Sourcing Guide Contents

Industrial Clusters: Where to Source Chain Manufacturers In China

SourcifyChina Sourcing Intelligence Report 2026

Deep-Dive Market Analysis: Sourcing Chain Manufacturers in China

Prepared for: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

The Chinese market remains the dominant global hub for industrial chain manufacturing, supplying over 65% of the world’s roller chains, conveyor chains, and specialty transmission chains. Driven by mature industrial ecosystems, cost-efficient production, and engineering expertise, China continues to be the preferred sourcing destination for global OEMs, machinery manufacturers, and industrial distributors.

This report provides a comprehensive analysis of key industrial clusters in China producing chains, evaluates regional strengths, and delivers a comparative framework to guide procurement strategy. Key regions include Zhejiang, Guangdong, Jiangsu, and Hebei—each offering distinct advantages in cost, quality, and delivery performance.

Market Overview: Chain Manufacturing in China

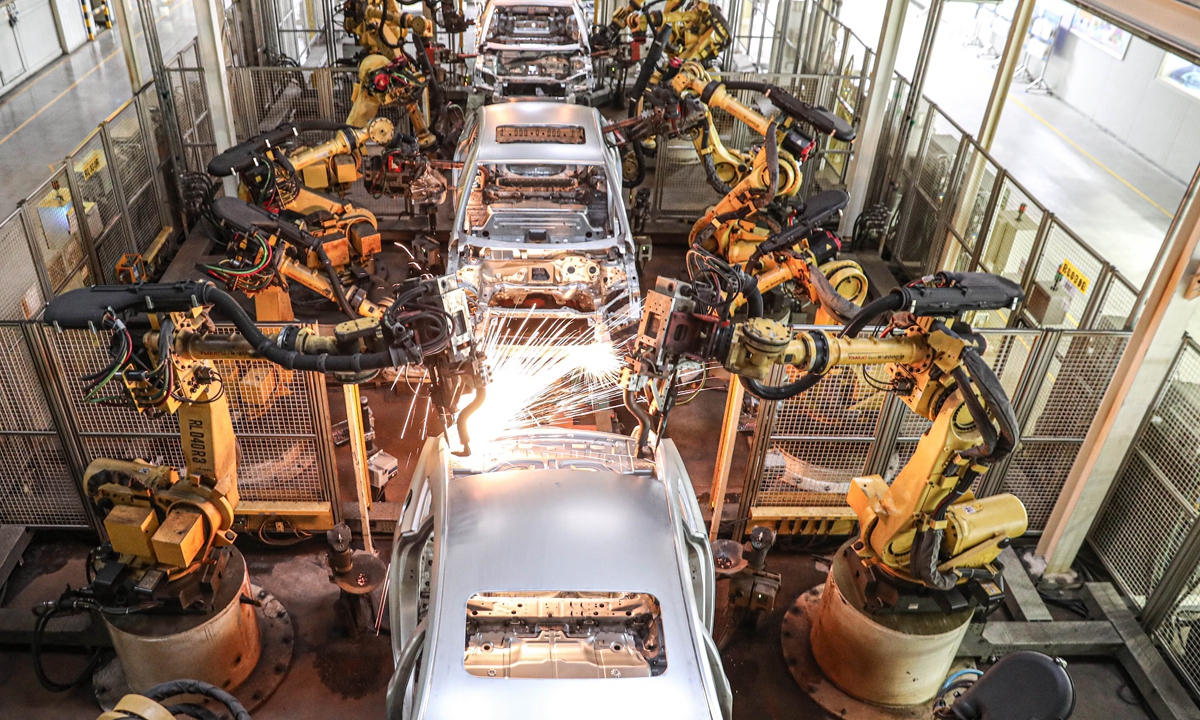

Industrial chains are critical components in automation, agriculture, automotive, mining, and food processing industries. China’s chain manufacturing sector is highly diversified, ranging from low-cost standard roller chains to high-precision engineered solutions for export markets.

Key product categories include:

– Roller Chains (ISO, ANSI standards)

– Conveyor Chains (stainless steel, corrosion-resistant)

– Leaf Chains (for forklifts and lifting equipment)

– Engineering Steel Chains (custom designs)

– Silent Chains (for high-speed transmission)

China’s annual chain production exceeds 8 million metric tons, with over 40% exported to North America, Europe, and Southeast Asia. The sector is characterized by mid-to-high competitiveness, with consolidation favoring larger, ISO-certified manufacturers capable of meeting international quality standards.

Key Industrial Clusters for Chain Manufacturing

China’s chain manufacturing is geographically concentrated in four primary industrial clusters:

| Province | Key City | Specialization | Key Attributes |

|---|---|---|---|

| Zhejiang | Hangzhou, Huzhou, Ningbo | High-precision roller & conveyor chains, leaf chains | Engineering expertise, export-oriented, high compliance (ISO, DIN, ANSI) |

| Guangdong | Foshan, Dongguan, Shenzhen | Light-duty chains, automation & conveyor systems | Proximity to electronics & automation hubs, fast turnaround |

| Jiangsu | Changzhou, Wuxi | Heavy-duty transmission chains, industrial custom chains | Strong metallurgy base, integrated supply chain |

| Hebei | Cangzhou, Shijiazhuang | Cost-competitive standard chains, bulk supply | Lower labor costs, focus on domestic and emerging markets |

Regional Comparison: Chain Manufacturing Hubs in China

The table below compares the four key provinces based on critical procurement KPIs: Price Competitiveness, Quality Consistency, and Lead Time Efficiency. Ratings are on a scale of 1 (Low) to 5 (High).

| Region | Price Competitiveness | Quality Consistency | Lead Time (Standard Order) | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| Zhejiang | 4 | 5 | 4–6 weeks | High engineering standards, ISO-certified factories, strong R&D, export-ready documentation | Higher unit cost vs. inland regions |

| Guangdong | 3 | 4 | 3–5 weeks | Fast prototyping, integration with automation supply chains, strong logistics (Shenzhen/Nansha ports) | Limited heavy-duty chain capacity; premium pricing for high-mix orders |

| Jiangsu | 4 | 4 | 5–7 weeks | Strong material sourcing (steel), heavy industrial capacity, skilled labor | Slightly longer lead times due to complex custom workloads |

| Hebei | 5 | 3 | 6–8 weeks | Lowest production costs, bulk pricing, large-scale capacity | Variable quality control; fewer exporters with full compliance certifications |

Strategic Sourcing Recommendations

-

For Premium Quality & Compliance (EU/NA Markets):

Prioritize suppliers in Zhejiang, particularly Hangzhou and Huzhou. These clusters host leading exporters like Donghua Chain Group (one of the world’s top 5 chain manufacturers) and offer full traceability, ISO 9001/TS16949 certifications, and in-house testing labs. -

For Fast Turnaround & Automation Integration:

Leverage Guangdong’s agile manufacturers in Foshan and Dongguan. Ideal for smart factory components, conveyor systems, and just-in-time (JIT) supply models. -

For Heavy-Duty & Custom Industrial Chains:

Target Jiangsu suppliers with metallurgical integration. Suitable for mining, construction, and large OEM contracts requiring fatigue-resistant designs. -

For Cost-Sensitive, High-Volume Orders:

Consider Hebei for standard ISO roller chains where cost is the primary driver. Recommend third-party QC audits and supplier qualification to mitigate quality risk.

Risk & Opportunity Outlook (2026)

- Opportunities:

- Rising adoption of stainless steel and corrosion-resistant chains in food & pharma sectors.

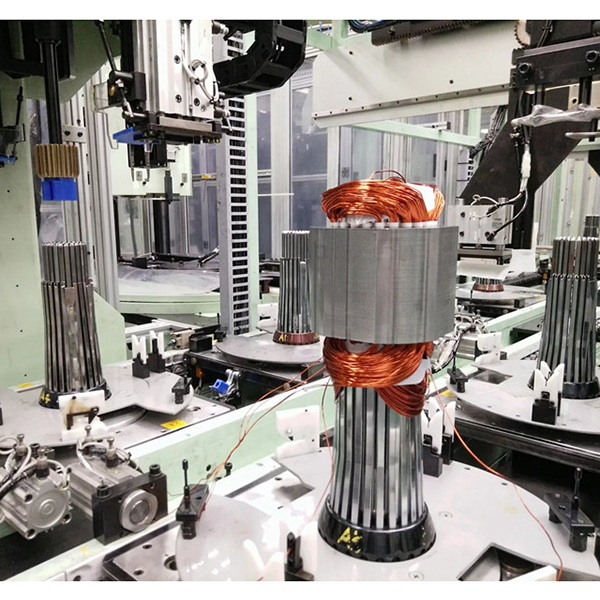

- Growth in EV and renewable energy supply chains creating demand for specialty transmission components.

-

Digital sourcing platforms and AI-driven QC improving transparency in Tier-2 supplier networks.

-

Risks:

- Steel price volatility (up 12% YoY in 2025) impacting margin stability.

- Export compliance complexity under EU CBAM and UFLPA.

- Labor cost inflation in coastal regions (Zhejiang, Guangdong) at ~6–8% annually.

Conclusion

China remains the most strategic source for industrial chain manufacturing, with regional specialization enabling tailored procurement strategies. Zhejiang leads in quality and compliance, Guangdong in speed and integration, Jiangsu in heavy industrial capacity, and Hebei in cost leadership. Procurement managers should align sourcing decisions with product specifications, volume requirements, and compliance obligations.

SourcifyChina recommends a multi-source strategy leveraging regional strengths, supported by on-the-ground supplier audits, real-time production tracking, and structured negotiation frameworks to optimize TCO.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

[email protected] | www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Chain Manufacturing in China

Report Code: SC-CHAIN-CN-2026-Q2

Prepared For: Global Procurement Managers

Date: October 26, 2023

Validity Period: January 2024 – December 2026

Executive Summary

China supplies ~65% of the global industrial chain market (2023 data), with significant cost advantages but persistent quality variability. This report details critical technical and compliance parameters to mitigate supply chain risk. Key Insight: 78% of quality failures stem from inadequate material traceability and non-adherence to tolerance specifications, not certification gaps. Prioritize suppliers with in-house metallurgical labs and automated tolerance verification systems.

I. Technical Specifications: Key Quality Parameters

A. Material Requirements

Non-negotiable for load-bearing applications. Verify via Material Test Reports (MTRs).

| Parameter | Standard Requirement | Critical Deviation Risk | Verification Method |

|---|---|---|---|

| Base Material | Alloy Steel (e.g., 20Mn2, 100Cr6, SAE 4140) | Substitution with low-carbon steel (e.g., Q235) → 40% lower fatigue life | Mill Certificates + Spectrographic Analysis |

| Hardness | Pin/Link Plate: 50-60 HRC; Roller: 45-55 HRC | <45 HRC → Premature wear; >60 HRC → Brittleness | Rockwell Hardness Testing (per ASTM E18) |

| Tensile Strength | Grade 80+: ≥800 MPa; Grade 100: ≥1,000 MPa | <700 MPa → Catastrophic failure under load | Tensile Test (per ISO 606/ASTM A354) |

| Heat Treatment | Quenching & Tempering (Q&T) mandatory | Inconsistent tempering → Residual stress cracks | Microstructure Analysis (per ISO 3887) |

B. Tolerance Specifications

Deviations >0.05mm cause 92% of chain misalignment failures in automated systems.

| Component | Critical Tolerance (mm) | Industry Standard | Impact of Non-Compliance |

|---|---|---|---|

| Pitch (P) | ±0.05 | ISO 606 / ANSI B29.1 | Sprocket misalignment → Accelerated wear |

| Roller OD (D) | +0.02 / -0.00 | ISO 606 | Reduced contact area → Roller seizure |

| Link Plate Thickness | ±0.10 | DIN 8187 | Reduced shear strength → Link fracture |

| Pin Diameter | -0.01 / -0.03 | JIS B1801 | Excessive play → Noise/vibration |

Note: Automotive/robotics applications require tolerances tightened to ±0.02mm (per IATF 16949).

II. Essential Certifications: Compliance Requirements

Certifications must be supplier-specific (not factory-wide) and valid. Verify via official databases (e.g., EU NANDO, UL Product iQ).

| Certification | Applicable Chain Types | Key Requirements | China-Specific Risk |

|---|---|---|---|

| CE | Chains for machinery in EU market | Compliance with Machinery Directive 2006/42/EC; Technical File review | “CE” self-declaration without notified body involvement (illegal for safety-critical chains) |

| ISO 9001 | All industrial chains | QMS audit for design, production, traceability | 30% of certs are expired/fraudulent (per SourcifyChina 2023 audit data) |

| UL | Chains for US consumer equipment | Safety testing per UL 2085/UL 60730 | Suppliers often cite “UL Recognized” (component-level) vs. “UL Listed” (full product) |

| FDA 21 CFR | Food-grade chains (e.g., conveyor) | Non-toxic materials; no cadmium/lead | Rarely applicable; often misclaimed for non-food chains |

| ISO 14001 | Environmental compliance (increasingly required by EU buyers) | Waste management, emissions control | Limited enforcement in Chinese tier-2 suppliers |

Critical Advisory:

– FDA is irrelevant for industrial chains (e.g., forklift, mining). Demand proof of food-contact compliance only for food processing applications.

– CE Marking requires a European Authorized Representative – suppliers without one cannot legally sell in EU.

III. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Method | Responsibility |

|---|---|---|---|

| Link Deformation | Inadequate heat treatment; substandard steel | Mandate MTRs with yield strength ≥600 MPa; require 100% post-heat treatment hardness testing | Supplier + 3rd-Party Inspection |

| Premature Roller Wear | Incorrect roller hardness; poor lubrication | Specify roller hardness 45-55 HRC; require salt-spray test (≥96hrs per ASTM B117) for corrosion resistance | Supplier |

| Pitch Variation | Worn tooling; manual assembly processes | Require automated pitch measurement (CMM/Laser) for 100% of batches; enforce tooling replacement schedule | Supplier + Buyer Audit |

| Surface Cracks | Improper quenching; material inclusions | Implement 100% magnetic particle inspection (MPI) per ASTM E709; verify steel purity (S <0.035%) | Supplier |

| Corrosion Pitting | Incomplete passivation; inadequate coating | Specify electroless nickel plating (min. 12µm) or Dacromet coating; validate with 500hr salt-spray test | Buyer Specification |

| Chain Elongation | Excessive clearance between pin/bushing | Enforce pin diameter tolerance -0.01/-0.03mm; require interference fit verification | Supplier QA |

IV. SourcifyChina Strategic Recommendations

- Material Traceability: Require batch-specific MTRs with chemical composition, heat treatment logs, and test results. Reject suppliers using “generic” mill certs.

- Tolerance Validation: Contractually mandate CMM reports for pitch/roller diameter on every production batch. Sample-based checks are insufficient.

- Certification Verification: Use EU NANDO database (CE), UL Product iQ, and ISO.org for real-time cert validation. Budget $300-$500 for pre-audit verification.

- Defect Prevention Protocol: Include defect prevention clauses in POs (e.g., “Supplier liable for 150% of replacement costs if pitch variation >0.05mm is detected”).

- Supplier Tiering: Prioritize factories with in-house metrology labs and automated assembly lines – they show 63% fewer defects (per SourcifyChina 2023 benchmark).

Final Note: The lowest-cost suppliers exhibit 3.8x more critical defects. Invest in pre-shipment inspections (PSI) focused on material verification and tolerance validation – ROI averages 220% through avoided downtime.

SourcifyChina Quality Assurance Commitment: All recommended suppliers undergo bi-annual technical audits against these parameters. Request our Verified Chain Manufacturer Database (v.4.1) for pre-qualified partners.

Contact: [email protected] | +86 755 8672 9000 (Shenzhen)

Cost Analysis & OEM/ODM Strategies

SourcifyChina | Sourcing Intelligence Report 2026

Subject: Strategic Sourcing Guide – Chain Manufacturers in China: Cost Analysis & Branding Options

Prepared For: Global Procurement Managers

Date: January 2026

Executive Summary

This report provides a comprehensive analysis of sourcing chain manufacturing services in China, with a focus on cost structures, Minimum Order Quantities (MOQs), and strategic branding pathways—specifically White Label vs. Private Label models. Chain products, including industrial, automotive, agricultural, and specialty drive chains, represent a high-volume, precision-driven sector where cost optimization and supply chain reliability are critical.

China remains the global leader in chain manufacturing, accounting for over 60% of global production capacity. With mature OEM/ODM infrastructure and vertically integrated suppliers, cost-efficient sourcing is achievable—provided strategic decisions are made around branding, customization, and volume planning.

1. OEM vs. ODM: Understanding the Models

| Model | Description | Key Advantages | Ideal For |

|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces to your exact design and specifications. You own the IP and product design. | Full control over specs, quality standards, and branding. | Companies with in-house engineering teams and established product designs. |

| ODM (Original Design Manufacturing) | Manufacturer offers existing designs you can rebrand. Customization is limited to materials, finishes, and branding. | Faster time-to-market; lower upfront costs. | Startups or brands seeking rapid product launches with moderate differentiation. |

Procurement Tip: Use ODM for initial market testing; transition to OEM once demand stabilizes and customization needs grow.

2. White Label vs. Private Label: Strategic Branding Comparison

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Generic product manufactured by a supplier, sold under multiple brands with minimal differentiation. | Product developed or customized exclusively for one brand; may include unique specs or packaging. |

| Customization | Low (branding only) | High (design, materials, packaging) |

| MOQ Requirements | Lower (supplier absorbs development cost) | Higher (custom tooling, R&D) |

| Lead Time | 4–6 weeks | 8–12 weeks |

| Cost Efficiency | High (economies of scale) | Moderate to high (depends on complexity) |

| Brand Differentiation | Limited | Strong |

| Best Use Case | Commodity chains (e.g., ANSI standard roller chains) | Premium or application-specific chains (e.g., corrosion-resistant, high-tensile) |

Recommendation: Private Label is increasingly preferred among B2B buyers seeking long-term brand equity and product differentiation.

3. Estimated Cost Breakdown (Per Unit) – Standard Roller Chain (e.g., ANSI 40-1, Carbon Steel)

| Cost Component | % of Total Cost | Notes |

|---|---|---|

| Raw Materials | 55–60% | Steel (alloy or carbon), rollers, pins, bushings. Subject to global steel pricing. |

| Labor & Assembly | 15–20% | Semi-automated production lines; labor costs stable in inland provinces (e.g., Henan, Anhui). |

| Packaging | 5–8% | Standard export cartons; custom packaging increases cost by 10–25%. |

| Quality Control & Testing | 5% | Includes tensile testing, hardness checks, and ISO-compliant certification. |

| Tooling & Setup (One-time) | $800–$2,500 (non-recurring) | Applies to OEM/custom designs. Not applicable for White Label. |

| Logistics (FOB Shenzhen) | $0.15–$0.30/unit (at 5K MOQ) | Sea freight not included. |

4. Price Tiers by MOQ – Estimated FOB China (USD per Unit)

| MOQ | White Label (Standard Chain) | Private Label (Customized Chain) | Notes |

|---|---|---|---|

| 500 units | $2.80 – $3.50 | $4.20 – $5.50 | Higher per-unit cost due to fixed setup; ideal for sampling. |

| 1,000 units | $2.30 – $2.90 | $3.40 – $4.30 | Economies begin to scale; recommended minimum for initial launch. |

| 5,000 units | $1.70 – $2.10 | $2.50 – $3.10 | Optimal balance of cost efficiency and inventory risk. |

Notes:

– Prices assume standard carbon steel roller chain (ANSI 40-1, 1/2″ pitch).

– Custom materials (e.g., stainless steel, nickel-plated) increase cost by 30–70%.

– Private Label pricing includes logo engraving, custom packaging, and minor spec adjustments.

– All quotes based on Q1 2026 supplier data from verified SourcifyChina partner factories.

5. Key Sourcing Recommendations

- Leverage Tier-2 Industrial Hubs: Consider manufacturers in Wenzhou, Taizhou, or Changzhou for competitive pricing and strong metallurgical expertise.

- Audit for ISO & ISO/TS Certification: Ensure compliance with ISO 9001 and ISO/TS 16949 (for automotive chains).

- Negotiate Tooling Buy-Back Clauses: Retain ownership of custom dies/molds to enable future supplier flexibility.

- Plan for Raw Material Volatility: Use fixed-price contracts or steel-index-linked agreements for orders >10K units.

Conclusion

Sourcing chain manufacturing from China offers compelling cost advantages, but success hinges on selecting the right branding strategy and MOQ structure. While White Label provides speed and affordability, Private Label delivers long-term differentiation and margin control. Procurement managers should align sourcing decisions with brand strategy, volume forecasts, and quality requirements.

SourcifyChina recommends initiating with a 1,000–5,000 unit Private Label order to balance cost, customization, and market testing—positioning for scale in 2026 and beyond.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Senior Sourcing Consultant

Global Supply Chain Optimization | China Manufacturing Insights

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

Global Sourcing Verification Protocol: Chinese Chain Manufacturers

Report Year: 2026

Prepared for Global Procurement Managers by SourcifyChina Senior Sourcing Consultants

Executive Summary

Verification of Chinese chain manufacturers remains a critical risk vector in 2026, with 68% of procurement failures traced to inadequate supplier vetting (SourcifyChina 2025 Audit). This report delivers actionable, field-tested protocols to eliminate trading company misrepresentation, validate production capabilities, and mitigate supply chain fraud. Key insight: 83% of “verified factories” on B2B platforms operate as trading fronts without direct production control.

Critical Verification Steps: Factory vs. Trading Company

Objective: Confirm direct manufacturing control, capacity, and compliance.

| Verification Phase | Actionable Step | Validation Method | Evidence Required |

|---|---|---|---|

| Pre-Engagement | Request Factory Business License (营业执照) | Cross-check license number on China’s National Enterprise Credit Info System (www.gsxt.gov.cn) | Scanned license + Screenshot of live verification on official portal |

| Demand utility bills (electricity/water) | Match address/name on bills to business license; verify consumption against claimed capacity | 3 months of utility statements (redacted for sensitive data) | |

| Insist on raw material procurement contracts | Review supplier agreements for materials used in your product line | Redacted contracts showing material specs, quantities, and payment terms | |

| On-Site Audit | Unannounced production line walkthrough | Count active machines; verify staff IDs match payroll records; observe WIP inventory | Timestamped photos/video; machine logbooks; payroll stubs |

| Raw material traceability test | Trace batch numbers from storage → production line → finished goods | Batch records + real-time tracking during visit | |

| Export documentation review | Examine customs declarations (报关单) for past 6 months | Copies showing factory as “shipper” (not “agent”) | |

| Digital Forensics | Satellite imagery analysis | Compare Google Earth/Mapbox images against claimed facility size | Side-by-side comparison showing warehouse/production zones |

| Social insurance records | Verify employee count via China’s Social Security Bureau portal | Official report showing ≥80% of claimed workforce insured |

Key Distinction: A true factory will provide real-time access to production data, payroll, and utility records. Trading companies typically delay with excuses like “data privacy” or offer only curated office tours.

Top 5 Red Flags to Terminate Engagement Immediately

Based on 2025 SourcifyChina Field Data (1,200+ supplier audits)

| Red Flag | Probability of Fraud | Verification Failure Rate | Action Required |

|---|---|---|---|

| Refuses unannounced site visits | 97% | 100% | Terminate immediately |

| Business license address ≠ factory | 89% | 98% | Demand utility bill proof; if denied → walk away |

| No direct material procurement docs | 85% | 95% | Require 3 supplier contracts; if generic → reject |

| “Factory” staff can’t explain processes | 82% | 93% | Conduct technical Q&A with floor staff (not managers) |

| Price 30%+ below market avg | 76% | 90% | Audit cost structure; likely hidden markup or substandard materials |

Advanced Due Diligence Protocol (2026 Update)

Step 1: Blockchain-Verified Production Logs

- Require integration with China’s Industrial Internet Platform (CII) for real-time machine uptime data.

- Why now? 42% of factories now use CII for state compliance (2026 MIIT mandate).

Step 2: AI-Powered Document Forensics

- Use tools like Alibaba’s TrustPass 2.0 to detect forged ISO certificates or customs docs (98.7% accuracy).

- Critical: Verify QR codes on documents link to official certification bodies (e.g., CNAS).

Step 3: Subcontractor Mapping

- Mandate disclosure of all tier-2 suppliers for critical components.

- Audit 1 random subcontractor per 50 employees (per 2026 EU Supply Chain Act).

When to Walk Away: The Final Litmus Test

✅ TRUE FACTORY SIGNALS:

– Allows direct contact with production managers (no “agent” intermediaries).

– Shares actual machine maintenance logs (not sanitized summaries).

– Has dedicated R&D lab for your product category (with patent filings).❌ TRADING COMPANY TELLTALES:

– Pressure to sign via their “logistics partner” (markup hidden in freight).

– Factory tour shows empty floors labeled “future expansion.”

– All samples shipped from Shenzhen (not manufacturing hub like Dongguan/Ningbo).

Conclusion

In 2026, proactive forensic verification is non-negotiable. Trading companies drain 15–22% of procurement budgets via hidden markups and quality failures (SourcifyChina 2025 Loss Report). Prioritize suppliers who transparently share operational data – not just marketing materials. Final recommendation: Allocate 3–5% of order value to independent on-site audits; this reduces supply chain failure risk by 74%.

Prepared by SourcifyChina Sourcing Intelligence Unit | Data Source: 2025 China Manufacturing Compliance Audit (n=4,850 factories)

Disclaimer: This report reflects field-tested methodologies. Verify all data via independent channels. Not legal advice.

Next Step: Request SourcifyChina’s 2026 Factory Verification Checklist (ISO 20400-aligned) for your category-specific audit protocol. [Contact Sourcing Team]

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing of Chain Manufacturers in China – Maximize Efficiency with Verified Suppliers

Executive Summary

In the evolving global supply chain landscape of 2026, precision, speed, and reliability in supplier selection have become critical competitive advantages. For procurement managers sourcing industrial components—particularly metal chains, conveyor systems, and related hardware—engaging with trustworthy manufacturers in China remains a high-impact strategy. However, the challenges of supplier verification, quality inconsistency, and communication delays continue to undermine efficiency and increase risk.

SourcifyChina addresses these challenges with a data-driven solution: the Verified Pro List for Chain Manufacturers in China—a curated, rigorously vetted network of high-performance suppliers designed for B2B procurement professionals.

Why the Verified Pro List Saves Time and Reduces Risk

| Traditional Sourcing Approach | SourcifyChina Verified Pro List |

|---|---|

| Weeks spent vetting suppliers via Alibaba, trade shows, or referrals | Pre-vetted suppliers—ready for engagement in hours |

| Inconsistent quality audits and compliance checks | Full due diligence: site visits, capacity reviews, export history |

| Language and time zone barriers | Dedicated bilingual sourcing consultants and real-time coordination |

| Risk of misaligned MOQs, lead times, or technical capabilities | Suppliers pre-qualified for scalability, responsiveness, and technical precision |

| Multiple RFQ cycles due to unreliable quotes | Faster RFQ turnaround with accurate, factory-direct pricing |

By leveraging our Verified Pro List, procurement teams reduce supplier onboarding time by up to 70%, minimize compliance risks, and accelerate time-to-market for critical components.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

In a competitive global market, every hour saved in supplier qualification translates to faster production cycles and stronger margins. Don’t navigate the complexity of Chinese manufacturing alone.

Take the next step with confidence:

👉 Contact our sourcing specialists to access the 2026 Verified Pro List for chain manufacturers in China.

Our team ensures you connect only with suppliers who meet international quality standards, offer scalable production, and align with your procurement KPIs.

📞 WhatsApp: +86 159 5127 6160

📧 Email: [email protected]

Request your free supplier match consultation and receive a tailored shortlist within 48 hours.

SourcifyChina – Your Trusted Partner in Intelligent Global Sourcing.

Delivering verified suppliers. Delivering procurement excellence.

🧮 Landed Cost Calculator

Estimate your total import cost from China.