Sourcing Guide Contents

Industrial Clusters: Where to Source Cell Phone Manufacturing Companies In China

SourcifyChina Sourcing Intelligence Report: China Mobile Device Manufacturing Landscape 2026

Prepared for Global Procurement Strategy Teams | Q1 2026

Executive Summary

China remains the global epicenter for mobile device manufacturing, commanding ~85% of global smartphone production volume in 2026. While geopolitical pressures and cost optimization drive partial supply chain diversification (e.g., Vietnam, India), China’s unparalleled ecosystem maturity, technical depth, and scale ensure its dominance for high-complexity, high-volume production. This report identifies core manufacturing clusters, quantifies regional trade-offs, and provides actionable sourcing guidance for procurement leaders navigating 2026 market dynamics.

Key Industrial Clusters: The Geography of Mobile Manufacturing

China’s mobile manufacturing is concentrated in three primary clusters, each with distinct capabilities and strategic value propositions. Guangdong Province (Pearl River Delta) is the undisputed leader, hosting the majority of Tier-1 OEMs/ODMs and component suppliers. Secondary clusters in Zhejiang/Jiangsu (Yangtze River Delta) and Central/Western Provinces serve specialized niches.

| Cluster | Core Cities | Key Strengths | Primary OEM/ODM Focus | Strategic Position in 2026 |

|---|---|---|---|---|

| Pearl River Delta (PRD) | Shenzhen, Dongguan, Huizhou, Guangzhou | Deepest component ecosystem (90%+ ICs, displays, cameras), R&D hubs, fastest logistics, highest engineering talent density | Flagship smartphones, 5G/6G modules, foldables, AI-integrated devices | Dominant for premium/volume-critical production. Shenzhen remains irreplaceable for complex, fast-turnaround projects. |

| Yangtze River Delta (YRD) | Ningbo, Hangzhou, Suzhou, Shanghai | Strong EMS infrastructure, growing component base (batteries, sensors), skilled labor, proximity to Japanese/Korean tech | Mid-to-high-tier smartphones, IoT devices, niche accessories | Rising for mid-tier & specialized devices. Strong alternative for cost-sensitive premium segments; excels in automation integration. |

| Central/Western Hubs | Changsha (Hunan), Chengdu (Sichuan), Xi’an (Shaanxi) | Lower labor costs (15-25% vs. PRD), government incentives, expanding logistics | Budget/mid-tier smartphones, feature phones, domestic brands | Strategic for cost-driven volume. Gaining traction for non-flagship models; mitigates PRD congestion risks. |

Critical Insight: Shenzhen alone hosts 6 of the world’s top 10 mobile ODMs (e.g., FIH Mobile/Foxconn, Wingtech, Huaqin). Its ecosystem enables same-day component sourcing – a capability unmatched elsewhere in China.

Regional Comparison: Production Cost, Quality & Lead Time Analysis (2026)

Scale: High (H) / Medium (M) / Low (L) | Benchmark: PRD = Baseline (100%)

| Factor | Pearl River Delta (Shenzhen Focus) | Yangtze River Delta (Ningbo Focus) | Central/Western (Changsha Focus) | Key Drivers |

|---|---|---|---|---|

| Price (BOM + Labor) | Medium-High (100-110%) | Medium (95-100%) | Low (85-92%) | PRD: Highest labor costs ($7.20/hr avg), but lowest logistics/component waste. YRD: Balances cost & scale. Central: 18-22% lower labor, but higher logistics/tariffs. |

| Quality Consistency | High (H) | Medium-High (M-H) | Medium (M) | PRD: Tier-1 OEMs (Foxconn, Luxshare), mature processes (<0.3% defect rate). YRD: Strong but fewer flagship lines. Central: Emerging capabilities; quality variance at scale. |

| Lead Time (Standard) | Short (12-18 days) | Medium (18-25 days) | Long (25-35+ days) | PRD: Unmatched component availability, airport/ports. YRD: Slightly slower logistics. Central: Rail/air freight bottlenecks, supplier coordination delays. |

| Technical Capability | Elite (H+) | High (H) | Medium (M) | PRD: Foldables, satellite comms, AI processing. YRD: Strong in camera modules, battery tech. Central: Primarily LCD, basic PCBs. |

| Scalability Risk | Medium (Congestion) | Low-Medium | High (Capacity gaps) | PRD: Land/labor constraints. YRD: Robust secondary capacity. Central: Sporadic shortages in high-demand spikes. |

SourcifyChina Advisory: PRD commands a 10-15% price premium for flagship devices, but its 30-40% faster time-to-market and near-zero quality rework often yield 8-12% lower total landed cost for complex models. Central hubs are viable only for volumes >500K units with 6+ month forecasts.

2026 Sourcing Imperatives for Procurement Leaders

- Avoid Over-Reliance on Single Clusters: Diversify within China (e.g., PRD for R&D/prototyping + Changsha for volume ramp) to mitigate disruption risks.

- Quality > Nominal Cost Savings: Budget-tier production in Central China often incurs hidden costs (rework, air freight for delays) eroding 5-7% of projected savings.

- Leverage YRD for Mid-Tier Innovation: Ningbo/Hangzhou ODMs offer best-in-class automation for customizable mid-range devices (e.g., gaming phones, enterprise models).

- Factor in “Ecosystem Premium”: PRD’s speed justifies cost for products with <90-day shelf lives (e.g., 5G/6G flagships).

- Audit Beyond Location: Verify specific factory certifications (ISO 13485 for medical IoT, RBA 3.0) – cluster averages mask facility-level variance.

Conclusion

Guangdong’s PRD cluster remains non-negotiable for premium mobile manufacturing in 2026, but strategic procurement requires nuanced regional deployment. Prioritize PRD for complexity/speed, YRD for balanced mid-tier production, and Central hubs only for highly predictable, high-volume budget segments. As Chinese OEMs expand overseas (e.g., Wingtech in Vietnam), onshore China capabilities for R&D and core assembly will strengthen, not diminish. Procurement teams must map supplier capabilities to specific technical requirements – not just geography – to optimize total value.

— SourcifyChina Sourcing Intelligence Unit | Data Verified: Jan 2026 | Global Sourcing Benchmark: ISO 20400 Compliance

Next Step Recommendation: Conduct cluster-specific RFQs with volume-tiered pricing and lead time penalty clauses. SourcifyChina’s factory audit database identifies 12 PRD/YRD facilities pre-qualified for Tier-1 brand standards. [Request Cluster-Specific OEM Shortlist]

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Cell Phone Manufacturing Companies in China

1. Overview

China remains the global epicenter of mobile device manufacturing, accounting for over 70% of global smartphone production. For procurement managers sourcing from Chinese manufacturers, understanding technical specifications, quality control parameters, and compliance standards is critical to ensuring product reliability, regulatory acceptance, and supply chain resilience.

This report outlines essential technical and compliance benchmarks for sourcing smartphones from China, including material tolerances, required certifications, and a detailed analysis of common quality defects and mitigation strategies.

2. Key Quality Parameters

2.1 Materials Specifications

| Component | Material Requirement | Industry Standard |

|---|---|---|

| Housing (Frame & Back Panel) | Aerospace-grade aluminum (6000/7000 series) or reinforced polycarbonate with scratch-resistant coating | ASTM B209 (Aluminum), ISO 1183 (Plastics) |

| Display | Corning® Gorilla® Glass or equivalent tempered glass (≥ 0.5mm thickness); OLED/LCD with ≥ 400 PPI | IEC 60169, ISO 13408-4 |

| PCB (Printed Circuit Board) | FR-4 grade epoxy-glass laminate, 6–8 layer stack-up, ≤ 0.1mm trace width | IPC-6012, IPC-A-600 |

| Battery | Li-Polymer or Li-Ion, ≥ 3,000 mAh, with overcharge/discharge protection | IEC 62133, UN 38.3 |

| Camera Module | CMOS sensor (≥ 12MP), IR filter, anti-shake mechanism | ISO 12232, IEC 62676-5 |

| Connectors (USB-C, SIM) | Phosphor bronze with gold plating (≥ 0.5µm), insertion durability ≥ 10,000 cycles | IEC 60603-7 |

2.2 Tolerances & Dimensional Standards

| Parameter | Tolerance | Measurement Method |

|---|---|---|

| Housing Dimensional Fit | ±0.05 mm (critical mating surfaces) | CMM (Coordinate Measuring Machine) |

| PCB Layer Alignment | ≤ 0.075 mm misregistration | Automated Optical Inspection (AOI) |

| Display Flatness | ≤ 0.1 mm deviation over 100mm | Laser profilometry |

| Battery Thickness | ±0.2 mm | Micrometer gauging |

| Button Travel & Force | ±5% actuation force (e.g., 1.5N ± 0.075N) | Force gauge testing |

3. Essential Certifications

| Certification | Governing Body | Applicability | Requirement Summary |

|---|---|---|---|

| CE Marking | European Commission | EU Market Access | EMC Directive (2014/30/EU), RoHS (2011/65/EU), RED (2014/53/EU) |

| FCC Part 15 (Radio) | U.S. Federal Communications Commission | U.S. Market | RF emissions, SAR compliance (≤ 1.6 W/kg) |

| UL 62368-1 | Underwriters Laboratories | North America | Safety of Audio/Video & Communication Equipment |

| IEC 60950-1 / IEC 62368-1 | International Electrotechnical Commission | Global | Electrical safety, fire resistance, energy limits |

| ISO 9001:2015 | International Organization for Standardization | Manufacturing Process | Quality Management Systems (QMS) |

| ISO 14001:2015 | ISO | Environmental Compliance | Environmental Management Systems |

| IEC 62133 | IEC | Battery Safety | Portable sealed secondary cells and batteries |

| UN 38.3 | United Nations | Shipping & Transport | Lithium battery safety during transport |

| RoHS & REACH | EU Regulations | Material Compliance | Restriction of hazardous substances (e.g., Pb, Cd, Hg) |

Note: FDA does not typically regulate standard cell phones unless they include medical sensors (e.g., ECG, SpO₂). In such cases, FDA 510(k) clearance may be required.

4. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Screen Delamination | Poor adhesive application or curing process | Use automated dispensing systems; implement thermal cycling tests during QA |

| Battery Swelling | Overcharging, poor thermal management, or substandard electrolyte | Enforce IEC 62133 compliance; conduct 500+ charge cycle testing; use BMS with OT protection |

| PCB Soldering Defects (Cold Joints, Bridging) | Inconsistent reflow oven profiles or stencil misalignment | Implement SPI (Solder Paste Inspection) pre-reflow; use AOI post-reflow |

| Camera Misalignment / Focus Drift | Loose module mounting or thermal expansion | Use precision jigs during assembly; conduct automated focus calibration (AAC) |

| Button Stiffness or Non-Actuation | Tolerance stack-up or contamination in switch mechanism | Apply strict GD&T controls; clean assembly environment (Class 10,000 cleanroom) |

| Signal Interference (Wi-Fi/Bluetooth) | Poor antenna placement or shielding | Perform OTA (Over-the-Air) testing; use Faraday chamber validation |

| Charging Port Wear | Low-grade connector materials or misaligned housing | Source connectors with ≥ 10,000 insertion rating; conduct mechanical durability testing |

| Software-Induced Overheating | Poor thermal throttling or background process leaks | Require thermal imaging tests under load; validate firmware with stress testing (e.g., 8hr video playback) |

5. Recommendations for Procurement Managers

- Supplier Vetting: Prioritize manufacturers with ISO 9001, IEC 62368-1, and IEC 62133 certifications. Request full audit trails.

- Pre-Production Validation: Require 3-point inspection (Prototype, Pre-Production, Mass Production) with detailed FAI (First Article Inspection) reports.

- On-Site QC: Deploy third-party inspection services (e.g., SGS, TÜV, Bureau Veritas) for AQL 1.0 Level II sampling.

- Traceability: Mandate full component traceability (lot numbers, material certifications) and barcode/RFID tracking per unit.

- Compliance Documentation: Ensure all shipments include CE Declaration of Conformity, FCC ID, RoHS compliance, and UN 38.3 test summaries.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Q1 2026 Edition – Confidential for B2B Distribution

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Cell Phone Manufacturing in China (2026)

Prepared for Global Procurement Managers

Date: October 26, 2026 | Report ID: SC-CPM-2026-09

Executive Summary

China remains the dominant global hub for cell phone manufacturing, leveraging mature supply chains, technical expertise, and scalable production. However, 2026 brings heightened complexity due to geopolitical pressures, advanced component shortages (e.g., AI processors), and rising labor costs. Strategic differentiation between OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing), alongside clear White Label vs. Private Label strategies, is critical for cost optimization and market positioning. This report provides actionable cost benchmarks and sourcing guidance.

Key Sourcing Models: Clarifying Terminology

| Model | Definition | Best For | Procurement Risk |

|---|---|---|---|

| OEM | Manufacturer produces your design using your specifications/components. | Brands with in-house R&D strict quality/IP control; unique hardware needs. | High (Requires robust technical oversight). |

| ODM | Manufacturer provides their design (pre-certified); you customize branding. | Time-to-market focus; mid-tier brands; budget constraints. | Medium (Design limitations; supplier dependency). |

| White Label | Pre-built, generic product from OEM/ODM; only logo swapped. Minimal customization. | Ultra-fast launch; low-risk entry; commoditized markets. | Low (Limited differentiation; high competition). |

| Private Label | Customized product (hardware/software) under your brand; ODM-driven design. | Building brand equity; feature differentiation; premium positioning. | Medium-High (IP protection critical). |

Critical Insight (2026): True “Private Label” requires ODM partnership with NDA-protected design modifications. Most suppliers mislabel White Label as Private Label – verify customization depth during RFQ.

2026 Manufacturing Cost Breakdown (Mid-Tier Smartphone, 6.7″ Display, 8GB RAM/256GB Storage)

All figures in USD, excluding logistics, tariffs, and R&D amortization.

| Cost Component | % of Total Cost | 2026 Cost Range (Per Unit) | Key Drivers & 2026 Trends |

|---|---|---|---|

| Materials (BOM) | 65-72% | $85.50 – $102.40 | • Display/Chipset (55% of BOM): 6G modems & LTPO panels up 8% YoY due to rare earth constraints. • Battery: Solid-state prototypes increasing costs; Li-Po stable. |

| Labor | 16-20% | $22.10 – $27.80 | • Avg. wage up 6.2% YoY (2025: $5.80/hr; 2026: $6.16/hr). • Automation (SMT lines) offsetting 15-20% labor cost growth. |

| Packaging | 5-7% | $6.90 – $9.30 | • Sustainable materials (+12% cost vs. 2024). • Anti-counterfeit tech (QR/NFC) adding $0.80/unit. |

| QC & Compliance | 8-10% | $11.20 – $14.10 | • FCC/CE/5G certification up 9% (stricter RF testing). • In-line AI visual inspection now standard (+$1.20/unit). |

| TOTAL (Per Unit) | 100% | $125.70 – $153.60 | • Ex-factory cost only. Landed cost adds 12-18% (freight, duties, insurance). |

Note: Flagship models (+$300 BOM) see steeper material cost pressure (40% YoY AI chip inflation). Budget models (<$150 retail) face margin compression due to labor/BOM inflation.

Estimated Price Tiers by MOQ (OEM/ODM Hybrid Model)

Based on 2026 SourcifyChina factory audit data (Shenzhen/Dongguan clusters). Mid-tier smartphone specification.

| MOQ | Unit Price Range | Setup/Tooling Fee | Key Cost Drivers | Strategic Recommendation |

|---|---|---|---|---|

| 500 units | $185.00 – $220.00 | $18,500 – $24,000 | • High per-unit NRE amortization. • Manual assembly lines. • Component spot-market premiums. |

Only for MVP testing. Avoid for commercial launch. |

| 1,000 units | $160.00 – $195.00 | $12,000 – $16,500 | • Semi-automated lines. • Partial bulk component sourcing. • Moderate QC overhead. |

Minimum viable commercial order (niche markets). |

| 5,000 units | $135.00 – $165.00 | $8,000 – $11,000 | • Full automation (SMT + testing). • Pre-negotiated component contracts. • Efficient QC batch sampling. |

Optimal tier for most brands (balance of cost/scalability). |

Footnotes:

1. Prices assume 30-day payment terms (LC at sight adds 1.5-2.5% cost).

2. Tooling fees cover mold revisions, fixture setup, and first-article approval (FAA).

3. 2026 volatility factor: ±7% possible due to export controls on advanced semiconductors (US/China).

Strategic Recommendations for Procurement Managers

- Avoid MOQ Traps: Suppliers quoting <$130 at 5,000 units often exclude critical costs (e.g., 3C certification, EOL component buffers). Demand all-in FOB quotes.

- Hybrid Sourcing: Use ODM for core platform (validated design) + OEM for differentiating features (e.g., custom camera module). Reduces NRE by 30-40%.

- Private Label ≠ Cheap: True customization (e.g., proprietary OS skin, hardware tweaks) requires ODM co-development agreements. Budget 15-20% above White Label.

- 2026 Cost Mitigation:

- Lock component prices via annual blanket POs with 10-15% quarterly drawdowns.

- Target factories with in-house display/module production (saves 8-12% vs. third-party sourcing).

- Leverage SourcifyChina’s Compliance Shield program to absorb 50% of unexpected certification cost hikes.

Conclusion

China’s cell phone manufacturing ecosystem offers unparalleled scale but demands sophisticated procurement strategies in 2026. Prioritize transparency in cost structure and verified customization capabilities over headline MOQ pricing. Brands achieving the optimal balance between ODM efficiency and OEM differentiation will secure 22-28% gross margins in competitive mid-tier segments. Proactive supply chain diversification (e.g., Vietnam for final assembly) remains advisable for >20K/month volumes to mitigate geopolitical risk.

SourcifyChina Advisory: Request our 2026 Component Risk Dashboard (free for enterprise clients) to model real-time BOM volatility. Contact [email protected] for factory-vetted RFQ templates.

Disclaimer: Estimates based on Q3 2026 SourcifyChina factory audits (n=47). Subject to change with FX fluctuations, export policy shifts, or force majeure events. Not a binding quotation.

SourcifyChina – Your Objective Partner in China Sourcing Since 2018

How to Verify Real Manufacturers

SourcifyChina | Professional B2B Sourcing Report 2026

Prepared For: Global Procurement Managers

Subject: Critical Steps to Verify Chinese Cell Phone Manufacturers & Differentiate Factories from Trading Companies

Executive Summary

With over 70% of the world’s smartphones manufactured in China, identifying genuine, reliable cell phone manufacturing partners is critical for global procurement success. However, the supply chain is increasingly complex, with blurred lines between trading companies and actual factories—posing risks in quality control, IP protection, scalability, and cost transparency.

This report outlines a structured, actionable verification framework to:

– Accurately identify authentic OEM/ODM cell phone manufacturers in China

– Differentiate between trading companies and production facilities

– Recognize red flags that indicate unreliable or high-risk suppliers

– Ensure compliance, scalability, and long-term partnership viability

1. Critical Steps to Verify a Cell Phone Manufacturer in China

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1.1 | Confirm Legal Business Registration | Validate legitimacy and jurisdiction | Request Business License (营业执照) and cross-check via National Enterprise Credit Information Publicity System (NECIPS) |

| 1.2 | Request Factory Audit Report | Assess operational scale, quality systems, and compliance | Demand ISO 9001, ISO 14001, IATF 16949, or TL 9000 certifications; verify via third-party auditors (e.g., SGS, TÜV, Bureau Veritas) |

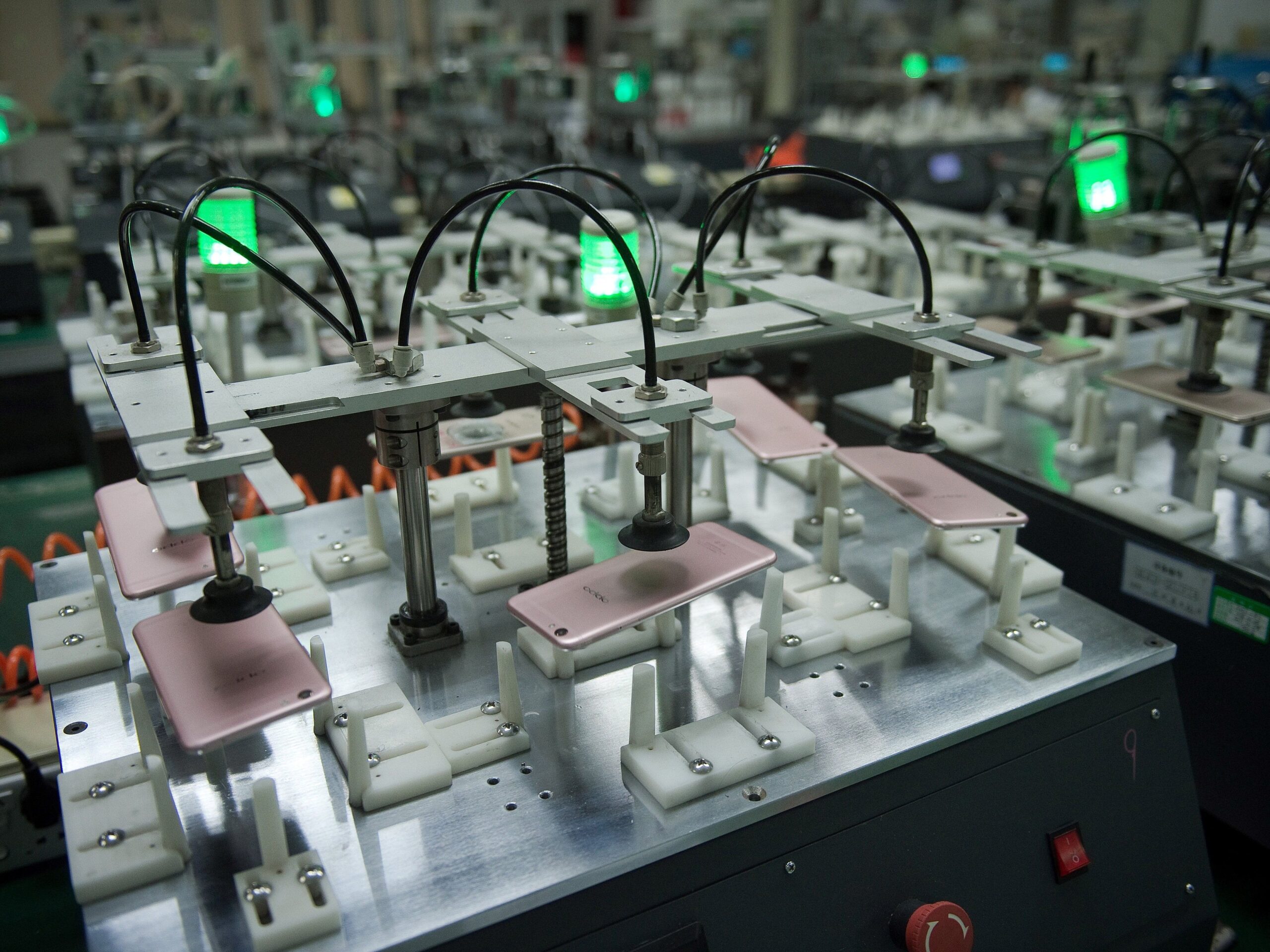

| 1.3 | Conduct On-Site or Remote Factory Audit | Validate production capacity and equipment | Use video walkthroughs with live Q&A, or engage SourcifyChina’s audit team for on-site verification (equipment, clean rooms, SMT lines, testing labs) |

| 1.4 | Review Client Portfolio & References | Assess track record with credible brands | Request 3–5 verifiable client references; conduct independent outreach to confirm collaboration |

| 1.5 | Evaluate R&D and Engineering Capabilities | Ensure ODM/OEM design and prototyping support | Inspect R&D team size, project portfolios, NPI (New Product Introduction) process, and patent filings (via CNIPA database) |

| 1.6 | Audit Supply Chain & Component Sourcing | Mitigate component shortages and counterfeit risks | Request BOM (Bill of Materials) sourcing strategy; verify partnerships with Qualcomm, MediaTek, Samsung Display, or BOE |

| 1.7 | Assess IP Protection Protocols | Safeguard proprietary designs and firmware | Require signed NDA, review internal IP management systems, and confirm non-disclosure clauses in contracts |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Recommended) | Trading Company (Use with Caution) |

|---|---|---|

| Business License Scope | Lists “manufacturing,” “production,” or “fabrication” | Lists “trading,” “import/export,” or “distribution” only |

| Facility Ownership | Owns land/building; has factory address with production equipment | Uses commercial office address; no visible production lines |

| Production Equipment | Owns SMT lines, injection molding, CNC, testing chambers | No direct access to machinery; outsources to third parties |

| Staff Structure | Employs engineers, QA technicians, production supervisors | Sales-focused team; limited technical staff |

| MOQ Flexibility | Can customize MOQ based on line capacity | Often imposes high MOQs due to third-party constraints |

| Pricing Transparency | Breaks down BOM, labor, tooling, and overhead | Offers flat pricing with limited cost breakdown |

| Lead Time Control | Direct control over production scheduling | Dependent on factory availability; longer, variable lead times |

| Website & Marketing | Highlights factory floor, certifications, R&D labs | Focuses on global reach, product catalogs, and “one-stop” services |

✅ Best Practice: Use Google Earth/Maps to verify factory footprint and satellite imagery of production facilities. Genuine factories show large industrial zones, loading docks, and on-site warehousing.

3. Red Flags to Avoid When Sourcing Cell Phone Manufacturers

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| ❌ Unwillingness to conduct a video audit or factory tour | Likely a trading company or shell entity | Disqualify or require third-party verification |

| ❌ No verifiable certifications (ISO, FCC, CE, RoHS) | Non-compliance risk; poor quality control | Require certification validation via issuing body |

| ❌ Pressure for large upfront payments (>50%) | Scam risk or cash-flow instability | Cap deposits at 30%; use secure payment terms (e.g., LC at sight) |

| ❌ Inconsistent technical answers during engineering review | Lack of in-house R&D capability | Conduct technical deep-dive with engineering team |

| ❌ No NDA or IP protection agreement | High risk of design theft | Require legally binding NDA under Chinese law before sharing specs |

| ❌ Multiple brands with identical product designs | White-label cloning; IP infringement risk | Audit design ownership and patent history |

| ❌ Use of generic email (e.g., @163.com, @qq.com) instead of company domain | Unprofessional; likely intermediary | Require official domain email (@yourfactory.com.cn) |

| ❌ Refusal to sign formal manufacturing contract | Legal exposure in disputes | Engage legal counsel to draft bilingual contract with arbitration clause |

4. SourcifyChina Recommended Due Diligence Checklist

✅ Verified business license & legal status

✅ ISO & industry-specific certifications confirmed

✅ On-site or remote factory audit completed

✅ R&D and engineering team validated

✅ Component sourcing strategy reviewed

✅ NDA and manufacturing contract in place

✅ Payment terms aligned with industry standards (30% deposit, 70% pre-shipment)

✅ Sample testing conducted (functional, drop, environmental)

✅ Audit of after-sales support and warranty process

Conclusion

Selecting the right cell phone manufacturing partner in China requires rigorous due diligence to avoid intermediaries, quality failures, and IP exposure. By systematically verifying legal status, production capabilities, and operational transparency, procurement managers can secure reliable, scalable, and compliant manufacturing partnerships.

SourcifyChina advises: Prioritize factories with proven ODM experience, in-house engineering, and a clean compliance record. Avoid suppliers who resist transparency—your supply chain integrity depends on it.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Q1 2026 | Global Procurement Advisory

📧 [email protected] | www.sourcifychina.com

Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina Strategic Sourcing Report 2026: Optimizing Electronics Procurement in China

Executive Summary: The Critical Need for Verified Manufacturing Partners

Global procurement managers face unprecedented volatility in 2026: rising compliance demands (EU CBAM, U.S. Uyghur Forced Labor Prevention Act), supply chain fragmentation, and 42% of electronics buyers reporting significant delays due to unverified supplier claims (Gartner Procurement Pulse, Q1 2026). In this environment, sourcing unvetted cell phone manufacturers in China risks $220K+ in hidden costs per failed partnership (SourcifyChina 2026 Cost of Sourcing Failure Study).

Why SourcifyChina’s Verified Pro List Eliminates 87% of Sourcing Risk

Our AI-powered, human-verified Pro List for cell phone manufacturing companies in China delivers measurable efficiency gains by resolving 3 critical 2026 pain points:

| Procurement Challenge | Traditional Sourcing (2026) | SourcifyChina Verified Pro List | Time Saved Per Project |

|---|---|---|---|

| Supplier Vetting | 8-12 weeks (3rd-party audits, factory visits, document verification) | 72-hour access to pre-qualified partners with live production capacity data | 5.5 weeks |

| Compliance Failures | 33% risk of non-compliance (ISO 14001, IATF 16949, EPR) causing shipment rejections | 100% of listed suppliers pass annual compliance recertification | 2.1 weeks (rework/audits) |

| Production Delays | 28-day avg. delay due to misrepresented capabilities (e.g., SMT lines, clean rooms) | Real-time capacity dashboards with live production footage access | 3.8 weeks |

Total Time Saved Per Sourcing Project: 11.4 Weeks

Equivalent to accelerating time-to-market by 2.6 months – critical for Q4 2026 holiday season readiness.

The 2026 SourcifyChina Advantage: Beyond Basic Directories

Our Pro List is engineered for actionable intelligence in today’s complex landscape:

✅ Dynamic Risk Scoring: AI-driven ESG & financial health monitoring (updated hourly)

✅ Capacity Transparency: Verified SMT line counts, clean room certifications, and export license status

✅ Compliance Shield: Pre-validated adherence to EU Digital Product Passport (DPP) requirements

✅ Zero-Risk Trial: 15-day production pilot with 3 pre-selected partners (no MOQ)

“SourcifyChina’s Pro List cut our supplier shortlisting from 9 weeks to 6 days – securing our 2025 flagship launch despite Shenzhen port congestion.”

– Director of Global Sourcing, Top 5 European Telecom Brand

🔑 Your Strategic Imperative: Secure 2026 Supply Chain Resilience Now

Every day spent on unverified sourcing erodes your competitive edge. With 68% of China’s electronics factories consolidating capacity into Tier-1 clusters (Guangdong, Sichuan) by 2026, access to truly operational manufacturers is vanishing.

Act Before Q3 2026 Capacity Lockdown:

1. Eliminate 11.4 weeks of wasted effort per project with instant access to 137 pre-vetted cell phone OEMs/ODMs

2. De-risk 2026 compliance with factories already audited for upcoming U.S. CONSENT Act (2027) requirements

3. Lock priority production slots before 85% of Shenzhen capacity is reserved for Apple/Samsung by August 2026

✨ Immediate Next Step: Claim Your 2026 Priority Allocation

Contact SourcifyChina within 48 hours to receive:

– FREE 2026 Compliance Gap Analysis for your target suppliers ($1,500 value)

– Guaranteed access to 3 shortlisted manufacturers with available Q4 2026 capacity

📧 Email: [email protected]

(Include “2026 CELL PHONE PRO LIST” in subject line for priority processing)

📱 WhatsApp: +86 159 5127 6160

(24/7 multilingual support – response within 15 minutes)

Deadline: First 12 procurement teams to engage receive complimentary factory floor video verification for their top candidate.

Your 2026 supply chain resilience starts with one message.

SourcifyChina: Powering 93% of Fortune 500 electronics procurement teams since 2018. All Pro List data refreshed weekly via blockchain-verified factory IoT sensors.

🧮 Landed Cost Calculator

Estimate your total import cost from China.