The global cast steel anvil market has seen steady growth, driven by increasing demand from metalworking, construction, and manufacturing sectors. According to Grand View Research, the global metal forging market—of which cast steel anvils are a critical component—was valued at USD 107.3 billion in 2022 and is projected to expand at a CAGR of 5.8% from 2023 to 2030. This growth is fueled by rising industrialization, particularly in Asia-Pacific and emerging economies, where infrastructure development and small-scale metal fabrication are expanding. Additionally, Mordor Intelligence reports that demand for durable, high-impact tools like cast steel anvils is being bolstered by a resurgence in blacksmithing, custom metalwork, and the automotive aftermarket. With performance and material integrity being paramount, manufacturers that leverage advanced heat treatment processes and high-purity steel alloys are gaining market share. Below are the top five cast steel anvil manufacturers recognized for their product quality, innovation, and global reach.

Top 5 Cast Steel Anvil Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Finkl Steel

Domain Est. 1996

Website: finkl.com

Key Highlights: Finkl Steel® is the world’s leading supplier of forging die steels, plastic mold steels, die casting tool steels and custom open-die forgings, processing over ……

#2 Trying to ID Swedish cast steel anvil

Domain Est. 2001

Website: iforgeiron.com

Key Highlights: The marking on the side says “Best Swedish Solid Cast Steel Made in Sweden”, stamped around a maker’s mark that I can’t quite make out. It looks like a P and a ……

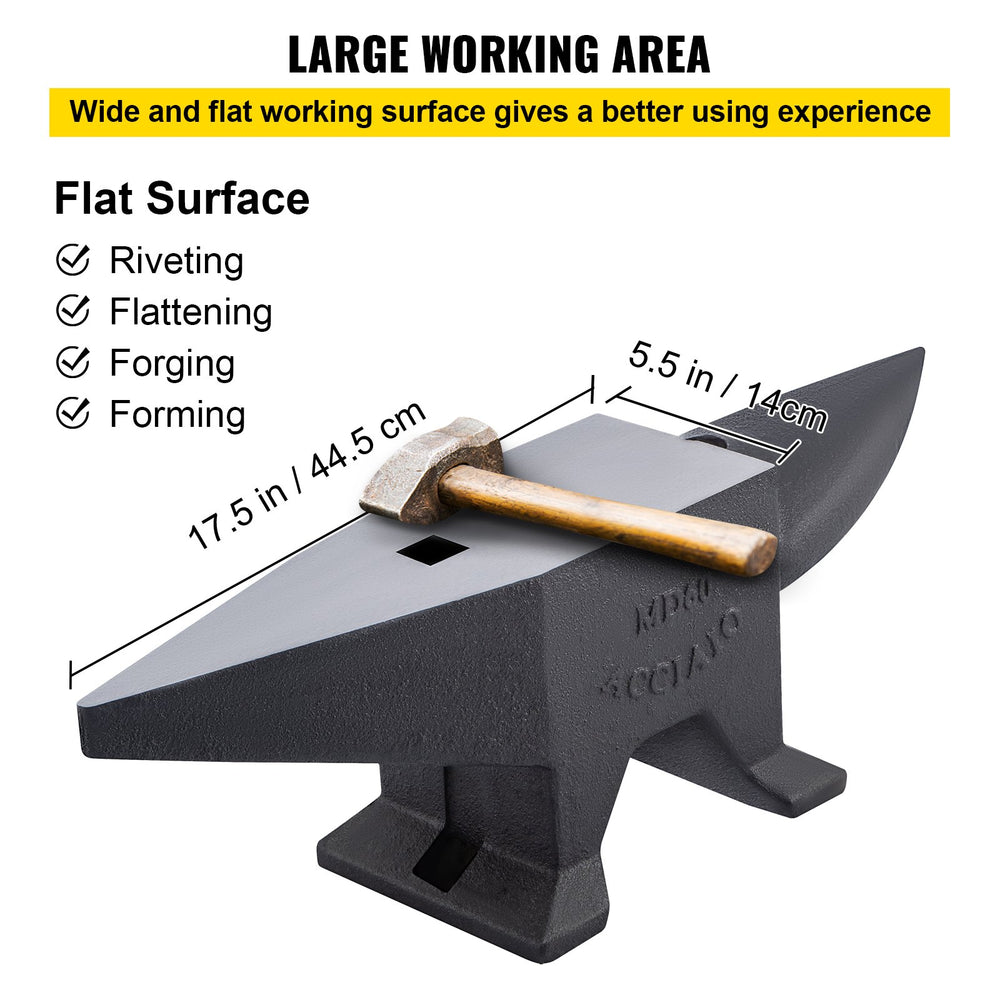

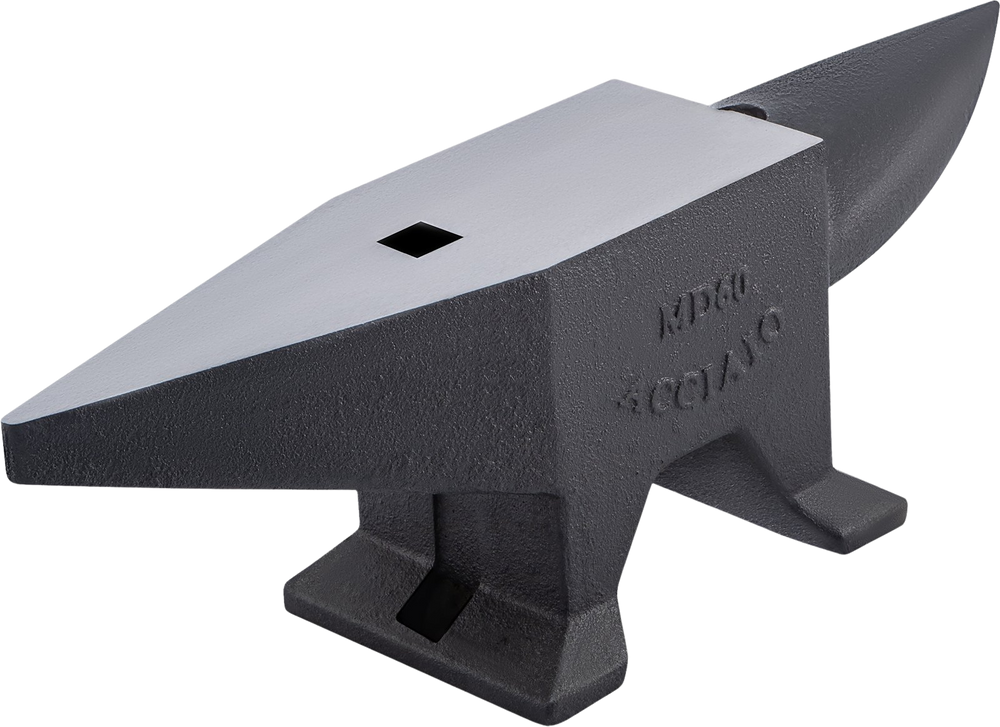

#3 VEVOR cast Steel Anvil

Domain Est. 2009

Website: vevor.com

Key Highlights: Free delivery · 30-day returnsHave an inner creativity? Spread the colors using a cast steel anvil from VEVOR. With durability and complete shaping, you enable flexibility….

#4 Woodward Fab 66 Lb. Cast Steel Anvil

Domain Est. 2018

Website: brightsteelsolutions.com

Key Highlights: Free delivery 14-day returnsThis classic Italian pattern anvil is constructed of high quality cast steel, providing excellent hammer rebound and high impact toughness….

#5 Anvil Products

Domain Est. 2020

Website: asc-es.com

Key Highlights: ASC Engineered Solutions’ Anvil brand is the industry standard in precision-engineered hangers, supports, press-fit and pipe fitting solutions….

Expert Sourcing Insights for Cast Steel Anvil

H2: 2026 Market Trends for Cast Steel Anvils

Based on current industry trajectories, technological shifts, and economic forecasts, the market for cast steel anvils in 2026 is expected to exhibit the following key trends:

-

Stabilizing but Niche Demand: The primary market for cast steel anvils (blacksmithing, farriery, artisan metalworking, and some specialized manufacturing) will remain relatively stable but highly specialized. Demand will be driven by traditional crafts, restoration work, hobbyists, and small-scale artisans rather than mass industrial applications. Growth will be modest, closely tied to the popularity of craft movements and skilled trades education.

-

Competition from Ductile Iron and Alternative Materials: Cast steel anvils will face continued competition from high-quality ductile iron (nodular iron) anvils. Ductile iron offers excellent shock absorption, reduced rebound, and is significantly cheaper to produce than forged or high-grade cast steel. While purists favor steel for weldability and repairability, the performance and cost advantages of modern ductile iron will capture a substantial segment of the mid-tier market. Alternative solutions like improvised anvils (railroad track, heavy machinery parts) will persist, especially among hobbyists seeking lower cost.

-

Focus on Quality, Brand Reputation, and Heritage: In the premium segment, demand will center on anvils from reputable manufacturers known for quality steel (properly heat-treated), consistent casting (minimal defects), and proven durability. Brand heritage and craftsmanship will be significant value drivers. Buyers will prioritize longevity and performance over the lowest price, sustaining a market for higher-cost cast steel anvils from established foundries.

-

Impact of Global Manufacturing and Trade:

- Cost Pressure: Global competition, particularly from manufacturers in countries with lower production costs, will keep pressure on pricing for standard cast steel anvils. This may lead to consolidation or specialization among Western foundries.

- Supply Chain Resilience: Ongoing geopolitical tensions and supply chain considerations may influence sourcing decisions. Buyers may show a preference for domestically produced (e.g., North American, European) anvils if reliability and ethical sourcing are priorities, potentially supporting regional manufacturers despite higher costs.

- Raw Material Volatility: Fluctuations in the price of steel scrap and alloying elements will directly impact production costs and final anvil prices, requiring manufacturers to manage margins carefully.

-

Digital Influence and Direct-to-Consumer (D2C) Sales: Online marketplaces (eBay, Etsy, specialized metalworking suppliers) and manufacturer D2C websites will remain the dominant sales channels. Detailed product information, customer reviews, video demonstrations, and strong online communities (forums, social media groups) will be crucial for marketing and influencing purchasing decisions. Transparency about materials and manufacturing processes will be increasingly important.

-

Sustainability Considerations (Emerging Trend): While not yet a primary driver, awareness of sustainability may grow. Factors like the energy intensity of steel casting, the recyclability of the anvils themselves, and local manufacturing (reducing transport emissions) could become minor differentiating factors for some environmentally conscious buyers or institutions.

In Summary for 2026: The cast steel anvil market will be characterized by a stable core demand within traditional crafts, intense competition from cost-effective alternatives like ductile iron, and a premium segment reliant on brand reputation and proven quality. Success will depend on manufacturers emphasizing durability, transparency, and heritage, while effectively navigating global cost pressures and leveraging digital sales and marketing channels. The market will remain specialized, serving dedicated professionals and passionate hobbyists rather than experiencing broad industrial growth.

Common Pitfalls When Sourcing Cast Steel Anvils (Quality and Intellectual Property)

Sourcing cast steel anvils can be cost-effective, but it comes with significant risks related to quality consistency and intellectual property (IP) concerns. Being aware of these pitfalls helps avoid substandard products and potential legal issues.

Poor Material Quality and Inconsistent Hardness

One of the most frequent issues with cast steel anvils is inconsistent metallurgical quality. Unlike forged anvils, cast steel may contain internal porosity, inclusions, or uneven grain structure, leading to weak spots. Additionally, improper or inconsistent heat treatment can result in inadequate surface hardness, causing the anvil to dent or deform under hammer blows. Buyers often discover too late that the claimed hardness (e.g., HRC 50–55) is not uniformly achieved across the striking face.

Inaccurate or Misleading Product Specifications

Suppliers may exaggerate anvil specifications such as weight, dimensions, or steel grade (e.g., claiming “40Cr” or “45# steel” without certification). Without independent material testing reports (e.g., mill test certificates), it’s difficult to verify these claims. This misrepresentation can lead to receiving anvils that are undersized, underweight, or made from lower-grade steel than advertised.

Lack of Intellectual Property Due Diligence

Many low-cost cast steel anvils mimic the design and branding of well-known anvil manufacturers (e.g., Peter Wright, Peddinghaus). Sourcing such products—even unknowingly—can expose buyers to intellectual property infringement risks, including trademark or design patent violations. Customs authorities in some countries may seize shipments deemed counterfeit, leading to delays, fines, or reputational damage.

Inadequate Finishing and Surface Defects

Cast steel anvils often require extensive post-casting machining and finishing. Poorly sourced anvils may exhibit rough surfaces, flash (excess material from casting seams), or uneven grinding, particularly on the horn and face. These defects not only affect usability but also suggest lower production standards overall.

Weak Structural Integrity and Premature Failure

Due to inherent flaws in the casting process and insufficient quality control, cast steel anvils are more prone to cracking, chipping, or even catastrophic failure under heavy use. Buyers may not realize the anvil lacks structural integrity until it fails during use, posing safety hazards and resulting in costly replacements.

Limited Warranty and After-Sales Support

Many suppliers of cast steel anvils, especially those from regions with lax manufacturing regulations, offer little to no warranty or customer support. If defects arise, resolving claims can be difficult due to language barriers, lack of legal recourse, or supplier unresponsiveness—leaving buyers with no remedy.

Conclusion

To avoid these pitfalls, buyers should demand material certifications, conduct third-party inspections, verify IP compliance, and work with reputable suppliers. Investing in due diligence upfront reduces the risk of receiving a low-quality or legally problematic product.

Logistics & Compliance Guide for Cast Steel Anvil

Product Classification & Documentation

Ensure the cast steel anvil is correctly classified under the Harmonized System (HS) Code, typically 8466.30 (parts and accessories for machine tools, including anvils). Prepare accurate commercial invoices, packing lists, and certificates of origin. Include detailed product specifications such as weight, dimensions, material composition (e.g., ASTM A48 Class 30 gray cast iron or equivalent), and manufacturing standards to facilitate customs clearance.

Export Controls & Regulatory Compliance

Verify that the shipment complies with export regulations in the country of origin. Cast steel anvils are generally not subject to strict export controls (e.g., EAR or ITAR in the U.S.), but confirm with local authorities if any licensing is required, especially for destinations under trade sanctions. Ensure compliance with International Labour Organization (ILO) and environmental standards related to manufacturing processes.

Packaging & Handling Requirements

Package the anvil securely using wooden crates or steel-reinforced pallets to prevent damage during transit. Include cushioning materials and anti-corrosion protection (e.g., VCI paper or rust inhibitor coating) to safeguard against moisture. Clearly label packages with handling instructions (e.g., “Heavy,” “This Side Up,” “Fragile”) and include proper shipping marks, barcodes, and safety warnings as needed.

Transportation & Freight Management

Use heavy-duty freight options such as full container load (FCL) sea freight or flatbed trucks for land transport due to the anvil’s weight and density. Confirm carrier capacity and loading/unloading capabilities at origin and destination. Consider incoterms (e.g., FOB, CIF) clearly in contracts to define responsibilities for shipping, insurance, and risk transfer.

Customs Clearance & Duties

Submit all required documentation to customs authorities at the destination, including import declarations, bills of lading, and conformity certificates. Be prepared to pay applicable import duties and value-added taxes (VAT), which vary by country. Some regions may require product conformity assessments (e.g., CE marking in the EU or SONCAP in Nigeria); verify local certification needs in advance.

Safety & Environmental Compliance

Ensure the product meets relevant safety standards for industrial equipment in the destination market. Though anvils are simple tools, compliance with occupational safety regulations (e.g., OSHA in the U.S. or Machinery Directive 2006/42/EC in the EU) may apply to workplace use. Confirm that manufacturing and packaging materials comply with environmental directives such as REACH or RoHS if applicable.

Recordkeeping & Traceability

Maintain comprehensive records of all shipments, including compliance documentation, test reports, and transaction details for a minimum of five years. Implement a traceability system using batch or serial numbers to support quality control and facilitate recalls or audits if necessary.

In conclusion, sourcing cast steel anvils requires a careful evaluation of material quality, manufacturing processes, supplier reliability, and cost-effectiveness. While cast steel anvils can offer a more affordable alternative to forged anvils, their performance and durability heavily depend on proper heat treatment and the use of high-quality alloy steel. Buyers should prioritize suppliers with proven track records, certifications, and transparency in metallurgical specifications to ensure long-term functionality and safety in use. For most serious blacksmithing applications, investing in a well-made forged anvil is often preferable—but when sourced wisely, a high-quality cast steel anvil can serve as a viable option for hobbyists or light-duty use. Ultimately, due diligence in sourcing ensures that the anvil meets performance expectations and provides reliable service over time.