The global construction tools market is experiencing steady growth, driven by rising infrastructure development and residential construction activities worldwide. According to Grand View Research, the global power tools market size was valued at USD 30.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. A key contributor to this growth is the increasing demand for specialized accessories such as cement mixing drill attachments, which enhance efficiency and reduce labor intensity in concrete and mortar preparation. As construction processes become more mechanized, the need for durable, high-performance mixing attachments has led to a surge in innovation among manufacturers. With the global cement industry consuming over 4 billion tons of cement annually, even small improvements in mixing efficiency can translate into significant time and cost savings on job sites. This growing demand has positioned cement mixing drill attachments as essential tools in both professional and DIY construction segments, fostering competitive advancements among top suppliers. The following list highlights the top seven manufacturers leading this niche through product innovation, material quality, and global distribution reach.

Top 7 Cement Mixing Drill Attachment Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Paddle Mixer-Cement Mixer Xo 1 R – Mix Up To 10 Gallons

Domain Est. 2000

Website: collomix.com

Key Highlights: The Xo 1 R is a compact and lightweight 1-speed machine for mixing smaller quantities. With a 1.4 HP motor, it’s powerful enough to mix multiple materials …Missing: attachment m…

#2 Drill Mixer Attachments

Domain Est. 1996

#3 Heavy Duty Mixing Paddles & Blades

Domain Est. 1997

Website: csunitec.com

Key Highlights: Our heavy-duty mixing paddles are made of robust welded steel and are galvanized for corrosion protection and abrasion resistance….

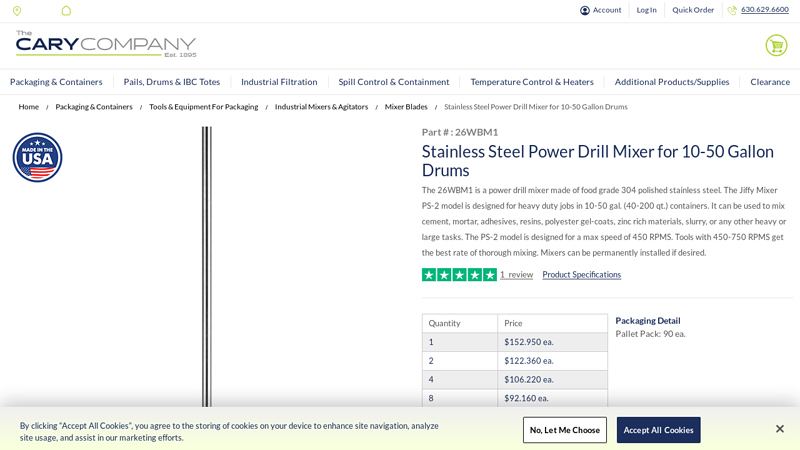

#4 Stainless Steel Power Drill Mixer for 10

Domain Est. 1999

Website: thecarycompany.com

Key Highlights: In stock Rating 5.0 (1) The Jiffy Mixer PS-2 model is designed for heavy duty jobs in 10-50 gal. (40-200 qt.) containers. It can be used to mix cement, mortar, adhesives, resins …

#5 Paint Mixer Drill Bit

Domain Est. 2000

Website: acslimited.co.uk

Key Highlights: A quality drill bit mixer. Attach to most modern drills. It allows additives to be throughly mixed into paints and coatings….

#6 Mixer Drill

Domain Est. 2021

Website: delitoolsglobal.com

Key Highlights: A mixer drill is a specialized power tool designed primarily for mixing materials such as paint, plaster, cement, adhesives, and grout….

#7 Best Mixing Drill for Professionals

Domain Est. 2017

Website: misterworker.com

Key Highlights: On Mister Worker®, you’ll find a curated selection of the best mixing drills from Makita designed for professionals seeking precision, power, and reliability….

Expert Sourcing Insights for Cement Mixing Drill Attachment

H2: 2026 Market Trends for Cement Mixing Drill Attachments

The global market for cement mixing drill attachments is poised for significant evolution by 2026, driven by advancements in construction technologies, growing infrastructure investments, and an increasing emphasis on labor efficiency and safety. As the construction and DIY sectors continue to expand—particularly in emerging economies—demand for reliable, high-performance mixing tools is expected to rise. The following trends are projected to shape the cement mixing drill attachment market through 2026:

-

Increased Adoption of Cordless and Battery-Powered Tools

With the broader shift toward cordless power tools in construction, cement mixing drill attachments are increasingly being designed to integrate seamlessly with high-torque cordless drills. This trend is driven by the demand for portability, reduced setup time, and improved worksite flexibility. Lithium-ion battery technology advancements will further enhance performance, enabling longer run times and more consistent mixing power, especially in remote or off-grid job sites. -

Focus on Ergonomic and Safety-Enhanced Designs

By 2026, manufacturers are expected to prioritize user safety and comfort. Innovations such as reduced vibration mechanisms, anti-torque guards, and lightweight composite materials will become standard in premium models. These features help minimize operator fatigue and reduce the risk of repetitive strain injuries—key concerns in prolonged mixing applications. -

Smart Technology Integration

The integration of smart technology into power tools is extending to attachments. By 2026, some cement mixing drill attachments may offer compatibility with smart drills that monitor torque, speed, and temperature in real time. These data insights can help prevent motor burnout, optimize mixing consistency, and extend tool lifespan—especially valuable in commercial and industrial settings. -

Growth in DIY and Home Improvement Markets

The rising popularity of home renovation and DIY projects, accelerated by social media and online tutorials, will drive consumer demand for affordable, easy-to-use cement mixing attachments. Entry-level models with simplified installation and universal drill compatibility will see increased sales, particularly in North America and Europe. -

Sustainability and Material Innovation

Environmental concerns are influencing material choices. Manufacturers are exploring recyclable and durable composites to reduce the environmental footprint of attachments. Additionally, longer-lasting blades and wear-resistant coatings will gain traction, reducing waste from frequent replacements. -

Expansion in Emerging Markets

Rapid urbanization in regions such as Southeast Asia, Africa, and Latin America will fuel demand for construction tools, including cement mixing attachments. Localized production and cost-effective models tailored to regional needs are expected to emerge, supporting market penetration. -

Consolidation and Brand Competition

The market is likely to witness increased competition among established power tool brands (e.g., DeWalt, Bosch, Makita) and new entrants offering specialized or budget-friendly attachments. Strategic partnerships between drill manufacturers and attachment suppliers could lead to bundled product offerings, enhancing consumer value.

In conclusion, by 2026, the cement mixing drill attachment market will be characterized by innovation in performance, usability, and sustainability. As construction methods become more efficient and user-centric, these attachments will play a crucial role in bridging the gap between manual labor and mechanized precision.

Common Pitfalls When Sourcing Cement Mixing Drill Attachments (Quality & Intellectual Property)

Sourcing cement mixing drill attachments involves navigating several potential pitfalls, particularly concerning product quality and intellectual property (IP) risks. Failing to address these can lead to equipment failure, safety hazards, legal issues, and reputational damage. Below are key areas to watch:

Poor Material and Build Quality

One of the most frequent issues is receiving attachments made from substandard materials or with poor manufacturing processes. Low-grade steel or inadequate heat treatment can result in rapid wear, bending, or even breakage during use. Welds may be weak or inconsistent, leading to structural failure under load. Always verify material specifications (e.g., high-tensile steel) and request quality certifications or test reports from suppliers.

Inaccurate Fit and Compatibility

Many generic attachments claim compatibility with popular drill models but fail to deliver a secure fit. Misaligned or loose connections can cause wobbling, reduced mixing efficiency, and potential damage to the drill. Confirm exact compatibility with your drill brand and model, and request dimension drawings or sample testing before large orders.

Lack of Safety Certification and Compliance

Some suppliers, particularly from unregulated markets, offer products that do not meet international safety standards (e.g., CE, ISO). Using non-compliant attachments can expose users to safety risks and may void the warranty on the drill. Ensure the product meets relevant safety and performance standards for your region.

Counterfeit or IP-Infringing Products

A significant IP risk arises when sourcing low-cost attachments that mimic patented designs from established brands (e.g., Bosch, DeWalt). These knockoffs often replicate proprietary connection systems or blade geometry without authorization. Purchasing such products can expose your business to legal liability, especially if sold in markets with strong IP enforcement. Always vet suppliers for original designs or proper licensing agreements.

Inadequate Intellectual Property Due Diligence

Buyers may unknowingly source from manufacturers that infringe on existing patents or registered designs. Without proper IP checks—such as patent landscaping or design freedom-to-operate analysis—your company could face cease-and-desist letters or customs seizures. Request IP declarations from suppliers and consider third-party legal review for high-volume or branded sales.

Inconsistent Quality Control and Batch Variability

Even if initial samples meet expectations, mass-produced batches may vary significantly in quality due to lax production oversight. Implement strict incoming inspection protocols and consider third-party quality audits or pre-shipment inspections to ensure consistency.

Hidden Costs from Short Lifespan and Downtime

Attachments that appear cost-effective upfront may wear out quickly, increasing replacement costs and project downtime. Evaluate total cost of ownership, including durability and maintenance, rather than focusing solely on purchase price.

To mitigate these risks, partner with reputable suppliers, conduct thorough technical and legal due diligence, and prioritize quality and compliance over short-term savings.

Logistics & Compliance Guide for Cement Mixing Drill Attachment

This guide provides essential information regarding the logistics handling, transportation, regulatory compliance, and safety requirements for the Cement Mixing Drill Attachment. Adherence to these guidelines ensures safe operations, legal compliance, and efficient distribution.

Product Overview

The Cement Mixing Drill Attachment is a tool designed to be used with power drills for efficient mixing of cement, mortar, grout, and similar viscous construction materials. It typically consists of a durable steel mixing paddle connected to a hex or chuck-compatible shaft. This attachment is intended for professional and DIY use in construction and renovation projects.

Regulatory Compliance

Electrical Safety (if applicable)

While the attachment itself is non-powered, it is used in conjunction with electric or battery-powered drills. Ensure compatibility with tools certified under relevant electrical safety standards:

– CE Marking (Europe): Compliant with the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive when used with certified tools.

– UL/CSA Certification: In North America, verify that the drill used meets UL 62841 (hand-held motor-operated tools) standards.

– The attachment does not require standalone electrical certification but must not interfere with the safe operation of certified tools.

Material Safety & RoHS Compliance

- The attachment is typically constructed from carbon steel or stainless steel with no hazardous substances.

- Confirm compliance with RoHS (Restriction of Hazardous Substances) Directive 2011/65/EU for sale in the EU.

- Ensure packaging and labeling reflect RoHS compliance where applicable.

REACH Regulation

- Verify that all materials used in manufacturing comply with REACH (EC 1907/2006), particularly regarding Substances of Very High Concern (SVHC).

- Provide Safety Data Sheet (SDS) upon request, especially for bulk industrial customers.

Packaging & Labeling Requirements

Packaging Standards

- Use durable, recyclable packaging to prevent damage during transit.

- Include protective wrapping or boxing to avoid deformation of the mixing paddle.

- Clearly label packages with:

- Product name and model number

- Manufacturer/supplier information

- Country of origin

- Weight and dimensions

- Handling symbols (e.g., “Fragile,” “This Side Up”)

Labeling for Compliance

- Affix required regulatory marks (e.g., CE mark) on packaging or product if applicable.

- Include multilingual instructions if distributing across regions.

- Barcode/UPC for retail tracking.

Shipping & Transportation

Domestic Shipping (US & Canada)

- Classify under HTS Code 8207.40.6030 (Accessories for tools, not elsewhere specified).

- No special hazardous classification; standard ground or air freight acceptable.

- Use carriers compliant with DOT (Department of Transportation) regulations for non-hazardous cargo.

International Shipping

- Harmonized System (HS) Code: 8207.40 (Tools for working in the hand, interchangeable tools)

- Comply with import regulations in destination countries (e.g., UKCA marking for the UK, INMETRO for Brazil if applicable).

- Prepare commercial invoice, packing list, and bill of lading/air waybill.

- Confirm customs duties and taxes based on destination.

Air Freight Considerations

- Non-restricted for air transport under IATA guidelines.

- Ensure packaging meets drop-test and stacking requirements.

- Avoid magnetic materials that could interfere with cargo screening.

Import & Export Documentation

Required Documents

- Commercial Invoice

- Packing List

- Bill of Lading (BOL) or Air Waybill (AWB)

- Certificate of Origin (may be required for preferential tariffs)

- Export Declaration (e.g., AES filing for US exports over $2,500)

Customs Clearance

- Ensure correct HS/EU CN code declaration to avoid delays.

- Be prepared to provide proof of compliance (e.g., RoHS declaration, CE self-certification documentation).

Storage & Handling

Warehouse Storage

- Store in dry, temperature-controlled environments to prevent corrosion.

- Stack packages securely; avoid excessive weight on lower pallets.

- Keep away from chemicals or moisture sources.

Handling Precautions

- Use gloves when handling to prevent cuts from sharp paddle edges.

- Inspect for damage before dispatch or use.

- Rotate stock using FIFO (First In, First Out) method to ensure product quality.

Safety & User Compliance

User Instructions

- Provide clear usage instructions, including:

- Compatible drill types and speed settings

- Maximum load recommendations

- Safety warnings (e.g., wearing PPE, securing material containers)

- Include warnings against use with flammable or explosive materials.

Personal Protective Equipment (PPE)

- Recommend users wear:

- Safety goggles

- Gloves

- Dust mask (when mixing dry cement)

- Hearing protection (if using high-speed drills)

Warranty & Product Liability

Warranty Terms

- Standard warranty: 12 months against manufacturing defects.

- Exclusions: Damage from misuse, improper installation, or unauthorized modifications.

Liability & Insurance

- Ensure product liability insurance covers usage risks.

- Conduct periodic risk assessments and maintain records of compliance audits.

Environmental & End-of-Life

Recycling

- The product is fully recyclable as scrap metal.

- Encourage end-users to dispose of through metal recycling channels.

- Comply with WEEE directive if classified as electrical accessory in certain configurations (typically not applicable for standalone attachments).

Sustainable Packaging

- Use minimal, recyclable packaging materials.

- Avoid plastic where possible; opt for cardboard or biodegradable alternatives.

Contact & Support

For compliance documentation, safety data sheets, or logistics inquiries, contact:

– Compliance Officer: [email protected]

– Logistics Support: [email protected]

– Customer Service: [email protected]

Ensure all product batches are traceable via lot numbers for recalls or audits.

Conclusion: Sourcing Cement Mixing Drill Attachment

After a thorough evaluation of available options, it is clear that sourcing a high-quality cement mixing drill attachment is essential for ensuring efficiency, durability, and safety in construction and masonry applications. Key factors such as motor power compatibility, material construction (preferably robust steel), ergonomic design, and reliable supplier reputation significantly impact performance and longevity.

Opting for a well-engineered attachment from a reputable manufacturer not only enhances mixing consistency and reduces physical strain but also minimizes downtime due to wear or failure. Additionally, considering supplier support, warranty, and availability of spare parts contributes to long-term cost-effectiveness.

In conclusion, investing in a dependable cement mixing drill attachment from a trusted source ensures optimal performance, improves project outcomes, and supports operational efficiency—making it a critical component for both professional contractors and DIY enthusiasts working with cement and mortar.