The global cement market is experiencing steady growth, driven by rising construction activities and infrastructure development worldwide. According to Mordor Intelligence, the global cement market was valued at USD 370.87 billion in 2023 and is projected to reach USD 478.72 billion by 2029, growing at a CAGR of 4.37% during the forecast period. This expansion is fueled by increasing demand for durable construction materials across residential, commercial, and industrial sectors. As one of the critical applications in outdoor and structural construction, fence post installations rely heavily on high-strength, weather-resistant cement formulations. With durability, setting time, and compressive strength being key performance indicators, selecting the right cement brand can significantly impact the longevity and stability of fence systems. In response to growing demand, several manufacturers have developed specialized cement products optimized for fence post applications—balancing rapid setting, ease of use, and resilience to environmental stressors. Based on market presence, product performance data, and technical specifications, here are the top six cement manufacturers offering reliable solutions for fence post installations.

Top 6 Cement For Fence Post Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

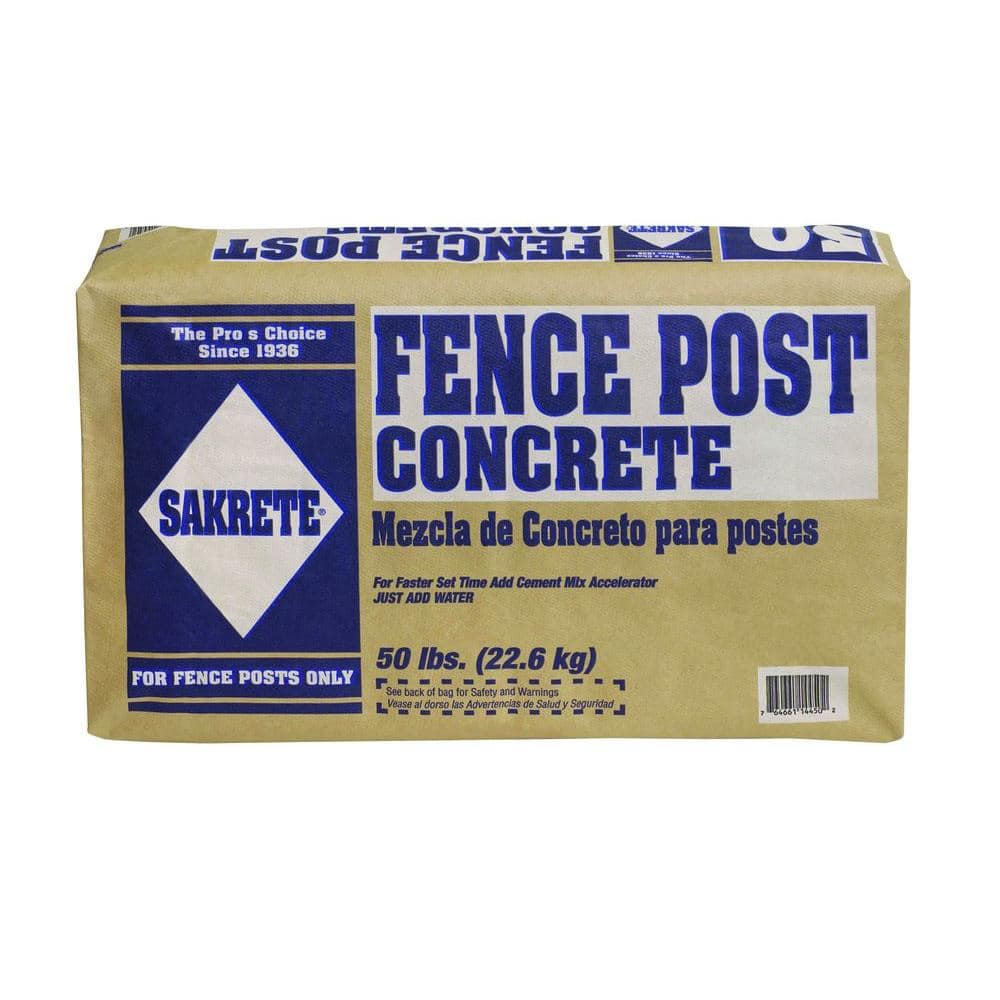

#1 Sakrete

Domain Est. 1997

Website: sakrete.com

Key Highlights: Fast-Setting Concrete Mix. When speed is the name of the game, Fast Setting Concrete Mix is your go-to. For no-mix post setting, same-day slabs, faster fences ……

#2 Superior Concrete Products

Domain Est. 1997

Website: concretefence.com

Key Highlights: Superior Concrete Products designs, manufactures, and installs premium precast concrete wall systems nationwide. Now offering AFTEC’s StoneTree® walls for ……

#3 Setting Fence Posts

Domain Est. 1997

Website: packagepavement.com

Key Highlights: A solid concrete base is important for firmly setting wood or metal posts. Below-ground areas of wood posts should be coated with a creosol equivalent….

#4 Rapid Set Postmix

Domain Est. 2007

Website: eastcoastfencing.com

Key Highlights: 30-day returnsGet your fencing and posts securely set in minutes with Rapid Set Postmix. Fast, easy, and reliable! Ideal for quick fixes and professional projects….

#5 Fast 2K

Domain Est. 2011

Website: fast2k.com

Key Highlights: Set posts in minutes with Fast 2K’s expanding foam fence post mix —replaces up to 100 lbs of concrete. Mix, pour, and build faster….

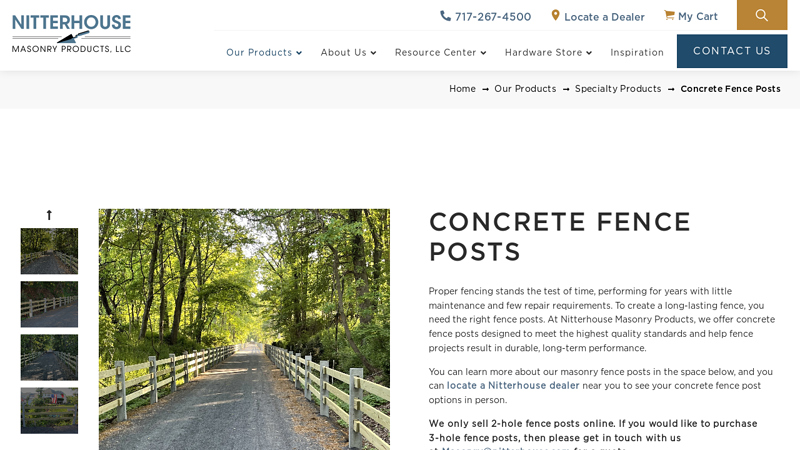

#6 Concrete Fence Posts

Domain Est. 2011

Website: nitterhousemasonry.com

Key Highlights: In stock $150 deliveryWe offer concrete fence posts designed to meet the highest quality standards and help fence projects result in durable, long-term performance….

Expert Sourcing Insights for Cement For Fence Post

2026 Market Trends for Cement for Fence Post

As we approach 2026, the market for cement used specifically in fence post applications is evolving due to shifts in construction practices, material innovation, environmental regulations, and regional demand. This analysis explores key trends shaping the cement for fence post sector over the coming years.

Growing Demand in Residential and Agricultural Sectors

The residential construction boom, particularly in suburban and rural areas across North America, Europe, and parts of Asia-Pacific, is a primary driver for fence post cement demand. Homeowners increasingly invest in property boundaries, privacy, and security, fueling demand for durable fencing solutions. Simultaneously, the agricultural sector continues to rely on fence posts for livestock management and land demarcation, especially in emerging economies. This sustained need supports steady consumption of setting-grade cement and pre-mixed concrete products designed for post installation.

Shift Toward Fast-Setting and Pre-Mixed Cement Solutions

A significant trend in 2026 is the rising preference for fast-setting and pre-mixed cement products tailored for fence posts. These ready-to-use solutions reduce labor time, minimize water usage, and improve consistency in setting strength. Manufacturers are innovating with polymer-modified blends that cure rapidly—even in cold weather—catering to DIY consumers and contractors alike. Brands such as Sakrete and Quikrete are leading this shift, promoting convenience and reliability.

Sustainability and Green Cement Innovations

Environmental concerns are reshaping the cement industry, including niche applications like fence posts. In 2026, there is increased regulatory pressure and consumer demand for low-carbon cement alternatives. Innovations such as geopolymer cements, calcium sulfoaluminate (CSA) cements, and blends incorporating fly ash or slag are gaining traction. While traditional Portland cement still dominates, eco-friendly options are entering the market, particularly in regions with strict emissions standards like the EU and California.

Regional Market Variations

Market dynamics vary significantly by region. In North America, demand is driven by housing starts and infrastructure renewal. In contrast, Asia-Pacific growth is fueled by rural development and agricultural expansion, particularly in India and Southeast Asia. In Africa, off-grid rural electrification and land privatization are increasing the need for durable fencing, boosting cement use. Latin America shows mixed trends, with growth in countries like Brazil balanced by economic volatility.

Impact of Alternative Materials and Installation Techniques

While cement remains the dominant method for securing fence posts, alternatives such as mechanical ground anchors, helical piles, and composite concrete sleeves are gaining attention. These methods reduce concrete use and offer easier installation or removal. However, cement continues to dominate due to its low cost, widespread availability, and proven performance. The market response includes hybrid solutions that use less cement but maintain structural integrity.

Supply Chain and Pricing Pressures

In 2026, the cement for fence post segment faces ongoing supply chain challenges, including energy costs, transportation logistics, and raw material availability. Geopolitical tensions and climate-related disruptions affect clinker and limestone supplies, leading to price volatility. As a result, manufacturers are localizing production and investing in supply chain resilience to ensure consistent product availability.

Technological Integration and Consumer Education

Digital platforms and mobile apps are playing a growing role in guiding consumers on proper cement use for fence posts. Augmented reality (AR) tools help visualize fence layouts, while AI-powered calculators recommend the right cement volume per post. Additionally, manufacturers are investing in educational content to promote correct mixing and curing practices, reducing installation failures and enhancing brand trust.

Conclusion

The 2026 market for cement used in fence posts reflects broader trends in construction: convenience, sustainability, and resilience. While traditional cement remains essential, innovation in formulations, application methods, and environmental performance is redefining the segment. Stakeholders who adapt to these trends—by offering eco-friendly products, embracing digital engagement, and optimizing supply chains—will be best positioned for long-term success.

Common Pitfalls When Sourcing Cement for Fence Posts (Quality & IP)

When installing fence posts, using the right cement is crucial for durability and stability. However, several common pitfalls related to quality and intellectual property (IP) can compromise the project. Being aware of these issues helps ensure a long-lasting, secure fence.

Poor Cement Quality

One of the most frequent issues is sourcing low-quality cement. Substandard products may not provide adequate bonding strength or resistance to weathering, leading to premature cracking or post instability. Always verify that the cement meets recognized industry standards (e.g., ASTM C150 or equivalent in your region) and avoid products with unclear labeling or suspiciously low prices.

Misleading Brand Names and Counterfeit Products

Some suppliers use brand names or packaging that closely resemble reputable manufacturers, leading to confusion. These counterfeit or imitation products often lack the formulation integrity of genuine cement. This not only affects performance but can also involve intellectual property (IP) infringement. Always purchase from authorized dealers and check for manufacturer holograms, batch numbers, or QR codes to verify authenticity.

Inadequate Product Specifications for Outdoor Use

Not all cement is suitable for fence post applications, which require resistance to moisture, freeze-thaw cycles, and ground movement. Using general-purpose cement instead of one designed for outdoor or structural use (like Portland cement Type I/II or fast-setting variants) can result in failure. Ensure the product specifications explicitly mention suitability for ground-contact and outdoor installations.

Ignoring Intellectual Property Rights in Product Selection

When selecting cement, especially from lesser-known brands, it’s important to ensure the product does not infringe on patented formulations or trademarks. Supporting legitimate manufacturers protects innovation and ensures you receive a tested, reliable product. Purchasing from IP-compliant sources also reduces the risk of legal complications and supports ethical business practices.

Lack of Traceability and Certification

Reputable cement products come with documentation, including certificates of conformity, safety data sheets, and batch traceability. Avoid suppliers who cannot provide these, as this may indicate poor quality control or IP violations. Traceability ensures accountability and helps in case of product failure or recalls.

By avoiding these pitfalls—prioritizing quality, verifying authenticity, and respecting IP—you ensure your fence posts are set in durable, reliable cement that stands the test of time.

Logistics & Compliance Guide for Cement for Fence Posts

Product Overview and Intended Use

Cement for fence posts is typically a pre-mixed concrete or rapid-setting concrete blend designed for securing fence posts into the ground. It is commonly sold in bags (e.g., 40 lb, 50 lb, or 60 lb) and must be handled, stored, transported, and disposed of in compliance with safety and regulatory standards.

Packaging and Labeling Requirements

- Ensure all bags are securely sealed and labeled with:

- Product name and intended use (e.g., “Fast-Setting Concrete Mix – For Fence Posts”)

- Net weight

- Manufacturer or distributor name and contact information

- Batch or lot number

- Safety warnings and handling instructions (e.g., “Protect from moisture,” “Wear gloves and eye protection”)

- Compliance with OSHA Hazard Communication Standard (HazCom) including GHS pictograms if applicable

Storage Guidelines

- Store in a dry, well-ventilated area away from direct moisture and extreme temperatures.

- Keep bags off the ground using pallets to prevent water absorption.

- Stack no higher than recommended by the manufacturer to avoid collapse.

- Ensure storage areas are secure from pests and unauthorized access.

- Separate from incompatible materials such as acids, fuels, or flammable substances.

Transportation and Handling

- Use appropriate manual handling techniques or mechanical aids (e.g., forklifts) to prevent injury during loading/unloading.

- Secure loads on transport vehicles to prevent shifting or damage.

- Protect from rain and moisture during transit using waterproof tarps or enclosed trailers.

- Comply with Department of Transportation (DOT) guidelines if transporting in large quantities across state lines—though cement is generally not classified as hazardous, proper documentation may be required for bulk shipments.

Safety and Personal Protective Equipment (PPE)

- Workers must wear:

- Gloves (nitrile or heavy-duty) to prevent skin irritation from alkaline materials

- Safety goggles or face shield to avoid eye contact with dry powder or wet mix

- Dust mask or respirator when handling dry cement to prevent inhalation of silica and alkaline dust

- Sturdy footwear and long-sleeve clothing recommended

- Provide access to water and emergency eyewash stations where mixing or handling occurs.

Environmental and Regulatory Compliance

- Cement is subject to environmental regulations due to its alkalinity and potential for dust emissions.

- Follow local, state, and federal guidelines (e.g., EPA, OSHA) regarding:

- Dust control during handling and mixing

- Spill response procedures (e.g., contain dry spills, avoid water runoff of wet concrete)

- Disposal of unused or contaminated material—do not dump in drains or waterways

- Recycling or reuse of packaging (e.g., paper bags may be recyclable if uncontaminated)

International Shipping Considerations (if applicable)

- For export, ensure compliance with destination country’s import regulations.

- Include proper shipping documentation (e.g., commercial invoice, packing list).

- Declare contents accurately; while cement is generally not hazardous, some countries may require phytosanitary or customs inspections for packaging materials.

- Use International Maritime Dangerous Goods (IMDG) or IATA guidelines only if mixed with regulated additives (rare for standard fence post cement).

Worker Training and Documentation

- Train all personnel on:

- Safe handling and mixing procedures

- Emergency response for skin/eye contact or inhalation

- Proper use of PPE

- Spill cleanup protocols

- Maintain records of safety data sheets (SDS), training logs, and incident reports as required by OSHA.

Disposal and End-of-Life Management

- Unused dry cement can sometimes be donated or reused; otherwise, dispose of in accordance with local solid waste regulations.

- Hardened concrete may be disposed of in non-hazardous landfill sites.

- Empty bags: Recycle if clean and dry; otherwise treat as general waste.

- Never dispose of cement slurry or wash water into storm drains—use settling pits or evaporation methods where permitted.

Summary and Best Practices

Adhering to logistics and compliance standards ensures safety, environmental protection, and regulatory alignment. Always consult the manufacturer’s SDS and local regulations to confirm specific requirements for your region and operation scale.

In conclusion, sourcing cement for fence post installation requires careful consideration of quality, quantity, cost, and availability. It is essential to choose a durable, weather-resistant cement—such as Portland cement or a pre-mixed concrete blend—suitable for below-ground applications to ensure long-term stability and resistance to environmental factors. Calculating the correct amount of cement needed per post will help minimize waste and control expenses. Local suppliers, home improvement stores, and online retailers offer various options, so comparing prices, delivery options, and customer reviews can lead to the most cost-effective and reliable choice. By planning ahead and sourcing cement from a reputable supplier, you can ensure a strong, durable fence foundation that will last for years to come.