The global diesel engine injector market, which includes components like the Cat C15 injectors, is experiencing steady growth driven by rising demand for high-performance heavy-duty engines in construction, mining, and transportation sectors. According to Grand View Research, the global diesel fuel injector market size was valued at USD 12.7 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This expansion is fueled by increasing emphasis on fuel efficiency, stringent emissions regulations, and the ongoing need for reliable aftermarket engine components. As one of Caterpillar’s most widely used engines in industrial and on-highway applications, the Cat C15 continues to generate consistent demand for high-quality replacement injectors. In response, manufacturers are investing in precision engineering and advanced materials to meet OEM performance standards. With the aftermarket segment accounting for a significant share of sales, choosing a reliable injector manufacturer is critical for maintaining engine efficiency and durability. Below are the top 9 manufacturers leading innovation and quality in Cat C15 injector production.

Top 9 Cat C15 Injectors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cat Heavy Duty Injectors

Domain Est. 2000

Website: industrialinjection.com

Key Highlights: 60-day returns10R0956SE-II Remanufactured CAT 3406 C15/C16 Injector – Industrial Injection 10R0956SE-II Remanufactured CAT 3406 C15/C16 Injector $489…

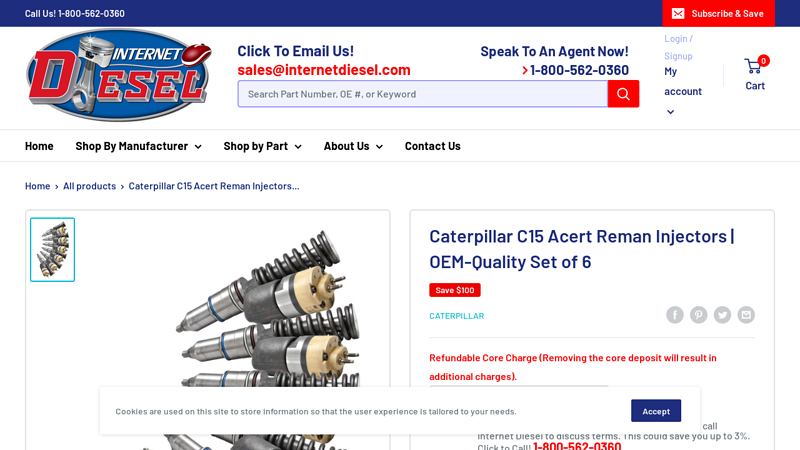

#2 Caterpillar C15 Acert Reman Injectors

Domain Est. 2005

Website: internetdiesel.com

Key Highlights: In stock $0.01 deliveryEnhance your engine’s performance with our premium OEM-remanufactured Caterpillar C-15 Acert injectors. Each set is sold exclusively in groups of six at $274…

#3 3406E and C15 Fuel Injectors, Caterpillar

Domain Est. 2010

Website: highwayandheavyparts.com

Key Highlights: Free deliveryOur Caterpillar 3046E and C15 fuel injectors meet or exceed all OEM specs. Get your heavy equipment running efficiently with great prices and fast shipping ……

#4 Products

Domain Est. 1999

Website: disa.it

Key Highlights: Parts and components suitable for fuel injection systems. Caterpillar, Cummins, Denso, Detroit Diesel, Ford / Navistar, John Deere Perkins….

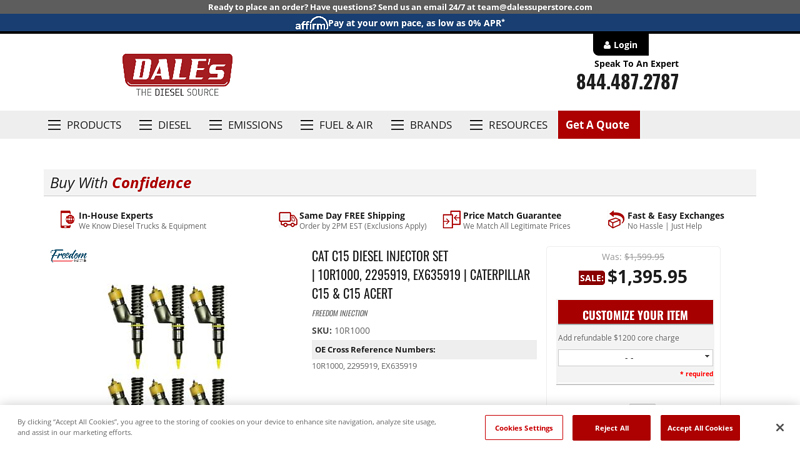

#5 CAT C15 Diesel Injector Set

Domain Est. 2010

Website: dalessuperstore.com

Key Highlights: In stock Free deliveryThese are premium remanufactured Caterpillar diesel injectors for the C15 & C15 ACERT engines. They feature precision nozzles and NEW solenoids….

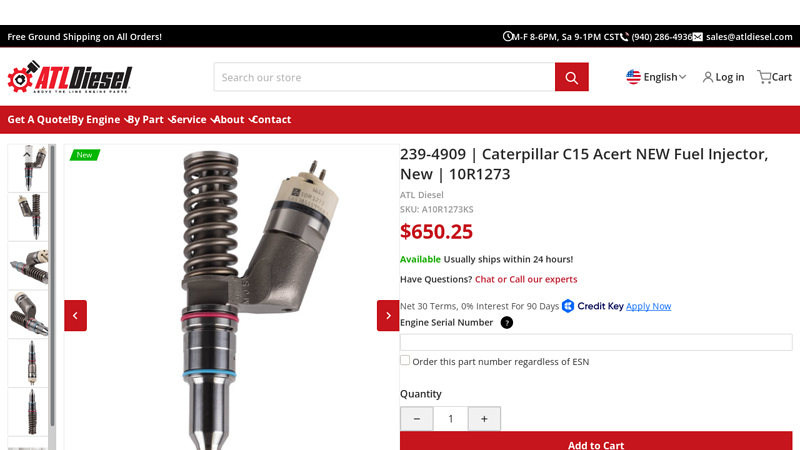

#6 239-4909

Domain Est. 2015

Website: atldiesel.com

Key Highlights: These injectors are Completely NEW EUI Fuel Injectors with all new internal components. All of our New Injectors & Fuel Nozzles are manufactured in an ISO9001: ……

#7 Diesel Injectors

Domain Est. 2015

#8 E.P.P 3406E/C15 FLOW MATCHED INJECTORS

Domain Est. 2018

Website: enhancedpowerproduct.com

Key Highlights: These injectors for the 3400 series cats are built custom just for Enhanced Power Products. Each injector goes through rigorous testing and are balanced to ……

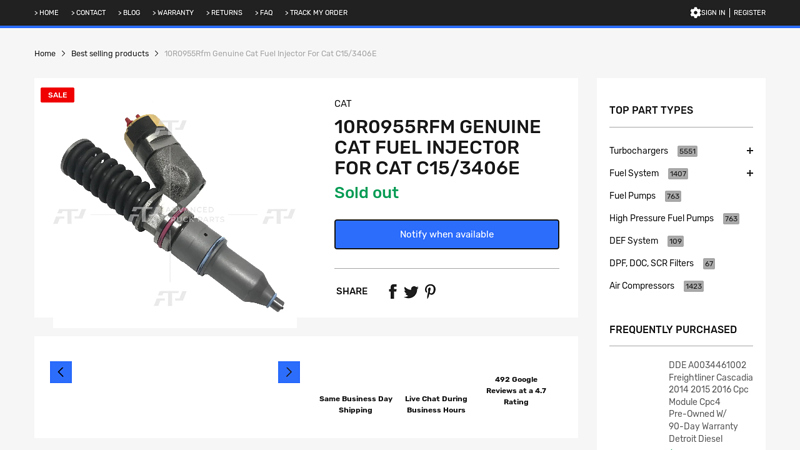

#9 10R0955Rfm Genuine Cat Fuel Injector For Cat C15/3406E

Domain Est. 2020

Website: advancedtruckparts.com

Key Highlights: Out of stockThis fuel injector for c15/3406e from CAT is designed to deliver reliable performance and durability. Key Features. Meets or exceeds applicable specifications ……

Expert Sourcing Insights for Cat C15 Injectors

H2: 2026 Market Trends for Cat C15 Injectors

As the heavy-duty engine sector evolves, the market for Cat C15 injectors in 2026 is shaped by a convergence of technological advancements, regulatory pressures, and shifting end-user demands. Although the Cat C15 engine platform has been largely superseded by newer models like the Cat C15 ACERT and the C15 in EPA 2007/2010-compliant configurations, a robust aftermarket for replacement and remanufactured injectors remains strong due to the extensive fleet of legacy machinery still in operation globally.

-

Continued Demand in the Aftermarket

Despite Caterpillar’s transition to more fuel-efficient and emissions-compliant engines, thousands of Cat C15-powered trucks, generators, mining equipment, and marine vessels remain in active service. The aging fleet drives consistent demand for replacement parts, particularly high-wear components like fuel injectors. In 2026, the aftermarket for Cat C15 injectors is expected to remain stable, supported by industrial maintenance cycles and the cost-effectiveness of rebuilding over replacing entire engines. -

Growth in Remanufactured and Recycled Components

Environmental sustainability and cost-efficiency are driving a surge in the remanufactured injector market. By 2026, remanufactured Cat C15 injectors are anticipated to capture a significant market share, as end-users prioritize affordable, high-performance alternatives with lower environmental impact. Certified remanufacturers using OEM-spec components and advanced testing procedures are gaining trust, especially in regions with strict emissions and downtime regulations. -

Regional Demand Variability

Demand for Cat C15 injectors in 2026 varies significantly by region. In North America and Western Europe, demand is primarily driven by maintenance of older equipment in agriculture, construction, and backup power systems. In contrast, emerging markets in Africa, Southeast Asia, and Latin America see higher demand due to the import of used machinery and limited access to newer engine models. These regions rely heavily on aftermarket and third-party injector solutions, fostering growth in both legal and gray markets. -

Technological Upgrades and Compatibility Challenges

While the C15 platform is mature, some operators are retrofitting older engines with modern injector technologies to improve fuel efficiency and reduce emissions. In 2026, compatibility between legacy C15 systems and newer high-pressure common rail (HPCR) components presents both challenges and opportunities. Injector manufacturers offering hybrid or upgraded solutions tailored to C15 engines may find a niche market willing to invest in performance enhancements. -

Impact of Digital Diagnostics and Predictive Maintenance

The integration of IoT and predictive maintenance technologies is influencing injector servicing practices. Fleet operators are increasingly using digital tools to monitor injector performance, enabling timely replacements before failure. This shift reduces unplanned downtime and increases demand for data-driven injector services. In 2026, suppliers offering smart diagnostics and injector health reports alongside their products are better positioned to meet evolving customer expectations. -

Supply Chain and Raw Material Pressures

Global supply chain volatility, particularly in rare earth metals and precision manufacturing components, continues to affect injector production costs. In 2026, geopolitical tensions and trade policies may influence the availability and pricing of both OEM and aftermarket Cat C15 injectors. Companies with diversified sourcing and localized production facilities are likely to gain a competitive edge.

In summary, the 2026 market for Cat C15 injectors is characterized by sustained aftermarket demand, growth in remanufactured parts, regional disparities, and increasing integration of digital maintenance tools. While the original engine platform is aging, its widespread deployment ensures ongoing relevance, making injector supply a resilient niche within the broader diesel engine aftermarket.

Common Pitfalls When Sourcing Cat C15 Injectors (Quality & Intellectual Property)

Sourcing replacement fuel injectors for the Caterpillar C15 engine—especially outside of authorized channels—can expose buyers to significant risks related to quality, performance, and intellectual property (IP) infringement. Understanding these pitfalls is critical to ensuring reliability, compliance, and long-term engine health.

Poor Quality and Performance Issues

One of the most prevalent risks when sourcing Cat C15 injectors is receiving units that fail to meet OEM (Original Equipment Manufacturer) specifications. Non-OEM or counterfeit injectors often use substandard materials and imprecise manufacturing processes, leading to:

- Inconsistent Fuel Atomization: Poor spray patterns reduce combustion efficiency, increasing fuel consumption and emissions.

- Premature Failure: Lower-quality seals, plungers, and nozzles wear quickly under high-pressure conditions, causing leaks or complete injector failure.

- Engine Damage: Faulty injectors can cause misfires, cylinder wash-down, or even catastrophic damage like piston melting due to incorrect fuel delivery.

- Lack of Calibration: Genuine Cat injectors are precisely calibrated. Counterfeit or remanufactured units may lack proper calibration, leading to unbalanced engine performance.

Intellectual Property (IP) Infringement and Legal Risks

Purchasing counterfeit or unauthorized replica injectors raises serious IP concerns:

- Trademark and Patent Violations: Many third-party injectors mimic Caterpillar’s design and branding, infringing on protected intellectual property. Distributors and end users may unknowingly participate in illegal activity.

- Voided Warranties: Using non-genuine parts typically voids engine warranties, leaving operators liable for expensive repairs.

- Regulatory Non-Compliance: In regions with strict emissions regulations (e.g., EPA, EU Stage standards), unauthorized injectors may not meet required emission control levels, exposing operators to fines or compliance issues.

Misleading Marketing and “Compatible” Claims

Many suppliers advertise injectors as “compatible” or “direct replacement” for Cat C15 engines. However, these claims often obscure critical differences:

- “Reconditioned” vs. “Remanufactured”: Not all rebuilt injectors undergo rigorous OEM-level testing. Some are merely cleaned or minimally repaired, leading to unreliable performance.

- Lack of Traceability: Genuine Cat parts include traceable serial numbers and quality certifications. Counterfeit products often lack documentation, making it difficult to verify authenticity or support warranty claims.

- Inconsistent Sourcing: Third-party suppliers may source injectors from multiple, unverified manufacturers, resulting in inconsistent quality between batches.

Supply Chain and Support Limitations

Even if a non-OEM injector performs adequately initially, long-term support is often lacking:

- No Technical Support: Unauthorized suppliers typically do not offer technical assistance or troubleshooting help when issues arise.

- Limited or No Warranty: Warranties on counterfeit or replica parts are often short, conditional, or unenforceable.

- Difficulty Sourcing Replacements: If a specific batch of injectors fails, securing matching replacements can be challenging due to inconsistent production standards.

Conclusion

To avoid these pitfalls, prioritize sourcing Cat C15 injectors through Caterpillar-authorized dealers or reputable suppliers who guarantee OEM specifications and authenticity. While genuine parts may carry a higher upfront cost, they ensure engine reliability, compliance, and protection against IP-related legal exposure. When considering alternatives, always verify certifications, traceability, and warranty terms to mitigate risk.

Logistics & Compliance Guide for Cat C15 Injectors

This guide outlines the essential logistics and compliance considerations for handling, transporting, storing, and disposing of Caterpillar C15 diesel fuel injectors. Adherence ensures operational efficiency, regulatory compliance, and environmental safety.

1. Handling & Packaging Requirements

Proper handling and packaging are critical to protect injector integrity and ensure safe transport.

- Clean Handling Procedures: Always handle injectors with clean gloves to prevent contamination from dirt, moisture, or oils. Avoid touching nozzle tips and sealing surfaces.

- Original Packaging: Use Cat-approved packaging or equivalent protective containers when possible. This includes sealed plastic bags, foam inserts, and rigid outer boxes.

- Protection from Damage: Ensure injectors are secured to prevent movement, vibration, or impact during transit. Use padding and void fillers to minimize shifting.

- Labeling: Clearly label each package with:

- Part number (e.g., 238-4567)

- Serial/lot number (if applicable)

- “Fragile – Precision Components”

- “Do Not Stack” (if necessary)

- Handling orientation arrows (if required)

2. Storage Conditions

Proper storage preserves injector performance and prevents degradation.

- Environment: Store in a clean, dry, temperature-controlled environment (10°C to 30°C / 50°F to 86°F recommended).

- Humidity Control: Maintain relative humidity below 60% to prevent internal corrosion.

- Contamination Prevention: Keep sealed in original packaging until ready for use. Store away from dust, chemicals, and high-traffic areas.

- Shelving: Place on clean, level shelves. Avoid direct contact with concrete floors. Do not stack heavy items on injector containers.

- Inventory Management: Implement a First-In, First-Out (FIFO) system. Track expiration dates if applicable (e.g., for remanufactured units with limited shelf life).

3. Transportation & Shipping

Ensure injectors arrive undamaged and in compliance with transportation regulations.

- Domestic Shipping (US): Use carriers compliant with DOT regulations for non-hazardous automotive parts. Injectors without residual fuel are typically non-hazardous.

- International Shipping: Comply with IATA/ICAO (air) or IMDG (sea) regulations if injectors contain residual fuel. Declare accurately; most Cat C15 injectors are non-hazardous when drained.

- Documentation: Include packing lists, commercial invoices (for international), and proof of origin. Maintain records for traceability.

- Temperature Exposure: Avoid extreme temperatures during transit (e.g., unconditioned cargo holds). Use climate-controlled options if necessary.

4. Import/Export Compliance

Cross-border logistics require adherence to international trade laws.

- HS Code: Use Harmonized System code 8409.91.00 (Parts of internal combustion engines) for Cat C15 injectors.

- Country-Specific Regulations: Verify import requirements in destination countries (e.g., CE marking in EU, INMETRO in Brazil, CCC in China).

- Export Controls: Confirm injectors do not fall under ITAR or EAR restrictions. Cat commercial injectors are generally not controlled.

- Customs Clearance: Provide accurate documentation including:

- Bill of Lading / Air Waybill

- Commercial Invoice

- Certificate of Origin

- Packing List

5. Environmental & Disposal Compliance

Proper end-of-life handling prevents environmental contamination.

- Used Injectors: Classify as WEEE (Waste Electrical and Electronic Equipment) in the EU or universal waste in the US if contaminated with fuel or oil.

- Hazardous Waste Determination: Test for TCLP (Toxicity Characteristic Leaching Procedure) if injectors have residual fuel or heavy metals. Most Cat injectors are non-hazardous when drained.

- Recycling: Partner with certified recyclers for metal recovery (e.g., stainless steel, copper). Cat Reman programs accept used injectors for proper reclamation.

- Documentation: Maintain disposal manifests and recycling certificates for audit purposes (minimum 3 years).

6. Regulatory & Safety Standards

Ensure operations meet industry and governmental requirements.

- EPA Regulations (US): Comply with Clean Air Act standards. Do not modify injectors in a way that defeats emissions controls (40 CFR Part 85).

- EU Emissions Standards: Adhere to Euro III/IV/V equivalent performance if used in regulated equipment.

- OSHA: Follow workplace safety guidelines when handling injectors (e.g., PPE, lifting procedures).

- REACH/ROHS (EU): Confirm compliance with chemical restrictions. Cat OEM parts are typically compliant.

7. Documentation & Traceability

Maintain records for compliance audits and warranty claims.

- Required Records:

- Purchase orders and receipts

- Shipping manifests

- Inventory logs

- Disposal/recycling certificates

- Injector serial/lot tracking (especially for fleet maintenance)

- Retention Period: Retain documentation for a minimum of 5 years or per local regulatory requirements.

8. Best Practices for Distributors & Repair Facilities

- Certification: Use only Cat-certified technicians for installation and testing.

- Calibration Records: Maintain injector calibration data post-service.

- Anti-Counterfeit Measures: Source injectors only from authorized Cat dealers or OEM suppliers. Verify authenticity via part markings and packaging.

- Training: Ensure staff are trained in handling, environmental compliance, and safety protocols.

By following this guide, logistics providers, maintenance teams, and supply chain managers can ensure Cat C15 injectors are managed safely, efficiently, and in full compliance with applicable regulations.

In conclusion, sourcing Cat C15 injectors requires careful consideration of quality, compatibility, and supplier reliability. Whether opting for new, remanufactured, or aftermarket injectors, it is essential to ensure they meet OEM specifications to maintain engine performance, fuel efficiency, and compliance with emissions standards. Partnering with reputable suppliers, verifying warranty offerings, and confirming core return policies can help minimize risks and ensure long-term reliability. Proper installation and calibration by qualified technicians further contribute to optimal injector function and engine longevity. Ultimately, investing in high-quality Cat C15 injectors from trusted sources ensures dependable operation and protects the overall health of the engine.