The global caster wheels market is experiencing steady growth, driven by rising demand across industrial, commercial, and institutional applications—particularly in environments with sensitive flooring such as wood. According to Grand View Research, the global caster wheels market size was valued at USD 5.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This growth is fueled by increasing construction and renovation activities, with a growing preference for non-marking, durable casters that protect hardwood and engineered flooring surfaces. As commercial workspaces, healthcare facilities, and residential sectors prioritize floor protection and smooth mobility, manufacturers are innovating with soft tread materials like polyurethane and thermoplastic elastomer (TPE) to meet performance and aesthetic demands. With wood floors commanding a significant share of premium interior finishes, the need for high-performance casters designed specifically for these surfaces has become a critical purchasing factor—making manufacturer quality, material engineering, and load performance more important than ever.

Top 10 Casters For Wood Floors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Colson Caster Homepage

Domain Est. 1995

Website: colsoncaster.com

Key Highlights: Since 1885, Colson Caster’s quality lines of casters and wheels have defined the caster industry. Proudly made in the USA for over 130 years….

#2 3

Domain Est. 1996

Website: store.hermanmiller.com

Key Highlights: In stock Rating 4.3 42 Shop the 3-inch Hard Floor or Carpet Caster and see our wide selection of Replacement Parts at the Herman Miller official store….

#3 POWERNAIL

Domain Est. 1996

Website: powernail.com

Key Highlights: Powernail is the premier company in the hardwood flooring industry for the manufacture of professional grade pneumatic nailers and flooring cleats….

#4 Casterland – Casters Supplier

Domain Est. 1997

Website: casterland.com

Key Highlights: 30-day returnsAs a premier caster manufacturing and wheels supplier, Casterland Canada delivers unparalleled service and inventory to meet your specific requirements….

#5 Casters for Hardwood Floors

Domain Est. 1999

Website: casterconnection.com

Key Highlights: Browse our inventory of swivel, rigid, vintage, locking (with brakes), non-marking, stem mount, plate mount, low-decibel, stainless steel,and ergonomic casters ……

#6 Plate Mounted and Stem Mounted Casters for Display Industry

Domain Est. 2010

Website: lmcaster.com

Key Highlights: Urethane coated iron, urethane plastic, or high-temperature nylon casters work well on inorganic flooring. For vinyl or rubber tiles, urethane coated iron, ……

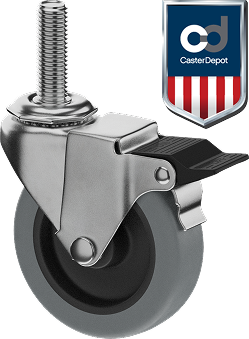

#7 CasterDepot.com

Domain Est. 2011

Website: casterdepot.com

Key Highlights: CasterDepot.com has a wide range of casters, caster wheels and caster accessories available for purchase….

#8 2″ Chair Caster

Domain Est. 2017

Website: casterhq.com

Key Highlights: Rating 5.0 The wheel is 2″ x 3/4″ wide. The metal body has a black oxide finish. Casters with soft rubber wheels provide the best floor protection for hard wood floors. ” ……

#9 The Best Caster Wheels for Hardwood Floors

Domain Est. 2002

Website: castercity.com

Key Highlights: Soft rubber caster wheels are an excellent choice for hardwood floors because they provide a smooth, quiet rolling action that is gentle on your flooring….

#10 Caster Wheels for Hardwood Floors

Domain Est. 2022

Website: castercentral.com

Key Highlights: These wheels provide durability and multi-function use, working well for both carpeted and hardwood floors….

Expert Sourcing Insights for Casters For Wood Floors

H2: 2026 Market Trends for Casters for Wood Floors

The global market for casters designed specifically for wood floors is poised for notable evolution by 2026, driven by shifting consumer preferences, advancements in material technology, and increasing demand across residential, commercial, and healthcare sectors. Key trends shaping the market include:

-

Rise in Hardwood Flooring Popularity

The growing preference for hardwood and engineered wood flooring in homes and offices is directly influencing the demand for floor-safe casters. Consumers are increasingly investing in premium interiors, making protection against scratches and dents a top priority. This trend is driving innovation in soft-wheel caster materials such as polyurethane, rubber, and thermoplastic elastomers (TPE). -

Innovation in Wheel Materials and Design

By 2026, manufacturers are expected to focus on eco-friendly, non-marking, and high-load-bearing caster wheels. Polyurethane casters, known for their durability and floor protection, are gaining dominance. Additionally, hybrid materials that combine strength with silent operation are being developed to meet noise-sensitive environments like libraries, clinics, and high-end homes. -

Growth in Home Office and Ergonomic Furniture

The sustained shift toward remote work has increased demand for ergonomic office furniture—chairs, standing desks, and mobile storage units—all of which require casters compatible with wood flooring. This trend is accelerating demand for lightweight, smooth-gliding, and scratch-resistant casters, particularly in North America and Europe. -

Expansion in Healthcare and Hospitality Sectors

Hospitals, clinics, and luxury hotels are prioritizing quiet, non-marking casters for medical carts, room service trolleys, and cleaning equipment. The need for hygiene, minimal floor damage, and operational quietness is pushing demand for antimicrobial-coated and precision-engineered casters suited for wood and LVT (luxury vinyl tile) hybrid flooring. -

Sustainability and Circular Design

Environmental regulations and consumer awareness are pushing manufacturers toward recyclable materials and modular caster designs that allow for easy repair and component replacement. By 2026, sustainable sourcing and reduced carbon footprint in production are expected to become key differentiators. -

E-Commerce and Direct-to-Consumer Sales Growth

Online retail platforms are making it easier for consumers to access specialized casters tailored for wood floors. Detailed product descriptions, customer reviews, and compatibility guides are improving purchase confidence, contributing to higher online sales volumes. -

Regional Market Dynamics

North America and Western Europe are leading markets due to high homeownership rates and renovation activity. Meanwhile, the Asia-Pacific region is witnessing rapid growth, especially in urban residential and commercial construction, where wood-look flooring is increasingly popular.

In conclusion, the 2026 outlook for casters for wood floors reflects a convergence of design innovation, material science, and evolving end-user needs. Companies that prioritize floor protection, quiet operation, sustainability, and aesthetic integration are likely to capture significant market share in this niche but growing segment.

Common Pitfalls Sourcing Casters for Wood Floors (Quality, IP)

Choosing the Wrong Wheel Material

One of the most frequent mistakes is selecting casters with wheels made from hard materials like steel, hard rubber, or rigid plastic. These can scratch, dent, or mar wood flooring, especially hardwood or finished surfaces. Always opt for soft, non-marking materials such as polyurethane, soft rubber, or specialized thermoplastic elastomers (TPE) that provide smooth rolling without damaging the floor.

Ignoring Load Capacity Specifications

Overlooking the caster’s load rating can lead to premature failure, wheel deformation, or floor damage. Exceeding the weight limit causes the wheels to flatten or crack, increasing the risk of gouging wood floors. Ensure the total load capacity of all casters exceeds the weight of the equipment or furniture by a safety margin (typically 20–25%).

Overlooking Floor Protection Features

Some casters lack protective features like precision bearings, sealed housings, or swivel locks. Poorly designed casters can wobble or shift unexpectedly, concentrating pressure on one spot and damaging the floor. Look for casters with swivel locks and precision ball bearings to ensure stability and even weight distribution.

Failing to Consider IP (Ingress Protection) Ratings

For environments exposed to moisture, dust, or cleaning agents (e.g., commercial kitchens, medical facilities, or workshops), ignoring IP ratings is a critical oversight. Low or no IP protection allows debris and liquids into the wheel mechanism, leading to corrosion, jamming, or increased rolling resistance—potentially dragging and scratching the wood floor during movement.

Selecting Inappropriate Wheel Diameter or Width

Small-diameter or narrow wheels exert higher pressure per square inch on the floor, increasing the likelihood of indentations, particularly on softer woods. Larger and wider wheels distribute weight more evenly, reducing floor damage. Choose appropriately sized wheels based on both load and floor type.

Prioritizing Cost Over Long-Term Value

Opting for the cheapest casters often results in poor materials, weak construction, and short lifespan. Low-quality casters may seem economical initially but can cause expensive floor repairs and frequent replacements. Invest in high-quality, floor-safe casters designed for longevity and performance.

Not Verifying Non-Marking Claims

Not all “non-marking” casters are created equal. Some lower-tier products may leave residue or scuff marks over time. Verify claims through product testing, reviews, or manufacturer specifications that confirm compatibility with hardwood or delicate finishes.

Overlooking Installation Compatibility

Mismatched mounting styles (e.g., plate vs. stem) or incorrect dimensions can lead to improper installation, resulting in instability or uneven weight distribution. This can cause furniture to tilt or shift, dragging casters across the wood floor and creating scratches. Always confirm mounting type and dimensions match your application.

Logistics & Compliance Guide for Casters for Wood Floors

Product Classification and HS Codes

When shipping casters designed specifically for wood floors, accurate product classification is essential for international trade compliance. These casters typically fall under Harmonized System (HS) codes related to wheels, casters, or furniture fittings. Common classifications include 8302.50 (wheels and casters for furniture) or 8716.90 (other parts and accessories of vehicles, if applicable). Confirm the exact HS code with your destination country’s customs authority, as misclassification can lead to delays, fines, or seized shipments.

Regulatory Compliance – Flooring Safety and Materials

Casters intended for use on wood floors must meet material safety and performance standards to prevent floor damage. Compliance with ASTM F627 (Standard Practice for Evaluating Performance of Casters on Resilient Flooring) is recommended, even though it primarily addresses commercial flooring. Additionally, ensure caster materials (e.g., thermoplastic rubber, polyurethane) are non-marking, non-abrasive, and free from phthalates or heavy metals restricted under regulations like REACH (EU) or CPSIA (USA).

Packaging and Shipping Requirements

Proper packaging is crucial to prevent damage during transit and ensure product integrity. Use durable, corrugated cardboard boxes with internal dividers or blister packs to secure individual casters. Label packages with weight, handling instructions (e.g., “Fragile,” “This Side Up”), and product specifications. For bulk shipments, palletize using stretch wrap and corner boards. Include packing lists and commercial invoices with clear descriptions such as “Non-Marking Casters for Hardwood Furniture” to facilitate customs clearance.

Import/Export Documentation

Prepare complete documentation for international shipments, including:

– Commercial invoice with itemized description, unit price, total value, and Incoterms (e.g., FOB, DDP)

– Packing list detailing carton count, weight, and dimensions

– Bill of Lading (BOL) or Air Waybill (AWB)

– Certificate of Origin, if claiming preferential tariffs under trade agreements

– Product compliance certificates (e.g., REACH, RoHS, if applicable)

Ensure all documents clearly state the intended use: “Casters for Use on Wood Floors – Non-Marking Design.”

Environmental and Chemical Compliance

Verify that caster materials comply with environmental regulations in target markets. In the European Union, ensure adherence to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances). In the U.S., confirm compliance with California Proposition 65 if applicable, particularly for phthalates or lead content. Suppliers should provide Material Safety Data Sheets (MSDS) or Safety Data Sheets (SDS) upon request.

Labeling and Product Marking

Each caster or retail package must include clear labeling with:

– Manufacturer or brand name

– Material type (e.g., “Soft Polyurethane Tread”)

– Load capacity rating (e.g., “Max 150 lbs per caster”)

– Compliance marks (e.g., CE, UKCA, if marketed in Europe)

– Warning statements such as “For Use on Hard Floors Only – Avoid Carpet”

Proper labeling supports end-user safety and reduces liability risks.

Warranty and Returns Logistics

Establish a clear returns policy for defective or damaged casters. Designate return centers or partner with third-party logistics (3PL) providers in key markets to handle reverse logistics efficiently. Include warranty information (e.g., “1-Year Limited Warranty Against Defects”) in packaging and online listings to meet consumer protection standards in regions like the EU and North America.

Storage and Handling Guidelines

Advise distributors and retailers on proper storage: keep casters in a cool, dry place away from direct sunlight and extreme temperatures to prevent material degradation. Avoid stacking heavy items on packaged casters to prevent deformation. Provide handling instructions to maintain product performance and appearance prior to sale.

By adhering to this logistics and compliance framework, businesses can ensure smooth distribution, regulatory alignment, and customer satisfaction for casters designed for wood floor applications.

In conclusion, sourcing the right casters for wood floors requires careful consideration of material, weight capacity, wheel size, and floor protection. Soft, non-marking materials such as polyurethane, rubber, or thermoplastic elastomer (TPE) are ideal for preventing scratches, dents, and scuff marks on wooden surfaces. Ensuring the caster’s load capacity meets or exceeds the weight of the furniture or equipment helps maintain durability and smooth mobility. Larger wheels typically roll more easily and distribute weight better, reducing floor indentation. Additionally, choosing swivel casters enhances maneuverability, while incorporating brakes can provide added stability when needed. By prioritizing floor-friendly materials and appropriate specifications, you can maintain the aesthetic and structural integrity of your wood floors while ensuring functional and long-lasting caster performance.