The global diesel engine filtration market has experienced steady growth, driven by rising demand for equipment reliability and emission compliance across on-highway and off-highway sectors. According to Mordor Intelligence, the heavy-duty diesel engine market—which includes widely used engines like the Caterpillar 3126—is projected to grow at a CAGR of approximately 5.2% from 2023 to 2028. A critical component in maintaining engine performance and longevity, the oil filter plays a pivotal role in contamination control, with the global engine oil filter market valued at USD 12.3 billion in 2022 and expected to expand at a CAGR of 4.8% through 2030, per Grand View Research. As fleet operators and industrial users prioritize uptime and cost-efficiency, OEM and aftermarket manufacturers of Cat 3126 oil filters are responding with advanced filtration technologies and expanded global distribution. In this evolving landscape, seven key manufacturers have emerged as leaders, combining product performance, wide availability, and rigorous testing to meet the demands of one of the most widely deployed diesel engines in North America and beyond.

Top 7 Cat 3126 Oil Filter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

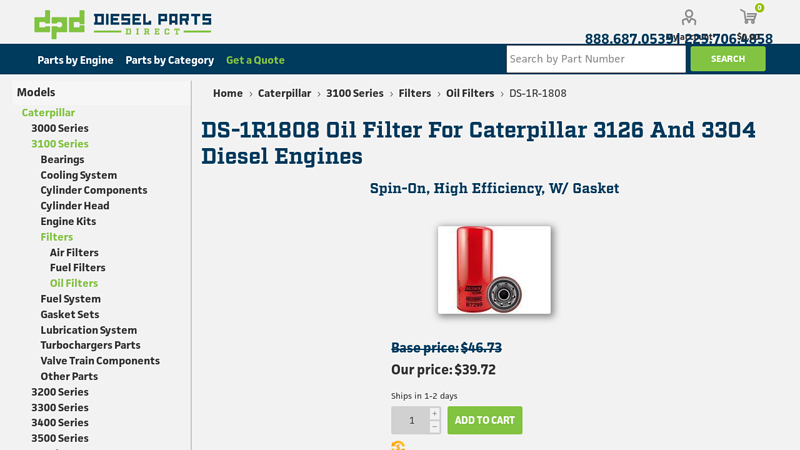

#1 DS

Domain Est. 2003

Website: dieselpartsdirect.com

Key Highlights: In stock $14.43 delivery1R-1808: Oil Filter for Caterpillar 3126 engines. This aftermarket part meets OEM specifications and is covered by a 12-month warranty….

#2 OEM CAT 3126 OIL FILTER : mesotrione

Website: neweuropetours.eu

Key Highlights: OEM CAT 3126 OIL FILTER is an integrated platform designed to provide fast, easy, and efficient customer support and service through digital channels….

#3 WIX 51791 Oil Filter

Domain Est. 1997

Website: wixfilters.com

Key Highlights: WIX HD Oil Filters provide superior engine protection with high-quality, high-capacity media for applications such as medium and heavy trucks, farm, ……

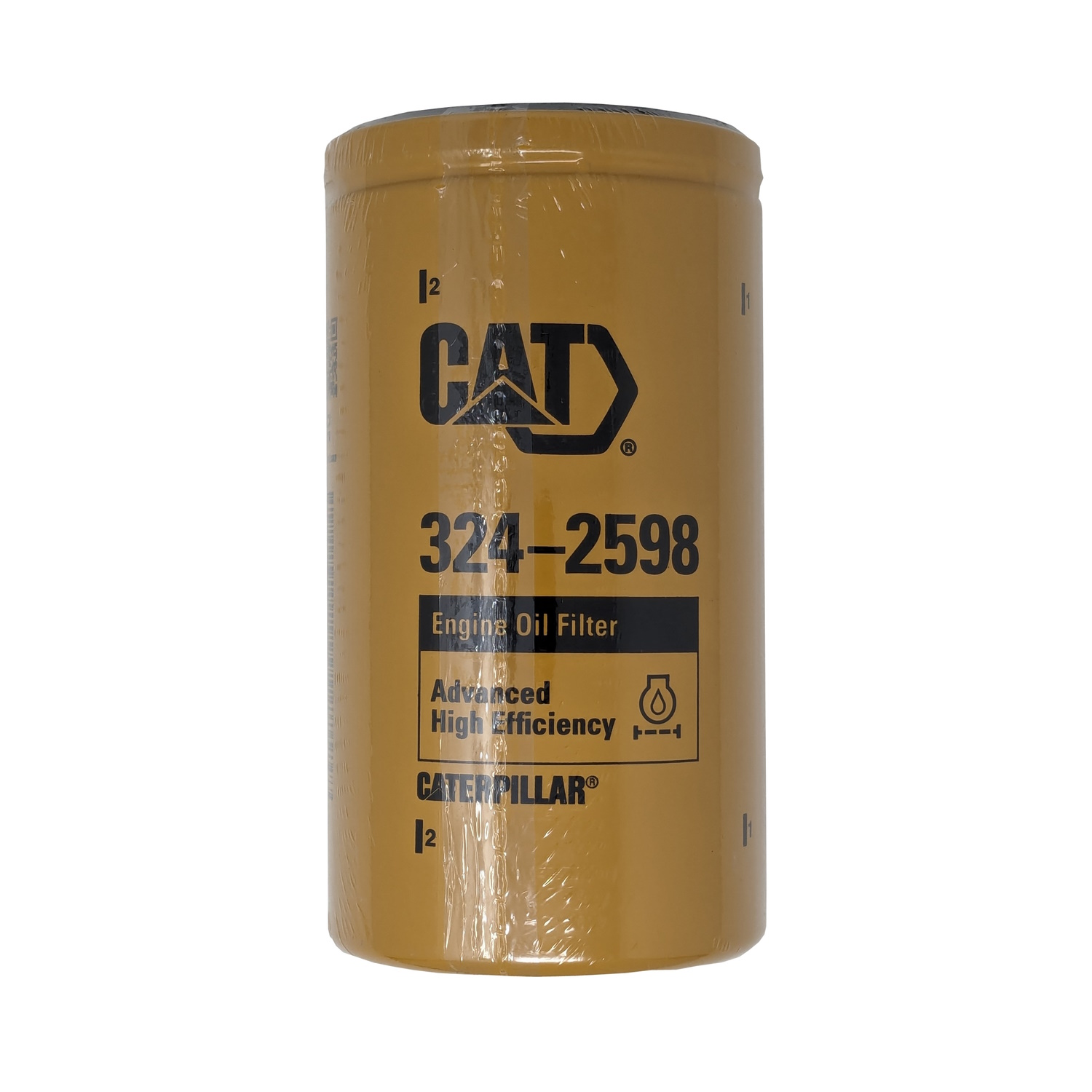

#4 Caterpillar 324

Domain Est. 1999

Website: marineengineparts.com

Key Highlights: Caterpillar 324-2598 Advanced Efficiency 3116 and 3126 Diesel Engine Oil Filter. Specifications: Replaces Caterpillar 116-9924, 5W-3407N, Baldwin B7223, BT398…

#5 Caterpillar 3126 Oil Filter

Domain Est. 2011

Website: fandjexports.com

Key Highlights: This Caterpillar 3126 Oil Filter has been sold. If you are looking for us to source a similar part please get in touch….

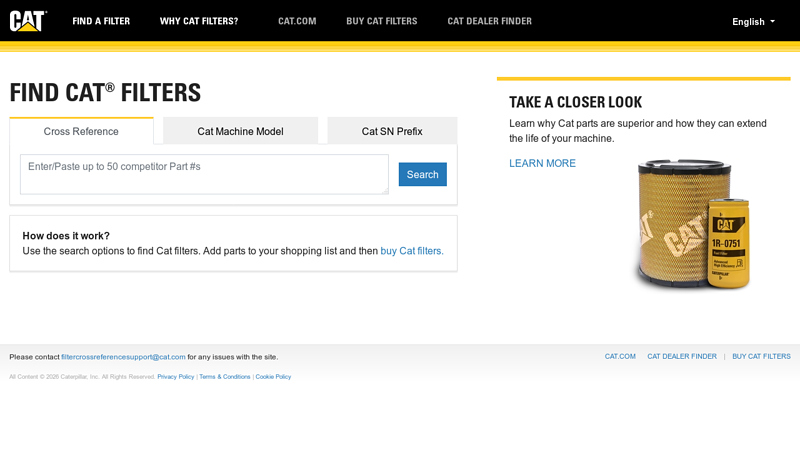

#6 CAT Filter Reference

Domain Est. 2014

Website: catfiltercrossreference.com

Key Highlights: Use the search options to find Cat filters. Add parts to your shopping list and then buy Cat filters….

#7 Buy online official CAT® Oil Filters

Domain Est. 2014

Expert Sourcing Insights for Cat 3126 Oil Filter

H2: 2026 Market Trends for Cat 3126 Oil Filters – Navigating a Transitioning Landscape

While the Cat 3126 engine itself is a legacy model, its widespread historical use ensures a persistent, albeit evolving, market for its oil filters (like the common FF-5512, FF-5514, or FF-5515) in 2026. The market dynamics are shaped by aging equipment, a shift towards alternatives, and changing service practices.

1. Declining Volume, Persistent Niche Demand:

* H2: The overall market volume for genuine new Cat 3126 oil filters is expected to be in a steady decline by 2026. This is driven by the natural attrition of the 3126 engine fleet as machines reach end-of-life and are replaced by newer models (like Cat C4.4, C6.6, or competitive Tier 4 Final engines) with different filter requirements.

* H2: However, a significant niche demand will persist. Thousands of Caterpillar 3126-powered machines (generators, agricultural equipment, older trucks, industrial machinery, marine applications) remain operational globally. As long as these engines run, they require oil changes and thus, oil filters. This creates a reliable, albeit shrinking, core market focused on maintenance and repair (MRO).

2. Dominance of Aftermarket and Compatible Filters:

* H2: The aftermarket segment will dominate the 2026 3126 oil filter market. As the engine ages, cost becomes a paramount concern for owners of older equipment. High-quality aftermarket and compatible filters (from brands like Baldwin, Donaldson, Wix, FleetGuard, and numerous value brands) offering equivalent filtration at significantly lower prices than genuine Cat filters will capture the vast majority of sales.

* H2: Genuine Cat filters will remain available primarily through Cat dealers and online parts channels, but their market share will be a fraction of the total, catering to customers prioritizing brand loyalty, warranty concerns (on extended service), or specific contractual requirements (e.g., some rental fleets).

3. Supply Chain Consolidation and Obsolescence Management:

* H2: Supply chains will be leaner and more specialized. Caterpillar and major distributors will likely manage 3126 filter stock strategically, potentially using “last time buy” announcements or producing in smaller, targeted batches to avoid overstocking obsolete parts. Expect potential short-term supply fluctuations.

* H2: Smaller, specialized industrial parts suppliers and online marketplaces (eBay, Amazon) will play a crucial role in fulfilling demand, often holding older stock or sourcing from global aftermarket manufacturers. Counterfeit or substandard filters may also circulate more readily in these channels, posing a risk.

4. Focus on Filtration Performance and Engine Longevity:

* H2: Despite the engine’s age, the critical importance of effective oil filtration for maximizing the remaining lifespan of 3126 engines will remain a key driver. Owners will seek filters meeting or exceeding OEM specifications (e.g., efficiency, dirt-holding capacity, burst pressure).

* H2: Marketing and selection will emphasize compatibility, filtration media quality (synthetic vs. cellulose blends), and meeting relevant standards (like ISO 4548), rather than cutting-edge technology (as found in filters for modern high-pressure common rail engines).

5. Digital Channels and Parts Identification:

* H2: Online parts lookup tools, e-commerce platforms, and digital marketplaces will be the primary channels for purchasing 3126 oil filters in 2026. Customers expect easy access to cross-reference charts, compatibility databases, and clear specifications.

* H2: Accurate parts identification (using the engine serial number to confirm the exact 3126 variant and required filter) will be increasingly important, as variations exist, to avoid incorrect purchases, especially given the reliance on online suppliers.

Conclusion:

The 2026 market for Cat 3126 oil filters will be characterized by a mature, declining, but essential MRO niche. Success will depend on aftermarket suppliers offering cost-effective, high-performance alternatives through robust digital distribution channels, while managing the challenges of consolidating supply chains and ensuring accurate parts matching. Genuine Cat filters will be a premium option for a diminishing segment. The core focus remains on reliability and supporting the extensive installed base of aging, yet still productive, 3126 engines.

Common Pitfalls When Sourcing Cat 3126 Oil Filters (Quality and Intellectual Property)

When sourcing replacement or aftermarket oil filters for the Caterpillar 3126 engine, buyers often encounter challenges related to quality control and intellectual property (IP) concerns. Being aware of these pitfalls helps ensure reliable engine performance and compliance with regulations.

Poor Quality Control in Aftermarket Filters

Many third-party manufacturers produce oil filters labeled as compatible with the Cat 3126. However, inconsistent manufacturing standards can lead to subpar filtration efficiency, inadequate burst pressure ratings, or weak sealing components. Filters that fail under operating conditions may allow contaminants into the engine, accelerating wear and potentially causing costly damage. Always verify that the filter meets OEM specifications such as filtration micron rating (typically 20–25 microns), flow rate, and burst strength.

Misrepresentation of Compatibility and Performance

Some suppliers falsely advertise their filters as “equivalent” or “OEM replacement” without proper testing or certification. This misrepresentation can mislead buyers into believing they are getting reliable performance. Always cross-reference part numbers and look for independent certifications (e.g., ISO standards) to validate claims.

Counterfeit and Grey Market Products

The market includes counterfeit Cat-branded filters that mimic genuine Caterpillar packaging and logos. These products often originate from unauthorized manufacturers and may infringe on Caterpillar’s trademarks and patents. Purchasing counterfeit filters not only risks engine damage but may also violate intellectual property laws. Buyers should source from authorized distributors or reputable suppliers with traceable supply chains.

Intellectual Property (IP) Infringement Risks

Selling or distributing filters that use Caterpillar’s registered trademarks (such as “Cat” or the Caterpillar logo) without authorization constitutes trademark infringement. Additionally, certain filter designs may be protected by patents, and replicating them without a license can lead to legal consequences. While generic filters that avoid branding and patented designs are legal, it’s essential to ensure that product descriptions and marketing materials do not imply official affiliation.

Lack of Warranty and Support

Genuine Cat oil filters come with manufacturer-backed warranties and technical support. Aftermarket or counterfeit filters often lack these protections. In the event of engine damage, proving filter failure and securing compensation can be difficult without proper documentation and manufacturer accountability.

Conclusion

To avoid these pitfalls, always purchase Cat 3126 oil filters from authorized dealers or trusted suppliers who provide verifiable product specifications and compliance documentation. Prioritize quality and authenticity over cost savings to protect engine longevity and ensure compliance with intellectual property regulations.

Logistics & Compliance Guide for Cat 3126 Oil Filter

Overview and Product Identification

The Cat 3126 Oil Filter is a genuine Caterpillar replacement part designed specifically for use with the Cat 3126 diesel engine. This filter ensures optimal engine performance by removing contaminants from engine oil. Correct identification is essential for compliance and performance. The standard Caterpillar part number is 1R-0772, though equivalent aftermarket part numbers may exist (e.g., Fleetguard LF9007, Baldwin BF7576, Wix 51348). Always verify compatibility with the engine model and serial number.

Regulatory and Environmental Compliance

Handling and disposal of used oil filters are subject to environmental regulations in most jurisdictions. The Cat 3126 Oil Filter contains residual oil and is classified as hazardous waste when spent. Compliance with the following regulations is mandatory:

- U.S. Environmental Protection Agency (EPA) – 40 CFR Part 279: Spent oil filters must be properly drained (crushed or hot-drained) to remove free-flowing oil before disposal. Improper handling may result in fines.

- Resource Conservation and Recovery Act (RCRA): Filters are regulated as solid waste if drained properly; otherwise, they are considered hazardous.

- State and Local Regulations: Many states (e.g., California, Washington) have stricter rules. Confirm local requirements for storage, labeling, and disposal.

- International Standards: In the EU, compliance with the Waste Electrical and Electronic Equipment (WEEE) Directive and national hazardous waste laws may apply. In Canada, follow provincial regulations under the Canadian Environmental Protection Act (CEPA).

Dispose of used filters through certified waste oil recyclers or authorized collection centers. Maintain records of disposal for audit purposes.

Packaging and Labeling Requirements

Ensure proper packaging and labeling throughout the supply chain:

- Original Packaging: Genuine Cat filters are shipped in branded cartons with the part number (1R-0772), Caterpillar logo, and barcodes.

- Hazard Communication (HazCom): While new filters are non-hazardous, packaging should include safe handling instructions. Material Safety Data Sheets (MSDS/SDS) are available from Caterpillar for manufacturing components.

- Storage Labeling: In warehouses, label storage areas clearly. Include part number, quantity, and date received to support inventory management and first-expired, first-out (FEFO) practices.

- Export Labeling: For international shipments, include bilingual (e.g., English/Spanish) labeling where required, and comply with International Maritime Dangerous Goods (IMDG) Code if applicable (usually not required for new filters).

Transportation and Shipping Guidelines

New Cat 3126 Oil Filters are generally non-hazardous and can be shipped via standard freight methods (LTL, parcel, air). Key considerations:

- Domestic (U.S.): Comply with Department of Transportation (DOT) regulations under 49 CFR. Filters are not classified as hazardous materials when new.

- International Shipping: Ensure compliance with IATA (air) or IMDG (sea) regulations. Declare as “Non-hazardous automotive parts” unless contaminated.

- Packaging Integrity: Use sturdy, moisture-resistant packaging to prevent damage. Avoid over-packing to reduce shipping weight and cost.

- Temperature and Storage Conditions: Store and transport in dry, temperature-controlled environments (ideally 40°F–100°F or 4°C–38°C) to prevent seal degradation.

Import/Export Documentation and Duties

When shipping across borders, proper documentation ensures compliance:

- Commercial Invoice: Must include detailed product description (“Oil Filter for Cat 3126 Engine”), part number (1R-0772), quantity, value, country of origin (typically USA), and Harmonized System (HS) Code.

- HS Code: Common classification is 8421.23.00 (filters for machinery) or 8409.91.90 (parts for internal combustion engines). Confirm with customs broker.

- Certificate of Origin: May be required for preferential tariff treatment under trade agreements (e.g., USMCA).

- Import Duties and Taxes: Vary by destination country. Check local tariff schedules. Some countries may impose environmental fees on automotive parts.

- Caterpillar Brand Protection: Beware of counterfeit parts. Use authorized distributors to ensure authenticity and avoid customs seizures.

Inventory Management and Shelf Life

- Shelf Life: Cat oil filters have an indefinite shelf life when stored properly in original packaging. However, inspect seals and gaskets for brittleness if stored over 5 years.

- Stock Rotation: Implement FEFO or FIFO (first-in, first-out) inventory practices.

- Storage Conditions: Keep in a clean, dry area away from direct sunlight and extreme temperatures. Avoid stacking heavy items on filter cartons.

Supplier and Distributor Compliance

- Source filters from authorized Caterpillar dealers or certified distributors to ensure authenticity and traceability.

- Verify supplier compliance with ISO 9001 (quality management) and environmental standards.

- Maintain purchase records for warranty claims and audits.

Disposal and Recycling Best Practices

- Drain Spent Filters: Use a filter puncturing device or centrifuge to remove residual oil. Retain oil for recycling.

- Recycling Programs: Partner with licensed recyclers who process metal casings and filter media.

- Documentation: Retain manifests and certificates of recycling for at least three years.

Summary and Key Compliance Actions

To ensure full compliance in logistics and handling of the Cat 3126 Oil Filter:

– Use correct part number (1R-0772) and verify compatibility.

– Follow EPA and local regulations for spent filter disposal.

– Maintain proper documentation for shipping and customs.

– Store and transport under recommended conditions.

– Partner with authorized suppliers and certified recyclers.

Adhering to this guide minimizes regulatory risk, supports environmental stewardship, and ensures engine reliability.

In conclusion, sourcing the correct oil filter for the Caterpillar 3126 engine is essential for maintaining optimal performance, longevity, and reliability of the engine. It is crucial to identify the exact specifications—such as OEM part number (e.g., CAT 1R-0770 or equivalent cross-references), filter dimensions, filtration efficiency, and bypass valve settings—to ensure compatibility and adequate protection against contaminants. Whether opting for genuine Caterpillar filters or high-quality aftermarket alternatives, verifying authenticity, reliability, and compliance with industry standards (like ISO 4020) is imperative. Additionally, purchasing from authorized dealers or reputable suppliers helps avoid counterfeit products and ensures warranty coverage. Regular maintenance intervals with the proper oil filter contribute significantly to engine efficiency and reduced downtime, making correct sourcing a key component of effective equipment management.