The chalk line and reel market has experienced steady growth, driven by rising construction activities and demand for precision tools in both residential and commercial projects. According to Grand View Research, the global hand tools market—under which chalk line reels fall—was valued at USD 13.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by increased infrastructure development, particularly across emerging economies, as well as a growing emphasis on tool durability and accuracy on job sites. As demand for reliable marking solutions continues to climb, manufacturers are innovating with improved reel mechanisms, longer-lasting strings, and ergonomic designs. In this evolving landscape, the following nine companies stand out as leading manufacturers of chalk line and reel products, combining performance, market presence, and technological advancement to meet the needs of professionals worldwide.

Top 9 Chalk Line And Reel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

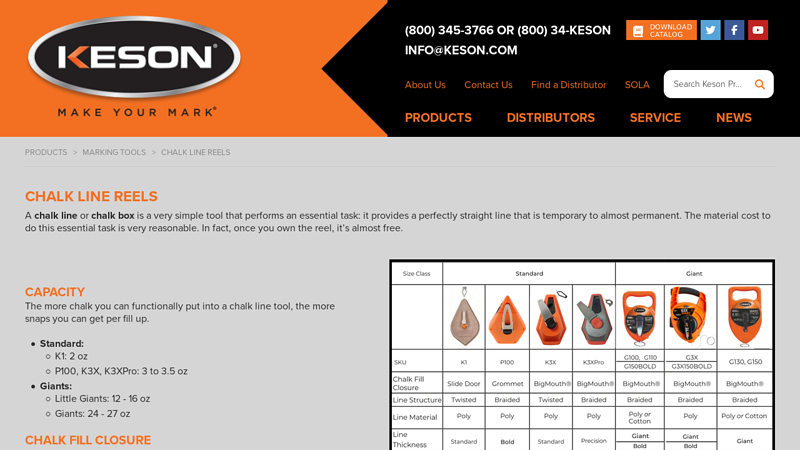

#1 Chalk Line Reels

Domain Est. 1997

Website: keson.com

Key Highlights: A chalk line or chalk box is a very simple tool that creates a perfectly straight line. Keson is the only US manufacturer of chalk and chalk line reels….

#2 Durable Strait

Domain Est. 2007

Website: amexlock.com

Key Highlights: Chalk Line Reel, aluminium case with thin marking thread. 100ft. // 30m. Thread length: 30m; Made of light weight aluminum, self-chalking and leak-proof….

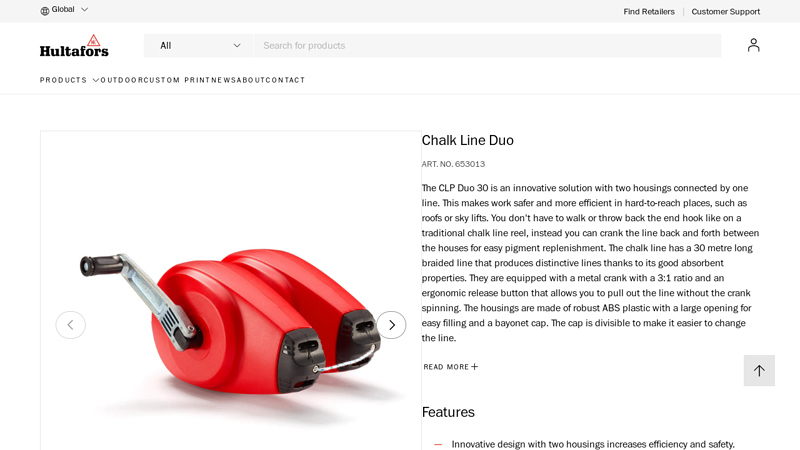

#3 Chalk Line Duo

Domain Est. 1997

Website: hultafors.com

Key Highlights: In stockInnovative design with two housings increases efficiency and safety. 30 meters of braided line provides distinctive lines thanks to high absorbency. Robust ……

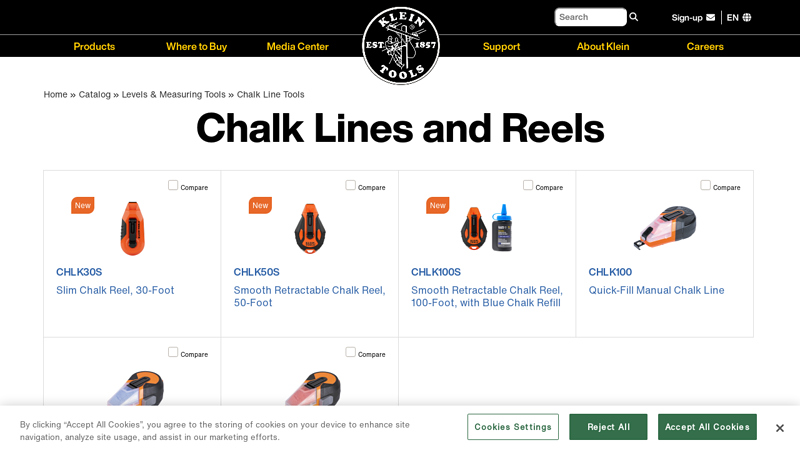

#4 Chalk Lines and Reels

Domain Est. 1998

Website: kleintools.com

Key Highlights: Chalk Lines and Reels ; CHLK100S Smooth Retractable Chalk Reel, 100-Foot, with Blue Chalk Refill Image. product number CHLK100S CHLK100S ; CHLK100 Quick-Fill ……

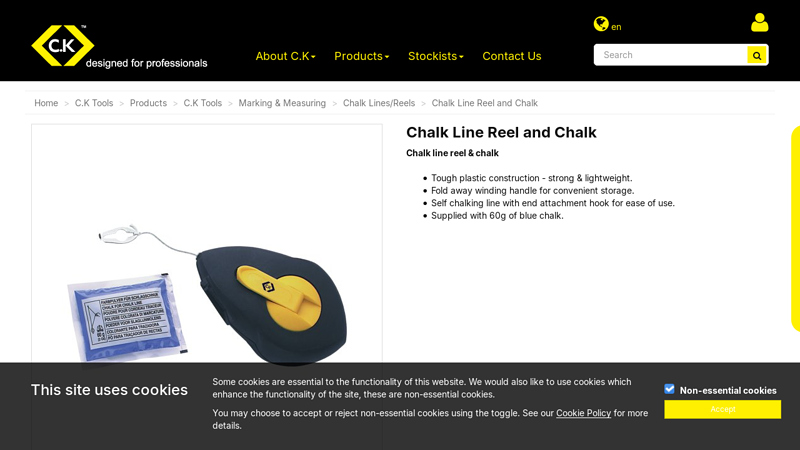

#5 Chalk Line Reel and Chalk

Domain Est. 1998

Website: ck-tools.com

Key Highlights: Tough plastic construction – strong & lightweight. Fold away winding handle for convenient storage. Self chalking line with end attachment hook for ease of use….

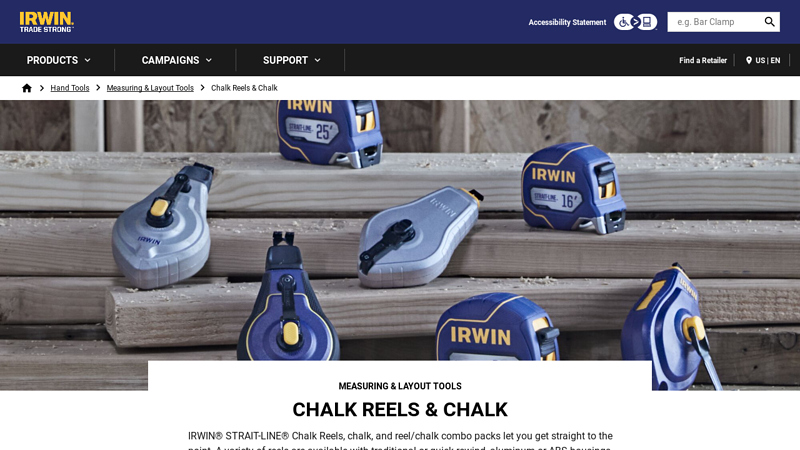

#6 Chalk Reels & Chalk

Domain Est. 2002

Website: irwintools.com

Key Highlights: IRWIN STRAIT-LINE Chalk Reels, chalk, and reel/chalk combo packs let you get straight to the point. A variety of reels are available with traditional or quick ……

#7 50′ Compact Chalk & Reel with Blue Chalk

Domain Est. 2004

Website: crescenttool.com

Key Highlights: Crescent Tools line of Chalk and Reels are feature-rich, making every pro’s work easier. Shop the 50′ Compact Chalk & Reel with Blue Chalk now….

#8 Chalk and Chalk Line Reels

Domain Est. 2023

Website: gundlachtools.com

Key Highlights: This chalk line reel features a BigMouth® Fill Port for easy chalk fill and a protected seal. Has a tough ABS plastic case with a flush mounted met….

#9 Chalk Reels & Mason Line

Domain Est. 1996

Expert Sourcing Insights for Chalk Line And Reel

2026 Market Trends for Chalk Line and Reel

The chalk line and reel market, while rooted in traditional construction and DIY practices, is evolving in response to broader industry shifts, technological advancements, and changing user expectations. By 2026, several key trends are expected to shape the landscape for manufacturers, distributors, and end users.

Growing Demand in Construction and Renovation Sectors

The global construction industry is projected to continue steady growth through 2026, particularly in infrastructure development, residential housing, and commercial renovations. As chalk lines remain essential for layout and alignment tasks in masonry, carpentry, and tiling, demand for reliable and efficient chalk line and reel tools will remain strong. Emerging markets in Asia-Pacific and Africa will contribute significantly to volume growth, while developed regions focus on replacement and premium product adoption.

Shift Toward Ergonomic and High-Performance Designs

Users are increasingly prioritizing tools that enhance comfort and reduce fatigue. By 2026, manufacturers are expected to emphasize ergonomic reel handles, improved grip materials, and lightweight yet durable housing. Reels with smoother winding mechanisms, one-handed operation, and consistent chalk flow will gain market share. Products designed for both professional contractors and serious DIYers will blur the line between utility and user experience.

Innovation in Chalk Formulations and Reel Technology

Traditional powdered chalk is being supplemented—and in some cases replaced—by liquid chalk markers and dust-free chalk alternatives. These innovations cater to indoor projects, environmentally sensitive sites, and users concerned with respiratory health. Reels compatible with liquid chalk cartridges or offering sealed, mess-free refills are anticipated to grow in popularity. Additionally, smart features such as built-in levels, magnetic bases, and laser integration may appear in premium models, combining tradition with modern functionality.

Sustainability and Eco-Conscious Materials

Environmental considerations are influencing tool manufacturing. By 2026, expect increased use of recycled plastics in reel housings and biodegradable chalk formulas. Brands emphasizing sustainability in packaging and production may gain a competitive edge, especially among younger, eco-aware consumers and green-building contractors.

E-Commerce and Direct-to-Consumer Sales Growth

Online retail platforms will continue to dominate tool distribution. Chalk line and reel manufacturers will invest more in digital marketing, influencer collaborations (e.g., with DIY content creators), and e-commerce-optimized product designs. Subscription models for refills or bundled tool kits may emerge, enhancing customer retention and brand loyalty.

Competition from Multi-Functional Layout Tools

While chalk lines remain indispensable, they face competition from laser levels and digital layout tools. However, chalk lines offer unmatched cost-effectiveness, simplicity, and visibility on uneven surfaces. The market will likely see hybrid tools—such as chalk reels with integrated lasers or magnetic clips—that combine the best of both worlds, ensuring relevance in a tech-forward environment.

In summary, the 2026 chalk line and reel market will be defined by innovation within tradition—balancing proven utility with enhancements in ergonomics, cleanliness, sustainability, and digital integration. Brands that adapt to these trends while maintaining reliability and affordability will lead the market.

Common Pitfalls Sourcing Chalk Line and Reel (Quality, IP)

Sourcing chalk lines and reels—especially for industrial or professional use—can present several challenges related to quality control and intellectual property (IP) risks. Being aware of these pitfalls helps ensure reliable performance and legal compliance.

Poor Material Quality and Construction

One of the most frequent issues is receiving chalk line reels made from substandard materials. Low-grade plastics can crack under stress or extreme temperatures, while weak metal components (e.g., hooks or gears) may fail during use. Inferior chalk formulas often result in inconsistent marking, poor adhesion, or excessive dust, reducing visibility and usability on job sites.

Inaccurate or Inconsistent Line Marking

A key function of a chalk line is delivering a straight, visible mark. Poorly manufactured reels may use low-tension springs or imprecise winding mechanisms, leading to slack lines or inconsistent snapping. Additionally, non-uniform chalk distribution results in broken or faint lines, which defeats the tool’s purpose and wastes time.

Lack of Durability in Harsh Environments

Many sourced chalk reels are not tested for durability in demanding conditions. Reels used on construction sites may be exposed to moisture, dust, UV light, and physical impact. Without proper sealing or rugged design, internal mechanisms can corrode or jam, drastically shortening the tool’s lifespan.

Misrepresentation of Branding and Counterfeit Products

Suppliers may offer products that mimic well-known brands (e.g., Stanley, Dewalt) but are unauthorized copies. These counterfeit items often carry fake logos or packaging, misleading buyers into believing they are purchasing authentic, high-quality tools. This not only affects performance but also exposes buyers to IP infringement risks.

Intellectual Property Infringement Risks

Sourcing generic or OEM-manufactured chalk lines without proper due diligence can lead to unintentional IP violations. Designs, logos, and patented mechanisms (e.g., auto-retract systems or ergonomic housings) may be protected under trademark or utility patents. Importing or selling such products without licensing can result in legal action, customs seizures, or product recalls.

Inadequate or Missing Safety and Compliance Certifications

Many low-cost suppliers fail to meet regional safety and compliance standards (e.g., CE, UKCA, or OSHA guidelines). Products may contain hazardous materials or lack proper labeling, posing risks to users and liability to distributors. Always verify compliance documentation before large-scale procurement.

Inconsistent Product Specifications Across Batches

When sourcing from manufacturers with poor quality control, product specifications—such as line length, chalk color, or reel size—can vary between batches. This inconsistency complicates inventory management and can disrupt workflows when tools don’t perform as expected.

Overlooking After-Sales Support and Warranty

Many budget suppliers offer little to no warranty or customer support. If a batch of reels fails prematurely, resolving the issue can be time-consuming or impossible, especially with overseas vendors. Lack of spare parts (e.g., replacement lines or chalk refills) further reduces long-term usability.

To avoid these pitfalls, conduct thorough supplier vetting, request samples, verify IP status, and insist on quality certifications before scaling production or distribution.

Logistics & Compliance Guide for Chalk Line and Reel

Chalk lines and reels are common tools in construction, masonry, and carpentry used to mark straight reference lines on surfaces. While seemingly simple, their international logistics and compliance involve several important considerations, particularly regarding materials, safety, and regulatory standards. This guide outlines key logistics and compliance aspects to ensure smooth import/export and safe use.

Product Classification and Tariff Codes

Proper classification under international trade systems is essential for customs clearance and duty assessment. Chalk lines and reels typically fall under the following Harmonized System (HS) codes:

-

HS Code 8205.59 – “Other hand tools (including glass cutters) not elsewhere specified or included, of iron or steel”

Note: This often applies to the reel mechanism, especially if made of metal. -

HS Code 9609.90 – “Other (non-mechanical) pencils and similar articles”

Note: May apply if the chalk line is considered a marking instrument, depending on construction.

Always verify the correct code with your local customs authority, as classification may vary based on material composition and primary function.

Packaging and Shipping Requirements

To ensure safe transport and regulatory compliance:

- Secure Packaging: Use durable, moisture-resistant packaging to prevent damage during transit. Individual units should be protected against crushing or deformation.

- Labeling: Include product name, model number, country of origin, weight, and handling symbols (e.g., “Fragile,” “This Side Up”).

- Hazardous Materials: Standard chalk lines (using non-toxic chalk powder) are not classified as hazardous. However, if the chalk contains dyes or additives regulated in certain countries (e.g., azo dyes in the EU), additional documentation may be required.

- Bulk Shipments: Palletize shipments using stretch wrap or strapping. Include packing lists and commercial invoices with each shipment.

Regulatory and Safety Compliance

Ensure product compliance with destination country regulations:

-

United States (OSHA & CPSC):

While chalk lines are not heavily regulated, they must not present a safety hazard. Products should comply with general consumer product safety standards under the Consumer Product Safety Commission (CPSC), particularly regarding choking hazards for small parts and non-toxic materials. -

European Union (CE Marking & REACH):

- REACH Regulation (EC 1907/2006): Ensure chalk powder and plastic/metal components are free from substances of very high concern (SVHCs).

- RoHS Directive (2011/65/EU): Apply if the reel contains electronic components (e.g., laser alignment models).

-

CE marking may be required if the product is marketed as a measuring or safety tool.

-

Canada (Health Canada & CCC):

Comply with the Canada Consumer Product Safety Act (CCPSA). Chalk should be non-toxic and labeled appropriately. -

Australia/New Zealand (AS/NZS Standards):

No specific standard for chalk lines, but general product safety rules under the Australian Consumer Law must be followed.

Environmental and Disposal Considerations

- Chalk Composition: Use non-toxic, biodegradable chalk formulations where possible (e.g., calcium carbonate or gypsum-based). Avoid lead or heavy metal compounds.

- Plastic Components: Reels made from recyclable plastics (e.g., PP, ABS) should be labeled with resin codes.

- Waste Disposal: Provide end-user guidance: chalk dust can be swept and disposed of as general waste; plastic/metal parts should be recycled where facilities exist.

Import/Export Documentation

Prepare and maintain the following documents for international shipments:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (especially for preferential tariff treatment)

- Safety or Compliance Declaration (if requested)

- SDS (Safety Data Sheet) – only if chalk contains regulated substances

Labeling and User Instructions

Include multilingual labeling as required by the destination market:

- Product name and model

- Manufacturer/importer contact information

- Country of origin

- Safety warnings (e.g., “Avoid inhalation of dust,” “Keep out of reach of children”)

- Instructions for use and maintenance

- Compliance marks (e.g., CE, UKCA, FCC if applicable)

Quality Assurance and Testing

Conduct periodic product testing to ensure:

- Structural integrity of the reel (spring mechanism, housing)

- Consistent chalk flow and line visibility

- Non-toxicity of chalk (via third-party lab testing)

- Compliance with relevant standards in target markets

Maintain test reports and certificates for audit purposes.

Conclusion

While chalk lines and reels are simple tools, adherence to logistics protocols and compliance standards is crucial for market access and user safety. By classifying products correctly, using safe materials, and meeting regional regulatory requirements, manufacturers and distributors can ensure reliable global operations and customer trust. Regularly review regulations as standards may evolve, especially concerning chemical content and environmental impact.

In conclusion, sourcing a chalk line and reel requires careful consideration of quality, durability, functionality, and cost-effectiveness. Whether for professional construction use or DIY projects, selecting the right chalk line and reel involves evaluating factors such as line strength, case ergonomics, ease of retraction, visibility of chalk, and refill availability. Sourcing from reputable suppliers or manufacturers ensures reliability and consistent performance. Additionally, comparing options across local hardware stores, online retailers, and bulk distributors can lead to favorable pricing and availability. Ultimately, investing in a high-quality chalk line and reel enhances accuracy, efficiency, and productivity on the job site, making it a worthwhile component of any tool collection.