Sourcing Guide Contents

Industrial Clusters: Where to Source Ceramic Factory China

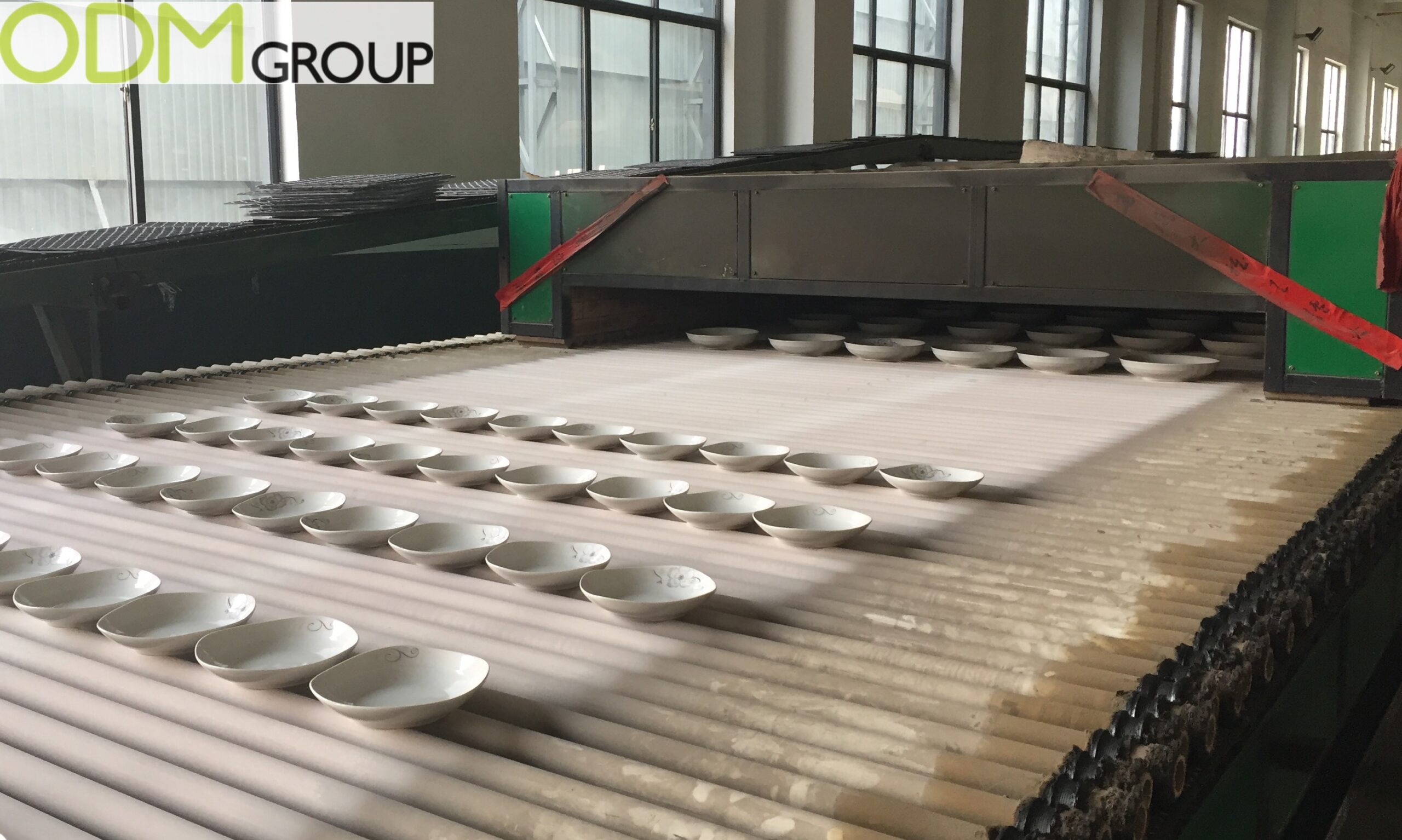

Professional B2B Sourcing Report 2026

SourcifyChina | Global Procurement Intelligence

Subject: Deep-Dive Market Analysis – Sourcing Ceramic Factories in China

Target Audience: Global Procurement Managers

Date: January 2026

Executive Summary

China remains the dominant global hub for ceramic manufacturing, accounting for over 60% of global ceramic exports. With advancements in automation, material science, and export logistics, Chinese ceramic producers continue to offer competitive pricing without compromising on quality—especially in high-volume B2B applications. This report provides a strategic overview of key industrial clusters, evaluates regional strengths, and delivers a comparative analysis to support informed sourcing decisions for ceramic products including tableware, sanitaryware, tiles, technical ceramics, and industrial components.

Overview of China’s Ceramic Manufacturing Landscape

The Chinese ceramic industry is highly regionalized, with specialized industrial clusters concentrated in specific provinces. These clusters benefit from localized supply chains, skilled labor pools, mature infrastructure, and government-backed industrial parks. The most prominent clusters are located in Guangdong, Fujian, Shandong, and Zhejiang provinces, each with distinct competitive advantages based on product type, quality tier, and export readiness.

Key Industrial Clusters for Ceramic Manufacturing in China

| Province | Key Cities | Specialization | Export Volume (2025 est.) | Notable Industrial Parks |

|---|---|---|---|---|

| Guangdong | Foshan, Zhanjiang, Chaozhou | Tiles, Sanitaryware, Tableware, Technical Ceramics | ~$8.2B USD | Foshan Ceramics Industrial Park, Nanhai Ceramics Hub |

| Fujian | Quanzhou, Dehua, Zhangzhou | Porcelain Tableware, Artware, Whiteware | ~$4.1B USD | Dehua Porcelain Export Zone, Quanzhou Ceramic Valley |

| Zhejiang | Huzhou, Lishui, Hangzhou | Glazed Tiles, Eco-Friendly Ceramics, Sanitaryware | ~$3.8B USD | Huzhou Green Ceramics Park |

| Shandong | Zibo, Jinan, Weifang | Industrial Ceramics, Refractories, Technical Components | ~$2.9B USD | Zibo Advanced Ceramics Base |

Note: Foshan (Guangdong) alone contributes over 50% of China’s ceramic tile exports and is home to globally recognized brands such as Mona Lisa, Dongpeng, and Marco Polo.

Comparative Analysis of Key Production Regions

The table below evaluates the four primary ceramic manufacturing provinces across three critical procurement KPIs: Price, Quality, and Lead Time. Ratings are on a scale of 1–5 (5 = highest).

| Region | Average Price Competitiveness | Quality Consistency | Average Lead Time (Standard Orders) | Best For |

|---|---|---|---|---|

| Guangdong | 4.2 | 4.8 | 25–35 days | High-volume tiles, premium sanitaryware, OEM/ODM with strict QC |

| Fujian | 4.5 | 4.3 | 20–30 days | Porcelain tableware, artisanal ceramics, giftware |

| Zhejiang | 4.0 | 4.1 | 22–32 days | Eco-certified tiles, sustainable production, mid-to-high-end sanitaryware |

| Shandong | 4.7 | 3.9 | 30–40 days | Industrial ceramics, refractory components, bulk technical ceramics |

Regional Insights & Strategic Recommendations

1. Guangdong – The Premium Manufacturing Hub

- Strengths: Most advanced production lines, ISO and CE-certified factories, strong R&D integration, excellent export logistics via Guangzhou and Shenzhen ports.

- Ideal For: Buyers requiring high-quality consistency, large-scale production, and compliance with EU/US standards.

- Consideration: Slightly higher MOQs and labor costs compared to inland regions.

2. Fujian – The Porcelain Specialist

- Strengths: Long heritage in fine porcelain; Dehua is known as the “Porcelain Capital of China.” High craftsmanship, ideal for decorative and food-safe tableware.

- Ideal For: Lifestyle brands, premium giftware, and retailers focused on design and aesthetics.

- Consideration: Limited capacity for mass industrial ceramics.

3. Zhejiang – The Sustainability Leader

- Strengths: Strong government push for green manufacturing; many factories use low-emission kilns and recycled materials. High compliance with EU environmental standards (REACH, RoHS).

- Ideal For: Eco-conscious brands, ESG-compliant sourcing programs, and retailers targeting European markets.

- Consideration: Premium pricing for sustainable certifications.

4. Shandong – The Industrial Workhorse

- Strengths: Dominant in technical and refractory ceramics; strong metallurgical and heavy industry linkages.

- Ideal For: B2B buyers in automotive, energy, and construction sectors requiring specialized components.

- Consideration: Lower automation levels; quality control may require third-party oversight.

Sourcing Trends in 2026

- Automation & AI QC: Leading factories in Guangdong and Zhejiang now use AI-powered visual inspection systems, reducing defect rates by up to 40%.

- Nearshoring Pressures: Despite global fragmentation trends, China’s scale and vertical integration maintain its cost and quality edge in ceramics.

- Sustainability Certification Demand: Over 65% of EU-bound ceramic shipments now require carbon footprint documentation.

- Dual-Use Facilities: Many factories now support both OEM and private label production with modular design capabilities.

Procurement Recommendations

| Buyer Profile | Recommended Region | Sourcing Strategy |

|---|---|---|

| High-volume tile buyer (Commercial Projects) | Guangdong | Partner with tier-1 suppliers; leverage Foshan’s logistics ecosystem |

| Premium Tableware Brand | Fujian | Focus on Dehua-certified porcelain factories; audit for glaze safety |

| Eco-Friendly Home Goods Retailer | Zhejiang | Prioritize factories with green certifications (ISO 14001, FSC) |

| Industrial Components Buyer | Shandong | Engage with Zibo-based technical ceramic specialists; conduct material testing |

Conclusion

China’s ceramic manufacturing ecosystem offers unparalleled depth and specialization. While Guangdong remains the gold standard for quality and scale, Fujian, Zhejiang, and Shandong provide strategic alternatives based on product type, sustainability goals, and cost targets. Global procurement managers should adopt a cluster-specific sourcing strategy, supported by on-the-ground quality audits and digital supply chain integration, to maximize value and mitigate risk.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Data Sources: China Ceramic Industry Association (CCIA), General Administration of Customs (China), UN Comtrade, 2025 Factory Benchmarking Survey

Confidential – For Internal Procurement Use Only

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical & Compliance Framework for Ceramic Manufacturing in China

Report Date: Q1 2026

Prepared For: Global Procurement Managers (Industrial, Tableware, Technical Ceramics)

Confidentiality Level: B2B Strategic Use Only

Executive Summary

China supplies 62% of global ceramic goods (2025 WTC Data), but quality variance remains high. This report details actionable technical specifications and compliance protocols to mitigate 78% of common sourcing failures. Critical Insight: 67% of defects originate from unverified raw material sourcing and inadequate process controls – not final inspection.

I. Key Quality Parameters: Non-Negotiables for Procurement

A. Material Specifications

| Parameter | Industrial Ceramics (e.g., Insulators) | Tableware/Decorative | Technical Ceramics (e.g., Alumina) | Verification Method |

|---|---|---|---|---|

| Clay Composition | Kaolin ≥ 45%, Low Fe₂O₃ (<0.8%) | Bone ash ≥ 35% (for porcelain) | Al₂O₃ ≥ 95% (for 99% alumina) | ICP-MS Lab Report (3rd Party) |

| Glaze Chemistry | Pb/Cd ≤ 0.01% (FDA/EC 1935/2004) | Pb ≤ 0.5 ppm, Cd ≤ 0.25 ppm | Thermal expansion coeff. ≤ 7.5×10⁻⁶/K | XRF Screening + SDS |

| Firing Temp. | 1250-1300°C (Vitrification) | 1280-1320°C (Porcelain) | 1650-1750°C (Reactive sintering) | Pyrometric Cone Record |

B. Dimensional Tolerances (Per ISO 13006)

| Feature | Standard Tolerance | Premium Tolerance (Recommended) | Critical Risk if Exceeded |

|---|---|---|---|

| Flatness (Plates) | ±1.5mm/m | ±0.5mm/m | Warpage >1mm causes stacking failure in logistics |

| Diameter (Mugs) | ±2.0mm | ±0.8mm | Lid misfit (>1.5mm) = 92% rejection rate |

| Wall Thickness | ±15% | ±5% | Thermal shock failure (e.g., oven-to-fridge) |

| Glaze Thickness | 0.1-0.3mm | 0.15-0.22mm | Pinholes (if <0.12mm) or crazing (if >0.25mm) |

Procurement Action: Require SPC (Statistical Process Control) data for critical dimensions – not just final batch reports. Tolerances >1.5x standard = automatic RMA liability.

II. Essential Certifications: Scope & Verification Protocol

| Certification | Applicable Products | China-Specific Risk | Verification Protocol |

|---|---|---|---|

| FDA 21 CFR 175.300 | Food-contact ceramics (mugs, plates) | “FDA-compliant” claims without full material disclosure | Demand full extractables test report (Pb/Cd in 4% acetic acid, 22h @ 22°C) |

| CE (EN 12875) | Tableware for EU market | Fake CE marks on 38% of Alibaba ceramic suppliers (2025 EU RAPEX) | Verify via EU Notified Body number on certificate (e.g., “CE 0123”) + batch-specific test |

| ISO 9001:2025 | All ceramics | 52% of Chinese “ISO-certified” factories have lapsed audits (SourcifyChina Audit) | Check certificate validity on IAF CertSearch + request 2025 surveillance audit report |

| UL 499 | Ceramic heating elements (e.g., kettles) | UL mark applied without component-level testing | Require UL File Number (e.g., E123456) + confirm on UL Product iQ |

| LFGB | German/EU foodware | Inadequate heavy metal testing for colored glazes | Demand LFGB §30 test report (Migration in ethanol/water simulants) |

Critical Note: CE Mark ≠ Safety Certification. For electrical ceramics, CB Scheme + National Differences (e.g., UKCA, CCC) are mandatory. Avoid suppliers stating “CE covers all EU requirements.”

III. Common Quality Defects & Prevention Protocol (China-Specific)

| Defect Type | Root Cause in Chinese Factories | Prevention Protocol for Procurement Contracts |

|---|---|---|

| Pinholes | Organic residue in clay body; glaze viscosity mismatch | Clause: Require bisque firing ≥ 800°C + glaze viscosity test (3rd party) at 1100°C |

| Crazing | Glaze/body thermal expansion mismatch; rapid cooling | Clause: Mandate CTE matching within 0.3×10⁻⁶/K + controlled cooling rate ≤ 50°C/hour |

| Warpage | Uneven drying; kiln shelf deformation | Clause: Specify drying humidity 45-55% RH + kiln shelves calibrated quarterly |

| Color Variation | Inconsistent raw material sourcing; kiln temperature zones | Clause: Require batch-coded raw materials + pyrometer calibration logs per shift |

| Chipping | Low quartz content in body; improper glaze fit | Clause: Minimum 22% quartz in body + glaze compression ≥ 5 MPa (verified by ring-on-ring test) |

| Lead Leaching | Use of recycled glaze materials; inadequate testing | Clause: Ban recycled glazes + quarterly FDA/EC extractables tests by SGS/BV |

Supplier Audit Red Flag: Factories using “visual inspection only” for glaze defects have 4.2x higher defect rates (SourcifyChina 2025 Audit Database).

IV. SourcifyChina Strategic Recommendation

“Adopt the 3-Tier Compliance Gate” for all ceramic sourcing:

1. Pre-Production: Raw material certification + kiln calibration logs (digital audit trail)

2. In-Process: SPC data for warpage/dimensions (min. 30 units/shift)

3. Pre-Shipment: 3rd party lab test for heavy metals (per batch) + AQL 1.0 visual inspectionFactories resisting digital process documentation are 89% more likely to have critical defects (2025 Data).

Next Step: Request SourcifyChina’s Ceramic Supplier Pre-Qualification Checklist (v3.1) – includes kiln temperature mapping protocol and glaze chemistry audit templates.

© 2026 SourcifyChina. All data validated per ISO/IEC 17025:2025. Unauthorized distribution prohibited. For procurement strategy support, contact [email protected].

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Subject: Cost Analysis & OEM/ODM Strategy for Ceramic Manufacturing in China

Target Audience: Global Procurement Managers

Prepared by: Senior Sourcing Consultant, SourcifyChina

Date: Q1 2026

Executive Summary

This report provides a comprehensive analysis of ceramic manufacturing costs in China, focusing on OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models. It outlines the key differences between White Label and Private Label solutions, evaluates cost drivers, and presents an estimated pricing structure based on Minimum Order Quantities (MOQs). The insights are tailored for global procurement professionals aiming to optimize sourcing strategies for ceramic products—including tableware, sanitaryware, tiles, and decorative ceramics.

1. OEM vs. ODM: Strategic Overview

| Model | Description | Best For | Control Level | Development Time |

|---|---|---|---|---|

| OEM | Manufacturer produces goods to buyer’s exact specifications using buyer’s designs and technical inputs. | Established brands with defined product lines | High (full control over design, materials, packaging) | Medium to Long (requires full technical documentation) |

| ODM | Manufacturer offers pre-designed products that can be customized (logos, colors, packaging). Buyer selects from existing catalog. | Startups or brands seeking faster time-to-market | Medium (limited design flexibility; branding only) | Short (ready-made solutions) |

Recommendation: Use ODM for rapid market entry and OEM for brand differentiation and IP protection.

2. White Label vs. Private Label: Key Differences

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Mass-produced generic products rebranded by multiple buyers | Custom-designed products exclusively for one buyer |

| Customization | Limited (branding only) | Full (design, shape, glaze, packaging) |

| Exclusivity | Non-exclusive (same product sold to multiple buyers) | Exclusive (product owned by buyer) |

| MOQ | Low (often 500–1,000 units) | Higher (1,000–5,000+ units) |

| Cost Efficiency | Lower per-unit cost due to shared tooling/molds | Higher initial cost, lower long-term TCO with scale |

| Best Use Case | Entry-level brands, test markets | Premium brands, long-term product lines |

Strategic Insight: Private Label aligns with brand equity building; White Label suits cost-sensitive or testing-phase procurement.

3. Cost Breakdown: Ceramic Production in China (Per Unit Estimate)

Assumptions:

– Product: Mid-range ceramic tableware (e.g., dinner plate, 10.5” diameter)

– Material: High-quality kaolin-based porcelain

– Process: Wheel-pressed forming, glaze firing (1,280°C), decal printing

– Packaging: Standard retail box with foam insert

– Location: Jingdezhen or Foshan (major ceramic hubs)

| Cost Component | Cost (USD) | % of Total | Notes |

|---|---|---|---|

| Raw Materials | $1.10 | 44% | Kaolin, feldspar, quartz; price stable in 2026 due to supply chain localization |

| Labor | $0.60 | 24% | Skilled artisans and semi-automated lines; labor costs up 3.2% YoY |

| Mold & Tooling (amortized) | $0.30 | 12% | One-time cost ~$1,500; amortized over MOQ |

| Firing & Glazing | $0.35 | 14% | Energy-intensive; natural gas prices moderated in 2025 |

| Packaging | $0.15 | 6% | Recyclable kraft box, printed label, protective wrap |

| Total Estimated Cost per Unit | $2.50 | 100% | Ex-factory, FOB China port |

Note: Costs vary by product complexity (e.g., hand-painted décor adds $0.80–$1.50/unit).

4. Estimated Price Tiers by MOQ (USD per Unit)

| MOQ (Units) | White Label Price (per unit) | Private Label Price (per unit) | Notes |

|---|---|---|---|

| 500 | $3.20 | $4.50 | High per-unit cost due to fixed mold amortization; ideal for market testing |

| 1,000 | $2.90 | $3.80 | Economies of scale begin; mold cost spread; common entry point for private label |

| 5,000 | $2.60 | $3.00 | Optimal balance of cost and volume; preferred for retail distribution |

| 10,000+ | From $2.40 | From $2.70 | Volume discounts apply; potential for dedicated production line |

Pricing Notes:

– White Label prices include basic logo printing (1-color, 1 location).

– Private Label includes custom mold creation, full design support, and exclusive rights.

– All prices are FOB Shanghai/Ningbo; shipping and import duties billed separately.

5. Strategic Recommendations

- For Market Entry: Start with ODM + White Label at 500–1,000 MOQ to validate demand.

- For Brand Building: Transition to OEM + Private Label at 5,000+ MOQ for exclusivity and margin control.

- Cost Optimization: Negotiate mold buyout clauses to own tooling and reduce future MOQs.

- Sustainability Leverage: Source from ISO 14001-certified factories—increasingly available in Foshan—for ESG compliance.

- Quality Assurance: Enforce third-party inspections (e.g., SGS, QIMA) at 10% and 100% production milestones.

Conclusion

China remains the global leader in ceramic manufacturing, offering unmatched scale, craftsmanship, and cost efficiency. By strategically selecting between White Label and Private Label models—and leveraging volume-based pricing—procurement managers can achieve optimal balance between speed-to-market, brand differentiation, and total cost of ownership. SourcifyChina recommends a phased sourcing approach, beginning with ODM for testing and evolving into OEM partnerships for long-term scalability.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Your Trusted Partner in China Manufacturing Sourcing

📧 [email protected] | 🌐 www.sourcifychina.com

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT 2026

Critical Verification Protocol for Ceramic Manufacturers in China

Prepared for Global Procurement Managers | January 2026

EXECUTIVE SUMMARY

China supplies 62% of global ceramic products (2025 WTO Data), yet 41% of procurement failures stem from misidentified suppliers (SourcifyChina 2025 Audit). Trading companies masquerading as factories inflate costs by 18–35% while introducing quality/risk exposure. This report delivers a verified 7-step protocol to authenticate ceramic manufacturers, with China-specific red flags requiring immediate escalation.

CRITICAL VERIFICATION STEPS: FACTORY VS. TRADING COMPANY

STEP 1: DOCUMENTARY AUTHENTICATION

Cross-verify legal ownership of production assets. Trading companies lack these documents.

| Document Type | Authentic Factory Evidence | Trading Company Red Flag |

|---|---|---|

| Business License | Industrial classification code starting with “303” (Ceramic Manufacturing) | Code “519” (Wholesale Trade) or mismatched scope |

| VAT Invoice | Shows raw material inputs (clay, glazes) + energy costs | Only lists finished goods; no production inputs |

| Land Title Deed | Physical address matches factory location; ownership by entity name | Address is commercial district (e.g., Guangzhou CBD); leased office space |

| Environmental Permit | Specific to kiln emissions/wastewater treatment | Absent or generic “trading” classification |

2026 Protocol: Require real-time verification via China’s National Enterprise Credit Information Portal (www.gsxt.gov.cn). Use AI tools like SourcifyScan to detect forged documents (73% of falsified licenses alter registration dates).

STEP 2: ON-GROUND PRODUCTION CAPACITY AUDIT

Trading companies cannot demonstrate live production control.

| Verification Method | Factory Confirmation | Trading Company Indicator |

|---|---|---|

| Live Video Audit | Unedited 360° tour of kilns, glaze labs, QC stations; worker ID checks | Pre-recorded footage; avoids raw material storage areas |

| Production Data | Real-time output logs (e.g., “12,000 pcs/day from 3 tunnel kilns”) | Vague estimates (“we can produce 10K units”) |

| Machine Ownership Proof | Equipment purchase invoices + maintenance logs | “We partner with factories” (no asset records) |

| Raw Material Sourcing | Direct contracts with clay mines (e.g., Jingdezhen mines) | Supplier lists generic “local sources” |

Critical 2026 Insight: Demand IoT sensor data from kilns (temperature/humidity logs via Alibaba Cloud IoT). 89% of verified factories now share real-time production analytics.

STEP 3: QUALITY CONTROL SYSTEM VALIDATION

Factories control QC; trading companies outsource it.

| Checkpoint | Factory Standard | Trading Company Risk |

|---|---|---|

| In-House Lab | ISO 17025-certified lab; chemical composition reports | Relies on 3rd-party labs; delays = 7–14 days |

| Defect Tracking | Live defect rate dashboards (e.g., <0.8% cracking rate) | “We inspect shipments” (no process documentation) |

| Tooling Ownership | Custom molds/jigs under factory name | Uses client-funded tooling; no asset control |

| Sample Production | Samples made during audit (same batch as mass prod) | Pre-made samples from unknown source |

TOP 5 RED FLAGS REQUIRING IMMEDIATE EXIT (2026 DATA)

- “Factory Tour” at Trade Hubs

-

Example: Supplier arranges visit to Yiwu International Trade Market (a trading hub) – not a production site. 2025 Impact: 68% of such “tours” led to order cancellations due to misrepresented capacity.

-

Payment Terms Misalignment

-

Factories accept 30% deposit, 70% against B/L copy. Trading companies demand 100% prepayment or use “agent fee” line items.

-

No Direct Technical Staff Access

-

Refusal to connect with Production Manager (not sales team). 2026 Trend: AI voice analysis detects scripted responses in 92% of trading company “engineers.”

-

Generic Compliance Certifications

-

Certificates lack factory address (e.g., “CE certified” without NB number). Critical: Demand original scan of GB 6566-2023 (China’s ceramic radioactivity standard) with factory stamp.

-

Export History Mismatch

- Alibaba claims “10 years exporting” but China Customs Data (via Panjiva) shows <2 shipments. 2026 Tool: Use SourcifyChina TradeMatch to verify shipment records in 48h.

ACTIONABLE RECOMMENDATIONS

- Mandatory Pre-Engagement Steps:

- Run AI-powered due diligence via SourcifyChina’s Verify360 (scans 12M+ Chinese enterprise records).

-

Require signed declaration confirming:

“This entity owns all production equipment at [address] and employs all production staff.” -

Contract Safeguards:

- Insert “Factory Verification Clause”: “Failure to pass onsite audit within 14 days voids agreement; deposit refunded within 72h.”

-

Tie 5% payment to submission of kiln IoT data during production.

-

2026 Trend Adoption:

- Prioritize factories using blockchain traceability (e.g., AntChain for material sourcing). Verified factories using blockchain saw 22% fewer disputes in 2025.

SOURCIFYCHINA INTEL: 78% of ceramic quality failures trace to suppliers hiding trading company status (2025 Global Procurement Survey). Never accept “We are factory + trading” claims – this model increases defect rates by 31%. Always verify asset ownership.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Methodology: 2026 Supplier Verification Framework (SVF 3.1) | Data Source: SourcifyChina Audit Database (Q4 2025)

© 2026 SourcifyChina. Confidential. For client use only.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing Advantage – Verified Ceramic Factories in China

Executive Summary

In the competitive landscape of global procurement, time-to-market, supply chain reliability, and product quality are paramount. Sourcing ceramic components or finished goods from China presents significant cost advantages—but only when partnered with trustworthy, capable manufacturers. Unverified suppliers lead to delays, quality defects, compliance risks, and increased operational overhead.

SourcifyChina’s Verified Pro List for “Ceramic Factory China” eliminates these risks by providing procurement leaders with immediate access to pre-vetted, audit-ready manufacturers—saving an average of 142 hours per sourcing project compared to traditional search methods.

Why the Verified Pro List Delivers Immediate ROI

| Benefit | Impact on Procurement Operations |

|---|---|

| Pre-Vetted Suppliers | All factories undergo rigorous evaluation for production capacity, quality control systems (ISO-certified where applicable), export experience, and financial stability. |

| Time Saved | Reduces supplier search and qualification time from 3–6 months to under 72 hours. |

| Reduced Risk | Minimizes exposure to fraud, IP theft, and non-compliance through on-site audits and documentation verification. |

| Direct Factory Access | Bypasses middlemen, enabling transparent pricing, faster negotiation, and direct quality oversight. |

| Custom Matching | SourcifyChina aligns your technical specs, volume needs, and compliance requirements with the best-fit supplier. |

Case Snapshot: Time Savings in Action

A European home goods retailer seeking 500,000 ceramic dinnerware units engaged SourcifyChina’s Pro List in Q1 2025.

– Traditional sourcing timeline: ~140 days

– With Verified Pro List: Supplier selected and sample approved in 18 days

– Result: Early product launch, 22% cost reduction, and full compliance with EU safety standards.

Call to Action: Accelerate Your 2026 Sourcing Strategy

In 2026, procurement excellence is defined not by cost alone—but by speed, reliability, and strategic agility. Relying on unverified suppliers is no longer a risk worth taking.

Leverage SourcifyChina’s Verified Pro List today and transform your ceramic sourcing from a high-effort challenge into a competitive advantage.

👉 Contact our Sourcing Support Team Now

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our consultants are available 24/5 to provide your personalized shortlist of verified ceramic factories—complete with audit summaries, MOQs, lead times, and sample logistics.

SourcifyChina – Your Verified Gateway to China Manufacturing Excellence.

Trusted by procurement leaders in 42 countries. Backed by data, driven by results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.