The global safety signage and hazard tape market has experienced steady growth, driven by increasing regulatory emphasis on workplace safety across construction, manufacturing, and public infrastructure sectors. According to Grand View Research, the global safety signage market was valued at USD 3.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by stringent occupational health and safety regulations, rising infrastructure investments, and heightened awareness of accident prevention. As demand for high-visibility caution tapes surges, manufacturers are innovating to meet industry standards for durability, brightness, and environmental resistance. In this evolving landscape, identifying reliable and compliant caution tape suppliers is critical for organizations aiming to maintain safety and regulatory adherence. Below is a data-informed overview of the top 10 caution tape manufacturers leading the market through product quality, global reach, and technological advancement.

Top 10 Caution Tape Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 tesa tape, inc.

Domain Est. 1997

Website: tesa.com

Key Highlights: Professional hand tearable, robust marking and warning tapes with high adhesive strength. Marking. Adhesive marking and warning tapes are robust, highly ……

#2 3M Barricade & Warning Tapes

Domain Est. 1988

Website: 3m.com

Key Highlights: Barricade and Warning Tapes identify and warn of unsafe or prohibited areas, sensitive equipment, or underground utilities. Available in various sizes, ……

#3 Barricade Tape: Caution, Danger & Custom Barrier Tapes

Domain Est. 1995

Website: seton.com

Key Highlights: 1–7 day deliveryCustom barricade tape (or custom caution tape) allows you to print a logo, specific safety instructions, or branding. This is an excellent ……

#4 High-Visibility Barricade Tape for Hazard Marking

Domain Est. 1996

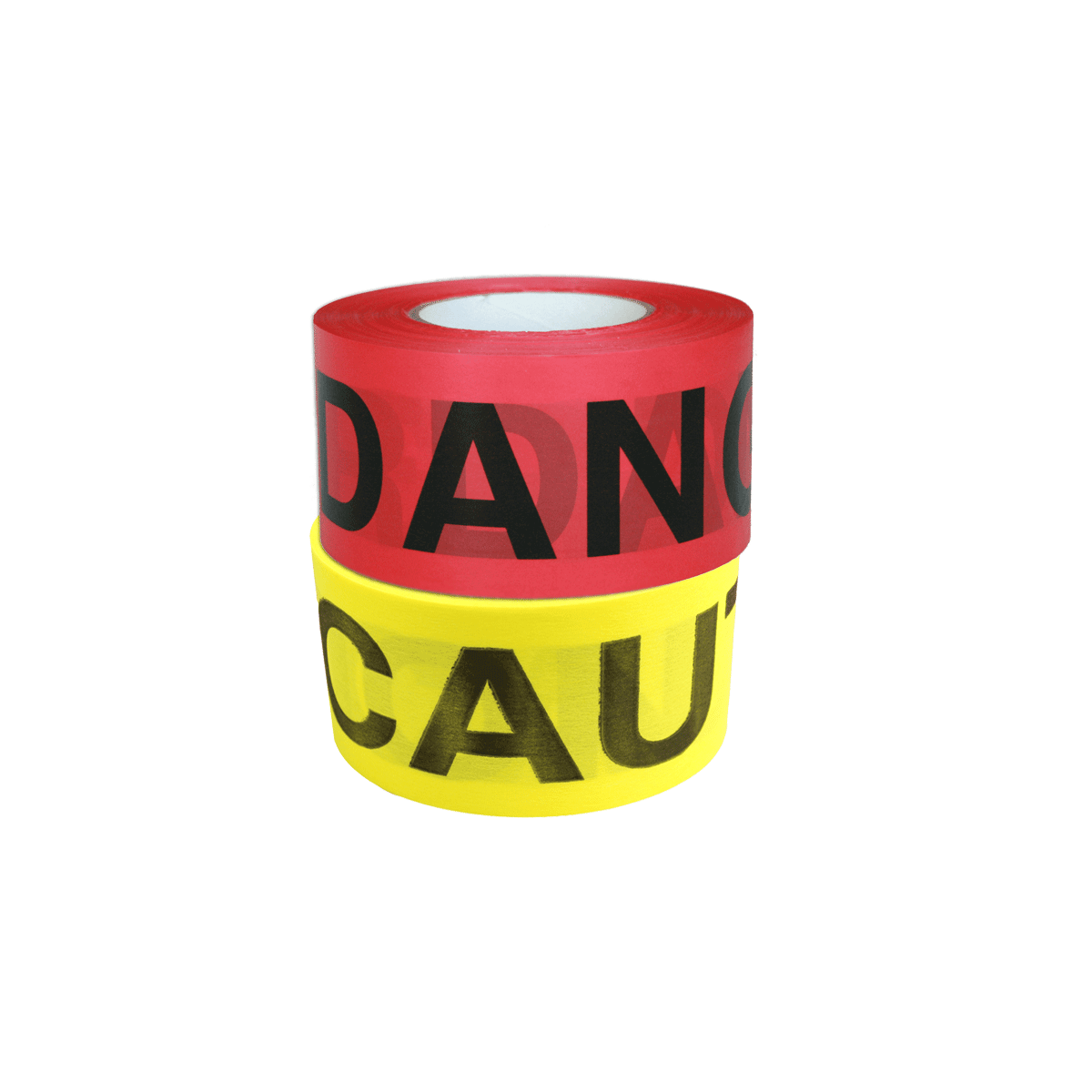

#5 Barricade/Caution Tape

Domain Est. 1996

Website: minerallac.com

Key Highlights: Barricade/Caution Tape ; 94360. 3″ x 1000′ “Danger” Barricade Tape, 4 Mil., Red ; 94625. 3″ x 1000′ “CAUTION” Barricade Tape; 2 Mil; Yellow w/ Black Lettering….

#6 Caution Tape

Domain Est. 1997

Website: keson.com

Key Highlights: Keson’s barricade tape delivers critical safety communication through bold, high-contrast messages that alert workers and the public to hazards, restricted ……

#7 Caution and Warning Tape

Domain Est. 1998

Website: bradyid.com

Key Highlights: 1-day deliveryThese caution and warning tapes block off potential hazards and are ideal for temporary use outdoors or permanent indoor warning….

#8 Barricade Tape “Caution Do Not Enter” 2 mil

Domain Est. 2012

#9 Barricade Tapes Archives

Domain Est. 2015

Website: tridentproducts.com

Key Highlights: $35 deliveryBarricade Tapes varieties include: Standard, Reinforced, Woven, Biodegradable, Day/Night, High Viz, and Repulpable. Caution, Danger, and custom messages….

#10 The Best Custom Caution Tape

Domain Est. 2021

Website: highlandconverting.com

Key Highlights: Get Customized. Be Recognized. · Custom printed barricade tape, custom flagging tape, and custom packaging tape. Premium quality, personal service….

Expert Sourcing Insights for Caution Tape

H2: Projected Market Trends for Caution Tape in 2026

The global caution tape market is poised for steady growth by 2026, driven by increasing safety regulations, infrastructure development, and rising awareness of workplace safety across key industries. This analysis explores the primary trends expected to shape the caution tape market in 2026 under the H2 (second half) outlook.

-

Increased Demand from Construction and Infrastructure Sectors

With major infrastructure projects underway in North America, Europe, and Asia-Pacific—spurred by government investments and urbanization—the construction sector will remain a dominant consumer of caution tape. Regulatory mandates requiring visible safety barriers on active sites will amplify demand for high-visibility tapes, especially those meeting ANSI and OSHA standards. -

Advancement in Material Technology

By 2026, manufacturers are expected to introduce next-generation caution tapes featuring enhanced durability, UV resistance, and eco-friendly materials. Biodegradable and recyclable tapes made from polyethylene alternatives or plant-based polymers will gain traction, aligning with global sustainability goals and corporate ESG initiatives. -

Growth in Industrial and Manufacturing Safety Spending

As industries adopt stricter safety protocols post-pandemic, spending on personal protective equipment (PPE) and safety signage—including caution tape—will rise. Automation and smart manufacturing setups will also require temporary hazard zoning, increasing usage in high-tech production environments. -

Expansion in Emerging Markets

Countries in Southeast Asia, Latin America, and Africa will see growing adoption of standardized safety practices, driven by foreign direct investment and industrial expansion. Local regulations are increasingly mirroring international safety standards, creating new market opportunities for both domestic and global caution tape suppliers. -

Digital Integration and Smart Caution Solutions

Innovative players may introduce “smart” caution tapes embedded with RFID tags or QR codes by 2026, enabling real-time hazard tracking and integration with site management systems. Though still in early adoption, these technologies could become standard in high-risk industries such as oil & gas and utilities. -

Price Volatility and Supply Chain Adjustments

Fluctuations in raw material prices—particularly polyethylene and pigments—may impact production costs. However, improved supply chain resilience and regional manufacturing hubs (especially in India and Vietnam) are expected to mitigate disruptions and support stable market growth.

Conclusion

By H2 2026, the caution tape market will reflect a blend of regulatory-driven demand, technological innovation, and sustainability trends. Companies that invest in eco-friendly products, comply with global safety standards, and expand into emerging markets are likely to gain competitive advantage. Overall, the market is forecasted to grow at a CAGR of approximately 4.5–5.2% through 2026, reaching an estimated value of USD 580–620 million.

Common Pitfalls When Sourcing Caution Tape (Quality and Intellectual Property)

Sourcing caution tape may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to safety risks, legal issues, and reputational damage. Below are common pitfalls to avoid:

Poor Material Quality and Durability

One of the most frequent issues is selecting caution tape made from substandard materials. Low-quality polyethylene or adhesive can degrade quickly when exposed to sunlight, moisture, or temperature extremes. This leads to fading, tearing, or adhesive failure, compromising the tape’s visibility and effectiveness in marking hazardous areas. Always verify UV resistance, tensile strength, and weatherproofing specifications before purchase.

Inadequate Visibility and Compliance

Not all caution tapes meet regulatory standards for visibility and warning messaging. Using tape with insufficient contrast, incorrect wording (e.g., missing required phrases like “Danger” or “Caution”), or non-compliant colors can result in OSHA, ANSI, or other regulatory violations. Ensure the tape adheres to relevant safety standards for your industry and region.

Counterfeit or Unauthorized Branded Tape

Be cautious of suppliers offering well-known branded caution tape (e.g., 3M, Brady) at unusually low prices. These may be counterfeit products that infringe on trademarks and fail to meet the original manufacturer’s quality standards. Using counterfeit tape not only exposes your organization to IP infringement liability but also risks unreliable performance in critical safety applications.

Lack of Proper Licensing for Custom Designs

If sourcing custom-printed caution tape with specific logos, slogans, or proprietary symbols, ensure you have the appropriate rights or licenses to use those graphics. Unauthorized use of copyrighted or trademarked material—even on safety products—can result in legal action. Always confirm IP ownership and obtain written permissions when necessary.

Insufficient Supply Chain Verification

Failing to vet suppliers thoroughly can result in inconsistent quality or unintentional IP violations. Some manufacturers may source materials or designs from unauthorized third parties. Conduct due diligence by auditing suppliers, requesting product certifications, and reviewing samples before large-scale procurement.

Overlooking Environmental and Disposal Considerations

Some caution tapes contain materials that are not environmentally friendly or are difficult to dispose of safely. Choosing non-compliant or non-recyclable tapes may conflict with corporate sustainability goals or local environmental regulations, leading to long-term compliance risks.

By addressing these quality and IP-related pitfalls proactively, organizations can ensure they source effective, compliant, and legally sound caution tape that supports both safety and operational integrity.

Logistics & Compliance Guide for Caution Tape

Product Overview

Caution tape, also known as safety tape or barricade tape, is a highly visible, typically plastic or fabric-based tape used to demarcate hazardous areas, restrict access, and warn individuals of potential dangers. It is commonly used in construction, manufacturing, emergency response, and maintenance environments.

Regulatory Compliance

-

OSHA Standards (U.S.):

Caution tape used in the United States must comply with OSHA regulations (29 CFR 1910.144 and 1910.211), which specify that caution signs and tapes should be displayed in areas where physical hazards exist. OSHA recommends a standard color scheme: yellow background with black lettering for general caution. -

ANSI Z535.5:

This standard provides guidelines for the design, application, and use of safety tags and barricade tapes. It reinforces color coding and legibility requirements, ensuring consistent hazard communication across industries. -

International Standards:

Outside the U.S., compliance with ISO 3864 (safety colors and signs) and local regulations (e.g., UK’s Health and Safety (Safety Signs and Signals) Regulations 1996) is required. Color coding may vary; for example, red and white striped tape may indicate fire protection equipment in some regions. -

REACH & RoHS Compliance (EU):

If shipping to the European Union, caution tape materials must comply with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, particularly for plastic-based tapes containing restricted substances.

Labeling and Marking Requirements

- All caution tape must display clear, legible warnings such as “CAUTION,” “DANGER,” or “HARD HAT AREA.”

- Text should be large enough to be readable from a distance (minimum 1-inch height recommended).

- Bilingual labeling may be required in regions with multiple official languages (e.g., Canada, EU member states).

- Include manufacturer name, batch number, and compliance marks (e.g., CE marking in the EU).

Packaging and Storage

-

Packaging:

Caution tape should be packaged in moisture-resistant, durable materials to prevent unrolling or damage during transit. Individual rolls are typically wrapped in polybags or shrink-wrapped bundles. -

Storage Conditions:

Store in a cool, dry place away from direct sunlight, extreme temperatures, and chemicals. UV exposure can degrade plastic tapes, reducing strength and visibility. -

Shelf Life:

Most caution tapes have a shelf life of 2–5 years. Check manufacturer specifications for exact duration and storage recommendations.

Transportation and Shipping

-

Domestic Shipping (U.S.):

Caution tape is generally non-hazardous and can be shipped via standard freight or parcel services (e.g., UPS, FedEx, LTL carriers). No special handling or documentation is required unless part of a hazardous material kit. -

International Shipping:

Ensure compliance with IATA (air), IMDG (maritime), or ADR (road) regulations if shipped alongside hazardous goods. While caution tape alone is not hazardous, documentation may be needed if part of safety kits for dangerous operations. -

Customs Documentation:

For cross-border shipments, include a commercial invoice with HS Code (e.g., 3919.10 for plastic adhesive tapes). Declare accurate product description, value, and country of origin.

Handling and Usage Guidelines

-

Installation:

Use appropriate supports (e.g., stands, posts, or existing structures) to properly display tape at visible heights (typically waist to eye level). Ensure tension is sufficient to avoid sagging but not overstretched. -

Environmental Considerations:

Avoid use in high-wind or wet conditions unless the tape is rated for outdoor use. Some tapes are UV-resistant and water-repellent for extended outdoor deployment. -

Disposal:

Dispose of used caution tape according to local waste regulations. Plastic tapes may be recyclable (check resin code); contaminated tape (e.g., with chemicals or biohazards) must be treated as hazardous waste.

Recordkeeping and Documentation

- Maintain records of:

- Product specifications and compliance certifications (e.g., OSHA, ANSI, CE)

- Batch numbers and expiration dates

- Safety data sheets (SDS), if applicable

- Shipping manifests and customs documentation for international shipments

Training and Best Practices

- Train personnel on proper deployment, regulatory requirements, and limitations of caution tape.

- Reinforce that caution tape is a visual warning only and does not replace physical barriers or engineering controls in high-risk areas.

- Conduct periodic inspections to ensure tape remains intact, visible, and properly positioned.

Conclusion

Proper logistics and compliance management for caution tape ensures workplace safety and regulatory adherence. By following applicable standards, correctly labeling and storing products, and maintaining documentation, organizations can effectively use caution tape as part of a comprehensive safety program.

In conclusion, when sourcing caution tape, it is essential to consider factors such as material durability, compliance with safety standards (e.g., ANSI, OSHA, or local regulations), proper labeling, visibility (including color and reflectivity), and environmental resistance. Choosing a reliable supplier that provides high-quality, consistent products ensures long-term effectiveness and safety on site. Additionally, evaluating cost-efficiency without compromising on quality helps maintain both safety and budgetary goals. By carefully assessing these aspects, organizations can procure caution tape that enhances hazard communication, supports workplace safety, and meets regulatory requirements.