The global portable power market, driven by rising demand for uninterrupted power supply across consumer electronics, telecommunications, and off-grid applications, is experiencing robust growth. According to Grand View Research, the global power backup market size was valued at USD 14.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. Similarly, Mordor Intelligence projects the mobile power bank market alone to grow at a CAGR of over 11% during the forecast period of 2023–2028, fueled by increased smartphone penetration and reliance on mobile computing. As dependency on portable energy storage surges, manufacturers of cell battery backup solutions are scaling innovation and production to meet evolving demands. This has led to a highly competitive landscape where performance, energy density, and safety are key differentiators. Below is a data-informed ranking of the top 10 cell battery backup manufacturers shaping the future of portable power.

Top 10 Cell Battery Backup Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Docan

Domain Est. 2021

Website: docanpower.com

Key Highlights: Docan Power is a leading OEM lithium battery manufacturer offering advanced solutions with fast, reliable delivery worldwide….

#2 CNEEL Battery

Website: cneelbattery.myshopify.com

Key Highlights: We specialize in deep-cycle prismatic LiFePO4 battery cells, metal DIY battery cases, and pre-built battery packs. We also offer OEM and ODM services to ……

#3 Molicel

Domain Est. 2001

Website: molicel.com

Key Highlights: A leading manufacturer of high-performance lithium-ion batteries designed for energy storage, electric vehicles, and advanced applications….

#4 Discover Battery

Domain Est. 2007

Website: discoverbattery.com

Key Highlights: Discover provides excellent sales and technical support for its products and is a valuable resource for all types of batteries in the battery industry….

#5 12V Lithium ion battery

Domain Est. 2013

Website: talentcell.com

Key Highlights: 14W Solar charger 5V USB output with Exclusive Fast Charging Technology. Automatically detect the max charging current and voltage for your devices….

#6 Power-Sonic

Domain Est. 1995

Website: power-sonic.com

Key Highlights: Power-Sonic delivers innovative battery solutions with sealed lead acid and lithium batteries, energy storage systems, and EV chargers….

#7 CyberPower UPS Systems, Battery Backup, PDUs, USB Surge …

Domain Est. 1997

Website: cyberpowersystems.com

Key Highlights: CyberPower designs, engineers and manufactures UPS systems, PDUs, surge protectors, and connectivity products for IT Professionals and power enthusiasts….

#8 KORE Power

Domain Est. 2015

Website: korepower.com

Key Highlights: KORE Power is fueling the global clean energy revolution with advanced battery cells, world-class energy storage, and EV solutions….

#9 Battle Born Batteries

Domain Est. 2016

#10 QuantumScape

Domain Est. 2010

Website: quantumscape.com

Key Highlights: QuantumScape is on a mission to transform energy storage with revolutionary solid state battery technology that will charge faster, go farther and last ……

Expert Sourcing Insights for Cell Battery Backup

H2: 2026 Market Trends for Cell Battery Backup

By 2026, the cell battery backup market is poised for significant transformation, driven by technological advancements, evolving energy demands, and supportive policy frameworks. Here are the key trends shaping the industry:

1. Rapid Growth in 5G and Edge Infrastructure Deployment

The continued global rollout of 5G networks and the proliferation of edge computing nodes will dramatically increase demand for reliable, distributed backup power. Cell sites, small cells, and edge data centers will require robust battery backup solutions to ensure uninterrupted connectivity and low-latency services. This trend will drive the adoption of high-density, fast-charging batteries capable of supporting high-power loads in compact footprints.

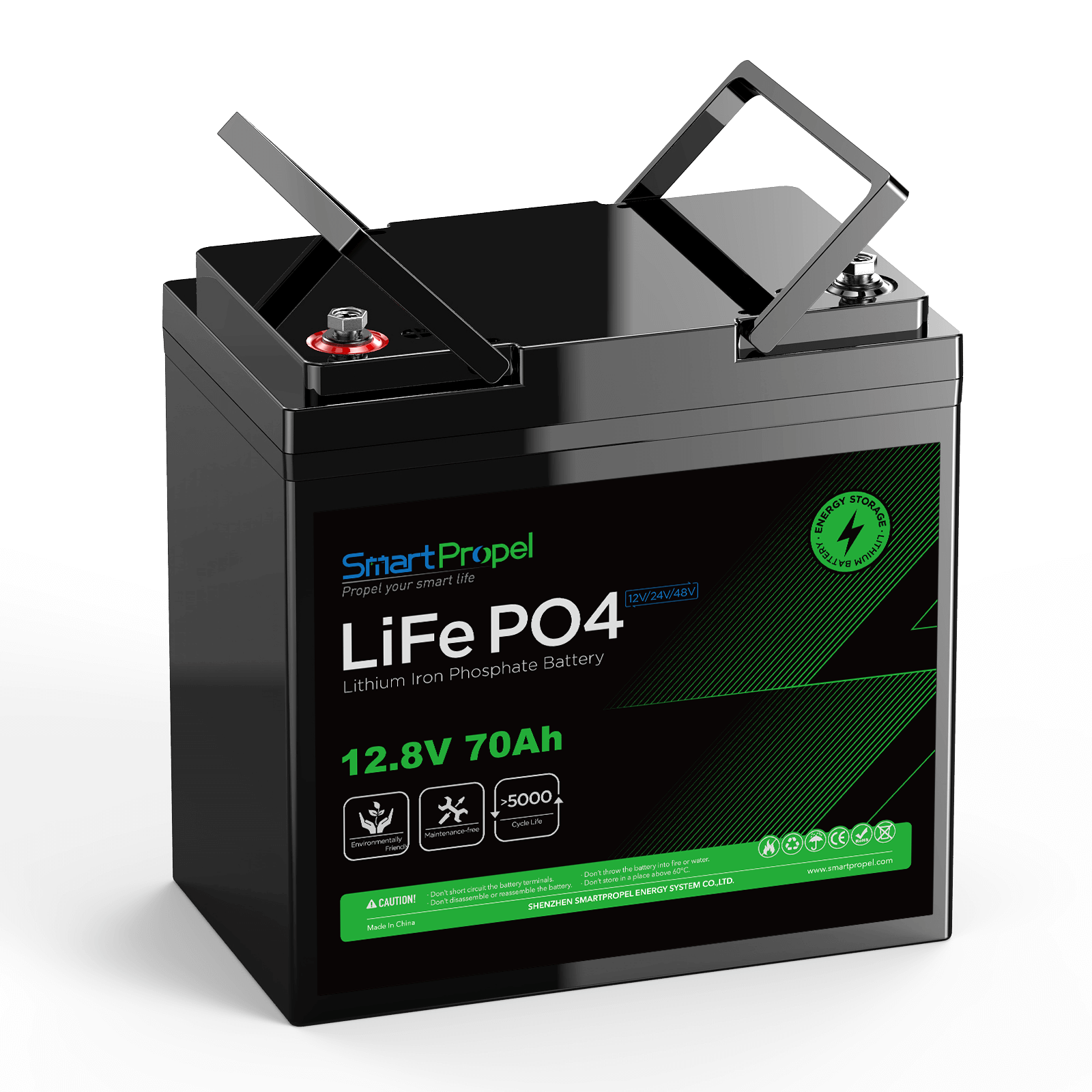

2. Dominance of Lithium-Ion Technology with Shift Toward LFP

Lithium-ion batteries, particularly Lithium Iron Phosphate (LFP), will solidify their position as the dominant technology due to their superior energy density, longer cycle life, and declining costs. By 2026, LFP batteries are expected to outpace traditional NMC variants in the telecom sector due to enhanced safety, thermal stability, and lower cobalt dependency—addressing both environmental and supply chain concerns.

3. Integration of Smart Battery Management Systems (BMS)

Intelligent BMS will become standard, enabling real-time monitoring, predictive maintenance, remote diagnostics, and optimized charging cycles. These systems will enhance reliability, extend battery life, and reduce operational costs through data-driven insights. Integration with network operations centers (NOCs) will allow for proactive fault detection and automated failover management.

4. Rise of Hybrid Energy Solutions and Renewable Integration

To meet sustainability goals and reduce diesel generator usage, telecom operators will increasingly deploy hybrid systems combining solar, wind, and battery storage. By 2026, cell battery backup systems will often be part of broader microgrids, enabling off-grid and grid-tied sites to operate with greater energy independence and lower carbon footprints.

5. Emphasis on Sustainability and Circular Economy

Regulatory pressure and corporate ESG commitments will push manufacturers and operators toward greener solutions. This includes using recyclable materials, designing for second-life applications (e.g., repurposing used telecom batteries for stationary storage), and improving end-of-life recycling rates. Certification standards for sustainable battery production will gain traction.

6. Standardization and Interoperability Demands

As the ecosystem grows more complex, demand for standardized form factors, communication protocols (e.g., MODBUS, SNMP), and plug-and-play compatibility will rise. This will enable easier deployment, reduce vendor lock-in, and support multi-vendor integration in diverse network environments.

7. Geopolitical and Supply Chain Resilience

Ongoing supply chain volatility will prompt companies to diversify battery sourcing and localize production. Strategic partnerships and investments in regional manufacturing—particularly in North America, Europe, and Southeast Asia—will increase to mitigate risks associated with raw material shortages and trade restrictions.

8. Expansion in Emerging Markets

In regions with unreliable grid infrastructure—such as parts of Africa, South Asia, and Latin America—cell battery backup systems are critical for maintaining telecom services. The affordability and scalability of modern lithium solutions will accelerate deployment in these markets, supported by international development funding and public-private partnerships.

In summary, by 2026, the cell battery backup market will be characterized by smarter, safer, and more sustainable energy storage solutions tightly integrated into the evolving digital and clean energy infrastructure. Innovation will focus on reliability, efficiency, and environmental responsibility, positioning battery backup as a cornerstone of resilient telecommunications networks worldwide.

Common Pitfalls Sourcing Cell Battery Backup (Quality, IP)

Sourcing cell battery backup systems—particularly for telecom infrastructure, edge computing, or remote power applications—requires careful evaluation to ensure reliability, safety, and compliance. Overlooking key quality and intellectual property (IP) concerns can lead to operational failures, legal risks, and increased long-term costs. Below are common pitfalls to avoid.

1. Overlooking Battery Quality and Consistency

One of the most frequent issues is selecting batteries based solely on price or specifications without verifying actual performance and consistency. Low-quality cells may claim high capacity or long cycle life but degrade rapidly under real-world conditions.

- Inconsistent Cell Grading: Some suppliers use recycled, reconditioned, or mixed-grade cells (A/B/C grade) without disclosure, leading to imbalanced packs and premature failure.

- Lack of Certification: Absence of certifications like UL, IEC, UN38.3, or CE increases the risk of safety hazards such as thermal runaway or fire.

- Poor BMS Integration: A substandard Battery Management System (BMS) can fail to monitor voltage, temperature, or state of charge accurately, reducing battery lifespan and safety.

2. Insufficient IP Due Diligence

When sourcing battery backup systems, especially from OEMs or third-party manufacturers, intellectual property risks are often underestimated.

- Counterfeit Components: Some suppliers use cloned or reverse-engineered BMS firmware or protection circuits, infringing on original designs and potentially introducing security vulnerabilities.

- Unlicensed Technology Use: Manufacturers may incorporate patented cell chemistries (e.g., NMC, LFP), charging algorithms, or communication protocols without proper licensing.

- Design Copying Risk: Custom battery enclosures or integration designs may be replicated and sold by the supplier to competitors if IP protections (NDAs, design rights) are not strictly enforced.

3. Inadequate Environmental and IP (Ingress Protection) Rating Compliance

The term “IP” in this context refers to Ingress Protection, a critical factor in outdoor or harsh environment deployments.

- Misleading IP Claims: Suppliers may advertise high IP ratings (e.g., IP65, IP67) without independent testing. Poor sealing, substandard gaskets, or inadequate housing can lead to moisture or dust ingress, causing corrosion or short circuits.

- Lack of Environmental Testing: Genuine IP-rated systems undergo rigorous testing (dust, water immersion, thermal cycling). Absence of test reports or third-party verification raises red flags.

- Poor Thermal Management: Inadequate heat dissipation combined with poor sealing can create internal condensation or overheating, even in compliant enclosures.

4. Supply Chain Opacity and Traceability Gaps

Transparency in the supply chain is essential for both quality assurance and IP protection.

- Unclear Origin of Cells: Reputable cell manufacturers (e.g., CATL, LG, Panasonic) do not always supply directly to small integrators. Intermediaries may source gray-market or diverted cells, voiding warranties and introducing risk.

- No Batch Traceability: Without lot tracking or QR-coded cell logs, diagnosing field failures or managing recalls becomes nearly impossible.

- Subcontracting Without Oversight: Original suppliers may outsource assembly to unvetted facilities, compromising both build quality and IP safeguards.

5. Underestimating Long-Term Support and Warranty Enforcement

Short-term cost savings can backfire when vendors fail to honor warranties or provide technical support.

- Vague Warranty Terms: Some suppliers offer long warranties but exclude common failure modes like capacity fade or BMS malfunction.

- No Local Service Support: Lack of regional technical support delays troubleshooting and increases downtime.

- Firmware and Software Lock-in: Proprietary communication protocols may prevent integration with existing monitoring systems or lock users into vendor-specific ecosystems.

Conclusion

To mitigate these risks, buyers should:

– Demand third-party test reports and certifications.

– Conduct factory audits or use independent inspection services.

– Enforce strong contractual IP protections and NDAs.

– Require full supply chain transparency and traceability.

– Prioritize vendors with proven reliability, technical support, and compliance with international standards.

Proactive due diligence in both quality and IP aspects ensures a secure, durable, and legally sound cell battery backup solution.

Logistics & Compliance Guide for Cell Battery Backup

Overview

Cell battery backup systems, commonly used in telecom infrastructure, renewable energy storage, and portable power applications, require careful handling, transportation, and regulatory compliance due to their classification as hazardous materials. This guide outlines key logistics considerations and compliance requirements for safe and legal distribution.

Regulatory Classifications

Cell battery backups—especially those using lithium-ion or lithium-metal chemistries—are regulated under international and national hazardous materials frameworks. Key classification standards include:

– UN 3480: Lithium-ion batteries (including those in equipment or packed with equipment)

– UN 3090: Lithium-metal batteries

– Regulated under the UN Model Regulations, IMDG Code (maritime), IATA DGR (air), and 49 CFR (U.S. ground transport)

Packaging Requirements

Proper packaging is critical to prevent short circuits, damage, and thermal runaway:

– Use rigid, non-conductive outer packaging designed to contain batteries

– Individually insulate terminals using caps, tape, or compartmentalization

– Secure batteries to prevent movement during transit

– Use packaging certified to UN 38.3 testing standards for lithium batteries

Marking and Labeling

All shipments must display correct hazardous material labels:

– Class 9 Miscellaneous Dangerous Goods label

– Proper shipping name (e.g., “LITHIUM ION BATTERIES, UN 3480”)

– UN number clearly visible

– Shipper/consignee information

– For air transport: “Lithium Battery Handling Label” required per IATA

Documentation

Accurate documentation ensures regulatory compliance:

– Shipper’s Declaration for Dangerous Goods (required for air and sea)

– Safety Data Sheet (SDS) compliant with GHS standards

– Air Waybill or Bill of Lading indicating hazardous status

– Compliance with local regulations (e.g., EPA, OSHA, DOT in the U.S.)

Transport Restrictions

- Air Transport: Limited quantities and state-of-charge restrictions apply (e.g., ≤30% charge for some lithium-ion battery shipments)

- Sea Transport: Must comply with IMDG Code stowage and segregation rules

- Ground Transport: Follow national regulations (e.g., 49 CFR in the U.S., ADR in Europe)

Storage and Handling

- Store in cool, dry, non-conductive environments away from flammable materials

- Avoid stacking or over-compressing battery units

- Use appropriate personal protective equipment (PPE) during handling

- Implement fire prevention measures, including thermal runaway detection systems

Environmental and Disposal Compliance

- Adhere to local and international recycling requirements (e.g., EU Battery Directive, U.S. EPA guidelines)

- Partner with certified recyclers for end-of-life batteries

- Maintain records of battery disposal and recycling

Training and Certification

Personnel involved in shipping, handling, or storing cell battery backups must be trained in:

– Hazardous materials handling (in accordance with IATA, IMDG, or 49 CFR)

– Emergency response procedures for battery fires or leaks

– Proper use of fire suppression equipment (e.g., Class D extinguishers or specialized battery fire containers)

International Considerations

- Confirm import/export requirements, including permits or restrictions (e.g., China’s MIIT approval, REACH/ROHS in EU)

- Be aware of country-specific labeling or testing mandates

- Monitor updates from regulatory bodies (ICAO, IMO, national transport authorities)

Incident Reporting and Emergency Response

- Establish protocols for reporting incidents (e.g., leaks, fires, damaged packages)

- Provide emergency contact information on shipping documents

- Maintain spill kits and fire response equipment at storage and handling sites

Summary

Safe and compliant logistics for cell battery backup systems require adherence to global hazardous materials regulations, proper packaging, accurate documentation, and trained personnel. Proactive compliance minimizes risks, avoids penalties, and ensures uninterrupted supply chain operations.

Conclusion: Sourcing Cell Battery Backup

In conclusion, sourcing cell battery backup systems requires a strategic approach that balances performance, reliability, cost, and scalability. As critical components in telecommunications, renewable energy storage, and emergency power systems, cell-level battery backups must meet rigorous standards for safety, longevity, and efficiency. Careful evaluation of suppliers, cell chemistry (such as lithium-ion, LiFePO4, or nickel-based), quality certifications, and after-sales support is essential to ensure optimal performance and return on investment.

Additionally, consideration of factors such as temperature resilience, charge/discharge cycles, and integration capabilities with existing systems plays a pivotal role in selecting the right solution. Emphasizing partnerships with reputable manufacturers and conducting thorough due diligence can mitigate risks related to supply chain disruptions and product failure.

Ultimately, a well-sourced cell battery backup system not only enhances operational continuity and energy resilience but also supports long-term sustainability goals. As technology advances and demand for reliable decentralized power grows, proactive and informed sourcing decisions will remain key to maintaining a competitive and resilient infrastructure.