The global cast iron plumbing pipe and fittings market is experiencing steady growth, driven by rising infrastructure development, increasing urbanization, and the need for durable, corrosion-resistant piping systems in both residential and commercial construction. According to Grand View Research, the global ductile iron pipes market—closely aligned with cast iron plumbing systems—was valued at USD 46.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by government initiatives to upgrade aging water infrastructure, particularly in North America and Europe, as well as heightened demand in emerging economies across Asia-Pacific and the Middle East. Additionally, cast iron’s proven longevity, sound dampening properties, and fire resistance continue to make it a preferred choice in sanitary drainage and waste management systems, despite competition from alternative materials. As demand persists, a select group of manufacturers have emerged as leaders in innovation, scale, and product reliability. Here’s a data-driven look at the top 10 cast iron plumbing pipe and fittings manufacturers shaping the industry.

Top 10 Cast Iron Plumbing Pipe And Fittings Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tyler Pipe

Domain Est. 1997

Website: tylerpipe.com

Key Highlights: We are a manufacturer of cast iron soil pipe & fittings for DWV plumbing systems. Our products are sustainable and environmentally safe that are made from more ……

#2 Cast Iron Soil Pipe Institute

Domain Est. 1997

Website: cispi.org

Key Highlights: The Cast Iron Soil Pipe Institute (CISPI) was organized in 1949 by the leading American manufacturers of cast iron soil pipe and fittings….

#3

Domain Est. 2008 | Founded: 1905

Website: american-usa.com

Key Highlights: Founded in 1905 in Birmingham, Alabama, AMERICAN is a manufacturer of fire hydrants, valves, ductile iron pipe and spiral-welded steel pipe for the waterworks ……

#4 U.S. Pipe

Domain Est. 1995

Website: uspipe.com

Key Highlights: US Pipe, a Quikrete company, offers a complete range of Ductile Iron Pipe, Restrained Joint Pipe, Fabrication, Gaskets, and Fittings….

#5 AB&I Foundry

Domain Est. 1996

Website: abifoundry.com

Key Highlights: AB&I produces quality cast iron soil pipe and fittings for Drain, Waste and Vent (DWV) plumbing systems. AB&I steadfastly adheres to ethical standards of ……

#6 Cast Iron Pipe & Fittings

Domain Est. 1997

Website: charlottepipe.com

Key Highlights: We produce a full line of service and extra-heavy cast iron soil pipe and fittings from 2 to 15 inches and double-hub pipe from 2 to 6 inches….

#7 McWane

Domain Est. 1997

Website: mcwane.com

Key Highlights: Across McWane, we make the pipes, valves, fire hydrants and fittings that together build our nation’s water infrastructure….

#8 Star Pipe Products

Domain Est. 1998

Website: starpipeproducts.com

Key Highlights: Star Pipe Products has manufactured ductile iron pipe fittings, joint restraints, and castings for the waterworks industry for over 40 years….

#9 Pipe Fittings

Domain Est. 2020

Website: asc-es.com

Key Highlights: ASC offers the broadest line of malleable iron fitting sizes in both black and galvanized finishes. Every fitting is manufactured and tested to ……

#10 Pam Building

Domain Est. 2021

Website: pambuilding.com

Key Highlights: PAM Building is specialized in the manufacture of cast iron above and below ground drainage systems for buildings….

Expert Sourcing Insights for Cast Iron Plumbing Pipe And Fittings

H2: 2026 Market Trends for Cast Iron Plumbing Pipe and Fittings

The global market for cast iron plumbing pipes and fittings is expected to experience a measured transformation by 2026, shaped by evolving construction practices, sustainability demands, and material competition. While traditional applications in municipal water and wastewater systems continue to provide steady demand, several key trends are influencing the trajectory of cast iron products in the plumbing sector.

Urban Infrastructure Renewal: Aging water infrastructure in North America and Europe is driving municipal investment in rehabilitation and replacement projects. Ductile iron pipes—modern, stronger variants of cast iron—are increasingly favored for underground water and sewer mains due to their durability and long service life (exceeding 100 years). This infrastructure push is expected to sustain demand through 2026, particularly in regions prioritizing resilient public works.

Sustainability and Longevity Appeal: As environmental regulations tighten, the sustainability profile of cast iron is gaining attention. Its recyclability (often made from up to 95% recycled material) and extended lifespan reduce lifecycle environmental impacts compared to plastic alternatives. Green building certifications such as LEED are beginning to recognize these benefits, boosting adoption in eco-conscious commercial and institutional projects.

Competition from Alternative Materials: Despite its durability, cast iron faces stiff competition from PVC, HDPE, and PEX, especially in residential and light commercial plumbing. These materials offer lower installation costs, lighter weight, and corrosion resistance. As a result, cast iron is increasingly concentrated in high-demand applications such as fire protection systems, noise-sensitive buildings (e.g., hospitals and hotels), and large-scale drainage systems where acoustic performance and fire resistance are critical.

Technological Advancements: Innovations in protective linings—such as cement mortar, epoxy, and polyurethane coatings—are enhancing the corrosion resistance of cast iron pipes, extending their usability in aggressive soil environments. Additionally, push-on joint systems and restrained joint designs are improving installation efficiency, reducing labor costs, and minimizing leakage risks, making cast iron more competitive in new construction.

Regional Market Dynamics: The Asia-Pacific region is emerging as a growth hotspot due to rapid urbanization and government-led water infrastructure development, particularly in India and Southeast Asia. Conversely, mature markets like the U.S. and Germany are focused on replacement cycles rather than expansion. China’s slowing construction sector may moderate demand growth, while Middle Eastern countries investing in desalination and wastewater recycling are creating new opportunities for durable piping solutions.

Regulatory Influence: Stricter water quality standards and leak detection requirements are prompting municipalities to upgrade to materials with proven reliability. In regions with high seismic activity, ductile iron’s flexibility and joint integrity are becoming compliance advantages, influencing procurement policies.

In summary, by 2026, the cast iron plumbing pipe and fittings market will likely remain niche in residential applications but will maintain strong relevance in municipal, industrial, and high-performance building sectors. Success will depend on manufacturers’ ability to innovate, emphasize lifecycle value, and differentiate cast iron based on durability, safety, and sustainability.

Common Pitfalls When Sourcing Cast Iron Plumbing Pipe and Fittings (Quality and IP)

Sourcing cast iron plumbing pipe and fittings involves navigating several potential issues related to product quality and intellectual property (IP). Being aware of these pitfalls can help ensure you receive reliable, compliant materials and avoid legal or performance-related problems.

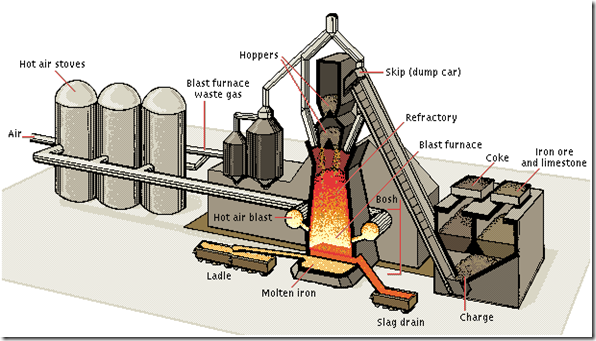

Poor Material Quality and Manufacturing Defects

One of the most frequent issues when sourcing cast iron components is receiving substandard materials. Low-quality cast iron may contain excessive impurities, inconsistent wall thickness, or improper alloy composition, leading to premature failure, leaks, or structural weakness. Defects such as sand inclusions, porosity, or cracks often result from inadequate casting processes. These flaws compromise the integrity of the piping system, especially in high-pressure or critical drainage applications.

Inadequate or Non-Compliant Coatings

Cast iron pipes and fittings typically require protective coatings—such as cement mortar lining or bituminous coating—to resist internal corrosion and external degradation. Sourcing products with insufficient, poorly applied, or missing coatings can drastically shorten service life. Some suppliers may cut costs by using subpar coating materials or skip coating altogether, leading to rapid deterioration when exposed to moisture or aggressive soils.

Misrepresentation of Standards and Certifications

Suppliers may claim compliance with ASTM A74, ASTM A888, or other relevant standards without proper certification. This misrepresentation includes falsifying test reports or providing generic documentation that doesn’t match the actual product. Always verify third-party certifications and request mill test reports (MTRs) to confirm compliance with required specifications for strength, dimensional tolerances, and material composition.

Counterfeit or Unlicensed Products Infringing IP

Intellectual property violations are a growing concern, particularly when sourcing from regions with lax enforcement. Some manufacturers produce copies of branded fittings or pipes that mimic patented designs, logos, or proprietary connection systems (e.g., no-hub or mechanical joint designs). These counterfeit products not only violate IP rights but often lack the engineering and testing behind genuine components, increasing the risk of system failure.

Lack of Traceability and Documentation

Reliable sourcing requires full traceability—from raw material origin to finished product. Poor documentation, missing heat numbers, or unclear batch tracking make it difficult to verify quality or conduct recalls if issues arise. Without proper records, it’s nearly impossible to prove compliance during inspections or audits, especially in regulated construction projects.

Inconsistent Dimensional Accuracy

Off-spec dimensional tolerances in pipes and fittings—such as incorrect diameters, hub depths, or spigot lengths—can lead to improper joint assembly, leaks, or difficulty during installation. Inconsistent manufacturing processes, particularly with unregulated suppliers, often result in parts that don’t fit together as intended, increasing labor costs and project delays.

Failure to Address Environmental and Regulatory Requirements

Some cast iron products may contain restricted substances or fail to meet environmental regulations (e.g., lead content limits or volatile organic compound emissions from coatings). Additionally, using unlicensed designs may expose buyers to legal liability, especially if the end-use project requires adherence to building codes or sustainability standards that mandate the use of certified, non-infringing materials.

Overlooking Supply Chain Transparency

Relying on intermediaries or unclear supply chains increases the risk of receiving diverted, expired, or repackaged goods. Lack of transparency makes it difficult to assess manufacturing practices, labor conditions, or adherence to quality management systems like ISO 9001. Always audit suppliers directly or through trusted third parties to ensure ethical and reliable sourcing.

Logistics & Compliance Guide for Cast Iron Plumbing Pipe and Fittings

Cast iron plumbing pipes and fittings are essential components in commercial, industrial, and residential drainage, waste, and vent (DWV) systems. Due to their weight, size, and material-specific handling requirements, proper logistics planning and compliance with regulatory standards are critical. This guide outlines key considerations for the transportation, storage, handling, and regulatory compliance of cast iron plumbing products.

Product Overview

Cast iron plumbing pipes and fittings are typically made from ductile iron or gray iron and are used primarily in DWV systems. These products are heavy, brittle, and susceptible to damage if not handled correctly. Common types include hubless (no-hub) and hub-and-spigot configurations, with various fittings such as elbows, tees, and couplings.

Packaging and Unitization

- Packing Standards: Pipes are generally bundled with steel strapping or placed in wooden crates. Fittings are often packed in corrugated boxes or palletized with edge protectors.

- Palletization: Use robust, heat-treated wooden or composite pallets rated for heavy loads. Ensure overhang does not exceed 6 inches on any side.

- Labeling: Clearly label each unit with product type, size, quantity, weight, and handling instructions (e.g., “Fragile,” “This Side Up”).

- Weather Protection: Use shrink wrap or waterproof covers to protect from moisture, especially for outdoor storage or sea transport.

Transportation Requirements

- Weight Considerations: Cast iron products are extremely heavy. Verify axle weight limits and vehicle capacity before loading.

- Load Securing: Use ratchet straps, dunnage, and load bars to prevent shifting. Pipes should be cradled to avoid chipping or cracking.

- Mode of Transport:

- Truck: Use flatbeds or dry vans with sufficient load capacity. Avoid open-top containers unless products are fully covered.

- Rail: Secure loads to prevent lateral movement. Use dunnage between layers.

- Ocean Freight: Palletized loads should be containerized (20’ or 40’ dry containers). Ensure cargo is moisture-protected and properly stowed.

- Transit Time: Minimize transit duration where possible to reduce risk of damage or exposure to extreme conditions.

Storage and Handling

- Storage Environment: Store indoors or under cover to prevent rust and contamination. Avoid direct contact with soil or standing water.

- Racking: Use sturdy racks designed for heavy materials. Stack pipes horizontally in layers with wooden dunnage between layers to prevent deformation.

- Fittings Storage: Keep in original packaging on raised pallets. Avoid stacking too high to prevent crushing.

- Handling Equipment: Use forklifts with appropriate load capacity. Never drag or roll pipe bundles on the ground.

- Safety Protocols: Provide PPE (gloves, steel-toed boots) and train personnel on safe lifting and handling techniques.

Regulatory Compliance

International Standards

- ASTM Standards: Ensure products comply with ASTM A74 (for hub-and-spigot cast iron soil pipe) and ASTM A888 (for hubless cast iron soil pipe).

- ISO Standards: Where applicable, confirm conformance to ISO 6594 for cast iron fittings.

Environmental & Safety Regulations

- REACH & RoHS (EU): Cast iron typically does not contain restricted substances, but verify with suppliers for compliance documentation.

- OSHA (USA): Follow guidelines for manual handling, fall protection, and material storage to ensure worker safety.

- DOT (USA): Comply with hazardous materials regulations if transporting coated or chemically treated products (rare, but possible).

Customs and Import/Export

- HS Code: Use Harmonized System code 7307.19 for cast iron pipes and 7308.90 for fittings (verify country-specific classifications).

- Documentation: Provide commercial invoices, packing lists, certificates of origin, and test reports (e.g., material certification).

- Import Duties & Taxes: Check local tariffs; some countries impose anti-dumping duties on imported iron products.

Quality Assurance and Inspection

- Pre-Shipment Inspection: Verify product dimensions, coating integrity, and packaging quality.

- In-Transit Monitoring: Use shock and tilt indicators for high-value shipments.

- Receiving Inspection: Check for cracks, warping, or rust upon delivery. Document and report damage immediately.

Sustainability and End-of-Life Considerations

- Recyclability: Cast iron is 100% recyclable. Partner with certified metal recyclers for scrap or obsolete materials.

- Carbon Footprint: Consider proximity of suppliers to reduce transportation emissions.

- Packaging Disposal: Recycle or reuse wooden crates and steel strapping where possible.

Conclusion

Proper logistics and compliance practices are essential to ensure the safe and efficient delivery of cast iron plumbing pipes and fittings. By adhering to packaging standards, transportation best practices, and regulatory requirements, stakeholders can reduce damage, avoid delays, and maintain product integrity throughout the supply chain. Always work with certified suppliers and logistics partners experienced in handling heavy, durable goods.

In conclusion, sourcing cast iron plumbing pipe and fittings requires careful consideration of quality, supplier reliability, compliance with industry standards, and long-term performance requirements. While cast iron remains a durable and acoustically efficient choice for drainage, waste, and vent (DWV) systems—especially in commercial and multi-story residential buildings—it is essential to partner with reputable manufacturers and suppliers who provide certified materials and technical support. With declining domestic production in some regions, global sourcing may be necessary, making logistics, lead times, and import regulations important factors in the procurement process. Additionally, alternatives such as ductile iron or HDPE should be evaluated based on project specifications and cost-efficiency. Ultimately, a strategic sourcing approach that balances performance, cost, and supply chain resilience will ensure the successful implementation of cast iron plumbing systems in construction projects.