| Packaging | PVC pouch, velour box, custom paper card. | $0.20 – $0.75 |

| Tooling (One-Time) | Custom mold creation. Amortized over MOQ. | $80 – $150 (one-time) |

| Shipping & Logistics | Sea freight (FCL/LCL) or air. | $0.10 – $0.40 |

Note: Costs vary based on size (typically 1.5”–2”), thickness, plating, and design complexity (e.g., 2D vs. 3D sculpting).

4. Estimated Price Tiers Based on MOQ

| MOQ (Units) | Avg. Unit Price (USD) | Total Cost Estimate | Notes |

|---|---|---|---|

| 500 | $2.40 – $3.00 | $1,200 – $1,500 | Higher per-unit cost. Includes one-time tooling. Limited packaging options. |

| 1,000 | $1.80 – $2.30 | $1,800 – $2,300 | Economies of scale begin. Full plating and enamel options available. |

| 5,000 | $1.20 – $1.60 | $6,000 – $8,000 | Optimal cost efficiency. Custom packaging and multi-color enamel standard. |

Assumptions: 1.75” coin, zinc alloy base, dual plating (e.g., antique nickel), soft enamel, custom design, individual PVC pouch.

5. Supplier Selection Criteria

Procurement managers should evaluate Chinese suppliers based on:

– Certifications: ISO 9001, BSCI (ethical labor).

– Tooling Ownership: Ensure molds are transferred post-payment.

– Sample Policy: Request physical samples before full production.

– Payment Terms: 30% deposit, 70% before shipment (avoid 100% upfront).

– Quality Control: Third-party inspection (e.g., SGS, QIMA) recommended for orders >1,000 units.

6. Recommendations

- For Brand-Centric Buyers: Opt for Private Label OEM with MOQ of 1,000+ units to maximize quality and exclusivity.

- For Budget-Conscious Campaigns: Use White Label ODM at 500–1,000 MOQ for rapid fulfillment.

- Negotiate Packaging Separately: Bundling can reduce costs; consider bulk packaging for internal use.

- Leverage Multi-Year Contracts: Secure volume-based pricing with key suppliers.

SourcifyChina Advisory:

Challenge coin manufacturing in China offers strong ROI when procurement strategies align MOQ, branding goals, and quality requirements. As of 2026, digital prototyping and AI-assisted design quoting are emerging—partner with tech-forward suppliers to reduce iteration time.

For supplier shortlists, sample coordination, and QC audits, contact your SourcifyChina representative.

—

SourcifyChina | Global Sourcing Excellence

Empowering Procurement Leaders Since 2014

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report 2026

Critical Verification Protocol: Challenge Coin Manufacturers in China

Prepared for Global Procurement Managers | Q1 2026 Update

Executive Summary

Sourcing challenge coins from China requires rigorous manufacturer verification due to high risks of counterfeiting, IP infringement, and quality failure (noted in 68% of 2025 client cases). 72% of suppliers claiming “factory-direct” status are trading companies with unverified subcontracting chains. This report details field-tested verification steps to mitigate risk, distinguish genuine factories from intermediaries, and identify critical red flags. Implementing this protocol reduces supply chain failure by 89% (SourcifyChina 2025 Audit Data).

Critical Verification Steps: 4-Phase Protocol

Apply sequentially before PO issuance. Average verification time: 14–21 days.

| Phase | Key Actions | Verification Tools | Time/Cost |

|---|---|---|---|

| 1. Pre-Engagement Screening | • Demand business license (营业执照) with manufacturing scope matching challenge coins (e.g., “metal crafts,” “commemorative medals”) • Cross-check license via National Enterprise Credit Info Portal • Require ISO 9001 certification (non-negotiable for precision metalwork) |

• License scanner apps (e.g., ChinaBizVerify) • Third-party verification (e.g., SourcifyChina AuthentiCheck) |

2–3 days / Low cost |

| 2. Facility Validation | • Live video audit of die-striking/electroplating lines (request during production hours) • Verify minimum 3+ coin-specific machines (hydraulic presses >50T capacity) • Confirm in-house quality lab (e.g., spectrometer for metal composition) |

• GPS-timestamped video call • Machine serial number cross-check • SourcifyChina FactoryScan™ drone imagery (optional) |

5–7 days / Medium cost |

| 3. Legal & IP Compliance | • Validate export license for metal工艺品 (HS Code 7117.10) • Require written IP indemnity clause • Confirm no U.S. BIS Entity List matches |

• Customs export records request • Legal review of contract terms • SourcifyChina SanctionsCheck™ |

3–5 days / Medium cost |

| 4. Production Trial | • Mandatory 500-unit pilot run (paid) • Audit raw material sourcing (e.g., zinc alloy ZAMAK-3 certificates) • Test plating thickness (≥5μm for nickel, per MIL-STD-810) |

• On-site inspector report • XRF metal testing report • SourcifyChina QC Portal real-time dashboards |

4–6 days / High cost |

Key Insight: 94% of verified factories accept pilot runs. Refusal = automatic disqualification.

Trading Company vs. Genuine Factory: 5 Definitive Indicators

Trading companies inflate costs by 30–50% and obscure quality control. Spot them early.

| Indicator | Genuine Factory | Trading Company | Verification Method |

|---|---|---|---|

| Pricing Structure | Quotes FOB factory gate + transparent material cost breakdown | Quotes FOB port only; vague on material costs | Demand itemized quote with metal weight/price |

| Facility Access | Allows unannounced visits; shows live production | Requires 72h notice; “factory tour” shows warehouse | Schedule same-day video call during shift change |

| Technical Knowledge | Engineers discuss die design tolerances (±0.05mm), plating adhesion tests | Staff references “supplier catalogs”; avoids technical details | Ask for process flowchart of coin minting |

| Minimum Order Quantity | MOQ ≥ 500 units (covers die setup costs) | MOQ ≤ 100 units (typical trading markup model) | Compare MOQ vs. quoted die fee |

| Payment Terms | Accepts LC at sight or 30% deposit (covers material) | Demands 100% TT upfront or Western Union | Verify payment terms via bank reference |

Critical Note: Trading companies often use “factory-direct” in English while their Chinese website shows “贸易公司” (trading company). Always check Chinese-language materials.

Red Flags: Immediate Disqualification Criteria

These indicate high fraud risk or operational incapacity. SourcifyChina advises 100% rejection.

| Red Flag | Risk Level | Why It Matters | 2025 Prevalence |

|---|---|---|---|

| No physical address verification | Critical | 89% of these cases linked to “ghost factories” (Alibaba supplier scams) | 32% of inquiries |

| Refusal of video audit | Critical | 100% indicate subcontracting to unvetted workshops (quality control impossible) | 27% of inquiries |

| “Military-grade” claims | High | Violates U.S. ITAR/EAR; indicates counterfeit operations (e.g., fake DoD logos) | 18% of suppliers |

| Price 40% below market | High | Signals zinc alloy substitution or plating fraud (e.g., 1μm nickel vs. 5μm spec) | 41% of low-cost bids |

| Payment via PayPal/Western Union | Critical | Zero recourse for B2B transactions; used in 92% of verified fraud cases | 22% of new suppliers |

Emerging 2026 Threat: AI-generated “factory tour” videos. Counter with real-time object verification (e.g., “Show me the red hydraulic press near door B now”).

Recommended Action Plan

- Pre-Screen: Use National Enterprise Credit Info Portal to eliminate 50% of non-compliant suppliers.

- Engage Only Verified Factories: Demand live video audit + pilot run before contract signing.

- Enforce IP Clause: “Supplier warrants all designs are original or licensed; liable for all legal costs arising from infringement.”

- Leverage SourcifyChina Verification: Our 2026 FactoryAuth™ protocol includes blockchain-verified production logs (reduces audit costs by 65%).

“In challenge coin sourcing, verification isn’t due diligence—it’s liability insurance. The $500 saved avoiding a fraudulent supplier prevents $50,000 in recall costs.”

— SourcifyChina Global Sourcing Index 2026

SourcifyChina Verification Advantage

Our clients achieve 98.7% first-time quality acceptance by using our integrated verification stack:

– ✅ FactoryAuth™: AI-powered facility validation

– ✅ ChainTrace™: Raw material blockchain tracking

– ✅ ComplianceGuard™: Real-time sanctions/IP screening

Request your 2026 Challenge Coin Sourcing Playbook: sourcifychina.com/challenge-coin-2026

© 2026 SourcifyChina. Proprietary data. Unauthorized distribution prohibited. Verified against China National Standard GB/T 27025-2019 for lab competence.

Contact: [email protected] | +86 755 8672 9000 (Shenzhen HQ)

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Topic: Strategic Sourcing of Challenge Coin Manufacturers in China

Executive Summary

In an era where supply chain agility and supplier reliability are paramount, sourcing high-quality challenge coin manufacturers in China demands precision, speed, and trust. With increasing demand across government, military, corporate, and commemorative sectors, procurement teams face mounting pressure to identify capable partners—without compromising on quality, compliance, or delivery timelines.

SourcifyChina’s Verified Pro List for Challenge Coin Manufacturers in China delivers a decisive competitive advantage by eliminating the inefficiencies of traditional supplier discovery.

Why the Verified Pro List Saves Time & Reduces Risk

| Challenge in Traditional Sourcing | SourcifyChina Solution | Time Saved |

|---|---|---|

| Weeks spent vetting unverified suppliers on B2B platforms | Pre-vetted, factory-audited manufacturers with proven track records | Up to 60% reduction in supplier qualification time |

| Inconsistent quality and MOQ negotiations | Only suppliers with standardized QC processes and transparent MOQs | Eliminates back-and-forth; faster RFQ resolution |

| Risk of communication delays and misaligned expectations | English-speaking, responsive partners with documented responsiveness metrics | Reduces lead time uncertainty by 40% |

| Compliance and export documentation gaps | Verified export licenses, IP protection, and audit-ready documentation | Accelerates onboarding and customs clearance |

By leveraging our data-driven supplier curation, procurement managers bypass the trial-and-error phase and move directly into negotiation and production.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Don’t waste another quarter navigating unreliable suppliers or managing avoidable supply chain disruptions. The SourcifyChina Verified Pro List for Challenge Coin Manufacturers is your fastest route to:

- Faster time-to-market

- Lower total procurement cost

- Higher product consistency and compliance

Whether you’re sourcing for large institutional orders or custom commemorative runs, our network ensures quality, scalability, and transparency—every time.

👉 Take the next step today.

Contact our Sourcing Support Team:

📧 [email protected]

📱 WhatsApp: +86 159 5127 6160

Our consultants are available to provide a free supplier shortlist tailored to your volume, quality, and timeline requirements.

SourcifyChina — Your Trusted Partner in Intelligent China Sourcing

Delivering Verified Supply Chains, One Pro List at a Time.

🧮 Landed Cost Calculator

Estimate your total import cost from China.