The global cementitious fiber board market is experiencing robust growth, driven by rising demand for durable, fire-resistant, and moisture-proof building materials across residential, commercial, and industrial sectors. According to a 2023 report by Grand View Research, the global fiber cement board market was valued at USD 4.8 billion and is expected to expand at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030. This growth is fueled by increasing construction activities in emerging economies, stricter building codes favoring non-combustible materials, and the growing preference for low-maintenance, sustainable building solutions. As demand surges, key manufacturers are investing in innovation, product diversification, and regional expansion to capture market share. In this evolving landscape, the following seven companies have emerged as leading cementitious fiber board manufacturers based on production capacity, global reach, technological advancement, and market presence.

Top 7 Cementitious Fiber Board Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Supplier of Quality Fiber Cement Board

Domain Est. 2014

Website: scginternational.com

Key Highlights: SCG International is a leading manufacturer and supplier of durable fiber cement board solutions and construction products….

#2 Kalsi Building Solutions

Domain Est. 2018

Website: kalsi-building-solutions.com

Key Highlights: Kalsi is one of a leading pioneer of fibre cement building materials for drywall construction, and forms part of the 60-brand strong, industrial group Etex….

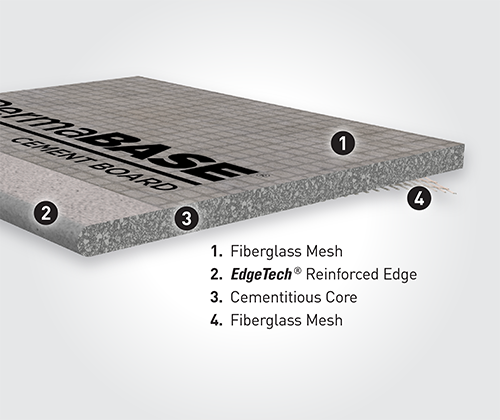

#3 Moisture & Mold Resistant Cement Board

Domain Est. 1999

Website: permabase.com

Key Highlights: PermaBASE Cement Board provides a durable surface designed to withstand prolonged exposure to moisture. Made with Portland cement, aggregate, and fiberglass ……

#4 Fiber Cement Siding

Domain Est. 2000

Website: nichiha.com

Key Highlights: Fiber cement siding is an engineered building material formed with a dry mix of fly ash, cement, sand, and wood fibers that’s pressed under high pressure ……

#5 Swisspearl Group

Domain Est. 2003

Website: swisspearl.com

Key Highlights: We turn natural raw materials into innovative and sustainable products made of fibre cement for facades, interiors, and garden areas….

#6 EQUITONE

Domain Est. 2009

Website: equitone.com

Key Highlights: EQUITONE fibre cement cladding – designed by and for architects. Durable, through-coloured facade panels for modern, sustainable architecture….

#7 Allura USA: #1 Fiber Cement Siding Manufacturer

Domain Est. 2014

Website: allurausa.com

Key Highlights: Long-lasting Allura products are built to last a decade without even breaking a sweat. They remain reliable and won’t lose their looks….

Expert Sourcing Insights for Cementitious Fiber Board

H2: Market Trends for Cementitious Fiber Board in 2026

The global cementitious fiber board (CFB) market is poised for notable growth and transformation by 2026, driven by evolving construction practices, increasing demand for sustainable and fire-resistant building materials, and technological advancements in composite manufacturing. The following analysis outlines key market trends expected to shape the cementitious fiber board industry in 2026:

-

Rising Demand in Residential and Commercial Construction

By 2026, continued urbanization—particularly in Asia-Pacific, Latin America, and parts of Africa—will fuel construction activities, boosting demand for durable and low-maintenance building materials. Cementitious fiber board, known for its resistance to moisture, mold, and fire, is increasingly favored for exterior cladding, soffits, and interior wall systems in both residential and commercial buildings. The growing popularity of prefabricated and modular construction methods will further enhance CFB adoption due to its dimensional stability and ease of installation. -

Sustainability and Green Building Regulations

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing architects and developers toward eco-friendly materials. Cementitious fiber boards, often made with cement, cellulose fibers, and recycled content, align well with sustainability goals. By 2026, manufacturers are expected to increasingly emphasize low-carbon production processes, use of fly ash or other industrial byproducts, and improved recyclability to meet strict environmental standards and appeal to environmentally conscious consumers. -

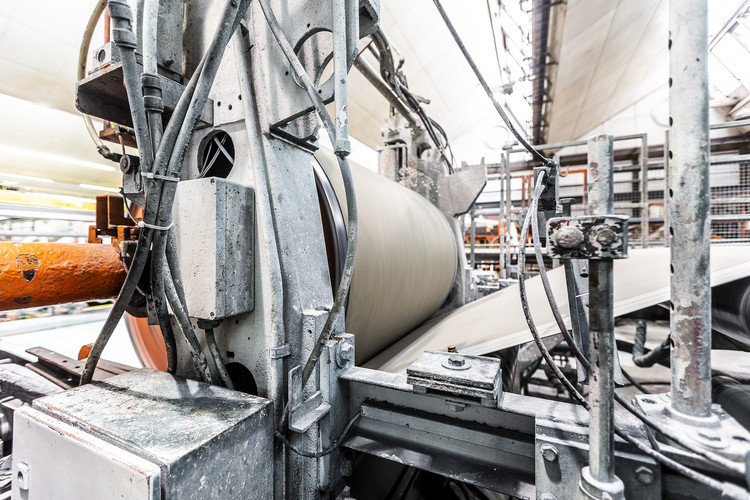

Technological Advancements and Product Innovation

Innovation in fiber reinforcement and surface treatment technologies will enhance the performance of CFB products. By 2026, expect to see next-generation CFB with improved impact resistance, reduced weight, and enhanced aesthetic finishes (e.g., wood grain, painted surfaces) that rival traditional siding materials. Integration with smart building systems—such as moisture-sensing coatings—could further differentiate high-end CFB products in premium construction markets. -

Regional Market Dynamics

Asia-Pacific will remain the largest and fastest-growing market for cementitious fiber board in 2026, driven by rapid infrastructure development in India, Vietnam, Indonesia, and China. North America will witness steady growth due to renovations in aging housing stock and increased use of CFB in multi-family and fire-prone regions (e.g., wildfire zones in the U.S. West). Europe’s market will expand moderately, supported by stringent fire safety codes and energy efficiency mandates. -

Competitive Landscape and Supply Chain Optimization

Leading manufacturers such as James Hardie, Etex Group, and Nichiha are expected to consolidate their market positions through R&D investments and geographic expansion. By 2026, vertical integration—controlling raw material sourcing and distribution—will become a competitive advantage. Additionally, supply chain resilience will be prioritized following recent global disruptions, with increased regional production to reduce lead times and logistics costs. -

Price Volatility and Raw Material Challenges

Fluctuations in cement and cellulose fiber prices—impacted by energy costs and regulatory policies—could affect CFB pricing. However, economies of scale and optimized formulations (e.g., higher filler content without compromising quality) will help mitigate cost pressures. Manufacturers investing in alternative fibers and cement substitutes will gain a strategic edge.

In conclusion, by 2026, the cementitious fiber board market will be characterized by strong demand in emerging economies, innovation in sustainable product development, and tighter integration with modern construction ecosystems. Stakeholders who prioritize performance, environmental compliance, and supply chain agility will be best positioned to capitalize on these evolving trends.

Common Pitfalls in Sourcing Cementitious Fiber Board (Quality and Intellectual Property)

Sourcing Cementitious Fiber Board (CFB) for construction or industrial applications requires careful evaluation to ensure both quality standards and intellectual property (IP) compliance. Below are common pitfalls to avoid:

Poor Quality Control and Substandard Materials

One of the most frequent issues when sourcing CFB is receiving products that do not meet required performance standards. Lower-tier manufacturers may cut corners by using inferior raw materials or inconsistent production processes, leading to:

- Reduced fire resistance and moisture durability

- Inconsistent board density and thickness

- Higher risk of warping, cracking, or delamination over time

Always verify that suppliers comply with international standards such as EN 12467 or ASTM C1325 and request third-party test reports.

Lack of Certification and Compliance Documentation

Many suppliers, particularly from emerging markets, may not provide full compliance documentation. Beware of:

- Missing CE marking, ICC-ES reports, or UL certifications

- Incomplete fire, toxicity, or structural performance data

- Unverified claims about environmental or safety standards

Insist on up-to-date certification and conduct independent audits when scaling procurement.

Intellectual Property Infringement Risks

Cementitious fiber board production often involves proprietary manufacturing technologies, formulations, or patented designs (e.g., specific fiber-reinforcement methods or surface treatments). Sourcing from unauthorized producers can lead to:

- Use of counterfeit or reverse-engineered products

- Legal liability for IP infringement in end-use markets

- Supply chain disruptions if IP holders issue cease-and-desist orders

Ensure suppliers have legitimate licensing agreements and avoid “generic” brands that mimic well-known patented products.

Inadequate Traceability and Supply Chain Transparency

Without clear traceability, it’s difficult to verify the origin and authenticity of CFB. Pitfalls include:

- Multi-tier subcontracting that obscures manufacturing sources

- Blending of materials from unverified batches

- No batch tracking or quality audit trails

Demand transparency in the supply chain and consider on-site factory inspections.

Misrepresentation of Product Specifications

Some suppliers exaggerate performance claims or provide ambiguous technical data sheets. Watch for:

- Vague descriptions of fiber content or curing processes

- Inflated fire or acoustic ratings not backed by test data

- Use of non-standard testing methods to simulate compliance

Cross-check specifications with independent laboratories or industry benchmarks.

Overlooking Long-Term Supplier Reliability

Choosing suppliers based solely on price can backfire. Risks include:

- Inconsistent batch-to-batch quality

- Limited R&D support or technical service

- No IP indemnification in contracts

Establish long-term partnerships with reputable manufacturers who invest in innovation and protect IP rights.

By addressing these pitfalls proactively, buyers can ensure they source high-quality, compliant, and legally sound Cementitious Fiber Board for their projects.

Logistics & Compliance Guide for Cementitious Fiber Board

Cementitious Fiber Board (CFB) is a durable, non-combustible building material widely used for exterior cladding, soffits, interior wall linings, and underlayment. Proper logistics and compliance management are essential to ensure product integrity, worker safety, and adherence to regulatory standards throughout the supply chain.

Product Handling and Storage

Cementitious Fiber Board is sensitive to moisture and physical damage. Proper handling and storage practices help maintain product quality and performance.

- Unloading: Use forklifts or material handlers with appropriate lifting straps or clamps. Avoid dragging or dropping panels to prevent chipping or cracking.

- Stacking: Store panels vertically on flat, level, and dry surfaces. If horizontal stacking is necessary, ensure a solid foundation with evenly spaced support battens to prevent warping.

- Moisture Protection: Keep panels under cover at all times, preferably in a dry warehouse. If stored outdoors, elevate off the ground and cover completely with waterproof tarpaulins, ensuring no water pooling occurs.

- Ventilation: Allow for air circulation around stored panels to minimize moisture retention, especially in humid environments.

Transportation Requirements

Transporting Cementitious Fiber Board requires secure packaging and protection from environmental exposure.

- Packaging: Panels are typically bundled with protective wrapping and secured with steel or plastic banding. Ensure packaging remains intact during transit.

- Securement: Use straps or load locks to prevent shifting during transport. Avoid over-compression of bundles to prevent edge damage.

- Weather Protection: Cover loads with waterproof tarps during open-bed transport. Avoid transporting in heavy rain or snow unless fully protected.

- Vehicle Compatibility: Use flatbed or enclosed trucks suitable for oversized or heavy loads, depending on panel dimensions and order volume.

Safety and Worker Protection

CFB contains crystalline silica and may generate dust when cut or drilled. Safety compliance is critical to protect workers.

- Personal Protective Equipment (PPE): Workers must wear NIOSH-approved respirators (N95 or higher), safety goggles, and gloves when handling or machining CFB.

- Dust Control: Use wet-cutting methods or local exhaust ventilation (LEV) systems when cutting, sanding, or drilling panels to minimize airborne silica dust.

- Training: Ensure all personnel are trained in OSHA silica standards (29 CFR 1926.1153) and proper handling procedures.

- Hazard Communication: Maintain Safety Data Sheets (SDS) on site and ensure GHS-compliant labeling of materials.

Regulatory Compliance

Adherence to national and international standards ensures CFB meets performance and safety requirements.

- Building Codes: Verify compliance with local building codes such as the International Building Code (IBC) and International Residential Code (IRC). CFB must meet fire resistance, moisture resistance, and structural performance criteria.

- Fire Ratings: Confirm product-specific fire classifications (e.g., ASTM E84 Class A Flame Spread) and ensure installation aligns with fire-rated assembly requirements.

- Environmental Regulations: Comply with EPA regulations regarding crystalline silica exposure and dust emissions. Follow proper disposal protocols for off-cuts and waste material.

- Green Building Standards: Many CFB products qualify for LEED credits due to durability, recyclability, and low VOC emissions. Confirm product eligibility through Environmental Product Declarations (EPDs) or Health Product Declarations (HPDs).

Import/Export and Trade Compliance

For international shipments, additional documentation and standards may apply.

- Customs Documentation: Provide accurate Harmonized System (HS) codes (typically 6811.82 or 6811.89 for fiber-cement sheets), commercial invoices, packing lists, and certificates of origin.

- Import Regulations: Comply with destination country requirements, such as CE marking in the EU, CCC in China, or BSI certification in the UK.

- Phytosanitary Measures: Wooden pallets or dunnage must meet ISPM 15 standards for international transport.

Quality Assurance and Documentation

Maintain traceability and compliance through proper documentation.

- Mill Certificates: Retain test reports and certifications for fire performance, durability, and material composition.

- Batch Tracking: Record lot numbers and delivery dates to support warranty claims or recalls.

- Compliance Labels: Ensure each panel or bundle carries manufacturer labels indicating product type, standards met, and handling instructions.

By following this guide, stakeholders in the supply chain can ensure the safe, efficient, and compliant handling of Cementitious Fiber Board from manufacturing to installation.

Conclusion for Sourcing Cementitious Fiber Board

In conclusion, sourcing cementitious fiber board requires a strategic approach that balances quality, cost, availability, and sustainability. This durable, fire-resistant, and moisture-resistant building material is ideal for use in wet areas, exterior cladding, and high-performance construction applications. When selecting suppliers, it is essential to evaluate product specifications, certifications (such as ASTM standards), manufacturing consistency, and environmental compliance to ensure long-term performance and safety.

Establishing relationships with reputable manufacturers and verified distributors helps mitigate supply chain risks and ensures timely delivery. Additionally, considering factors such as lead times, logistics, and regional availability can significantly impact project timelines and overall costs. Embracing sustainable sourcing practices—by choosing products with recycled content and low environmental impact—also aligns with green building standards and regulatory requirements.

Ultimately, a well-informed sourcing strategy for cementitious fiber board enhances construction efficiency, ensures compliance with industry standards, and contributes to the durability and resilience of the built environment.