The global shower tray market is experiencing steady growth, driven by rising residential and commercial construction activities, increasing demand for durable and low-maintenance bathroom fixtures, and a growing preference for premium materials such as cast iron. According to Grand View Research, the global bathroom fixtures market was valued at USD 54.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. Cast iron, known for its exceptional strength, longevity, and timeless aesthetic, remains a preferred choice for high-end shower floor applications despite competition from materials like acrylic and fiberglass. Its superior heat retention, resistance to chipping, and ease of cleaning make it a top contender in luxury and commercial installations alike. As demand for durable and sustainable bathroom solutions grows—particularly in North America and Europe—manufacturers specializing in cast iron shower floors are expanding production and innovation efforts to meet evolving consumer expectations. In this data-backed landscape, identifying the top performers in quality, design, and market presence becomes essential for architects, builders, and homeowners alike.

Top 7 Cast Iron Shower Floor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sterling Plumbing

Domain Est. 1994

Website: sterling.kohler.com

Key Highlights: From easy installation to rock-solid durability, check out why STERLING ® products are the pros’ choice for getting the job done on time and on budget….

#2 Shower Bases

Domain Est. 1996

Website: acorneng.com

Key Highlights: Acorn’s precast, commercial shower bases are available in Terrazzo and Solid Surface materials with ADA-compliant options. Durable, easy to maintain, ……

#3 Cast Marble Shower Pans for Hotels & Multifamily

Domain Est. 1997

Website: minceymarble.com

Key Highlights: Discover Mincey Marble’s durable, groutless shower pans built for hotels, apartments, and student housing. Low maintenance and made in the USA….

#4 Porcelain Shower Base Options

Domain Est. 1997

Website: bootz.com

Key Highlights: Bootz Offers Brilliant Porcelain Shower Base Options Including Various Shower Base Dimensions….

#5 Vintage Tub & Bath

Domain Est. 2000

Website: vintagetub.com

Key Highlights: Vintage Tub & Bath, a leading bath & kitchen hardware supplier carries the industry’s highest quality bath & kitchen products for affordable prices….

#6 Onyx Shower Bases

Domain Est. 2001

Website: onyxcollection.com

Key Highlights: Standard Shower Base Options: Low Profile Curb, Mid Height Curb, Full Height Curb, Neo Angle, Dual Curb, Low Profile with Ramp….

#7 Cast Iron Adjustable Shower Drains

Domain Est. 2021

Website: ipsplumbingproducts.com

Key Highlights: Cast Iron Adjustable Shower Drains · Cast Iron Adjustable Shower Drain – Round Cast Brass Grate · Cast Iron Adjustable Shower Drain – Square Cast Brass Grate….

Expert Sourcing Insights for Cast Iron Shower Floor

H2: 2026 Market Trends for Cast Iron Shower Floors

The cast iron shower floor market is poised for notable shifts by 2026, influenced by evolving consumer preferences, sustainability demands, and advancements in bathroom design. While cast iron remains a premium material due to its durability and timeless appeal, several key trends are expected to shape its market trajectory over the next few years.

-

Growing Demand for Vintage and Classic Aesthetics

A resurgence in vintage and traditional bathroom designs is expected to drive demand for cast iron shower floors. Homeowners and designers seeking a nostalgic, high-end look—often associated with clawfoot tubs and period-style bathrooms—are increasingly opting for cast iron fixtures. This trend is particularly strong in home renovation and luxury real estate sectors, where aesthetic authenticity adds value. -

Premiumization and Customization

Consumers are increasingly willing to invest in high-quality, long-lasting bathroom components. Cast iron shower floors, known for their robustness and ability to retain heat, are being positioned as premium products. Manufacturers are responding with customizable options in color, finish, and size, allowing integration into diverse bathroom styles—from farmhouse chic to modern classical. -

Sustainability and Longevity Focus

As eco-consciousness grows, the long lifespan of cast iron—often exceeding 50 years with proper care—makes it an attractive sustainable choice. Unlike plastic or fiber-reinforced alternatives that degrade over time, cast iron is recyclable and requires minimal replacement, aligning with circular economy principles. This durability is a key selling point in green building certifications and environmentally driven renovations. -

Competition from Lightweight Alternatives

Despite its benefits, cast iron faces growing competition from lighter, more cost-effective materials such as solid surface composites, engineered stone, and high-density polymers. These alternatives offer easier installation and lower structural requirements, appealing to modern construction practices. By 2026, the cast iron segment may remain niche, dominant in high-end and restoration markets but less prevalent in new mass-market builds. -

Regional Market Variations

In North America and parts of Europe, cast iron retains strong cultural and architectural relevance, supporting steady demand. In contrast, emerging markets in Asia and the Middle East may show limited adoption due to preferences for modern, minimalist designs and logistical challenges associated with cast iron’s weight and handling. -

Innovation in Coating and Maintenance

To combat traditional drawbacks—such as susceptibility to chipping and rust—manufacturers are investing in advanced enamel coatings and anti-corrosion technologies. By 2026, expect improved finishes that enhance stain resistance and ease of cleaning, making cast iron shower floors more practical for everyday use.

In conclusion, while the cast iron shower floor will likely remain a niche segment within the broader bathroom fixtures market, its appeal in luxury, restoration, and design-forward applications ensures continued relevance. Success in the 2026 market will depend on innovation, strategic positioning, and alignment with sustainability and aesthetic trends.

Common Pitfalls When Sourcing Cast Iron Shower Floors (Quality & Intellectual Property)

Sourcing cast iron shower floors requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to product failures, legal disputes, and reputational damage. Below are key pitfalls to avoid:

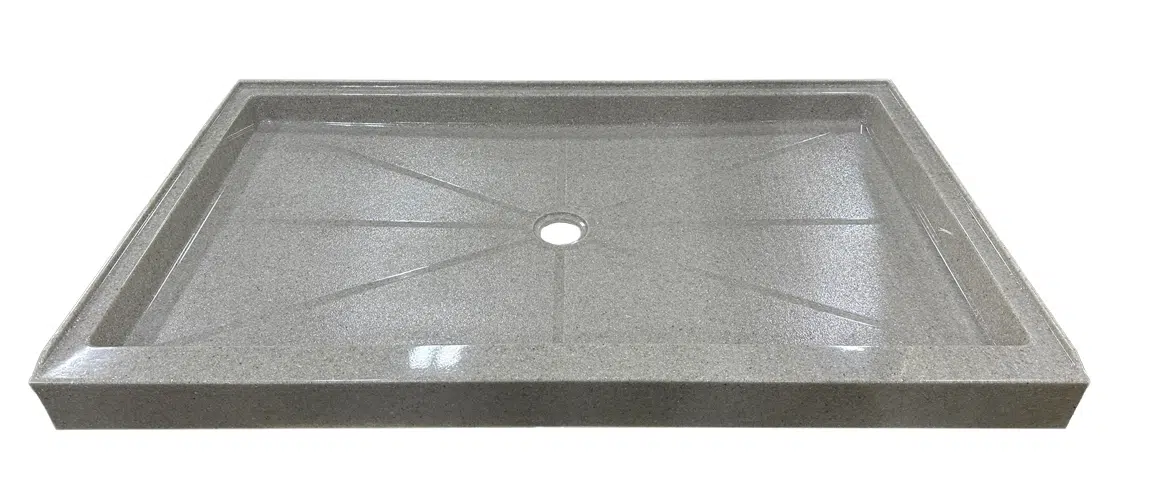

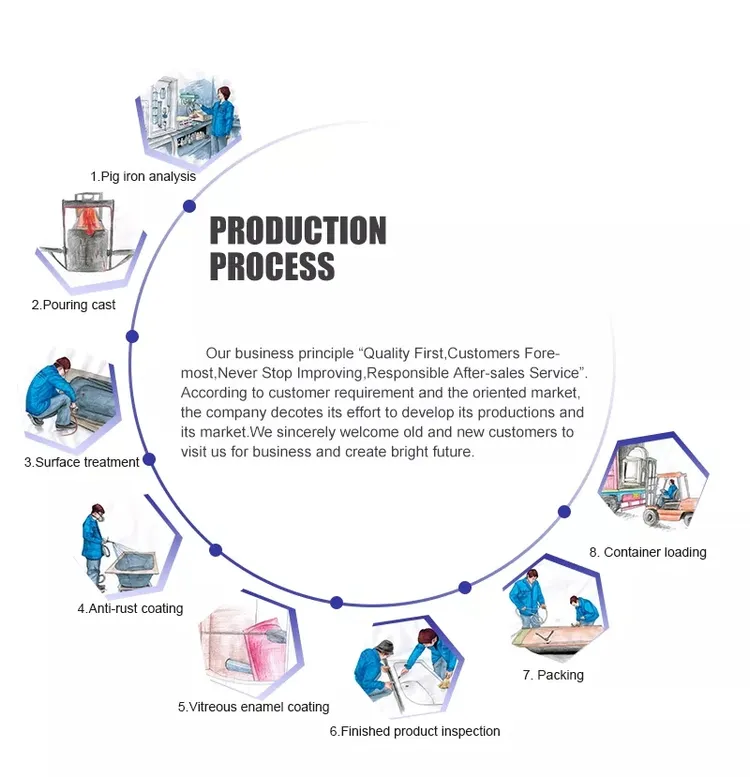

Poor Material Quality and Manufacturing Defects

One of the most frequent issues is receiving cast iron shower bases made from substandard materials or produced with inconsistent manufacturing processes. Low-grade cast iron may contain excessive impurities, leading to brittleness, cracking, or warping over time. Inadequate casting techniques can result in porosity, uneven thickness, or weak structural integrity. These flaws compromise durability, especially under constant exposure to moisture and thermal stress. Buyers must insist on material certifications (e.g., ASTM A48) and conduct factory audits or third-party inspections to verify production standards.

Inadequate or Inconsistent Enamel Coating

The enamel finish on cast iron shower floors is critical for both aesthetics and corrosion resistance. A common pitfall is sourcing units with thin, uneven, or poorly bonded enamel coatings. Such coatings are prone to chipping, cracking, or delamination—especially around drain areas or high-impact zones. Inferior firing processes or improper surface preparation before enameling exacerbate these risks. Ensure suppliers adhere to strict enameling standards (e.g., ISO 2977) and provide test reports for coating thickness and adhesion.

Lack of Proper Drain Design and Waterproofing

Many low-quality cast iron shower floors suffer from poor drainage integration or inadequate sealing mechanisms. A poorly positioned or undersized drain can lead to water pooling, mold growth, and structural deterioration. Additionally, substandard flanges or gaskets may fail over time, causing leaks. Verify that the design includes a properly sloped basin (typically 1/4″ per foot) and that drain assemblies are corrosion-resistant and compatible with standard plumbing systems.

Intellectual Property Infringement Risks

Sourcing from manufacturers who replicate patented or trademarked designs poses serious IP risks. Some suppliers may offer “look-alike” cast iron shower floors that closely mimic well-known brands, potentially violating design patents or registered industrial designs. Importing or selling such products can result in customs seizures, legal action, and financial liability. Always conduct due diligence: request proof of design rights, review supplier portfolios for originality, and avoid vendors offering suspiciously similar products at unusually low prices.

Insufficient Testing and Certification

Reputable cast iron shower floors should undergo rigorous performance testing for load capacity, impact resistance, and water retention. A common oversight is accepting products without documented proof of compliance with relevant standards (e.g., ASME A112.19.2, CSA B45.4). Suppliers from regions with lax regulatory oversight may skip these tests altogether. Require test reports and certifications before finalizing orders, and consider independent lab verification for high-volume purchases.

Inadequate Packaging and Handling Leading to Damage

Cast iron is heavy and susceptible to impact damage during transit. Poor packaging—such as insufficient corner protection or lack of moisture barriers—can result in chipped enamel or cracked bases upon arrival. This not only increases costs due to replacements but also delays projects. Ensure suppliers use robust, export-grade packaging specifically designed for fragile, heavy fixtures.

Hidden Costs from Non-Compliance or Rework

Choosing a low-cost supplier without verifying quality or IP status often leads to hidden expenses. These include costs associated with returns, on-site rework, warranty claims, or legal defense in IP disputes. A slightly higher initial investment in a verified, compliant product typically delivers better long-term value and reduces project risk.

By proactively addressing these pitfalls—through supplier vetting, technical specifications, and legal diligence—buyers can ensure they source durable, compliant, and legally sound cast iron shower floors.

Logistics & Compliance Guide for Cast Iron Shower Floor

Product Specifications and Handling Requirements

Cast iron shower floors are heavy, durable bathroom fixtures requiring careful handling due to their weight and brittle nature. Typical units range from 100 to 200 lbs (45–90 kg), depending on size and design. The enamel finish is susceptible to chipping or cracking if dropped or impacted. Proper lifting techniques and equipment—such as forklifts, pallet jacks, or team lifts—are essential during all stages of handling. Units should remain on their original pallets or protective crating until installation.

Packaging and Shipping Standards

Shipments must be secured on wooden pallets with corner boards and stretch-wrapped to prevent shifting. Double-walled corrugated cardboard or wooden crates are recommended to protect the surface and edges. Each unit should be individually wrapped in foam or bubble wrap beneath the outer packaging. Clearly label packages with “Fragile,” “This Side Up,” and “Heavy Item” indicators. Use freight carriers experienced in handling heavy, high-value bathroom fixtures, and ensure shipment includes lift-gate service at delivery.

Transportation and Carrier Selection

Due to weight and fragility, cast iron shower floors should be shipped via LTL (Less Than Truckload) freight. Choose carriers compliant with FMCSA (Federal Motor Carrier Safety Administration) regulations and with experience in building materials delivery. Confirm that vehicles are equipped with lift gates and that drivers are trained in handling heavy residential fixtures. Avoid air cargo due to cost and handling risks; ground freight is the standard and most reliable method.

Import/Export Compliance (if applicable)

For international shipments, ensure compliance with destination country regulations. Provide accurate Harmonized System (HS) codes—typically 6910.10 or 7324.21, depending on finish and composition. Comply with import duties, customs documentation (commercial invoice, packing list, bill of lading), and any local plumbing or construction material standards. Products entering the EU must meet CE marking requirements; those entering the U.S. should comply with EPA and state-level plumbing codes.

Regulatory and Safety Compliance

Cast iron shower floors must conform to relevant plumbing and safety standards. In the U.S., adherence to the International Plumbing Code (IPC) and ICC-ASSE 1072 (where applicable) is recommended. Verify that the product meets slip-resistance requirements (e.g., ASTM C1028 or ANSI A137.1). The enameled coating should be free of lead and comply with CPSIA (Consumer Product Safety Improvement Act) and Proposition 65 (California) if sold in the U.S. Manufacturers must provide certification of compliance upon request.

Installation and Site Delivery Protocols

Coordinate deliveries with job site readiness. Confirm access routes can support heavy loads—narrow staircases, elevators, or doorways may restrict movement. Deliveries should be scheduled when installers are present to inspect for damage and sign off on condition. Never roll or drag the unit; use dollies with soft wheels and padded straps. Store horizontally in a dry, protected area if not installed immediately.

Damage Reporting and Warranty Claims

Inspect shipments upon delivery. Note any damage—chips, cracks, or dents—on the carrier’s delivery receipt and take photos before unpacking. Report damage to the carrier and supplier within 24–48 hours. Most manufacturers offer limited warranties covering material and workmanship but exclude damage from improper handling. Keep all packaging for at least 30 days in case returns or inspections are required.

Conclusion: Sourcing a Cast Iron Shower Floor

After evaluating various factors such as durability, aesthetic appeal, longevity, and maintenance, sourcing a cast iron shower floor proves to be a sound investment for high-quality bathroom installations. Cast iron offers exceptional strength, resistance to wear, and a timeless look that complements both traditional and modern designs. While the initial cost and weight of cast iron may be higher compared to alternative materials like acrylic or fiberglass, its long-term performance and minimal maintenance needs provide excellent value over time.

When sourcing, it is essential to work with reputable suppliers or manufacturers known for quality craftsmanship and enamel finishing to prevent chipping and rust. Custom sizing, compatibility with existing plumbing, and proper installation support should also be considered to ensure longevity and functionality. Additionally, environmentally conscious buyers may appreciate cast iron’s recyclability and long service life, reducing replacement frequency and waste.

In conclusion, despite logistical and cost challenges, a cast iron shower floor stands out as a premium, durable, and elegant choice for discerning homeowners and designers seeking both performance and timeless style. Careful sourcing from trusted providers will ensure a reliable product that can last generations with proper care.