The global structured cabling market, driven by rising demand for high-speed data transmission in commercial and residential infrastructures, is witnessing steady expansion. According to Grand View Research, the global Ethernet cable market was valued at USD 7.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. A key contributor to this growth is the widespread adoption of Cat 5 and Cat 5e cables, which remain prevalent in networking installations due to their cost-effectiveness and reliable performance for up to 100 Mbps (and 1 Gbps with Cat 5e). Despite the emergence of higher-category cables like Cat 6 and Cat 6a, Cat 5 infrastructure continues to play a critical role, particularly in legacy systems and budget-conscious deployments. This sustained demand has solidified the position of established termination and manufacturing specialists who ensure consistent quality, compatibility, and compliance with TIA/EIA standards. As network reliability hinges on proper cable termination, the performance of these top manufacturers directly impacts data integrity and system efficiency across industries.

Top 10 Cat 5 Cable Termination Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Optical Cable Corporation

Domain Est. 1996

Website: occfiber.com

Key Highlights: OCC is dedicated to being a diverse manufacturer of high-performance connectivity products and solutions in the world….

#2 SCP

Domain Est. 2001

Website: scpcat5e.com

Key Highlights: A leading manufacturer and global supplier of low-voltage cables and accessories. We provide quality products for residential and commercial applications….

#3 Cat 5e and Cat 5 Connectors

Domain Est. 1992

Website: te.com

Key Highlights: TE SEACON Cat5 and Cat5e Ethernet connectors are rigorously tested to ensure they can withstand harsh environments without impacting Ethernet cable ……

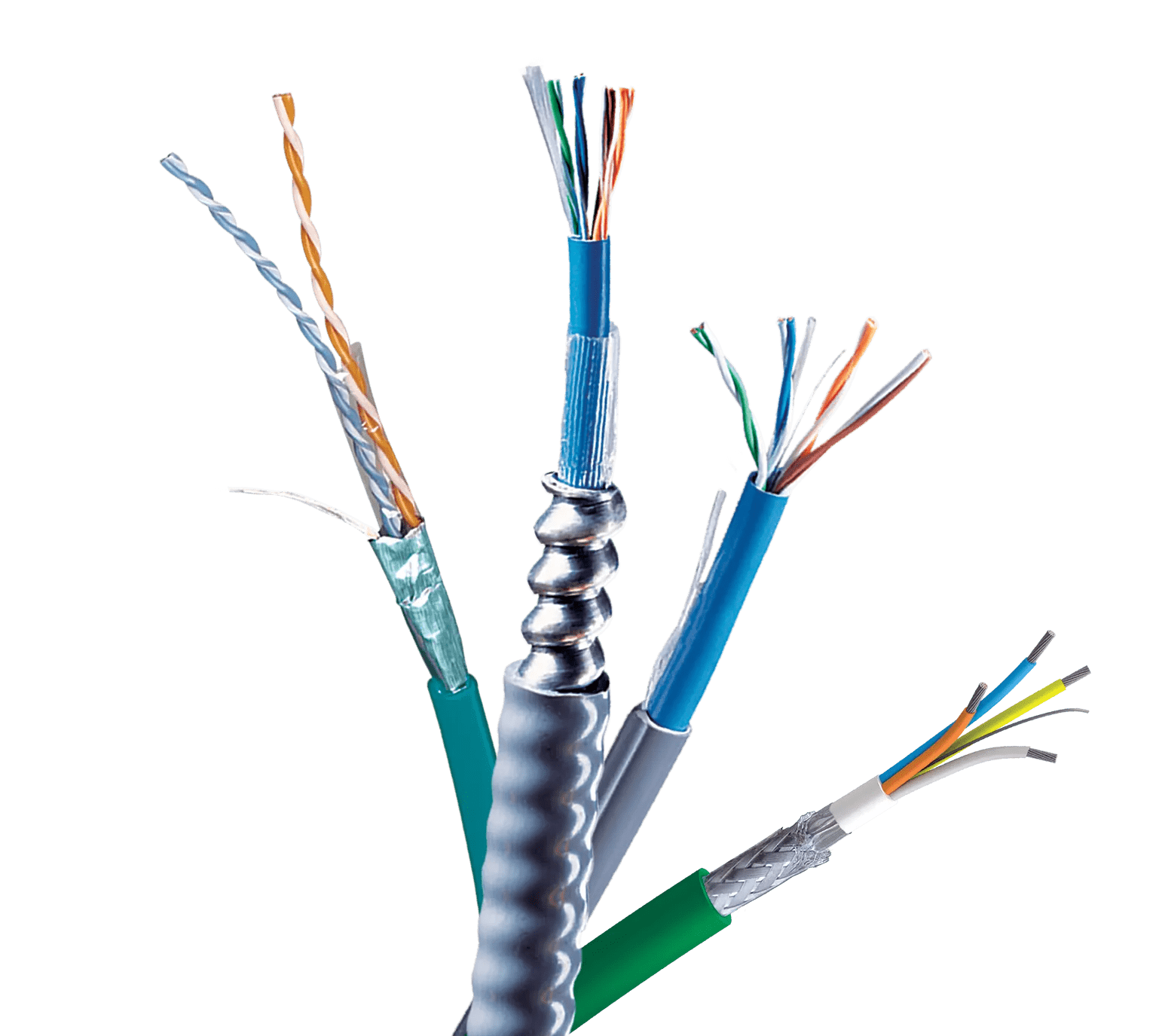

#4 Category 5e Cable

Domain Est. 1997

Website: belden.com

Key Highlights: Belden offers several Category 5e performance levels. Our top-of-line 1200 Series cable provides headroom beyond the TIA-568-C.2 Category 5e standard….

#5 Product

Domain Est. 1997

Website: klarkteknik.com

Key Highlights: Rating 4.3 (3) The Cat 5e Network cable is as advertised very good quality. The down side is the reel is a bit difficult to reel in and out although it is constructed very ……

#6 Cables

Domain Est. 1998

Website: cables.com

Key Highlights: Buy cables, fiber optic cables, Cat6 cables, Cat5 Cables, ethernet cables, power cords, patch cables, HDMI and custom cables. Shop for cables….

#7 Cablesys: Pre

Domain Est. 2002

Website: cablesys.com

Key Highlights: Cablesys manufactures data center grade Ethernet cable and connectivity; pre-terminated patch panels, patch cables, CAT6, CAT6A, UTP, FTP, CMR, and CMP….

#8 CAT5E

Domain Est. 2004

Website: phantomcables.com

Key Highlights: Cat 5 was short lived once Category 5 Enhanced (or Cat 5e) came along. Cat 5e patch cables are tested up to 350MHz at 1 Gbps. Cat 6 or Category 6 Patch Cables…

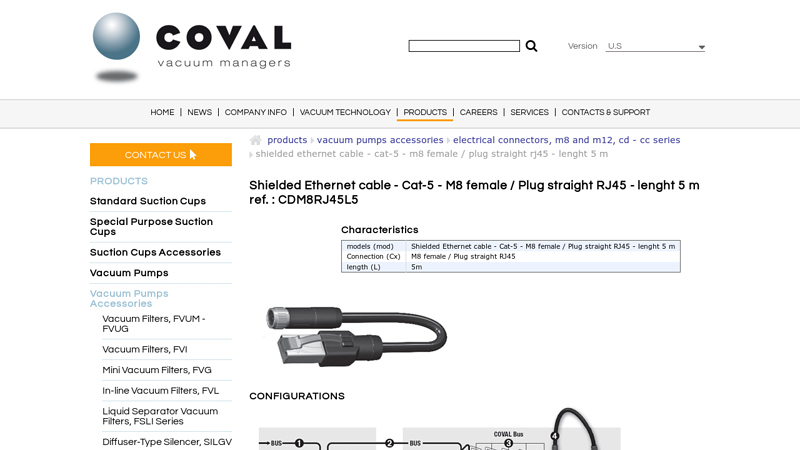

#9 Shielded Ethernet cable

Domain Est. 2007

Website: coval-inc.com

Key Highlights: models (mod), Shielded Ethernet cable – Cat-5 – M8 female / Plug straight RJ45 – lenght 5 m ; Connection (Cx), M8 female / Plug straight RJ45 ; length (L), 5m ……

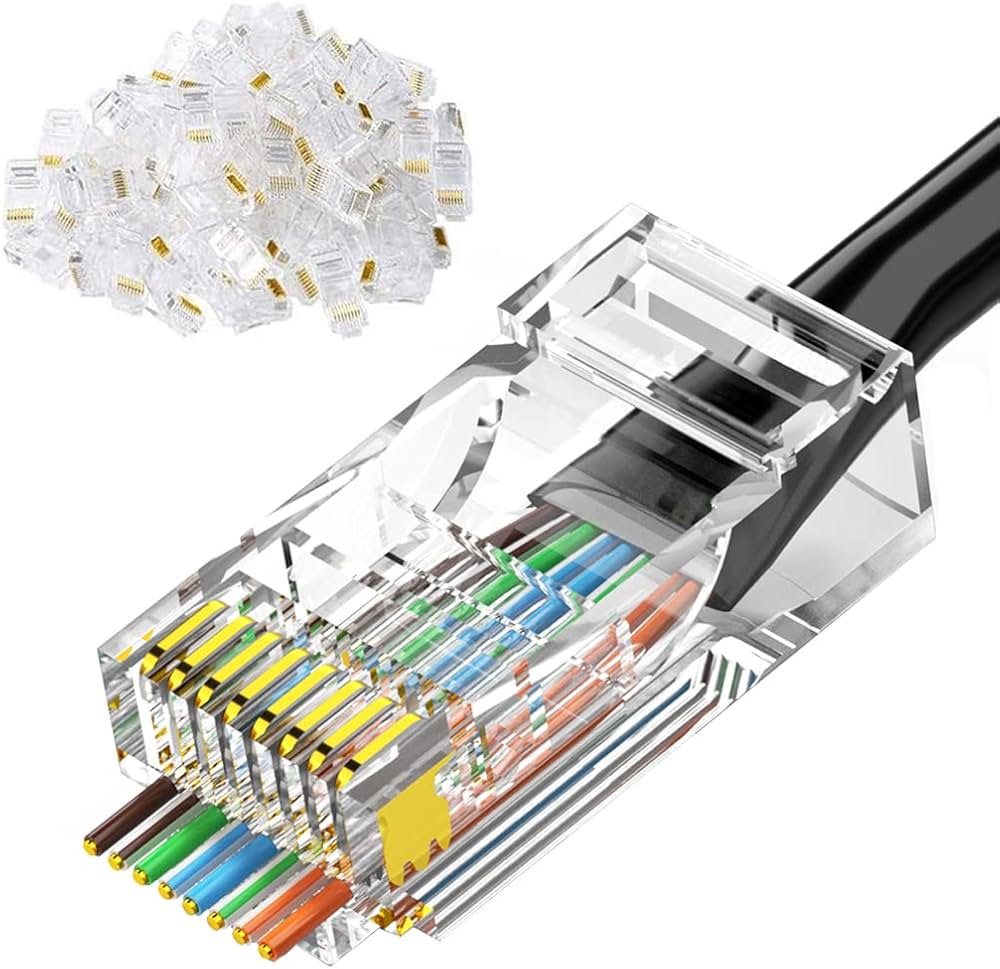

#10 CAT5e RJ45 Standard Connectors

Domain Est. 2012

Expert Sourcing Insights for Cat 5 Cable Termination

2026 Market Trends for Cat 5 Cable Termination

The Cat 5 cable termination market in 2026 is shaped by the interplay of legacy infrastructure maintenance, cost-driven deployments, and gradual technological displacement. While overshadowed by newer cabling standards, Cat 5 termination remains relevant in specific segments, driven by economic and practical factors.

Declining but Persistent Demand in Legacy and Cost-Sensitive Sectors

By 2026, Cat 5 cable termination services and components continue to serve a shrinking but stable market. Primary demand stems from the maintenance and repair of existing infrastructure in older commercial buildings, industrial facilities, and residential units where upgrading to Cat 6 or higher is not yet economically justified. Small businesses, educational institutions with tight budgets, and emerging markets prioritize affordability, making Cat 5 termination a viable solution for basic network connectivity needs such as VoIP phones, legacy security systems, and low-bandwidth data applications. The availability of inexpensive termination tools, connectors, and patch panels ensures continued accessibility for low-cost installations.

Competition from Higher-Performance Standards and Wireless Alternatives

The market faces significant pressure from the widespread adoption of Cat 6, Cat 6A, and fiber optic cabling, which support higher data rates (up to 10 Gbps) and future-proof installations. New commercial and enterprise builds increasingly specify these higher categories, reducing the footprint of new Cat 5 deployments. Additionally, advancements in Wi-Fi 6E and Wi-Fi 7 diminish reliance on wired connections for end-user devices, further limiting demand for copper termination. As a result, Cat 5 termination is increasingly viewed as a stopgap or transitional solution rather than a long-term investment.

Niche Applications and Retrofitting Opportunities

Despite broader declines, Cat 5 termination retains relevance in niche applications. It is commonly used in Power over Ethernet (PoE) deployments for IP cameras, access control systems, and basic IoT devices where high bandwidth is unnecessary. Retrofitting older buildings with limited space or structural constraints also favors Cat 5 due to its smaller bend radius and ease of installation compared to thicker cables. Additionally, audio-visual systems and building automation networks often leverage existing Cat 5 infrastructure, sustaining demand for skilled termination services.

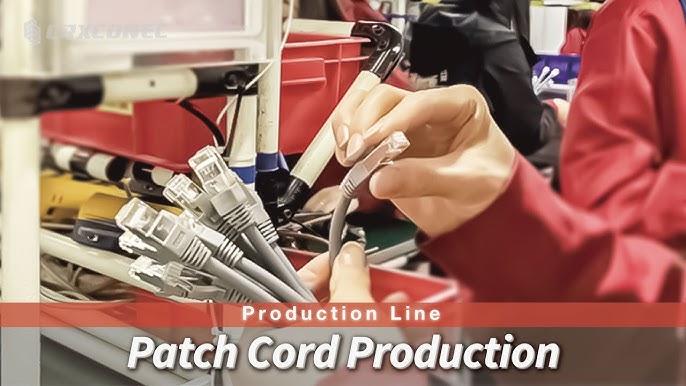

Consolidation and Specialization Among Service Providers

By 2026, the service landscape has consolidated, with larger integrators focusing on advanced cabling while smaller, specialized contractors dominate Cat 5 termination. These specialists offer cost-effective solutions for repair and small-scale installations, often bundling termination with broader network maintenance packages. Training programs emphasize backward compatibility skills, ensuring a workforce capable of supporting aging infrastructure.

In summary, the 2026 Cat 5 cable termination market operates in a niche capacity—supported by legacy systems, budget constraints, and specific low-bandwidth applications—while facing steady erosion from superior cabling technologies and wireless innovation. Its role is increasingly one of maintenance and replacement rather than new deployment, ensuring gradual but sustained relevance through the decade.

Common Pitfalls Sourcing Cat 5 Cable Termination (Quality, IP)

Sourcing Cat 5 cable termination components—such as RJ45 connectors, punch-down blocks, and patch panels—requires careful attention to quality and environmental protection, particularly regarding ingress protection (IP) ratings. Overlooking key factors can lead to network failures, reduced performance, or costly rework. Below are common pitfalls to avoid:

Poor Connector Material Quality

Low-cost RJ45 connectors often use inferior copper alloys or thin plating, leading to increased resistance, signal attenuation, and intermittent connections. Non-compliant connectors may not meet TIA/EIA-568 standards, compromising data transmission integrity.

Inadequate Shielding and EMI Protection

Cat 5 cables used in electrically noisy environments require proper shielding. Sourcing unshielded (UTP) termination components in areas with high electromagnetic interference (EMI) can result in crosstalk and data errors. Always verify whether shielded (STP or FTP) termination hardware is needed and ensure continuity of the shield path.

Non-Compliance with Industry Standards

Using termination hardware not certified to recognized standards (e.g., ANSI/TIA-568, ISO/IEC 11801) can result in performance issues. Components may claim “Cat 5” compatibility but fail to support the required 100 MHz bandwidth or proper wire gauge handling.

Incorrect Termination Tool Compatibility

Punch-down blocks and connectors must match the type of termination tool (e.g., 110 or Krone style). Using incompatible tools leads to poor insulation displacement connections (IDC), increasing the risk of signal loss or physical damage.

Overlooking Environmental Ingress Protection (IP Rating)

In outdoor, industrial, or high-moisture environments, termination points must be protected. Sourcing enclosures or jacks without appropriate IP ratings (e.g., IP65, IP67) exposes connections to dust, water, and corrosion—leading to premature failure. Always match IP ratings to the installation environment.

Inconsistent Crimping Quality

For field-terminated cables, poor-quality crimping tools or improper technique results in unreliable connections. Using non-professional or worn crimpers can damage connector contacts or fail to secure the cable jacket, increasing strain on the conductors.

Mislabeling and Counterfeit Products

Counterfeit or misleadingly labeled components are common in low-cost supply chains. These may appear to meet specifications but fail under load or over time. Purchase from reputable suppliers and verify certifications when possible.

Lack of Strain Relief

Termination points without proper strain relief (e.g., bootless connectors, unsecured patch panels) are vulnerable to cable movement and physical stress, leading to broken wires or dislodged connections—especially in high-traffic areas.

By addressing these pitfalls during procurement and installation, you ensure reliable, high-performance network infrastructure and reduce long-term maintenance costs.

Logistics & Compliance Guide for Cat 5 Cable Termination

Proper termination of Category 5 (Cat 5) Ethernet cables is essential for ensuring reliable network performance, safety, and adherence to industry standards. This guide outlines the key logistics and compliance considerations for successful Cat 5 cable termination.

Required Tools and Materials

Ensure all necessary tools and materials are available before beginning termination:

- Cat 5 cable (solid or stranded, as specified)

- RJ-45 connectors (8P8C modular plugs)

- Cable stripper (designed for twisted-pair cables)

- Crimping tool (compatible with RJ-45 connectors)

- Cable tester (basic continuity or advanced network tester)

- Patch panel or keystone jack (if terminating to fixed infrastructure)

- Labeling system (for identification and traceability)

- Workbench or clean, dry workspace

Logistics planning should include verifying quantities, ordering supplies in advance, and ensuring compatibility between components (e.g., plug type and cable conductor size).

Compliance with Industry Standards

Cat 5 termination must comply with established telecommunications standards to ensure interoperability and performance:

- TIA/EIA-568: Governs structured cabling standards; specifies wiring schemes (T568A or T568B).

- ANSI/TIA-568.2-D: Provides test requirements for balanced twisted-pair cabling.

- ISO/IEC 11801: International standard for generic cabling systems.

Wiring Scheme Consistency:

– Use either T568A or T568B across all terminations within a network.

– Maintain consistency between patch cords and jacks to avoid crossover issues.

– Document the chosen scheme for future reference.

Safety and Environmental Compliance

Adhere to safety and environmental regulations during termination activities:

- Workplace Safety: Follow OSHA guidelines (or local equivalents) for tool use and electrical safety.

- Ventilation: Ensure adequate airflow when stripping or crimping in enclosed spaces.

- Waste Disposal: Recycle cable scraps and plastic packaging according to local environmental regulations.

- ESD Precautions: Use anti-static mats or wrist straps in sensitive environments to prevent electrostatic discharge damage.

Termination Best Practices

To ensure high-quality and compliant terminations:

- Cable Preparation:

- Strip approximately 1 inch (2.5 cm) of outer jacket without nicking inner conductors.

-

Untwist pairs just enough to align wires—excessive untwisting degrades signal performance.

-

Wire Alignment:

- Arrange wires in the correct order (T568A or T568B) and straighten them.

-

Trim ends evenly to ensure full insertion into the RJ-45 connector.

-

Crimping:

- Insert the connector into the crimping tool.

-

Apply firm, even pressure to secure the contacts and strain relief.

-

Testing:

- Use a cable tester to verify continuity, correct pinout, and absence of shorts or crosstalk.

- Retest any failed cables and re-terminate if necessary.

Documentation and Traceability

Maintain compliance through thorough documentation:

- Label both ends of each cable with unique identifiers.

- Record cable runs, termination points, and test results.

- Store documentation in a centralized system for maintenance and troubleshooting.

Final Quality Assurance

Before deployment:

- Re-inspect all terminations for proper crimping and wire alignment.

- Confirm that all cables pass performance testing.

- Ensure patch panels and wall jacks are securely mounted and labeled.

By following this logistics and compliance guide, network installers can ensure Cat 5 cable terminations meet performance, safety, and regulatory requirements, supporting reliable and scalable network infrastructure.

Conclusion on Sourcing Cat 5 Cable Termination:

Sourcing Cat 5 cable termination involves evaluating several key factors including cost, quality, availability, and compatibility with existing network infrastructure. While Cat 5 cables are largely superseded by Cat 5e and Cat 6 in modern installations due to higher performance demands, they remain suitable for basic Ethernet applications up to 100 Mbps over short distances. When sourcing termination components—such as RJ45 connectors, punch-down blocks, and patch panels—it is essential to ensure compatibility with Cat 5 specifications to maintain reliable signal integrity.

Opting for reputable suppliers and certified components helps prevent issues related to crosstalk, signal loss, or network instability. Additionally, considering future scalability may justify investing in higher-category components even when terminating Cat 5 cable, as this supports easier upgrades. Ultimately, proper sourcing combined with skilled installation ensures efficient, cost-effective, and durable network connectivity, meeting current needs while allowing for potential advancements in network performance.