The global structural connectors market, which includes ceiling joist hangers, was valued at USD 9.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030, according to Grand View Research. This steady growth is driven by rising construction activity, stricter building codes, and increased demand for durable, engineered fastening solutions in residential and commercial projects. As one of the key components in structural framing, ceiling joist hangers ensure secure load transfer and long-term stability—making them indispensable in modern construction. With growing urbanization and infrastructure investments, especially in North America and Asia-Pacific, manufacturers are ramping up innovation in galvanized steel formulations, load capacities, and installation efficiency. Amid this expanding landscape, several leading companies have emerged as top suppliers of high-performance ceiling joist hangers, combining engineering excellence with compliance to international standards. Here are the top 6 ceiling joist hanger manufacturers shaping the industry in 2024.

Top 6 Ceiling Joist Hangers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Joist Hangers

Domain Est. 1995

Website: strongtie.com

Key Highlights: These hangers include designs that provide multiple nailing pattern options to enable value engineering for different loads. Joist hangers for this category ……

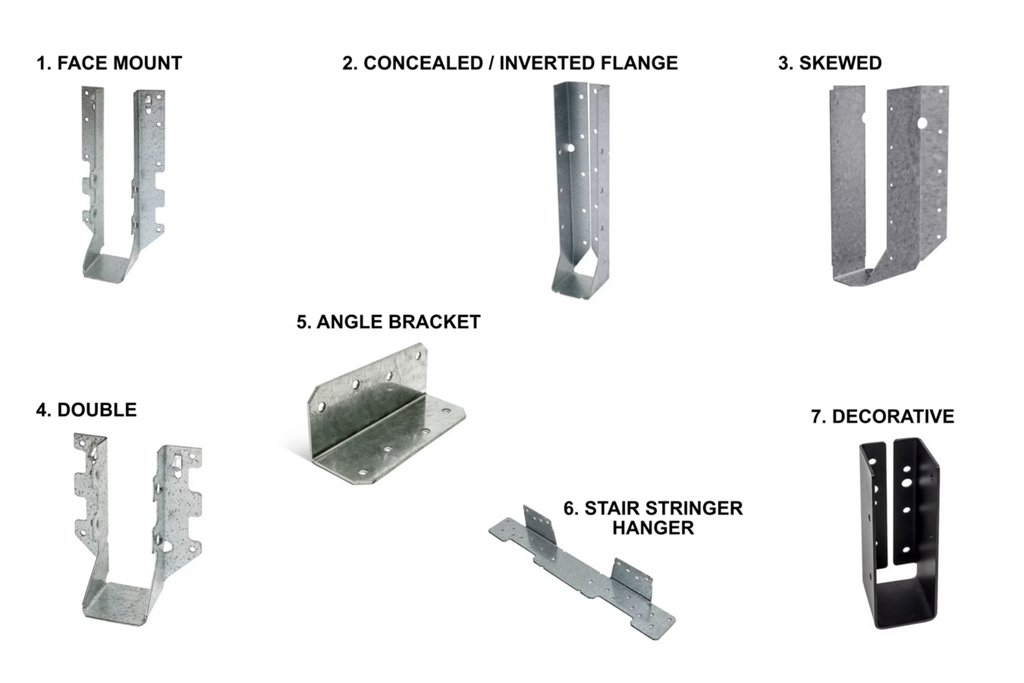

#2 Types of Joist Hangers

Domain Est. 1996

Website: trex.com

Key Highlights: Joist hangers are available in a variety of sizes and configurations at home centers, lumberyards, and specialty decking suppliers….

#3 Trimjoist

Domain Est. 1996

Website: trimjoist.com

Key Highlights: TrimJoist® is the marriage of an open-web floor truss and a trimmable, wooden I-joist, bringing the best features of each to the relationship….

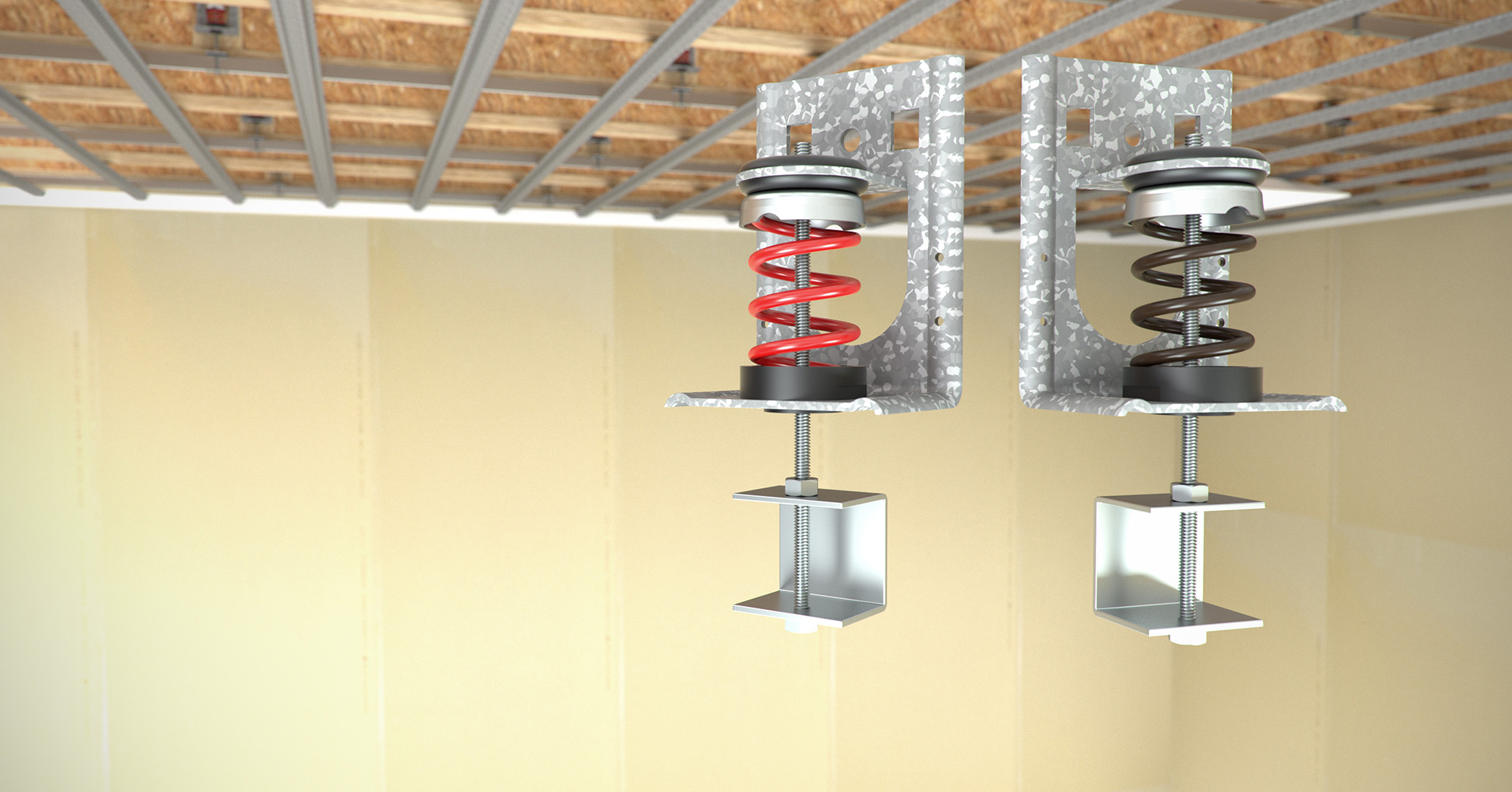

#4 KINETICS® ICW Wood

Domain Est. 1996

Website: kineticsnoise.com

Key Highlights: This vibration energy easily passes through wall studs or ceiling joists and radiates out on the other side as bothersome airborne noise….

#5 JUS SERIES

Domain Est. 2002

Website: mitek-us.com

Key Highlights: The HUS, JUS, and MUS hanger series offers double shear nailing. MiTek’s dimple allows for 30° to 45° nailing through the joist into the header resulting in ……

#6 Truss T Hanger

Domain Est. 2003

Website: trussthanger.com

Key Highlights: Truss-T Hanger is the new industry standard for hanging pipe, electrical, HVAC, fire suspension, and more in open web bar joist….

Expert Sourcing Insights for Ceiling Joist Hangers

H2: 2026 Market Trends for Ceiling Joist Hangers

The ceiling joist hanger market is poised for significant evolution by 2026, driven by advancements in construction technology, sustainability demands, and shifting global building practices. Key trends shaping the industry include:

-

Increased Demand in Residential Construction

With global urbanization and housing shortages prompting residential development booms—particularly in North America, Europe, and parts of Asia—the demand for reliable structural components like ceiling joist hangers is rising. The popularity of open-concept designs and multi-story homes further amplifies the need for robust joist support systems. -

Growth in Renovation and Retrofit Projects

Aging infrastructure and a growing emphasis on energy efficiency are fueling renovation markets. Ceiling joist hangers are increasingly used in retrofitting older buildings to meet modern safety and insulation standards, especially in seismic and high-wind zones where structural integrity is critical. -

Shift Toward Sustainable and Lightweight Materials

The construction industry’s push for sustainability is influencing the materials used in hanger manufacturing. By 2026, expect greater adoption of recycled steel and corrosion-resistant coatings that extend product life. Additionally, lightweight composite hangers may emerge as alternatives, reducing shipping emissions and simplifying installation. -

Technological Integration and Smart Hardware

While still in early stages, smart building technologies are beginning to influence structural components. Some manufacturers are exploring joist hangers with embedded sensors to monitor load stress and structural health—particularly in commercial and high-end residential applications. -

Regional Market Diversification

North America remains a dominant market due to strict building codes and high DIY activity. However, rapid construction growth in Southeast Asia, the Middle East, and Africa is creating new opportunities. Manufacturers are tailoring product lines to meet regional code requirements and climatic conditions. -

Supply Chain Optimization and Localized Production

Post-pandemic supply chain disruptions have prompted companies to localize production. By 2026, more ceiling joist hanger manufacturers are expected to establish regional production hubs to reduce lead times, tariffs, and logistics costs. -

Enhanced Product Design and Installation Efficiency

Innovations such as pre-aligned nail holes, twist-resistant designs, and adjustable hangers are improving installation speed and accuracy. These features are especially valuable in labor-constrained markets where time savings directly impact project costs.

In summary, the 2026 ceiling joist hanger market will be defined by innovation, sustainability, and regional expansion. Companies that invest in R&D, adhere to evolving building codes, and adapt to local market needs will be best positioned to capitalize on these trends.

Common Pitfalls When Sourcing Ceiling Joist Hangers (Quality, IP)

Sourcing ceiling joist hangers involves more than just finding a component that fits—it requires careful attention to quality and intellectual property (IP) considerations to ensure structural integrity and legal compliance. Overlooking these aspects can lead to safety hazards, project delays, and legal liabilities.

Poor Material Quality and Manufacturing Standards

One of the most frequent pitfalls is selecting joist hangers made from substandard materials or manufactured without adherence to recognized building codes. Low-quality hangers may use thinner gauge steel, insufficient galvanization, or poor weld integrity, compromising load-bearing capacity and long-term durability. Always verify that products meet ASTM or equivalent standards (e.g., ASTM A153 for galvanizing, ASTM A653 for steel) and are certified by recognized testing agencies (e.g., ICC-ES).

Lack of Structural Certification and Load Ratings

Ceiling joist hangers must be engineered for specific load conditions and approved for the intended application. Sourcing uncertified or generic hangers without traceable load tables and engineering stamps can result in non-compliance with building regulations. Ensure each product comes with documented load ratings, installation guidelines, and approval from a licensed engineer where required.

Inadequate Corrosion Protection for Intended Environment

Using hangers with inappropriate corrosion resistance—such as standard galvanized steel in high-moisture or coastal environments—can lead to premature rust and failure. Always match the hanger’s protective coating (e.g., hot-dip galvanized, ZMAX, stainless steel) to the project’s environmental exposure. Failure to do so undermines both quality and longevity.

Counterfeit or Non-Branded Products

The market sometimes includes counterfeit or unbranded joist hangers that mimic reputable brands but lack proper testing and quality control. These products often bypass intellectual property protections and safety certifications. Sourcing from unauthorized distributors increases the risk of receiving such items, which may not meet code requirements and could void insurance or liability coverage.

Intellectual Property Infringement

Manufacturers invest in the design, testing, and branding of joist hangers, protected under patents and trademarks. Sourcing generic or “compatible” hangers that replicate patented designs without authorization constitutes IP infringement. This not only exposes contractors and builders to legal risk but also undermines innovation and safety standards upheld by original equipment manufacturers (OEMs).

Absence of Traceability and Documentation

Reliable suppliers provide full traceability—including batch numbers, mill certifications, and test reports. Sourcing hangers without proper documentation makes it difficult to verify quality, respond to inspections, or manage recalls. In regulated construction projects, this lack of transparency can result in rejected work or compliance failures.

Conclusion

To avoid these pitfalls, always source ceiling joist hangers from reputable suppliers, verify certifications, confirm environmental suitability, and ensure compliance with both quality standards and intellectual property rights. Due diligence in procurement protects structural performance, legal standing, and project integrity.

Logistics & Compliance Guide for Ceiling Joist Hangers

Product Overview and Intended Use

Ceiling joist hangers are engineered metal connectors designed to support ceiling joists in framing applications. They ensure secure attachment between joists and supporting structures such as headers, beams, or walls. These hangers are typically used in residential and light commercial construction to maintain structural integrity and comply with building codes.

Material Specifications and Standards

Ceiling joist hangers are commonly manufactured from galvanized steel or stainless steel to resist corrosion and ensure durability. They must conform to recognized industry standards, including:

– ASTM A653/A653M (Standard Specification for Steel Sheet, Zinc-Coated)

– ICC-ES AC13 (Acceptance Criteria for Metal Plate Connected Wood Trusses)

– IAPMO UES ER-143 (Evaluation Report for Joist Hangers)

Manufacturers must provide documentation confirming compliance with these standards for code approval.

Load Capacity and Engineering Documentation

Each ceiling joist hanger model has specified load capacities based on orientation, fastener type, and wood species. Load tables must be provided by the manufacturer and referenced during design. Key considerations include:

– Vertical load (downward force) ratings

– Lateral torsional restraint capabilities

– Uplift resistance (if applicable)

Engineers and builders must verify that selected hangers meet or exceed the structural demands of the application.

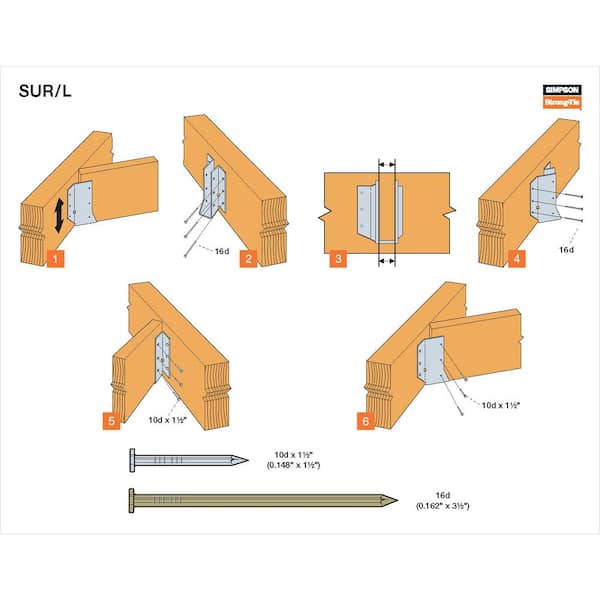

Fastener Requirements

Proper installation requires specific fasteners as specified by the manufacturer. Typically:

– Use only approved nails (e.g., 10d common, 10d x 1¾” nails) or structural screws

– Fasteners must be corrosion-resistant when used in treated lumber or high-moisture environments

– Do not substitute fasteners not listed in the manufacturer’s installation instructions

Improper fastening compromises load capacity and voids product warranties.

Installation Compliance

Installation must follow manufacturer guidelines and local building codes. Critical practices include:

– Hangers must be fully seated on the supporting member

– Joist must be tightly fitted into the hanger seat

– All nail/screw holes must be filled unless otherwise specified

– Hangers must be oriented correctly (e.g., with proper top flange alignment)

Inspection during framing is required to ensure compliance before drywall or insulation conceals the work.

Building Code and Regulatory Compliance

Ceiling joist hangers must be approved for use under the International Building Code (IBC) and International Residential Code (IRC). Compliance is verified through:

– ESR (Evaluation Service Report) or ICC-ES listing

– Local jurisdiction acceptance based on third-party testing

– Stamping or labeling indicating load ratings and code compliance

Always confirm that products used are listed for the intended application and geographic region.

Storage and Handling Logistics

To maintain product integrity during transport and storage:

– Store in a dry, covered area to prevent rust and moisture damage

– Keep hangers in original packaging until point of use

– Handle with care to avoid bending or deformation of flanges

– Segregate galvanized and stainless steel hangers to prevent galvanic corrosion

Shipping and Inventory Management

Best practices for logistics include:

– Use palletized shipments with secure strapping

– Label packages clearly with product type, size, and quantity

– Rotate stock using FIFO (First In, First Out) method

– Maintain inventory records aligned with project schedules to avoid shortages or overordering

Quality Assurance and Traceability

Manufacturers should provide batch traceability and mill certification upon request. Contractors should:

– Verify product markings (model number, load stamp, manufacturer ID) upon delivery

– Retain product cut sheets and approval documents for inspection

– Report any non-conforming or damaged products immediately

Environmental and Safety Considerations

- Recycle packaging materials (cardboard, plastic wrap, metal scraps) responsibly

- Wear appropriate PPE (gloves, eye protection) when handling sharp metal edges

- Follow OSHA guidelines for working at heights during installation

Conclusion

Proper selection, handling, and installation of ceiling joist hangers are essential for structural safety and regulatory compliance. Always consult manufacturer specifications and local building authorities to ensure all aspects of logistics and application meet required standards.

In conclusion, sourcing ceiling joist hangers requires careful consideration of structural requirements, building codes, material compatibility, and load specifications. It is essential to select the appropriate type and size of hanger based on the joist dimensions, spacing, and the expected load to ensure safety and compliance with local regulations. Sourcing from reputable suppliers or manufacturers that provide certified, high-quality products guarantees durability and performance. Additionally, proper installation following manufacturer guidelines is crucial to maintain structural integrity. By evaluating these factors thoroughly, builders and contractors can effectively source ceiling joist hangers that support long-term stability and safety in construction projects.