The global market for motor capacitors, including CBB61 types widely used in HVAC systems, fans, and appliances, is experiencing steady growth driven by rising demand for energy-efficient motors and automation across residential and industrial sectors. According to Grand View Research, the global motor capacitors market was valued at USD 2.5 billion in 2022 and is expected to expand at a compounded annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence projects continued expansion in the passive components market, with increased adoption of reliable, long-life capacitors in consumer electronics and smart home devices fueling demand for high-quality CBB61 capacitors. As market needs evolve, several manufacturers have emerged as leaders in performance, durability, and innovation. Below are the top six CBB61 capacitor manufacturers shaping the industry through advanced production capabilities and global distribution networks.

Top 6 Cbb61 Capacitor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China CBB61 Fan capacitor Manufacturer, Supplier, Factory

Domain Est. 2008

Website: dfcapacitor.com

Key Highlights: CBB61 Fan capacitor That is specially for electric fan,air-conditioner,electric water pump and electric motor etc.With frequency 50/60Hz,voltage 250VAC….

#2 China CBB61 Capacitor Manufacturers

Domain Est. 2020

Website: ruva-capacitors.com

Key Highlights: China CBB61 Capacitor manufacturers – Select high quality CBB61 Capacitor products in best price on Ningguo Yuhua Electrical Products Co.,Ltd….

#3 jb Capacitors

Domain Est. 2002

Website: jbcapacitors.com

Key Highlights: jb has Motor capacitor, there are different type in jb. There are box type, round type with plastic case and Aluminum case….

#4 Motor Capacitors – Reliable Start & Run Solutions

Domain Est. 2002

Website: kingtronics.com

Key Highlights: Kingtronics motor capacitors ensure dependable starting and running performance for AC motors. Designed for HVAC systems, compressors, and pumps with high ……

#5 CBB61 Capacitor

Domain Est. 2022

Website: kscapacitor.com

Key Highlights: CBB61 is a Motor Run and Start AC Capacitors used in fans, and ventilators. CBB61 motor run capacitors utilize low-loss metalized polypropylene film for ……

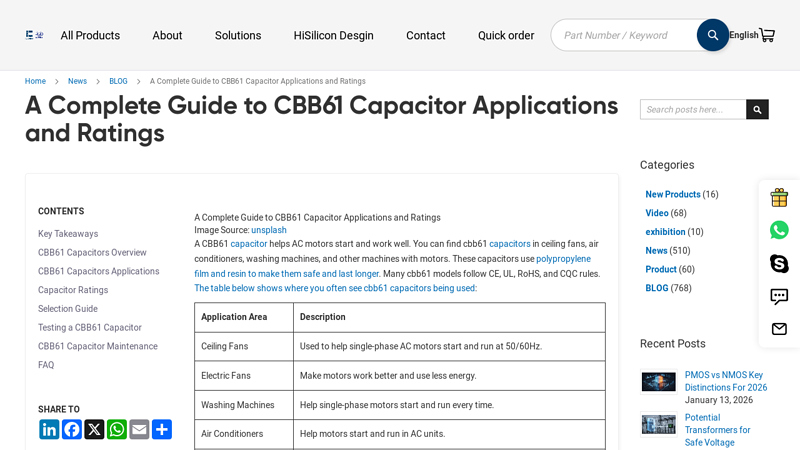

#6 A Complete Guide to CBB61 Capacitor Applications and Ratings

Domain Est. 2013

Website: ic-online.com

Key Highlights: CBB61 capacitors power AC motors in fans and appliances. See key ratings, applications, and tips for selecting the right CBB61 capacitor for your needs….

Expert Sourcing Insights for Cbb61 Capacitor

2026 Market Trends for CBB61 Capacitors

The CBB61 capacitor market is poised for steady evolution by 2026, driven by technological advancements, shifting energy efficiency standards, and growing demand across key application sectors. As a staple in motor-run applications—particularly in HVAC systems, refrigeration units, and industrial machinery—CBB61 capacitors (polypropylene film capacitors) are seeing significant transformation influenced by global sustainability goals and digitalization trends.

Rising Demand in Energy-Efficient Appliances

A primary driver shaping the 2026 CBB61 capacitor market is the global push toward energy efficiency. Governments and regulatory bodies are enforcing stricter energy standards for household and commercial appliances. This has led to increased adoption of high-efficiency motors in air conditioners, washing machines, and refrigerators—all of which rely on CBB61 capacitors for stable motor operation. Manufacturers are opting for capacitors with higher temperature tolerance, longer lifespan, and improved reliability to meet Energy Star and similar certifications, boosting demand for premium-grade CBB61 models.

Growth in HVAC and Residential Cooling Systems

With rising global temperatures and urbanization, especially in emerging economies across Asia-Pacific and the Middle East, demand for air conditioning systems is surging. Since CBB61 capacitors are critical components in single-phase AC motors used in compressors and fans, this trend directly translates into higher capacitor consumption. The residential and commercial HVAC sector is expected to remain the largest end-user segment for CBB61 capacitors through 2026, with market growth closely tied to construction activity and climate resilience investments.

Technological Advancements and Miniaturization

By 2026, capacitor manufacturers are prioritizing innovation in materials and design to meet the need for compact, high-performance components. Developments such as metallized polypropylene films with self-healing properties and enhanced thermal conductivity are enabling smaller footprint capacitors with improved reliability. These advancements allow OEMs to design sleeker, more efficient appliances without sacrificing performance—making next-generation CBB61 capacitors more attractive in space-constrained applications.

Supply Chain Resilience and Regional Manufacturing Shifts

The post-pandemic emphasis on supply chain security continues to influence the CBB61 capacitor market. Geopolitical tensions and logistics disruptions have prompted companies to diversify sourcing and increase local production. By 2026, regions like Southeast Asia and India are expected to expand their manufacturing capabilities for film capacitors, reducing reliance on traditional hubs. This shift supports faster time-to-market and lowers costs, benefiting regional appliance and motor manufacturers.

Sustainability and Environmental Regulations

Environmental regulations are increasingly impacting capacitor design and disposal. The phase-out of certain materials and the emphasis on recyclability are pushing manufacturers to develop eco-friendly CBB61 capacitors. By 2026, expect greater adoption of lead-free terminations, biodegradable casings, and reduced use of hazardous substances in compliance with RoHS and REACH directives. These sustainability trends are becoming key differentiators in competitive markets.

Competitive Landscape and Pricing Pressures

The CBB61 capacitor market remains highly competitive, with numerous regional and global players. While demand is growing, price sensitivity—especially in cost-driven markets—continues to pressure manufacturers. To maintain margins, companies are investing in automation and high-yield production processes. Additionally, value-added services such as application engineering support and customized solutions are becoming more common to differentiate offerings in a crowded marketplace.

In summary, the 2026 CBB61 capacitor market will be shaped by energy efficiency mandates, technological innovation, and regional manufacturing trends. Companies that adapt to evolving regulatory environments and invest in high-reliability, sustainable products are likely to gain a competitive edge in this mature yet dynamic segment.

Common Pitfalls When Sourcing CBB61 Capacitors (Quality and IP)

Sourcing CBB61 capacitors—commonly used in motor run and start applications—can pose several challenges, particularly concerning quality assurance and intellectual property (IP) risks. Being aware of these pitfalls is crucial to ensuring reliability, compliance, and long-term cost efficiency.

Poor Quality Control and Inconsistent Performance

One of the most frequent issues when sourcing CBB61 capacitors, especially from low-cost suppliers or unknown manufacturers, is inconsistent quality. Capacitors may fail prematurely due to poor dielectric materials, inadequate sealing, or substandard metallization. This can lead to motor failures, increased maintenance costs, and safety hazards. Always verify supplier certifications (e.g., ISO 9001, RoHS, UL, CCC) and request independent test reports or samples for performance validation.

Misrepresentation of Specifications

Some suppliers may exaggerate or falsify key electrical parameters such as capacitance tolerance, voltage rating, or temperature range. A capacitor labeled as 450V AC might not sustain that voltage over time, leading to breakdowns. It’s essential to conduct independent testing or require third-party certification (e.g., TÜV, VDE) to confirm that the specifications match the actual product performance.

Counterfeit or Reconditioned Components

The market, particularly in unregulated supply chains, is vulnerable to counterfeit CBB61 capacitors. These may be recycled, remarked, or made with inferior materials. Counterfeits often fail under load and can compromise the safety of end products. To mitigate this risk, source only from authorized distributors or directly from reputable manufacturers with traceable lot numbers.

Lack of Intellectual Property Protection

When designing or branding capacitors, especially under private labels, there is a risk of IP infringement. Some manufacturers may copy designs, logos, or technical specifications from established brands without permission. This exposes buyers to legal liability and reputational damage. Ensure supplier agreements include clear IP clauses and conduct due diligence on manufacturing partners to confirm original design rights.

Inadequate Compliance with Regional Standards

CBB61 capacitors used in consumer or industrial equipment must comply with regional safety standards (e.g., UL in North America, CE in Europe, CCC in China). Sourcing non-compliant capacitors can result in product recalls, import denials, or legal penalties. Verify that capacitors meet the required certifications for your target market and that documentation is up to date.

Unreliable Long-Term Supply and Traceability

Many low-cost suppliers lack robust supply chain management, leading to inconsistencies in material sourcing and production batches. This affects long-term reliability and makes traceability difficult during failure analysis. Establish partnerships with suppliers who maintain batch records, offer long-term availability, and support product lifecycle management.

Conclusion

To avoid these pitfalls, prioritize due diligence: audit suppliers, demand certifications, test samples rigorously, and use legal agreements to protect IP. Investing time in vetting sources pays off in product reliability, regulatory compliance, and brand integrity.

Logistics & Compliance Guide for CBB61 Capacitor

Overview of CBB61 Capacitor

The CBB61 capacitor is a metallized polypropylene film capacitor commonly used in single-phase AC motor applications such as air conditioners, refrigerators, and fans. It functions primarily as a run capacitor to improve motor efficiency and performance. Due to its electrical function and materials, proper logistics handling and compliance with international and regional regulations are essential.

Regulatory Compliance Requirements

Electrical Safety Standards

CBB61 capacitors must comply with electrical safety standards relevant to their target markets:

– IEC 60252-1: International standard for AC motor capacitors – specifies performance, testing, and safety requirements.

– UL 810: U.S. safety standard for motor capacitors – required for products sold in North America.

– EN 60252-1: European adaptation of IEC 60252-1, aligning with EU CE marking directives.

– CCC (China Compulsory Certification): Mandatory for capacitors sold in China.

Manufacturers must ensure certification marks are present on products and packaging to demonstrate compliance.

RoHS Compliance (Restriction of Hazardous Substances)

CBB61 capacitors must comply with RoHS directives in applicable regions:

– EU RoHS (2011/65/EU): Restricts the use of lead, mercury, cadmium, hexavalent chromium, PBB, and PBDE.

– China RoHS: Requires labeling and restriction of hazardous substances in electronic products.

Ensure material declarations and test reports (e.g., via GC-MS or XRF analysis) are available to prove RoHS compliance.

REACH Regulation (EU)

Under REACH (EC 1907/2006), manufacturers and importers must:

– Register substances of very high concern (SVHC) if present above threshold levels.

– Provide Safety Data Sheets (SDS) upon request.

Verify that capacitor materials (e.g., dielectric film, casing, impregnants) do not contain unauthorized SVHCs.

WEEE Directive (Waste Electrical and Electronic Equipment)

CBB61 capacitors fall under WEEE category 5 (household appliances) or 6 (electrical tools). Producers must:

– Affix the crossed-out wheeled bin symbol on products or packaging.

– Register with national WEEE compliance schemes.

– Contribute to recycling and recovery programs in EU member states.

Packaging and Labeling Requirements

Product Labeling

Each CBB61 capacitor should be clearly labeled with:

– Rated capacitance (µF) and tolerance (e.g., ±5%)

– Rated voltage (e.g., 450V AC)

– Frequency rating (e.g., 50/60 Hz)

– Safety certifications (e.g., UL, CCC, CE)

– Manufacturer name or trademark

– Manufacturing date or batch code

Packaging Standards

- Use anti-static and moisture-resistant packaging to protect capacitors during transit.

- Clearly mark outer cartons with handling symbols (e.g., “Fragile,” “Keep Dry,” “Do Not Stack Excessively”).

- Include compliance labels (e.g., CE, RoHS) on packaging where required.

- Provide multilingual documentation (datasheets, safety warnings) for international shipments.

Transportation and Logistics

Shipping Classification

- CBB61 capacitors are generally not classified as hazardous goods under IATA, IMDG, or ADR regulations, provided they are not damaged or defective.

- However, damaged capacitors may leak dielectric fluid or pose electrical risks; such units should be handled as defective electronics.

- No special UN number or hazardous material declaration is typically required for intact units.

Storage Conditions

- Store in a dry, temperature-controlled environment (typically 5°C to 35°C).

- Avoid exposure to direct sunlight, moisture, and corrosive atmospheres.

- Use FIFO (First In, First Out) inventory practices to prevent aging.

Import/Export Documentation

Ensure the following documents accompany international shipments:

– Commercial invoice with HS code (e.g., 8532.22.00 – fixed capacitors with dielectric of plastics)

– Packing list

– Certificate of Compliance (e.g., RoHS, REACH, UL)

– Bill of Lading or Air Waybill

– Importers must verify customs duties and local conformity requirements (e.g., KC mark in South Korea, PSE mark in Japan).

End-of-Life and Environmental Responsibility

- CBB61 capacitors should be recycled through certified e-waste handlers.

- Do not dispose of in regular landfill due to plastic and metallic content.

- Encourage customers to return end-of-life units through take-back programs where applicable.

Summary

Proper logistics and compliance management for CBB61 capacitors ensures safe handling, regulatory adherence, and market access. Key focus areas include certification to electrical standards (IEC, UL, CCC), compliance with environmental regulations (RoHS, REACH, WEEE), accurate labeling, and safe transportation practices. Maintaining up-to-date documentation and monitoring regulatory changes are essential for global trade.

Conclusion for Sourcing CBB61 Capacitors:

Sourcing CBB61 capacitors requires a strategic approach that balances quality, cost, reliability, and compliance. These capacitors are widely used in motor-run applications such as fans, pumps, and air conditioning units due to their stable performance, high reliability, and durability under continuous operation. When selecting suppliers, it is essential to prioritize manufacturers or distributors that adhere to international standards (such as IEC, UL, or CCC) and provide proper certification to ensure performance and safety.

Key considerations include capacitance value accuracy, voltage rating, temperature tolerance, and physical dimensions to ensure compatibility with target applications. Additionally, evaluating supplier reputation, minimum order quantities, lead times, and after-sales support plays a crucial role in maintaining production consistency and reducing downtime.

In conclusion, successful sourcing of CBB61 capacitors involves partnering with reputable, certified suppliers, conducting regular quality audits, and maintaining a diversified supply chain to mitigate risks. By focusing on these factors, businesses can ensure a steady supply of high-quality capacitors that meet technical requirements and contribute to the long-term reliability of their end products.