The global compact excavator market, driven by increasing infrastructure development and urbanization, is projected to grow at a CAGR of 6.8% from 2023 to 2030, according to Grand View Research. As demand rises for machines like the popular 3-ton class Caterpillar 303, a growing number of manufacturers have emerged as key suppliers of compatible parts, attachments, and even OEM-equivalent models. Fueled by cost-efficiency demands and supply chain diversification, especially in Asia-Pacific and North America, the competitive landscape now includes both established industrial players and agile regional manufacturers. In this data-driven overview, we identify the top five Caterpillar 303 manufacturers—evaluated on production capacity, global market share, customer reviews, and parts compatibility—positioning them within a rapidly expanding $27.4 billion compact excavator ecosystem.

Top 5 Caterpillar 303 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 303 CR Mini Excavator

Domain Est. 1993

Website: cat.com

Key Highlights: The Cat 303 CR Mini Excavator delivers high performance in an under 2-ton compact size machine for construction, landscaping and demolition jobs….

#2 [PDF] Cat® 303 CR Mini Excavator

Domain Est. 2000

Website: s7d2.scene7.com

Key Highlights: compact radius design lets you access and work in the tightest areas. Dig-to-blade and dozer blade float features allow for easy cleanup. SAFETY ON THE JOB SITE….

#3 New Cat Machines

Domain Est. 2000

Website: holtcat.com

Key Highlights: The Cat 303 CR Mini Excavator delivers power and performance in a compact size to help you work in a wide range of applications….

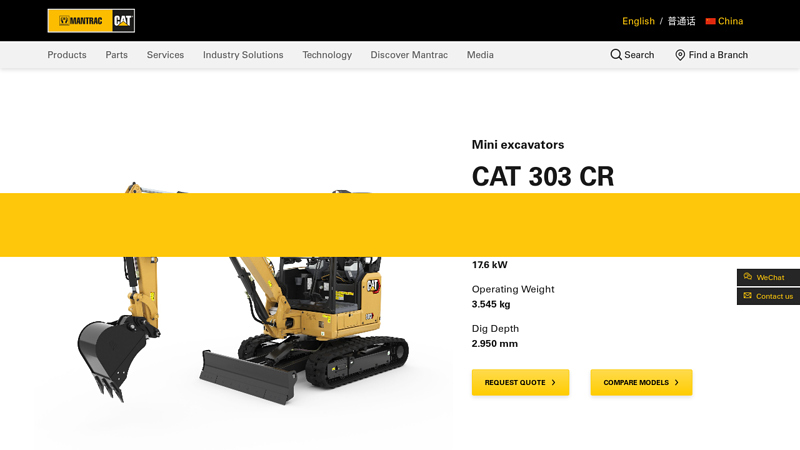

#4 Cat 303 CR Mini Hydraulic Excavator

Domain Est. 2002

Website: mantracgroup.com

Key Highlights: Meets U.S. EPA Tier 4 Final and EU Stage V emission standards. Note, Advertised power is tested per the specified standard in effect at the time of manufacture….

#5 303 CR Mini Hydraulic Excavator

Domain Est. 2004

Website: petersoncat.com

Key Highlights: The Cat® 303 CR Mini Excavator delivers power and performance in a compact size to help you work in a wide range of applications. Engine. Net Power. 23.60 hp….

Expert Sourcing Insights for Caterpillar 303

H2: Caterpillar 303 Market Trends in 2026

As of 2026, the market for the Caterpillar 303 compact hydraulic excavator is being shaped by a convergence of technological innovation, sustainability mandates, evolving customer demands, and broader economic conditions. The Cat® 303—available in standard (303), Compact (303 CR), and Next Generation (303 NG) configurations—remains a pivotal model in the sub-3.5-ton size class, widely used in construction, landscaping, utility work, and rental fleets. Key market trends influencing its trajectory in 2026 include:

1. Accelerated Electrification and Alternative Power

Caterpillar’s strategic push toward low- and zero-emission solutions is reshaping the 303 product ecosystem. By 2026, the Caterpillar 303 Electric (303E)—a battery-electric variant launched in prior years—has gained significant traction, especially in urban environments and indoor applications where noise and emissions regulations are stringent. Adoption is being driven by:

– Stricter emissions regulations in Europe (Stage V+), North America (Tier 4 Final enforcement + proposed EPA rules), and parts of Asia.

– Total Cost of Ownership (TCO) advantages, including lower fuel and maintenance costs for electric models in high-utilization scenarios.

– Incentives and green financing programs supporting electrified equipment purchases.

Even the diesel-powered 303 NG models are seeing efficiency enhancements through updated engine calibrations and improved hydraulics, aligning with transitional market demands.

2. Growth in Rental and Fleet Utilization

The rental market continues to dominate demand for compact excavators like the 303. In 2026, rental companies are prioritizing:

– Versatility and reliability—the 303’s compact radius, ease of transport, and robust performance support high fleet utilization.

– Fleet modernization—rental houses are upgrading to newer 303 NG and electric models to meet contractor expectations for fuel efficiency, telematics, and reduced downtime.

– Subscription-based and usage-based rental models, enabled by Cat Connect™ telematics, are gaining popularity, allowing contractors flexible access without long-term investment.

3. Digitalization and Telematics Integration

Cat Connect technology is now standard or widely adopted across new 303 models. In 2026, data-driven operations are a key differentiator:

– Remote monitoring of fuel consumption, operating hours, and maintenance alerts improves fleet management.

– Predictive maintenance reduces unplanned downtime, increasing machine availability.

– Job site integration with digital planning tools allows contractors to optimize machine usage and track productivity in real time.

4. Demand for Compact and Zero-Tail-Swing Models

Urbanization and confined-space work continue to drive demand for compact excavators. The 303 CR (Compact Radius) variant remains highly popular due to:

– Zero tail swing, allowing safe operation near walls and structures.

– Easy transport on small trailers, reducing logistics costs.

– High breakout force and lift capacity relative to its size, appealing to utility and residential contractors.

5. Global Infrastructure Investment and Regional Variations

- North America and Europe: Steady demand supported by infrastructure modernization (e.g., broadband deployment, water system upgrades) and green building initiatives.

- Asia-Pacific: Rapid urban development in countries like India, Vietnam, and Indonesia fuels demand, though price sensitivity favors reconditioned and used units.

- Emerging Markets: Increased availability of financing and Cat Certified Rebuild programs is expanding access to 303 models in Latin America and Africa.

6. Focus on Operator Comfort and Safety

Ergonomic cabins, improved visibility, and intuitive controls in the 303 NG series enhance operator satisfaction and retention—a critical factor in labor-constrained markets. Features like standard ROPS/FOPS canopies, backup cameras, and seatbelt interlocks also align with rising safety standards.

Conclusion

In 2026, the Caterpillar 303 remains a market leader in the compact excavator segment, adapting dynamically to industry shifts. Its success hinges on Caterpillar’s ability to balance innovation—particularly in electrification and digitalization—with reliability, service support, and total cost efficiency. As sustainability and productivity become increasingly intertwined, the 303 platform is well-positioned to serve both traditional and next-generation construction workflows.

Common Pitfalls When Sourcing a Caterpillar 303 Excavator

Sourcing a Caterpillar 303 mini excavator—whether new, used, or through third-party suppliers—can present several challenges, particularly concerning quality and intellectual property (IP). Being aware of these pitfalls helps ensure you receive a genuine, reliable machine.

Quality-Related Pitfalls

Purchasing Counterfeit or Non-Genuine Parts

One of the most significant quality risks is unknowingly acquiring a machine rebuilt with counterfeit or imitation components. These parts often fail prematurely, compromise safety, and can void warranties. They may mimic genuine Cat® parts superficially but lack rigorous testing and material standards.

Inadequate Maintenance History or Odometer Fraud

Used Caterpillar 303s from unreliable sources may have incomplete or falsified service records. Hour meter tampering is common in some markets, leading buyers to overestimate the machine’s remaining lifespan and reliability. Without verified documentation, assessing true wear and tear becomes difficult.

Poor Reconditioning Standards

Refurbished or remanufactured units from unauthorized dealers may not meet Cat’s stringent reconditioning protocols. This can result in issues like subpar welding, improper engine overhauls, or faulty hydraulics, leading to unexpected downtime and repair costs.

Lack of Certification and Inspection

Sourcing from sellers who don’t provide third-party inspection reports or Cat Certified Used documentation increases the risk of hidden structural damage, undercarriage wear, or engine problems. Skipping professional inspection can lead to costly surprises post-purchase.

Intellectual Property (IP) Pitfalls

Dealing with Unauthorized Resellers or “Grey Market” Equipment

Purchasing from unauthorized distributors or parallel importers may expose buyers to machines with questionable IP provenance. These units might lack proper licensing, have altered identification numbers, or be imported in violation of regional distribution agreements, potentially leading to legal or compliance issues.

Risk of Non-Compliant or Cloned Control Systems

Modern Cat 303 models include proprietary electronics, telematics (like Cat Connect®), and engine control modules protected by IP laws. Unauthorized reprogramming or cloning of these systems—common in refurbished or gray-market machines—can infringe on intellectual property and disable critical features like remote monitoring or service alerts.

Misrepresentation of Brand Authenticity

Some sellers may market replicas, rebadged machines, or knock-offs as genuine Cat 303s. These machines infringe on Caterpillar’s trademarks and patents, offering substandard performance while misleading buyers about origin and support eligibility.

Voided Support and Software Access

Using non-genuine software updates or unauthorized firmware modifications can trigger IP protection mechanisms, locking out access to Cat’s diagnostic tools, warranty services, and over-the-air updates. This limits long-term usability and support options.

Mitigation Strategies

To avoid these pitfalls:

– Purchase only through authorized Caterpillar dealers or Cat Certified Used channels.

– Request full service history and conduct an independent pre-purchase inspection.

– Verify machine serial numbers against Caterpillar’s database.

– Avoid deals that seem too good to be true—especially on used or “refurbished” models.

– Confirm software authenticity and ensure telematics systems are factory-original.

By prioritizing authorized channels and due diligence, buyers can safeguard both machine quality and compliance with intellectual property standards.

Logistics & Compliance Guide for Caterpillar 303

The Caterpillar 303 mini excavator is a widely used machine in construction and infrastructure projects. Proper logistics planning and regulatory compliance are essential for its safe and legal transport, operation, and maintenance. This guide outlines key considerations for moving and using the Cat 303 in accordance with industry standards and legal requirements.

Transportation and Handling

Transporting the Caterpillar 303 requires careful planning to ensure safety and regulatory compliance. The machine typically weighs between 3,300–3,500 kg (7,275–7,716 lbs), depending on configuration and attachments.

- Trailer Requirements: Use a lowboy or flatbed trailer with a minimum capacity of 5,000 kg (11,000 lbs) to accommodate the excavator and securement equipment.

- Loading/Unloading: Always use ramps rated for the machine’s weight. Engage the travel lock and lower attachments (bucket and arm) fully during transport.

- Securement: Secure the machine with at least four heavy-duty tie-down straps or chains attached to designated lifting points. Ensure tension is evenly distributed.

- Permits: Check local regulations—some jurisdictions require permits for oversized or heavy loads, even for mini excavators transported on public roads.

Regulatory Compliance

Operating and transporting the Cat 303 must align with regional and national regulations.

- DOT/Transportation Regulations (USA): Comply with FMCSA guidelines for weight distribution, lighting, and securement. Machines over 4,536 kg (10,000 lbs) GVWR may require registration and inspection.

- EU Standards (ADR/CE): Ensure transport vehicles comply with ADR road safety standards. The machine itself must carry CE marking, indicating conformity with health, safety, and environmental protection standards.

- Operator Certification: In most regions (e.g., OSHA in the U.S., CPCS in the UK), operators must be trained and certified to operate excavators. Maintain records of training and certifications on-site.

- Emissions Compliance: The Cat 303 meets Tier 4 Final/Stage V emission standards. Confirm local emission regulations, especially in low-emission zones (e.g., city centers in Europe).

Site Safety and Operational Compliance

Safe operation on-site is critical for compliance and accident prevention.

- Pre-Operation Inspection: Conduct daily equipment checks (fluids, hydraulics, lights, tracks, and safety features) as per Cat’s Operation & Maintenance Manual.

- Worksite Hazard Assessment: Perform a site survey to identify underground utilities, unstable ground, overhead lines, and traffic patterns. Use utility locating services before digging.

- Fall Protection & Signaling: Ensure operators wear seatbelts. Use spotters when operating near traffic or blind spots. Install ROPS (Roll-Over Protective Structure) and FOPS (Falling Object Protective Structure) compliant cabs.

- Noise and Vibration: Comply with local noise ordinances. The Cat 303 operates at approximately 97 dB(A). Use hearing protection and limit operating hours in residential zones if required.

Environmental and Waste Management

Minimize environmental impact during transport and operation.

- Spill Prevention: Equip transport vehicles with spill kits. Confirm hydraulic and fuel systems are leak-free before loading.

- Fluid Disposal: Used oil, coolant, and filters must be disposed of in accordance with EPA (U.S.) or equivalent environmental regulations (e.g., WEEE and Hazardous Waste Regulations in the EU).

- Erosion Control: On job sites, implement silt fences or berms to prevent sediment runoff when excavating near water bodies.

Documentation and Recordkeeping

Maintain accurate records to demonstrate compliance.

- Transport Logs: Keep records of transport routes, weights, permits, and driver credentials.

- Maintenance Records: Track all servicing, repairs, and part replacements per Cat’s recommended intervals.

- Incident Reports: Document any accidents, near misses, or equipment malfunctions.

- Compliance Certificates: Retain copies of operator certifications, equipment inspections, and emission compliance documentation.

International Shipping Considerations

For cross-border or overseas transport:

- Customs Documentation: Prepare a commercial invoice, bill of lading, and packing list. Include HS code 8429.52 for excavators.

- Import Duties and Taxes: Research destination country tariffs. Some regions offer reduced rates for construction equipment.

- COC (Certificate of Conformity): Required in many countries to verify the machine meets safety and emissions standards.

- Battery and Fuel Regulations: Drain fuel to safe levels for air or sea freight. Remove batteries if required by IATA/IMDG regulations.

Adhering to this logistics and compliance guide ensures safe, legal, and efficient use of the Caterpillar 303 across various operational environments. Always consult local authorities and Cat dealers for region-specific requirements.

Conclusion for Sourcing the Caterpillar 303 Excavator

Sourcing the Caterpillar 303 mini excavator proves to be a strategic and reliable choice for small to medium-scale construction, landscaping, and utility projects. Known for its durability, fuel efficiency, and ease of operation, the Cat 303 offers excellent performance in tight spaces while maintaining the robust build quality synonymous with the Caterpillar brand.

When sourcing this machine, considering both new and pre-owned options from authorized dealers, reputable resellers, or rental return units can offer significant value. Emphasis should be placed on verifying machine history, maintenance records, and warranty availability to ensure long-term reliability and minimize downtime.

Additionally, availability of spare parts, service support from Cat’s global dealer network, and operator training resources enhance the ownership experience and reduce total cost of operation. Whether purchased outright, leased, or rented, the Caterpillar 303 delivers strong return on investment through productivity, uptime, and resale value.

In conclusion, sourcing the Cat 303 mini excavator aligns well with operational needs requiring compact size, powerful performance, and trusted brand support—making it a recommended choice for contractors and equipment managers seeking reliability and efficiency in their fleet.

![[PDF] Cat® 303 CR Mini Excavator](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-cat-303-cr-mini-excavator-518.jpg)