The global car wash equipment market is experiencing robust growth, driven by rising vehicle ownership, increasing demand for water-efficient cleaning solutions, and the proliferation of automated car wash systems. According to a report by Mordor Intelligence, the market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of over 6.5% from 2024 to 2029. Similarly, Grand View Research estimates that the market will expand at a CAGR of 6.8% during 2023–2030, fueled by technological advancements and the integration of IoT and sensor-based automation in car wash machinery. Within this expanding landscape, carriage washer systems—known for their efficiency, consistency, and space optimization—have emerged as a preferred solution for both commercial and fleet operations. As demand intensifies, manufacturers are competing on innovation, durability, and sustainability. Here, we spotlight the top nine carriage washer manufacturers leading this transformation with data-backed performance, market reach, and product innovation.

Top 9 Carriage Washer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AR North America

Domain Est. 1999

Website: arnorthamerica.com

Key Highlights: Manufacturer & supplier of Triplex Plunger Pumps, Blue Flex Diaphragm Pumps & top pressure washing accessories for OEMs & pros….

#2 Jenfab

Domain Est. 1996

Website: jenfab.com

Key Highlights: At Jenfab, we build aqueous industrial parts washers that clean parts and components for many industries including automotive, manufacturing, and medical….

#3 Seastrom Manufacturing

Domain Est. 1997

Website: seastrom-mfg.com

Key Highlights: As a full-service washer manufacturer and supplier, Seastrom offers the most comprehensive online catalog of high-quality standard washers and specialty ……

#4 Simoniz USA

Domain Est. 2003

Website: simoniz.com

Key Highlights: Industry-leading manufacturer of cleaning and protection products for auto dealerships, professional car washes, and professional building maintenance ……

#5 AR Blue Clean

Domain Est. 2005

Website: arblueclean.com

Key Highlights: Free delivery over $100 30-day returnsBlue Clean Pressure Washers are versatile, portable, and lightweight. Remove dirt and grime from your DIY projects with minimal effort. Perfec…

#6 ALVEY WASHING EQUIPMENT

Domain Est. 1996

Website: cinind.com

Key Highlights: Alvey’s garbage can washers & tray washers are the trusted name in the commercial kitchen and food industry, precisely engineered to clean various products….

#7 Torque Washers for Carriage Bolts

Domain Est. 1997

Website: wclco.com

Key Highlights: A complete line of unique square-holed Torque Washers is now available from WCL Company. The square-holed washer is designed for use with a carriage bolt….

#8 Washers

Domain Est. 1998

#9 Metal Washers

Domain Est. 2018

Website: patriotbolt.com

Key Highlights: Welcome to Patriot Bolt and Fastener, a leading provider of high-quality metal washers for the Oil and Gas, Energy, and Aerospace industries….

Expert Sourcing Insights for Carriage Washer

H2: 2026 Market Trends for Carriage Washers

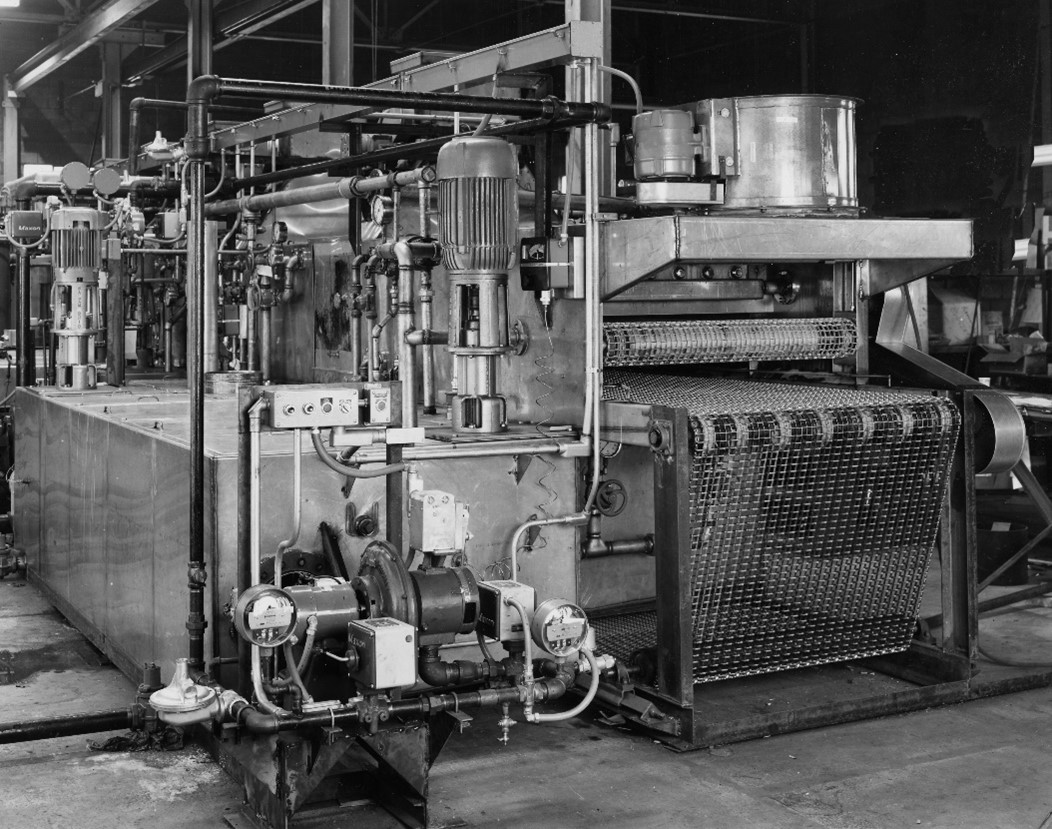

The global market for carriage washers—industrial cleaning systems used primarily in the rail, automotive, and manufacturing sectors—is projected to experience notable transformation by 2026, driven by technological innovation, sustainability mandates, and evolving industry demands. Key trends shaping the carriage washer market include automation, environmental regulations, integration of smart technologies, and regional shifts in industrial activity.

1. Accelerated Adoption of Automation and Robotics

By 2026, fully automated carriage washing systems are expected to dominate new installations. Advancements in robotics and programmable logic controllers (PLCs) enable precise cleaning of complex undercarriage and exterior surfaces with minimal human intervention. This trend is particularly evident in high-throughput environments like mass transit systems and freight rail operations, where downtime must be minimized. Automated systems also reduce labor costs and improve worker safety, making them a strategic priority for operators.

2. Emphasis on Water and Energy Efficiency

Environmental regulations are increasingly stringent, especially in Europe and North America, pushing manufacturers to develop eco-friendly carriage washers. Closed-loop water recycling systems, low-flow nozzles, and energy-efficient pumps are becoming standard features. By 2026, over 60% of new systems are expected to include water recovery capabilities, reducing consumption by up to 80%. This aligns with corporate sustainability goals and helps operators comply with local environmental standards.

3. Integration of IoT and Predictive Maintenance

Carriage washers are evolving into smart systems through IoT integration. Sensors monitor system performance, water quality, detergent levels, and mechanical wear in real time. Data is transmitted to cloud platforms for analytics, enabling predictive maintenance and remote diagnostics. By 2026, smart washers are anticipated to reduce unplanned downtime by 30–40%, significantly improving operational efficiency for rail and fleet operators.

4. Growth in Public Transit and Rail Infrastructure Investment

Governments worldwide are investing heavily in public transportation and rail modernization to reduce urban congestion and carbon emissions. Initiatives such as the EU’s Green Deal and infrastructure bills in the U.S. and India are driving demand for new rail fleets and associated maintenance infrastructure—including advanced carriage washing systems. This trend is expected to fuel double-digit growth in the carriage washer market in key regions through 2026.

5. Regional Market Diversification

While Europe and North America remain mature markets with a focus on retrofitting and upgrading existing systems, Asia-Pacific is emerging as the fastest-growing region. Countries like China, India, and Indonesia are expanding urban metro systems and high-speed rail networks, creating robust demand for new carriage washers. Local manufacturing and lower installation costs are further accelerating adoption in these markets.

6. Customization and Modular Design

As rail fleets become more diverse—ranging from traditional locomotives to light rail vehicles and autonomous shuttles—there is a growing need for modular and customizable washer systems. By 2026, manufacturers are expected to offer scalable solutions that can be adapted to different vehicle dimensions, cleaning requirements, and site constraints, enhancing flexibility and return on investment.

In conclusion, the 2026 carriage washer market will be defined by intelligent, sustainable, and highly efficient systems tailored to the needs of modern transportation infrastructure. Companies that invest in automation, digital integration, and green technologies will be best positioned to capitalize on these emerging opportunities.

Common Pitfalls Sourcing a Carriage Washer (Quality, IP)

Sourcing a carriage washer—especially one that must meet specific quality standards and intellectual property (IP) requirements—can present several challenges. Overlooking these pitfalls may lead to product failures, legal issues, or supply chain disruptions. Below are key areas of concern:

Quality Inconsistencies

Suppliers may offer carriage washers with inconsistent material composition, dimensional accuracy, or surface finish. Without stringent quality control and verified certifications (e.g., ISO 9001), there’s a risk of receiving substandard components that compromise mechanical performance or longevity. Always require material test reports, conduct factory audits, and implement incoming inspection protocols.

Lack of IP Protection and Risk of Counterfeiting

Carriage washers, particularly those used in patented machinery, may be protected by intellectual property rights. Sourcing from unauthorized or non-compliant suppliers can lead to IP infringement, exposing your company to legal liability. Ensure suppliers provide documentation proving design rights or proper licensing, and avoid vendors offering “compatible” or “generic” versions without clear IP clearance.

Inadequate Material Specifications

Using incorrect materials (e.g., non-stainless steel in corrosive environments) can lead to premature wear or failure. Suppliers might substitute cheaper alloys to cut costs. Clearly specify material grades (e.g., AISI 304, 316) and verify compliance through material certifications and third-party testing.

Poor Tolerance and Fit Issues

Carriage washers often require tight dimensional tolerances to function correctly within assemblies. Off-spec parts can cause misalignment, increased wear, or mechanical binding. Confirm that suppliers have the capability to maintain required tolerances (e.g., ±0.05mm) and request first-article inspections.

Insufficient Testing and Validation

Some suppliers may skip critical performance tests such as load capacity, corrosion resistance (e.g., salt spray testing), or hardness checks. Require evidence of batch testing and, where applicable, performance validation under real-world conditions.

Hidden Supply Chain Risks

Sub-tier suppliers may introduce unverified components or unethical practices (e.g., conflict materials). Conduct supply chain mapping and require transparency to mitigate quality and reputational risks.

By proactively addressing these pitfalls—through rigorous supplier qualification, clear technical specifications, and IP diligence—companies can ensure reliable, compliant, and high-quality carriage washer sourcing.

Logistics & Compliance Guide for Carriage Washer

This guide outlines the essential logistics and compliance considerations for the transportation, handling, and operation of a Carriage Washer—commonly used in rail or industrial cleaning applications. Adhering to these guidelines ensures safety, regulatory compliance, and efficient operations.

Transportation and Handling

Ensure the Carriage Washer is securely fastened during transit using appropriate restraints and load-distribution methods. Use certified lifting equipment when loading/unloading, and confirm that transport vehicles meet weight and dimension regulations. Route planning should avoid low-clearance zones and structurally unsuitable roads. Documentation, including waybills and equipment manifests, must accompany the unit at all times.

Regulatory Compliance

Comply with all local, national, and industry-specific regulations, including those from OSHA (Occupational Safety and Health Administration), DOT (Department of Transportation), and EPA (Environmental Protection Agency). Operators must be trained and certified in accordance with relevant safety standards. The Carriage Washer must meet applicable emissions, noise, and electrical safety codes. Regular audits and documentation reviews are required to maintain compliance.

Environmental Considerations

Implement spill containment and wastewater management protocols in accordance with Clean Water Act regulations. All cleaning agents and solvents must be EPA-approved and handled in compliance with hazardous material (HAZMAT) guidelines. Discharge of wash water must be directed to approved treatment systems or retention basins; never into storm drains or natural waterways.

Operational Safety

Conduct pre-operation inspections to verify mechanical integrity and safety system functionality. Establish exclusion zones during operation and use visible warning signage. Provide operators with appropriate personal protective equipment (PPE), including eye protection, gloves, and hearing protection. Emergency stop mechanisms must be accessible and regularly tested.

Maintenance and Recordkeeping

Perform scheduled maintenance as per manufacturer specifications and maintain detailed logs of all service activities, repairs, and inspections. Calibration of pressure systems, water flow meters, and chemical dosing units must be documented. Retain records for a minimum of three years or as required by jurisdictional standards.

Training and Certification

Ensure all personnel involved in the operation, maintenance, or transport of the Carriage Washer complete formal training programs. Certifications must be current and on file, with refresher courses conducted annually. Training should cover equipment operation, emergency procedures, environmental compliance, and hazard communication.

Incident Reporting and Response

Implement a clear incident reporting protocol for accidents, spills, or equipment failures. Report significant events to relevant regulatory authorities within mandated timeframes. Maintain an on-site emergency response plan, including spill kits, containment tools, and contact information for emergency services.

Conclusion for Sourcing Carriage Washers

In conclusion, sourcing carriage washers requires a strategic approach that balances quality, cost, and reliability. After evaluating potential suppliers, assessing material specifications, and considering factors such as dimensional accuracy, load-bearing capacity, and corrosion resistance, it is evident that selecting the right supplier is critical to ensuring optimal performance and longevity of mechanical assemblies. Partnering with reputable manufacturers who adhere to international standards (e.g., ISO, DIN, or ANSI) and can provide consistent quality, timely delivery, and responsive customer support will significantly reduce operational risks and maintenance costs. Additionally, exploring both domestic and global sourcing options can offer cost advantages, provided due diligence is maintained in quality control and supply chain resilience. Ultimately, a well-informed sourcing decision for carriage washers contributes to improved efficiency, safety, and reliability across various industrial and automotive applications.