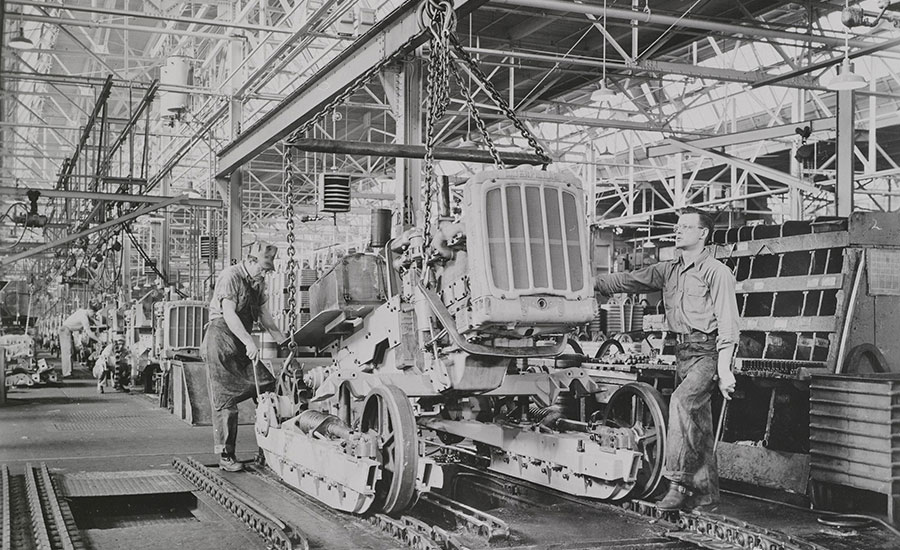

The global construction and agricultural machinery aftermarket is experiencing robust expansion, driven by rising equipment penetration, aging fleets, and increasing demand for cost-effective maintenance solutions. According to Mordor Intelligence, the global construction equipment aftermarket was valued at USD 78.4 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029. As one of the industry leaders, Caterpillar Inc. commands a significant share of the heavy equipment market, fueling sustained demand for reliable replacement parts. This growth trajectory underscores the critical role of third-party manufacturers in supplying high-quality tractor components—from undercarriage systems to hydraulic assemblies—that ensure machine uptime and operational efficiency. In this competitive landscape, a select group of manufacturers have emerged as top suppliers, combining precision engineering, OEM compliance, and global distribution networks to meet the needs of dealers, repair shops, and end users worldwide.

Top 6 Caterpillar Tractor Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Caterpillar

Domain Est. 1995

Website: caterpillar.com

Key Highlights: Caterpillar is the world’s leading manufacturer of construction and mining equipment, diesel and natural gas engines, industrial turbines and ……

#2 Buy Vintage Caterpillar OEM Parts Online

Domain Est. 2007

Website: vpartsinc.com

Key Highlights: We offer extensive vintage Caterpillar OEM parts online so you can buy what you need to keep that machinery up and running….

#3 Products & Services – North America

Domain Est. 1993

Website: cat.com

Key Highlights: Cat Electric Power Parts. Order genuine Cat® generator parts and maintenance kits to keep your power systems running—24/7 availability and dealer support….

#4 Cat parts, Caterpillar parts

Domain Est. 1996

Website: kellytractor.com

Key Highlights: Kelly Tractor stocks a large inventory of new, remanufactured, and used Cat parts, Caterpillar parts available for sale. Please contact us at 305-592-5360….

#5 Your Online Source for Caterpillar Equipment & Machinery Parts

Domain Est. 2000

Website: holtcat.com

Key Highlights: Your one stop shop for new Cat certified parts, service information and equipment schematics based on your make and model or serial number….

#6 Order Online: Fast Delivery for Parts

Domain Est. 2003

Website: miltoncat.com

Key Highlights: We carry parts for all our lines, CAT as well as allied lines including Genie, Metso and Sullair; for new machines, old machines and very, very old machines….

Expert Sourcing Insights for Caterpillar Tractor Parts

H2: 2026 Market Trends for Caterpillar Tractor Parts

The global market for Caterpillar tractor parts is poised for notable shifts by 2026, driven by technological advancements, sustainability demands, and evolving end-user needs across agriculture, construction, and mining sectors. As a leading manufacturer of heavy machinery, Caterpillar Inc. continues to influence the aftermarket parts landscape through innovation, digital integration, and strategic supply chain management. The following key trends are expected to shape the Caterpillar tractor parts market in 2026:

-

Rise of Remanufactured and Sustainable Parts

Environmental regulations and cost-efficiency demands are fueling growth in the remanufactured parts segment. Caterpillar’s Reman program, which recycles used components into like-new quality parts, is gaining traction as customers prioritize sustainability and lower lifecycle costs. By 2026, remanufactured engines, hydraulics, and transmissions are projected to account for over 30% of aftermarket sales, especially in mature markets like North America and Europe. -

Digitalization and Predictive Maintenance

Caterpillar’s integration of telematics (via Cat Connect® technologies) is transforming parts demand. Real-time equipment monitoring enables predictive maintenance, reducing unplanned downtime and optimizing parts replacement cycles. By 2026, data-driven maintenance platforms will influence over 50% of parts procurement decisions, with customers increasingly relying on digital diagnostics to forecast when and which parts need servicing. -

Growth in Emerging Markets

Expanding infrastructure projects in Asia-Pacific, Africa, and Latin America are boosting demand for durable, high-performance tractor parts. Countries like India, Indonesia, and Nigeria are investing heavily in agricultural mechanization and construction, driving demand for genuine Caterpillar components. Localized distribution networks and partnerships with regional dealers will be critical to capturing this growth. -

Supply Chain Resilience and Localization

Geopolitical tensions and past supply chain disruptions have prompted Caterpillar to diversify sourcing and increase regional manufacturing. By 2026, localized production of high-demand parts—such as filters, undercarriage components, and engine parts—will improve delivery times and reduce dependency on global logistics. This trend supports faster turnaround for customers and strengthens Caterpillar’s competitive edge. -

Counterfeit Parts Challenge and Brand Protection

The proliferation of counterfeit tractor parts remains a concern, particularly in developing markets. Caterpillar is expected to enhance anti-counterfeiting measures through blockchain-based part authentication and QR-coded traceability by 2026. These efforts will protect brand integrity and ensure customer safety and equipment performance. -

Electrification and Alternative Powertrains

While full electrification of tractors remains limited, hybrid and low-emission models are gaining momentum. Caterpillar’s investment in sustainable technologies will influence parts demand, with increasing need for battery systems, electric actuators, and thermal management components. Although traditional diesel-related parts will dominate, the transition will create new opportunities in niche segments.

In conclusion, the 2026 market for Caterpillar tractor parts will be defined by sustainability, digital integration, and geographic expansion. Caterpillar’s focus on innovation, customer support, and supply chain agility positions it to maintain leadership in a competitive and evolving aftermarket landscape.

Common Pitfalls When Sourcing Caterpillar Tractor Parts

When sourcing parts for Caterpillar tractors, buyers often encounter significant challenges that can impact equipment performance, uptime, and legal compliance. Avoiding these common pitfalls is crucial for maintaining operational efficiency and protecting your investment.

Quality Inconsistencies in Non-OEM Parts

One of the most prevalent issues is the variability in quality among aftermarket or imitation parts. While OEM (Original Equipment Manufacturer) Caterpillar parts are engineered to exact specifications, many third-party alternatives use inferior materials or manufacturing processes. This can lead to premature wear, reduced performance, and increased downtime. Buyers may be tempted by lower prices, but substandard parts often result in higher long-term costs due to frequent replacements and potential damage to other components.

Risk of Counterfeit or Non-Genuine Parts

The market for heavy equipment parts is rife with counterfeit products that mimic Caterpillar branding. These fake parts may look identical but fail to meet performance and safety standards. They often lack proper certification and traceability, making it difficult to verify authenticity. Using counterfeit parts can void warranties, compromise equipment reliability, and even pose safety hazards in critical applications.

Intellectual Property (IP) and Trademark Violations

Sourcing non-genuine parts can expose buyers and suppliers to intellectual property risks. Caterpillar actively protects its trademarks, patents, and design rights. Distributing or using parts that infringe on these rights—such as those bearing unauthorized Cat® branding—can lead to legal action, fines, or seizure of goods. Even well-intentioned buyers may unknowingly support IP violations when purchasing from unverified suppliers.

Lack of Traceability and Certification

Genuine Caterpillar parts come with full traceability, including serial numbers and certification documentation. Many alternative parts lack this transparency, making it difficult to verify compliance with industry standards or conduct root cause analysis in case of failure. This absence of documentation can also complicate insurance claims or regulatory audits.

Inadequate Supplier Verification

Working with unqualified or unauthorized dealers increases the risk of receiving poor-quality or counterfeit parts. Buyers should verify a supplier’s authorization status through Caterpillar’s official dealer network and check for certifications, customer reviews, and industry reputation. Skipping due diligence can lead to supply chain disruptions and compromised part integrity.

Avoiding these pitfalls requires diligence, supplier vetting, and a preference for genuine Caterpillar parts—especially for critical components where reliability and safety are paramount.

Logistics & Compliance Guide for Caterpillar Tractor Parts

Overview

This guide outlines the essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence related to Caterpillar tractor parts. Ensuring proper procedures are followed guarantees product integrity, regulatory compliance, and operational efficiency across the supply chain.

Parts Identification and Classification

Accurate identification of Caterpillar parts using part numbers (P/N), serial numbers, and model compatibility is critical. Use Caterpillar Electronic Technician (Cat ET) software or the Caterpillar Parts Catalog to verify part specifications. Classify parts by type (e.g., engine, hydraulic, electrical), size, weight, and sensitivity (e.g., temperature, shock) to determine appropriate handling and shipping methods.

Packaging and Labeling Requirements

All parts must be packaged according to Caterpillar’s packaging standards to prevent damage during transit. Use original Caterpillar packaging when available or equivalent protective materials (e.g., anti-static bags, foam inserts, wooden crates for heavy components). Labels must include:

– Caterpillar part number and description

– Serial number (if applicable)

– Handling instructions (e.g., “Fragile,” “This Side Up”)

– Country of origin

– Hazard warnings (if applicable, e.g., oils, batteries)

– Barcodes for inventory tracking

Storage and Inventory Management

Store parts in a clean, dry, temperature-controlled environment to prevent corrosion, contamination, or degradation. Implement FIFO (First In, First Out) inventory practices. Use Warehouse Management Systems (WMS) compliant with Caterpillar dealer requirements for tracking stock levels, expiration dates (e.g., seals, fluids), and part traceability.

Transportation and Shipping

Use freight carriers experienced in industrial equipment logistics. Select transport mode (LTL, FTL, air, or sea) based on part urgency, size, and destination. Secure heavy or sensitive components to prevent movement during transit. Ensure all shipments comply with domestic and international transport regulations, including:

– International Maritime Dangerous Goods (IMDG) Code (for hazardous materials)

– IATA regulations (for air freight)

– FMCSA rules (for U.S. ground transport)

Import/Export Compliance

For cross-border shipments, ensure adherence to customs regulations:

– Accurate Harmonized System (HS) code classification

– Proper completion of commercial invoices, packing lists, and certificates of origin

– Compliance with U.S. Customs and Border Protection (CBP), EU import rules, or other regional authorities

– Adherence to export controls under EAR (Export Administration Regulations) or ITAR when applicable

Regulatory and Environmental Compliance

Caterpillar parts may be subject to environmental and safety regulations:

– Proper handling and disposal of waste parts (e.g., used oils, batteries, filters) per EPA, RCRA, or EU WEEE directives

– Compliance with REACH and RoHS regulations for chemical content in materials

– Documentation of conflict minerals sourcing if required

Quality Assurance and Traceability

Maintain full traceability through documentation of part origin, repair history (if applicable), and warranty status. Use Caterpillar’s Dealer Service Network (DSN) tools for warranty claims and service reporting. Conduct regular audits to ensure compliance with Caterpillar’s Global Service Standards (GSS).

Documentation and Recordkeeping

Retain all logistics and compliance documents for a minimum of seven years, including:

– Bills of lading and shipping manifests

– Customs documentation

– Certificates of conformance

– Inventory logs and audit reports

– Environmental disposal records

Training and Compliance Monitoring

Ensure staff are trained on Caterpillar logistics protocols, hazardous material handling, and regulatory requirements. Conduct periodic internal audits and compliance reviews. Stay updated on changes to Caterpillar policies and international trade regulations through official Caterpillar dealer communications and regulatory agencies.

Emergency Response and Risk Management

Develop contingency plans for supply chain disruptions, damage, or loss. Report incidents involving hazardous materials immediately per local, national, and Caterpillar reporting protocols. Maintain insurance coverage appropriate for the value and risk profile of stored and in-transit parts.

In conclusion, sourcing Caterpillar tractor parts requires a strategic approach that balances authenticity, cost, availability, and reliability. Opting for genuine OEM parts ensures compatibility, durability, and optimal performance, making them a worthwhile investment for critical components. However, high-quality aftermarket options can offer cost-effective alternatives without significantly compromising on performance, particularly for less vital parts.

To ensure a successful sourcing process, it’s essential to work with authorized dealers, reputable suppliers, or trusted online platforms that provide verifiable part histories and warranties. Regular maintenance and timely replacement of parts can extend the lifespan of the equipment and minimize downtime, enhancing overall operational efficiency.

Ultimately, proper research, supplier verification, and a clear understanding of equipment needs will lead to informed decisions, ensuring that Caterpillar tractors continue to perform reliably in demanding environments. Prioritizing quality and authenticity in part sourcing contributes not only to machine longevity but also to safety and productivity in agricultural, construction, and industrial operations.