The global caster wheel and hardware market has seen steady expansion, driven by increasing demand across industrial, healthcare, and logistics sectors. According to Mordor Intelligence, the global caster wheels market was valued at approximately USD 5.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2029. This growth is underpinned by rising industrial automation, e-commerce warehouse expansion, and the need for efficient material handling solutions. As critical components in mobility systems, caster screws—responsible for securing casters to equipment frames—have gained prominence in both performance and durability specifications. With manufacturers increasingly focusing on load capacity, corrosion resistance, and ease of installation, the demand for high-quality caster screws has intensified. In this competitive landscape, a select group of manufacturers have distinguished themselves through innovation, precision engineering, and comprehensive product offerings. Based on market presence, product range, and technical capabilities, the following analysis highlights the top 10 caster screws manufacturers shaping the industry’s future.

Top 10 Caster Screws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 STEINCO

Domain Est. 1996

Website: steinco.com

Key Highlights: STEINCO – manufacturer of swivel castors, twin wheel castors, rigid casters & more. Use our product search & get detailed product information here!…

#2 Albion Casters: The Caster Experts

Domain Est. 2000

Website: albioncasters.com

Key Highlights: Trust Albion Casters: the Caster Experts for your Industrial-Strength Caster needs. Swivel and rigid casters and wheels for industrial uses….

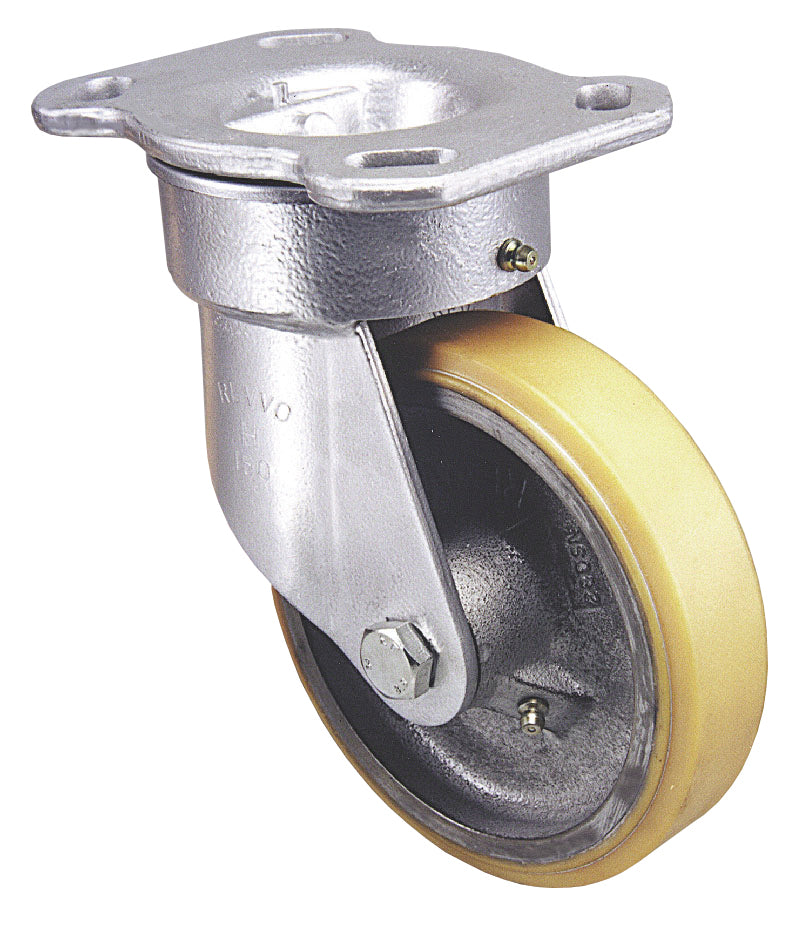

#3 Revvo Caster

Domain Est. 2001

Website: revvocaster.com

Key Highlights: Revvo is part of the leading manufacturing company worldwide of casters and wheels for medical, industrial, commercial, and institutional applications….

#4 Caster City

Domain Est. 2002

Website: castercity.com

Key Highlights: YOUR TRUSTED CASTER MANUFACTURER AND DISTRIBUTOR. Simply provide your details and caster requirements and one of our expert sales engineers will be in touch….

#5 Casters

Domain Est. 2013

Website: proxdirect.com

Key Highlights: Single 8-inch Industrial Grade Caster Wheel for ProX ATA Flight Utility Console Speaker Cases – Plate 4.5 x 4 in. 14mm Magnetic Hex Socket for Bolts – 65mm ……

#6 McMaster

Domain Est. 1994

Website: mcmaster.com

Key Highlights: McMaster-Carr is the complete source for your plant with over 700000 products. 98% of products ordered ship from stock and deliver same or next day….

#7 Aerol Casters: Military

Domain Est. 1997

Website: aerol.com

Key Highlights: Aerol is renowned for its exceptional design and manufacturing of premium casters, running gear, and ground support equipment….

#8 Stainless Steel Casters, Swivel Brake & Replacement Wheels …

Domain Est. 1999

Website: allstatescasters.com

Key Highlights: Explore a wide selection of stainless steel casters, replacement caster wheels, cart and metal caster wheels, swivel brake casters, and medium-duty casters….

#9 CasterDepot.com

Domain Est. 2011

Website: casterdepot.com

Key Highlights: CasterDepot.com has a wide range of casters, caster wheels and caster accessories available for purchase….

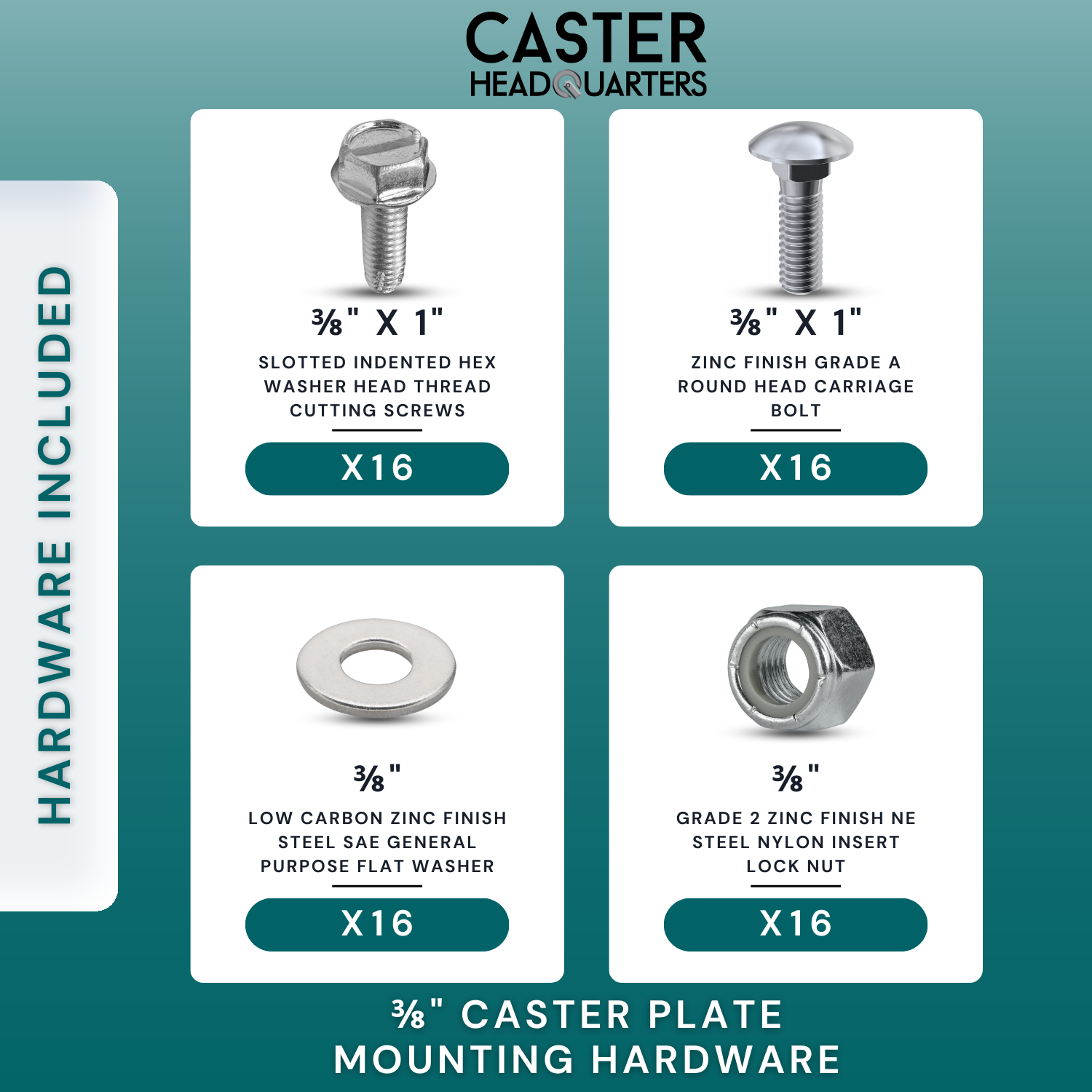

#10 Caster Plate Mounting Hardware & Bolts

Domain Est. 2017

Website: casterhq.com

Key Highlights: Free delivery over $250 30-day returnsWe provide a comprehensive selection of caster mounting hardware, including bolts, screws, washers, and lock nuts, ready to ship immediately….

Expert Sourcing Insights for Caster Screws

2026 Market Trends for Caster Screws

As industrial automation, logistics, and material handling sectors continue to evolve, the market for caster screws—a critical yet often overlooked component in mobility systems—is poised for notable shifts by 2026. These small fasteners play a vital role in securing casters to equipment such as carts, medical devices, industrial machinery, and furniture. The following analysis outlines key trends expected to shape the caster screw market in 2026.

Rising Demand in Material Handling and E-Commerce Logistics

The exponential growth of e-commerce and warehouse automation is a primary driver for caster screw demand. With fulfillment centers expanding globally and investing in mobile shelving units, automated guided vehicles (AGVs), and conveyor systems, the need for durable, high-performance caster assemblies—including reliable screws—is increasing. By 2026, the material handling sector is projected to account for over 40% of caster screw consumption, particularly in North America and Asia-Pacific.

Manufacturers are responding by producing corrosion-resistant, load-rated caster screws compatible with smart logistics equipment. Stainless steel and zinc-plated variants are gaining preference due to their longevity in high-traffic environments.

Shift Toward Lightweight and High-Strength Materials

In tandem with broader engineering trends, caster screw producers are focusing on lightweight yet durable materials. Aluminum alloy and high-tensile steel screws are becoming more common, especially in applications requiring reduced equipment weight without compromising structural integrity—such as medical carts and aerospace ground support tools.

By 2026, innovations in composite-metal hybrid fasteners may begin to enter niche markets, offering improved fatigue resistance and vibration damping. These advancements are particularly relevant in industries where equipment reliability is critical.

Growth in Medical and Healthcare Equipment

The healthcare sector is emerging as a high-growth market for precision caster screws. With increasing demand for mobile medical carts, patient beds, diagnostic equipment, and surgical tables, manufacturers require screws that meet strict regulatory standards for hygiene, strength, and noise reduction.

Antimicrobial coatings and smoother thread designs to minimize wear and noise are expected to become standard features by 2026. Additionally, compliance with ISO 13485 and FDA regulations will be a key differentiator for suppliers targeting medical applications.

Regional Manufacturing Shifts and Supply Chain Localization

Geopolitical factors and supply chain resilience concerns are prompting companies to localize production. In 2026, North America and Europe are likely to see a rise in regional caster screw manufacturing to reduce dependency on Asian imports, particularly China.

Nearshoring trends in Mexico and Eastern Europe are creating opportunities for local suppliers who can offer just-in-time delivery and customized fastener solutions. This shift is also encouraging greater investment in automation and precision machining technologies to maintain cost competitiveness.

Sustainability and Circular Economy Initiatives

Environmental regulations and corporate sustainability goals are influencing product design. By 2026, recyclability and reduced carbon footprint will be key considerations in caster screw production. Manufacturers are exploring closed-loop recycling of metals, energy-efficient manufacturing processes, and minimal packaging.

Some industry leaders are beginning to offer take-back programs for used caster assemblies, enabling the recovery and reuse of screws and other components—aligning with circular economy principles.

Smart Fasteners and Integration with IoT

While still in early stages, the integration of smart technologies into fasteners could impact the caster screw market by 2026. Embedded sensors in high-value applications—such as aerospace or critical medical devices—could monitor screw tension, temperature, or wear over time.

Though widespread adoption is unlikely before 2030, pilot programs and R&D investments in “smart fasteners” are expected to increase, particularly in industries where predictive maintenance and equipment uptime are paramount.

Conclusion

The caster screw market in 2026 will be shaped by technological innovation, regional manufacturing dynamics, and growing demand from high-performance sectors like logistics, healthcare, and automation. While traditionally a commoditized product, caster screws are evolving into engineered components with specialized material, regulatory, and performance requirements. Companies that invest in quality, sustainability, and application-specific solutions will be best positioned to capture market share in this increasingly sophisticated landscape.

Common Pitfalls When Sourcing Caster Screws (Quality, IP)

Sourcing caster screws may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to significant operational, legal, and reputational risks. Below are common pitfalls to avoid:

Poor Material and Manufacturing Quality

Low-cost caster screws often use substandard materials (e.g., low-grade steel or zinc-plated fasteners) that lack durability, leading to premature failure under load or in harsh environments. Inadequate heat treatment or poor thread precision can result in stripping, breakage, or inconsistent torque performance. These failures compromise equipment safety and increase maintenance costs.

Misrepresentation of IP and Design Infringement

Some suppliers may offer screws that closely mimic patented or proprietary designs (e.g., specialized thread profiles, locking mechanisms, or integrated features). Sourcing such components without proper licensing can expose your company to intellectual property infringement claims, legal disputes, and supply chain disruptions.

Inconsistent Compliance with Industry Standards

Caster screws used in regulated industries (e.g., medical, automotive, aerospace) must often meet specific standards (e.g., ISO, DIN, ASTM). Suppliers may claim compliance without proper certification or traceability, risking non-conformance and product recalls.

Lack of Traceability and Documentation

Reputable suppliers provide material certifications (e.g., mill test reports), batch traceability, and quality control documentation. Omitting these makes it difficult to verify quality, investigate failures, or meet audit requirements—especially critical in safety-sensitive applications.

Overlooking Environmental and Corrosion Resistance

For outdoor or corrosive environments, screws require appropriate coatings (e.g., hot-dip galvanizing, stainless steel). Sourcing screws with inadequate IP ratings (Ingress Protection) or corrosion resistance leads to rust, seizing, and functional degradation over time.

Supplier Reliability and Hidden Costs

Choosing suppliers based solely on low unit price can backfire. Unreliable delivery, poor communication, and hidden costs from rework or downtime due to defective screws often outweigh initial savings. Additionally, unauthorized resellers may lack technical support or warranty coverage.

Avoiding these pitfalls requires thorough supplier vetting, clear specifications, and due diligence on both quality assurance processes and IP compliance.

Logistics & Compliance Guide for Caster Screws

Overview

Caster screws—also known as stem screws or mounting screws—are essential components used to attach casters to furniture, equipment, and industrial machinery. Proper logistics handling and compliance with regulations ensure product quality, safety, and legal adherence during manufacturing, shipping, and distribution.

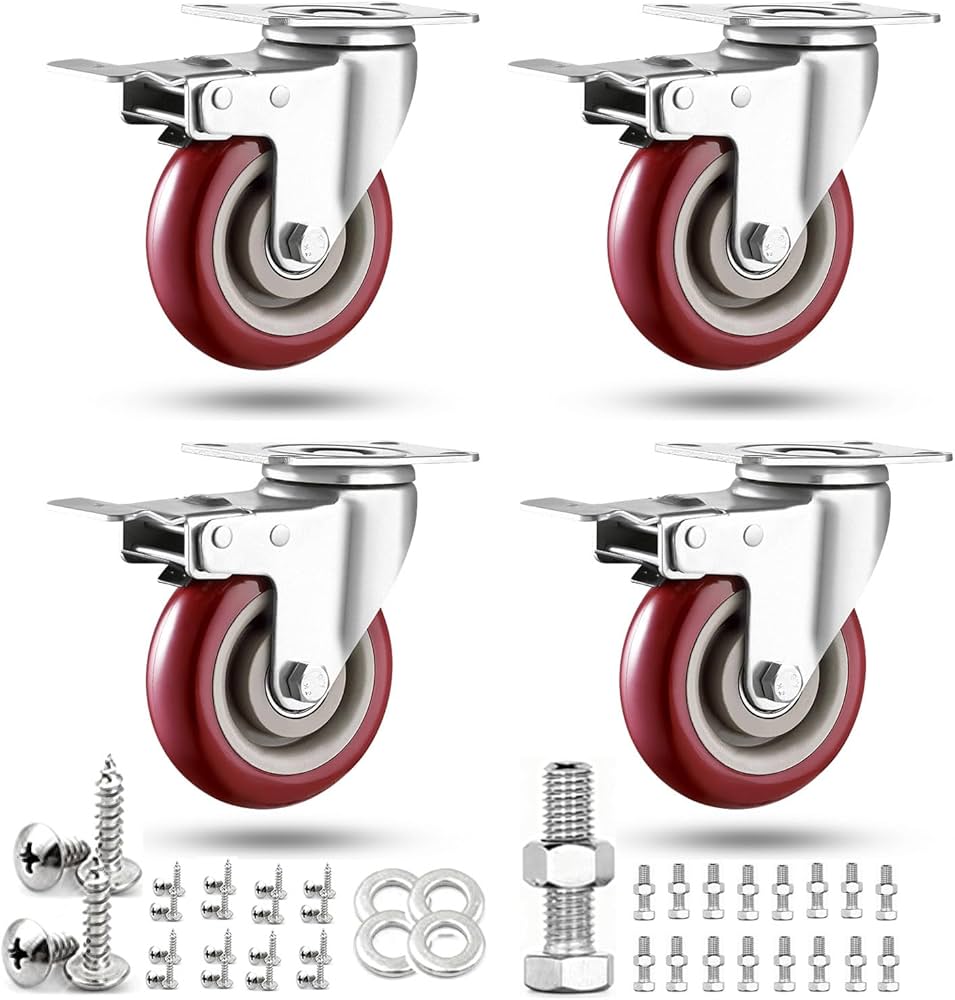

Material and Packaging Specifications

Caster screws are typically made from carbon steel, stainless steel, or zinc-plated alloys. They must be packaged to prevent corrosion, damage, and contamination.

– Use moisture-resistant packaging (e.g., vacuum-sealed bags or VCI paper) for metal screws.

– Bulk packaging should include labeled poly bags or corrugated boxes with dividers to avoid tangling.

– Individual blister packs or clamshells are recommended for retail distribution.

– Clearly label packages with product ID, material type, size, quantity, and compliance marks.

Transportation and Storage

Proper handling during transit and storage is crucial to maintain product integrity.

– Store in a dry, temperature-controlled environment to prevent rust and degradation.

– Stack containers securely to avoid crushing or deformation.

– Use standard pallet configurations (e.g., 48” x 40”) for efficient loading and compliance with carrier requirements.

– Avoid exposure to extreme temperatures or corrosive substances during transport.

– Follow international shipping standards (e.g., ISTA 3A) for vibration and drop testing when exporting.

Regulatory Compliance

Caster screws must meet regional and international regulatory standards depending on the application and destination market.

– RoHS (EU): Comply with Restriction of Hazardous Substances Directive if sold in the European Union. Ensure lead, cadmium, and other restricted substances are below permissible limits.

– REACH (EU): Register and report SVHCs (Substances of Very High Concern) as required.

– Proposition 65 (California, USA): Provide warnings if screws contain listed chemicals such as lead or chromium.

– UL/CSA (North America): While not always required for individual screws, compliance may be necessary if part of a certified assembly.

– Customs & Tariff Classification: Classify under the appropriate HS Code (e.g., 7318.15 for threaded screws of iron or steel). Provide accurate documentation including commercial invoices, packing lists, and certificates of origin.

Export Documentation

For international shipments, ensure all required documents are complete and accurate.

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (preferably with chamber of commerce stamp)

– Material Test Reports (MTRs) upon request

– RoHS or REACH Compliance Declaration (if applicable)

Quality Assurance & Traceability

Maintain rigorous quality control and traceability protocols.

– Implement ISO 9001-compliant quality management systems.

– Conduct regular inspections for thread accuracy, strength, and surface finish.

– Use batch numbering for full traceability from raw material to final shipment.

– Retain test records and inspection reports for a minimum of five years.

Environmental and Sustainability Considerations

- Recycle scrap metal and packaging materials wherever possible.

- Source materials from suppliers with sustainable practices.

- Minimize packaging waste through optimized design and reusable containers.

- Comply with WEEE (Waste Electrical and Electronic Equipment) directives if screws are used in EEE products.

Conclusion

Effective logistics and compliance management for caster screws ensures reliability, safety, and market access. Adhering to packaging, transportation, regulatory, and environmental standards supports long-term business success and customer satisfaction. Regular audits and updates to compliance protocols are recommended to respond to evolving regulations.

In conclusion, sourcing caster screws requires careful consideration of several key factors including material quality, thread type and size, load capacity, corrosion resistance, and compatibility with the intended caster and equipment. Evaluating suppliers based on reliability, lead times, cost-effectiveness, and adherence to industry standards ensures a consistent supply of durable and high-performing components. By prioritizing these aspects, organizations can enhance equipment functionality, prolong lifespan, reduce maintenance costs, and support operational efficiency. Proper sourcing of caster screws, though a small detail, plays a significant role in the overall performance and safety of mobile equipment across industrial, commercial, and medical applications.