The global diesel engine filter market is witnessing steady growth, driven by stringent emissions regulations and rising demand for high-performance filtration solutions in heavy-duty applications. According to Grand View Research, the global diesel particulate filter market size was valued at USD 11.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. A significant portion of this demand stems from the aftermarket and OEM sectors supporting diesel engines like the Cummins 6.7L, widely used in pickup trucks, construction equipment, and commercial vehicles. As emissions standards tighten and engine longevity becomes a key performance metric, CCV (Crankcase Ventilation) filters—critical for managing blow-by gases and maintaining engine efficiency—have become essential components. With increasing adoption in North America and growing industrialization in emerging markets, the need for reliable CCV filter manufacturers has surged. The following analysis identifies the top six manufacturers excelling in producing high-quality CCV filters specifically engineered for the Cummins 6.7 platform, combining data on product performance, market presence, and technological innovation to guide procurement and replacement decisions.

Top 6 Ccv Filter Cummins 6.7 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mopar Crankcase Vent (CCV) Filter 2007.5

Domain Est. 2017

Website: blessedperformance.com

Key Highlights: In stock Rating 4.3 13 Shop Blessed Performance for the Mopar OEM Replacement Crankcase (CCV) Filter Part Number 68002433AC for your 2007.5-2024 Dodge Ram 6.7L Cummins Engine….

#2 Engine hours vs miles for CCV filter

Domain Est. 2005

Website: cumminsforum.com

Key Highlights: I plan on doing the CCV filter early to avoid the effects of a clogged one. Much of mu driving is short trips with a few vacations….

#3 Ram 6.7 Liter Cummins Diesel Crankcase breather element(CCV)

Domain Est. 2005

Website: dieselfiltersonline.com

Key Highlights: Ram 6.7 Liter Cummins Diesel Crankcase breather element(CCV) ; $129.95 As low as $123.45 · 68677813AA · Crankcase Filter(CCV) ; $218.95 · Rating: 100%. 3 Reviews….

#4 CCV Crankcase Vent Reroute Kit For 07

Domain Est. 2019

Website: truckmasterdiesel.com

Key Highlights: Free delivery over $100 30-day returns90° vent hose encourages oil drain back and helps eliminate drips. This kit does retain the stock CCV filter. Fits For 2007.5-2017 Dodge 6.7L …

#5 6.7L Cummins CCV Delete & Reroute Kits for Ram 2500/3500

Domain Est. 2019

Website: spelabautoparts.com

Key Highlights: Eliminate crankcase pressure issues. Shop CCV delete kits, open breathers, and catch cans for 2007.5-2024 Ram 6.7L Diesel. Stop turbo oil leaks forever….

#6 Doc’s Diesel: One

Domain Est. 2021

Website: docsdiesel.com

Key Highlights: Free delivery over $99 30-day returnsDoc’s Diesel offers a premium selection of aftermarket replacement filters for your diesel trucks including Engine, Fuel, Oil, and Cabin Filter…

Expert Sourcing Insights for Ccv Filter Cummins 6.7

H2: 2026 Market Trends for CCV Filters in Cummins 6.7L Engines

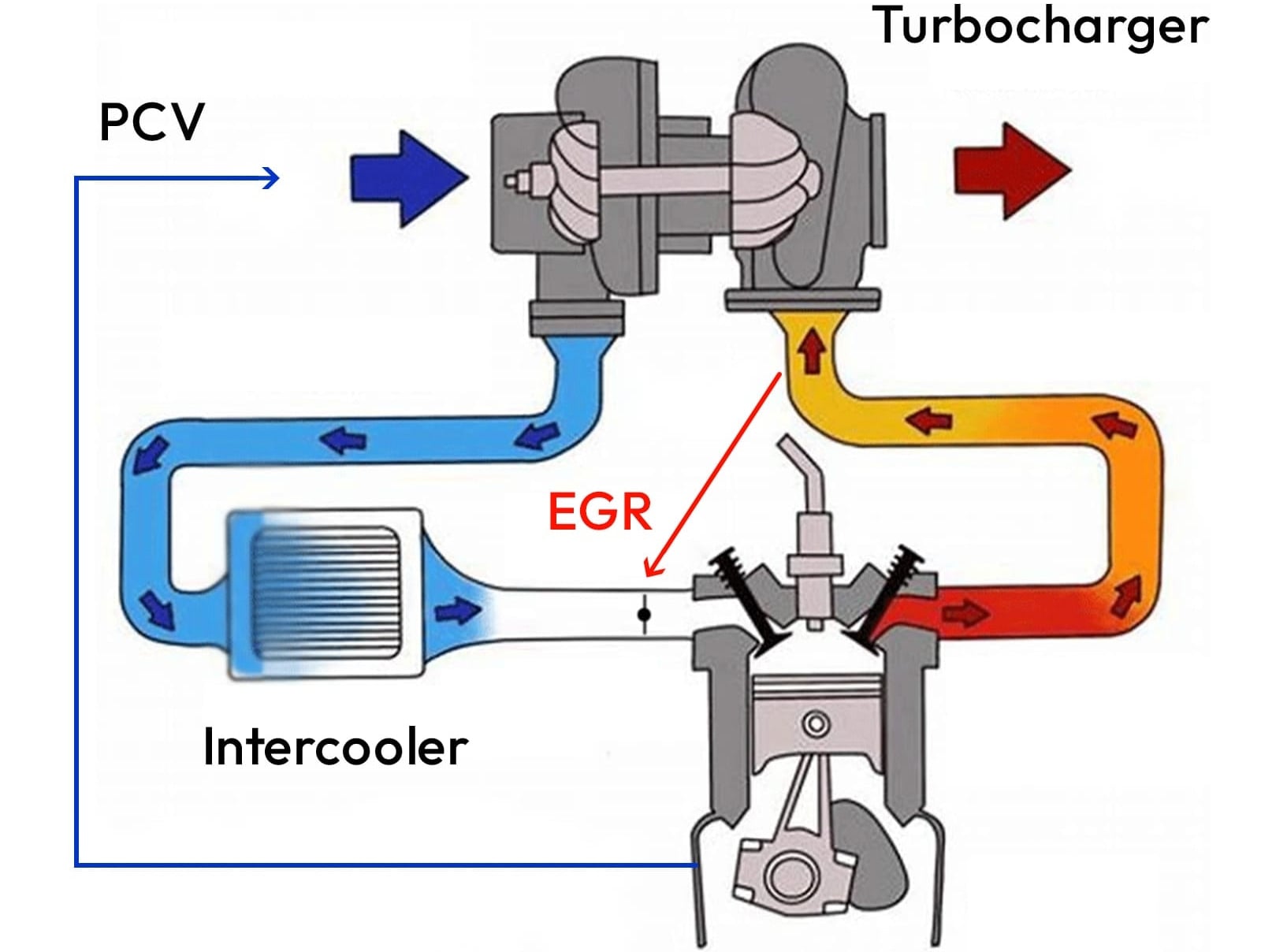

The market for Crankcase Ventilation (CCV) filters in Cummins 6.7L diesel engines is expected to experience notable shifts by 2026, driven by evolving emissions regulations, advancements in diesel engine technology, and increasing demand for improved engine longevity and performance. The CCV system, a critical component in managing crankcase pressure and reducing oil consumption, is becoming more sophisticated, particularly in heavy-duty pickup trucks like the Ram 2500/3500 equipped with the Cummins 6.7L engine.

One of the primary drivers shaping the 2026 CCV filter market is stricter environmental regulation. Governments in North America and Europe continue to tighten emissions standards, pushing manufacturers and aftermarket suppliers to develop more efficient CCV filtration systems that minimize oil mist and hydrocarbon release into the atmosphere. As a result, high-efficiency, OEM-compliant CCV filters are expected to gain market share over basic or modified systems.

Additionally, the rising cost of diesel engine repairs is encouraging fleet operators and individual owners to invest in preventive maintenance solutions. CCV filters play a key role in preventing carbon buildup in intake manifolds and turbochargers — a common issue in the Cummins 6.7L engine. By 2026, demand is projected to grow for upgraded aftermarket CCV filters that offer enhanced filtration, easier maintenance, and extended service intervals.

Technological innovations are also influencing product development. Leading suppliers are integrating multi-stage filtration, advanced coalescing media, and integrated heating elements (to combat cold-weather condensation) into next-generation CCV filters tailored for the Cummins 6.7L. These features improve reliability in extreme operating conditions and support the engine’s performance in both on-road and off-road applications.

Moreover, the aftermarket for performance-enhancing diesel components remains strong. Enthusiasts and tuners often modify their Cummins engines for increased power, which places additional stress on the CCV system. This trend is expected to sustain demand for high-flow, performance-oriented CCV kits that maintain emissions compliance while supporting modified engine setups.

In summary, the 2026 market for CCV filters in Cummins 6.7L engines will be shaped by regulatory pressures, technological innovation, and the growing emphasis on engine durability. OEMs and aftermarket brands that offer reliable, efficient, and easy-to-maintain CCV filtration solutions are likely to lead the market as diesel vehicle owners prioritize long-term engine health and environmental compliance.

Common Pitfalls When Sourcing CCV Filters for Cummins 6.7 (Quality and Intellectual Property Concerns)

Poor Quality Components

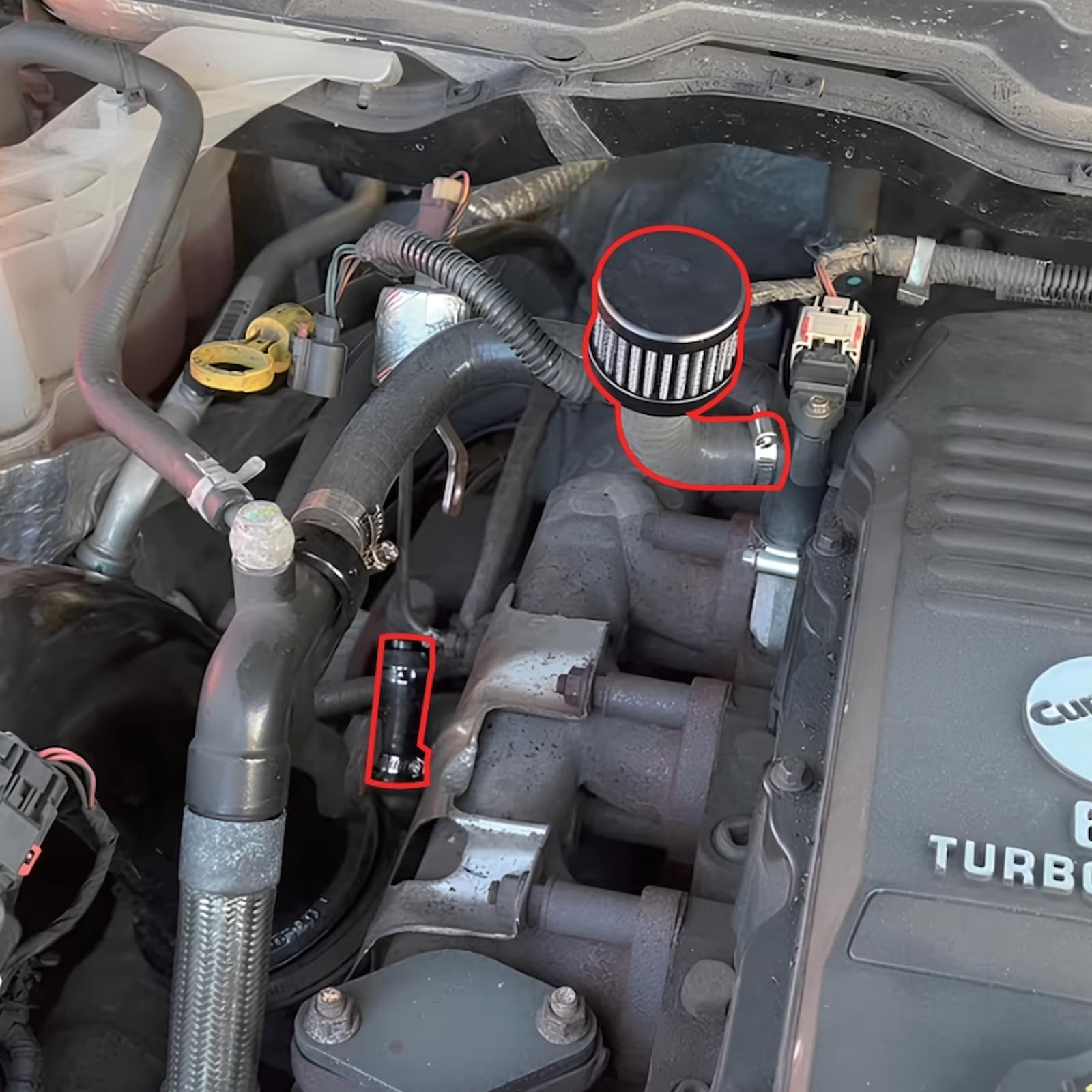

One of the most frequent issues when sourcing CCV (Crankcase Ventilation) filters for the Cummins 6.7L engine is encountering substandard materials and construction. Low-quality filters may use inferior filtration media that fail to effectively separate oil mist and contaminants, leading to increased engine wear, reduced performance, and potential damage to turbochargers or EGR systems. Additionally, weak housing materials can crack under engine heat and vibration, resulting in oil leaks and emissions issues.

Lack of OEM Specifications Compliance

Many aftermarket CCV filters do not adhere to Cummins’ original engineering specifications. This can result in improper fitment, incorrect flow rates, or inadequate pressure regulation. Using a non-compliant filter may void warranties and trigger fault codes in the engine management system, especially on newer diesel platforms with sensitive emissions controls.

Counterfeit or Misrepresented Parts

The market is flooded with counterfeit or falsely branded CCV filters claiming to be OEM-equivalent or genuine Cummins parts. These products often mimic packaging and part numbers but lack proper quality control and performance validation. Buyers risk purchasing fake components that compromise engine reliability and longevity.

Intellectual Property (IP) Infringement

Some manufacturers of aftermarket CCV filters replicate Cummins’ patented designs, such as internal baffle configurations or mounting interfaces, without authorization. This constitutes intellectual property infringement and raises legal and ethical concerns. Sourcing such parts—knowingly or unknowingly—can expose businesses to supply chain liability, especially in commercial or fleet operations where compliance is closely monitored.

Inadequate Testing and Certification

Reputable CCV filters undergo rigorous testing for efficiency, durability, and emissions compliance. However, many low-cost alternatives lack proper certification (e.g., ISO, SAE standards) or independent performance validation. Without these, there is no assurance that the filter will perform reliably under real-world operating conditions.

Shortened Service Intervals and Hidden Costs

While some non-OEM CCV filters appear cost-effective upfront, they often require more frequent replacement due to poor oil separation or clogging. This increases long-term maintenance costs and downtime, negating any initial savings. Poor filtration can also lead to costly repairs from oil fouling in intake systems.

Supply Chain Transparency Issues

Many suppliers, especially online marketplaces, provide little to no information about the origin or manufacturing process of CCV filters. This lack of transparency makes it difficult to assess quality or verify claims, increasing the risk of inadvertently sourcing from unethical or non-compliant manufacturers.

To avoid these pitfalls, always source CCV filters from authorized distributors, verify part numbers against Cummins documentation, and prioritize suppliers with traceable manufacturing practices and clear compliance with IP and quality standards.

Logistics & Compliance Guide for CCV Filter – Cummins 6.7

Product Overview

The Crankcase Ventilation (CCV) Filter for Cummins 6.7L engines is a critical emissions and engine protection component. It manages crankcase pressure and removes oil mist and contaminants from blow-by gases before they are recirculated into the intake system. Proper logistics handling and regulatory compliance are essential for distribution, installation, and environmental adherence.

Packaging & Handling

Ensure CCV filters are stored in original, sealed packaging to prevent contamination. Handle with clean gloves to avoid introducing debris or oils. Store in a dry, temperature-controlled environment (10°C to 30°C / 50°F to 86°F) away from direct sunlight and moisture. Avoid stacking heavy items atop packages to prevent filter media damage.

Shipping & Transportation

Ship via ground or air freight using tamper-evident packaging. Clearly label boxes with “Fragile,” “This Side Up,” and “Protect from Moisture.” Use climate-controlled transport when possible, especially in extreme temperatures. Maintain chain-of-custody documentation for traceability. Adhere to carrier-specific hazardous material regulations if applicable (e.g., if packaged with lubricants or cleaning agents).

Inventory Management

Track lot numbers and expiration dates (if applicable) using barcode or RFID systems. Practice FIFO (First In, First Out) inventory rotation to ensure older stock is distributed first. Conduct regular audits to verify stock integrity and prevent counterfeit parts from entering the supply chain.

Regulatory Compliance

Comply with EPA emissions standards under 40 CFR Part 85 and 86, as the CCV system is part of the engine’s emissions control system. Replacement filters must meet or exceed OEM (Original Equipment Manufacturer) specifications to maintain emissions compliance. Products sold in California must adhere to CARB (California Air Resources Board) Executive Order (EO) requirements—verify EO number and certification status prior to distribution.

Import/Export Considerations

For international shipments, classify the CCV filter under the correct HS Code (e.g., 8421.39 for air filtration equipment). Provide accurate commercial invoices, packing lists, and certificates of conformity. Comply with destination country import regulations, including REACH (EU), RoHS, and local environmental standards. Retain export documentation for a minimum of five years.

Installation & End-User Compliance

Only certified technicians should install the CCV filter per Cummins technical service bulletins (TSBs) and OEM guidelines. Improper installation may void engine warranties and lead to emissions violations. Provide end users with installation checklists and maintenance schedules recommending filter replacement every 30,000–50,000 miles, or as specified by fleet maintenance protocols.

Environmental & Disposal Requirements

Used CCV filters may contain residual oil and contaminants. Dispose of as hazardous waste in accordance with local, state, and federal regulations (e.g., EPA 40 CFR Part 261). Partner with certified waste management providers for proper recycling or disposal. Maintain disposal records for compliance audits.

Documentation & Recordkeeping

Maintain comprehensive records including:

– Certificates of Conformance (CoC)

– Batch testing reports

– Shipping manifests

– Customs documentation

– End-of-life disposal receipts

Retention period: minimum 7 years for emissions-related components under EPA guidelines.

Quality Assurance & Traceability

Implement a quality management system (e.g., ISO 9001) to ensure product consistency. Conduct periodic audits of suppliers, logistics partners, and installation centers. Each CCV filter should be traceable to manufacturing lot, test results, and distribution path to support recalls or compliance investigations if needed.

Conclusion for Sourcing CCV Filter for Cummins 6.7L Engine:

Sourcing a CCV (Crankcase Ventilation) filter for the Cummins 6.7L engine requires careful consideration of vehicle application, filter quality, compatibility, and maintenance requirements. The CCV system plays a critical role in engine performance and longevity by managing crankcase pressure and removing harmful contaminants and oil vapors. Aftermarket CCV filters offer benefits such as improved engine cleanliness, reduced oil consumption, and prevention of soot buildup in the intake system—common issues in diesel engines like the Cummins 6.7L.

When selecting a CCV filter, it is essential to choose a reputable brand that offers durable construction and proper filtration efficiency. Options from trusted manufacturers such as BD Diesel, Fleece Performance, or OEM Cummins parts provide reliable performance and are designed to meet or exceed factory specifications. Additionally, ensuring compatibility with your specific model year and engine configuration (e.g., Ram pickup, Sprinter van, or industrial application) is crucial for proper fitment and function.

In conclusion, investing in a high-quality CCV filter is a proactive maintenance step that enhances engine reliability, improves air quality within the crankcase, and supports long-term performance of the Cummins 6.7L engine. Regular inspection and timely replacement of the filter will maximize these benefits and help avoid costly repairs down the road.