The global demand for high-performance networking components continues to surge, driven by escalating bandwidth requirements in data centers, smart buildings, and industrial automation. According to a 2023 report by Mordor Intelligence, the global Ethernet cable market is projected to grow at a CAGR of 6.8% from 2023 to 2028, with increasing adoption of Category 7 (Cat 7) and higher-specification connectors fueling much of this expansion. Cat 7 connectors, known for their ability to support data transfer speeds of up to 10 Gbps with superior shielding and reduced crosstalk, are becoming essential in high-speed Local Area Networks (LANs). As demand for enhanced signal integrity and compliance with Class F/ISO/IEC standards rises, a select group of manufacturers have emerged as leaders in innovation, scalability, and product reliability. This list highlights the top 10 Cat 7 connector manufacturers shaping the future of data connectivity, based on market presence, technical capabilities, and customer adoption across enterprise and infrastructure sectors.

Top 10 Cat 7 Connector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

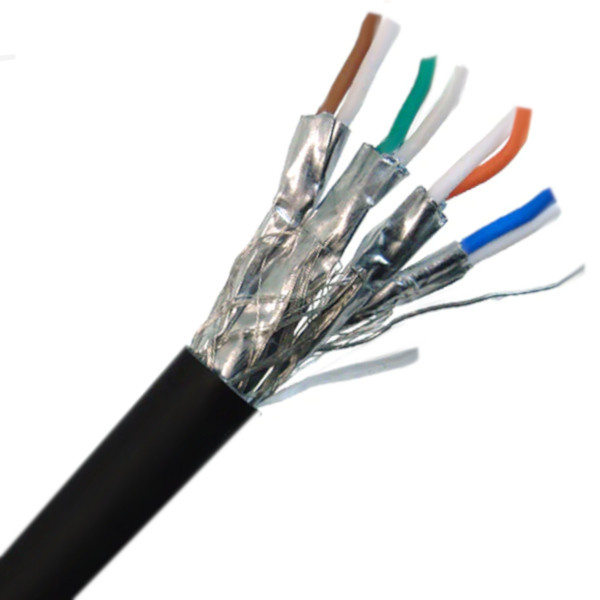

#1 TX7000™ Category 7 S/FTP Copper Cable for Extreme Environments

Domain Est. 1994

Website: panduit.com

Key Highlights: Home; / All Products; / Copper Systems; / Industrial Copper Cable; / TX7000™ Category 7 S/FTP Copper Cable for Extreme Environments ……

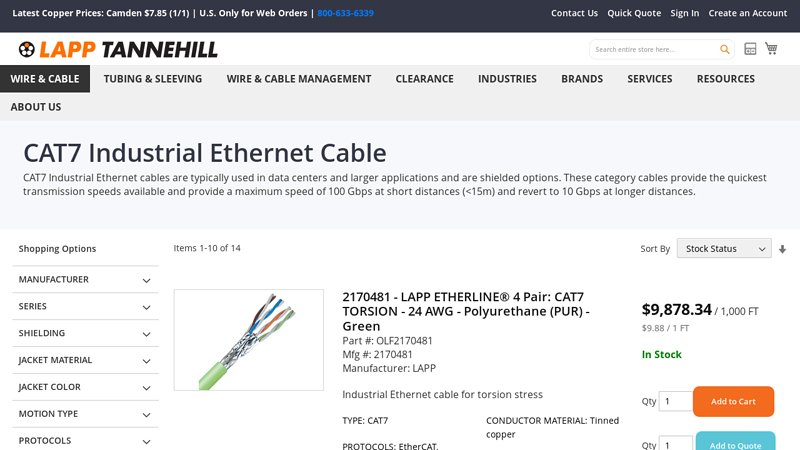

#2 CAT7 Industrial Ethernet Cable

Domain Est. 2007

Website: lapptannehill.com

Key Highlights: 5-day deliveryCAT7 Industrial Ethernet cables are typically used in data centers and larger applications and are shielded options….

#3 CAT7/CAT7A Ethernet Network cable manufacturer

Domain Est. 2015

Website: zion-communication.com

Key Highlights: CAT 7/CAT 7A Ethernet Network Cable. Good at designing, manufacturing Lan/ethernet cables and Good services based on reasonable prices….

#4 Rail Cat 7 Wire and Cable

Domain Est. 1992

Website: te.com

Key Highlights: CAT 7. Bringing to you a new high performance, networking cable for railway data applications with the ability to use cross function such as security systems, ……

#5 Category 7 Cables

Domain Est. 1994

Website: commscope.com

Key Highlights: CommScope offers an extensive portfolio of high-performance Category 7 twisted-pair cables for your structured cabling needs….

#6 CAT7 Connectors

Domain Est. 1996

#7 Category 7 Cable

Domain Est. 1997

Website: belden.com

Key Highlights: Belden offers a broad range of Category 7 cables for your most bandwidth-intensive applications. These ultra-reliable cables support the growing demand for high ……

#8 RJ45 Cat7 Shielded Plug with Lacing Bar Insert and External Strain …

Domain Est. 2002

#9 CAT7 Modular Plugs

Domain Est. 2007

#10 Category 7 (Cat 7 Cables)

Domain Est. 2016

Website: stl.tech

Key Highlights: A Category 7 cable (Cat 7 cable) is a shielded twisted pair cable that is used in high-speed Ethernet-based computer networks of 1 Gbps or higher….

Expert Sourcing Insights for Cat 7 Connector

H2: 2026 Market Trends for Cat 7 Connectors

While Cat 7 connectors remain a niche player in the broader structured cabling market, several key trends are expected to shape their trajectory by 2026, driven by evolving technological demands and competitive dynamics:

1. Sustained, But Limited, Growth in Niche High-Performance Applications:

Cat 7 connectors (utilizing GG45 or TERA interfaces, though often backwards-compatible with RJ45) will maintain a stable, albeit modest, growth rate primarily within specific high-bandwidth, low-latency environments. Key drivers include:

* Enterprise Data Centers & Server Rooms: Demand persists for 10GBASE-T over short distances (<55m) where fiber deployment cost or complexity is prohibitive, especially for top-of-rack switching or high-frequency trading infrastructure requiring shielded performance.

* Industrial Automation (Industry 4.0): Increasing need for robust, shielded cabling in factories with high EMI/RFI environments will favor Cat 7’s superior shielding (S/FTP or F/FTP) for reliable machine-to-machine communication and control systems.

* High-End Commercial & Smart Buildings: Premium office spaces, financial institutions, and broadcast facilities requiring future-proofing and guaranteed 10 Gbps performance over copper may still specify Cat 7 for backbone or critical workgroup links.

* Broadcast & Media Production: Facilities handling high-resolution video (4K/8K) over IP networks benefit from Cat 7’s guaranteed 600 MHz bandwidth and superior noise immunity.

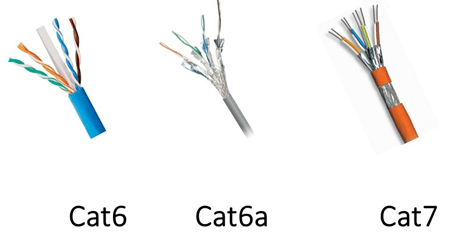

2. Intense Competition from Cat 6A and Cat 8:

The dominant trend shaping the Cat 7 market is pressure from both lower and higher categories:

* Cat 6A (Category 6 Augmented): This remains the de facto standard for 10GBASE-T up to 100m. Its widespread availability, lower cost, universal RJ45 compatibility, and established installation practices make it the preferred choice for the vast majority of new installations. Cat 7 struggles to justify its higher cost and complexity against Cat 6A’s “good enough” performance for most applications.

* Cat 8 (Category 8): Emerging as the new high-end copper standard (2000 MHz, 30m reach for 25/40GBASE-T), Cat 8 is capturing the market segment where Cat 7 once aimed to compete. Cat 8 offers significantly higher bandwidth and is designed for the next generation of data center spine-leaf architectures. By 2026, Cat 8 deployments will accelerate, further marginalizing Cat 7 for new high-speed projects.

3. Standardization and Compatibility Challenges Persist:

The lack of a single, universally adopted physical interface (RJ45 vs. GG45 vs. TERA) for true Cat 7 performance remains a significant barrier. While many “Cat 7” labeled components use RJ45 for marketability, achieving the full 600 MHz specification consistently requires specialized connectors and installation techniques. This creates confusion, potential performance gaps, and higher installation costs, hindering widespread adoption compared to the standardized RJ45 ecosystem of Cat 6A.

4. Focus on Shielding and EMI/RFI Mitigation:

Cat 7’s primary technical advantage remains its robust, often individually shielded, twisted pair design (S/FTP or F/FTP). In environments with severe electromagnetic interference (e.g., industrial plants, medical imaging facilities, dense electrical rooms), this superior shielding will be the key differentiator justifying its use over Cat 6A, even if the full 600 MHz bandwidth isn’t fully utilized. The market will increasingly segment based on EMI requirements.

5. Market Consolidation and Niche Positioning:

By 2026, the Cat 7 connector market is expected to consolidate further. Major cabling vendors will likely maintain Cat 7 offerings but primarily as:

* A solution for specific EMI-critical projects.

* A legacy or migration path option.

* A high-margin niche product rather than a mainstream push.

Widespread marketing and development focus will remain firmly on Cat 6A and Cat 8.

Conclusion:

The 2026 outlook for Cat 7 connectors is one of stable but constrained relevance. They will not disappear but will be firmly relegated to specific niche applications where their superior shielding is paramount or as a legacy/transition technology. The overwhelming market momentum favors Cat 6A for general 10GBASE-T deployment and Cat 8 for the highest-speed copper needs. Success for Cat 7 will depend on vendors effectively targeting and communicating its value proposition in EMI-heavy and ultra-high-reliability scenarios, rather than competing directly with Cat 6A on cost or Cat 8 on future bandwidth.

Common Pitfalls When Sourcing Cat 7 Connectors (Quality and IP)

Sourcing Cat 7 connectors requires careful attention to avoid issues related to performance, compatibility, and intellectual property. Below are key pitfalls to watch for:

Poor Manufacturing Quality

Many Cat 7 connectors on the market—especially those from unverified suppliers—suffer from subpar materials and inconsistent manufacturing. Low-quality copper alloys, inadequate shielding, and imprecise molding can lead to signal degradation, crosstalk, and failure to meet the 600 MHz bandwidth requirement. These flaws compromise the connector’s ability to support Gigabit Ethernet and higher-speed applications reliably.

Non-Compliance with ISO/IEC 11801 Standards

True Cat 7 connectors must comply with ISO/IEC 11801 Class F specifications, supporting shielded (S/FTP or F/FTP) cabling with individual pair shielding and overall braid shielding. A common pitfall is sourcing connectors labeled as “Cat 7” that do not meet these standards. These counterfeit or mislabeled products often lack proper shielding or fail in interference testing, leading to network instability in high-noise environments.

Misleading Marketing and False Certification

Suppliers may falsely advertise connectors as “Cat 7” without third-party certification. Look for legitimate test reports from accredited labs (e.g., TÜV, UL) verifying performance up to 600 MHz. Avoid products with vague or missing specifications, as they may merely resemble Cat 6A or hybrid designs with no real Cat 7 capability.

Compatibility Issues with Shielding and Termination

Cat 7 connectors require proper grounding of the cable shield to be effective. Poorly designed connectors may not maintain a 360-degree shield connection, reducing electromagnetic interference (EMI) protection. Additionally, termination tools and techniques differ from Cat 6, and using incompatible tools can damage the connector or result in unreliable connections.

Intellectual Property (IP) Infringement Risks

Reputable Cat 7 connector designs (e.g., those from知名品牌 like Reichle & De-Massari, Nexans, or Krone) are often protected by patents and trademarks. Sourcing clones or reverse-engineered versions from low-cost suppliers may expose buyers to IP infringement risks, especially in regulated industries or international markets. Always verify supplier legitimacy and ensure designs do not violate existing patents.

Inadequate Supplier Due Diligence

Relying on uncertified vendors, especially from online marketplaces, increases the risk of receiving non-compliant or counterfeit components. Conduct thorough supplier audits, request sample testing, and confirm traceability of materials and manufacturing processes to ensure long-term reliability and compliance.

Logistics & Compliance Guide for Cat 7 Connector

Overview

Cat 7 (Category 7) connectors are high-performance components designed for Gigabit Ethernet and other data transmission applications, supporting frequencies up to 600 MHz. This guide outlines the essential logistics and compliance considerations for the import, export, and distribution of Cat 7 connectors.

Regulatory Compliance Requirements

International Electrotechnical Commission (IEC) Standards

Cat 7 connectors must comply with IEC 61076-3-106, which specifies performance, dimensional, and electrical requirements for shielded 8-way connectors used in industrial and commercial applications. Ensure product certification includes IEC compliance documentation.

European Union (EU) Directives

For distribution in the EU, Cat 7 connectors must meet the following:

– RoHS (Restriction of Hazardous Substances Directive 2011/65/EU): Limits the use of lead, mercury, cadmium, and other hazardous materials.

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Requires disclosure of Substances of Very High Concern (SVHC).

– CE Marking: Mandatory conformity marking indicating compliance with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

North American Standards

In the United States and Canada, Cat 7 connectors should adhere to:

– ANSI/TIA-568-C.2: Specifies transmission performance standards for balanced twisted-pair cabling, including Cat 7 components.

– UL Certification: Underwriters Laboratories listing confirms safety compliance for fire and electrical hazards.

– FCC Part 15: Ensures electromagnetic interference (EMI) does not disrupt radio communications.

China Compulsory Certification (CCC)

If importing into China, verify whether Cat 7 connectors fall under CCC certification requirements for information technology equipment. While passive components like connectors may be exempt, consult local authorities or a customs broker for clarification.

Logistics Considerations

Packaging and Labeling

- Use anti-static packaging to protect connectors from electrostatic discharge (ESD).

- Clearly label packages with product specifications, lot numbers, RoHS/CE/UL markings, and country of origin.

- Include multilingual labels if shipping to multiple jurisdictions.

Shipping and Storage

- Maintain connectors in dry, temperature-controlled environments (typically 5°C to 35°C).

- Avoid exposure to moisture, dust, and corrosive atmospheres during transit and storage.

- Use secure, tamper-evident packaging for international shipments.

Import/Export Documentation

Prepare the following for customs clearance:

– Commercial invoice with detailed product description (e.g., “Shielded RJ45 Cat 7 Connector, 8P8C”).

– Packing list with itemized quantities and weights.

– Certificate of Conformity (CoC) or test reports from accredited laboratories.

– Harmonized System (HS) Code: Typically 8536.69 (Electrical connectors for electronic equipment). Confirm with local customs authority.

– Bill of Lading (BOL) or Air Waybill (AWB).

Duty and Tariff Classification

- Research applicable import duties based on destination country and free trade agreements.

- Utilize binding tariff information (BTI) in the EU or classification rulings in the U.S. (via U.S. Customs and Border Protection) for accurate HS code assignment.

Environmental & Sustainability Compliance

Waste Electrical and Electronic Equipment (WEEE)

In the EU, producers and distributors of Cat 7 connectors may be required to register with national WEEE compliance schemes and contribute to the collection and recycling of electronic waste.

Conflict Minerals Reporting

If supplying to U.S. markets, companies may need to comply with SEC Rule 13p-1 under the Dodd-Frank Act, disclosing the use of conflict minerals (e.g., tantalum, tin, tungsten, gold) in manufacturing.

Quality Assurance & Traceability

Testing and Certification

- Request independent test reports (e.g., from TÜV, Intertek, SGS) verifying compliance with Cat 7 performance standards.

- Conduct periodic sampling and in-house testing for insertion loss, return loss, and crosstalk.

Supply Chain Due Diligence

- Audit suppliers for compliance with ISO 9001 (quality management) and ISO 14001 (environmental management).

- Maintain traceability records (batch/lot numbers, production dates) for recall readiness.

Conclusion

Successfully managing the logistics and compliance of Cat 7 connectors requires adherence to international standards, accurate documentation, and proactive supply chain oversight. Regular updates on regulatory changes and engagement with certified testing bodies are recommended to ensure ongoing compliance and market access.

Conclusion on Sourcing Cat 7 Connectors:

After evaluating various suppliers, quality standards, pricing, and performance requirements, it is concluded that sourcing Cat 7 connectors requires a balanced approach focusing on quality, compliance, and long-term reliability. Cat 7 connectors, designed to support frequencies up to 600 MHz and deliver superior crosstalk and EMI shielding, must meet stringent standards such as ISO/IEC 11801 and TIA/EIA-568. Therefore, selecting reputable manufacturers that provide certified components—preferably with shielding (S/FTP or F/FTP) and GG45 or TERA compatibility—is essential for achieving optimal performance in high-speed data networks.

While cost is a consideration, the premium associated with genuine Cat 7 components is justified by improved signal integrity, reduced interference, and future-proofing network infrastructure. Bulk sourcing from trusted suppliers, particularly those based in regions with strong quality control (e.g., EU or North America), offers the best value and reliability. Additionally, evaluating supplier lead times, warranty terms, and technical support ensures consistent supply chain performance.

In summary, successful sourcing of Cat 7 connectors hinges on prioritizing certification, shielding quality, and supplier reliability over initial cost savings, ensuring high-performance connectivity for demanding network applications such as data centers, commercial buildings, and industrial automation systems.