The global carpet accessories market, including carpet edging tape, is witnessing steady growth driven by rising construction activities, increasing demand for modular flooring solutions, and expanding commercial infrastructure. According to a report by Mordor Intelligence, the global carpet and rug market was valued at approximately USD 74.6 billion in 2023 and is projected to grow at a CAGR of over 5.2% through 2029. This expansion is supported by the growing need for durable, cost-effective, and easy-to-install floor finishing products—such as carpet edging tape—in both residential and commercial applications. As modular carpet installations gain popularity in offices, educational institutions, and healthcare facilities, the demand for high-quality edge binding solutions continues to rise. With increasing emphasis on product durability, fire resistance, and aesthetic integration, manufacturers are focusing on innovation and material optimization. In this evolving landscape, the top nine carpet edging tape manufacturers are emerging as key players, combining technical expertise, scalable production, and global distribution networks to meet rising industry demands.

Top 9 Carpet Edging Tape Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 relink 2318 b

Domain Est. 1995

Website: tapesolutions.saint-gobain.com

Key Highlights: Our Double Sided Acrylic Adhesive Tape, with its high deposition properties, has optimized adhesion to carpet backings, ideal for use as Industrial Carpet Tape!…

#2 Clear Carpet Binding Tape

Domain Est. 1997

#3 twilltape.com

Domain Est. 1998

Website: twilltape.com

Key Highlights: Welcome to twilltape.com. Click on one of our categories to see our selection of twill tapes. Orders usually ship the same or next business day….

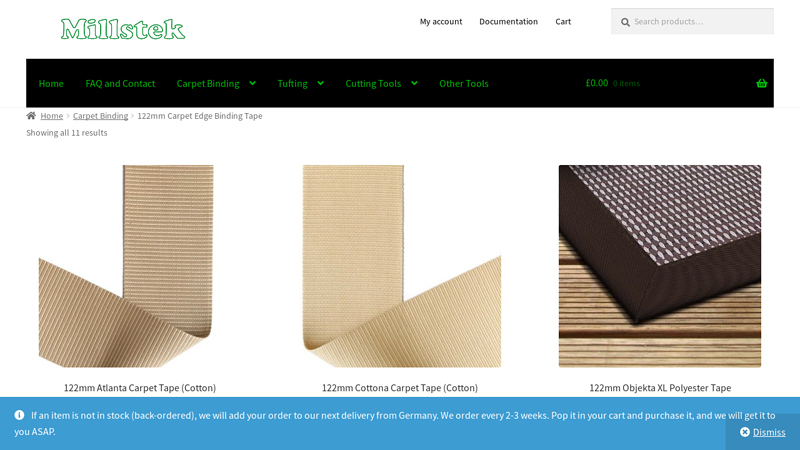

#4 122mm Carpet Edge Binding Tape

Domain Est. 2000

Website: millstek.com

Key Highlights: 30-day returnsCarpet Binding Tape for the edges of carpets, rugs, runners, mats and staircases. Woven from Cotton, polyester or polypropylene carpet edge binding tape can ……

#5 Bond’s Sisal Binding Tapes

Domain Est. 2000

Website: bondproducts.com

Key Highlights: Bond’s sisal binding tapes are perfect for binding a currently popular rug choice – the attractive and durable sisal rug….

#6 ALM Carpet Binding Tape

Domain Est. 2008

Website: almcarpetbindingtape.com

Key Highlights: 100% polyester, superior quality, NON – FRAYING individually woven binding tape. Available in over 95 colors of 7/8′′ tape. Packaged in two separate rolls of ……

#7 Carpet making

Domain Est. 2019

Website: ribbonrope.com

Key Highlights: Carpet edging tape is a high quality, durable webbing. Mostly, carpet edging tape is used for carpets in interior designs. One way to work with the webbing is ……

#8 Jaspa Woven

Domain Est. 2021 | Founded: 1946

Website: jaspawoven.co.uk

Key Highlights: We are the UK’s largest supplier of carpet edging binding tapes for stair runners & rugs. Weaving since 1946 we offer the most extensive range….

#9 Binding Tape for Back Tufting

Domain Est. 2022

Expert Sourcing Insights for Carpet Edging Tape

H2: 2026 Market Trends for Carpet Edging Tape

The global carpet edging tape market is poised for steady evolution by 2026, driven by shifting consumer preferences, technological advancements, and sustainability imperatives. Key trends shaping the landscape include:

1. Accelerated Demand for Sustainable and Eco-Friendly Materials

Environmental consciousness will be a dominant force. Consumers and commercial specifiers alike are prioritizing low-impact solutions. By 2026, expect significant growth in edging tapes made from recycled materials (e.g., post-consumer plastics, recycled rubber), bio-based polymers, and water-based adhesives. Brands emphasizing transparent sourcing, recyclability, and reduced carbon footprints will gain competitive advantage. Certifications like Cradle to Cradle or Declare labels will increasingly influence purchasing decisions.

2. Expansion in DIY and Home Renovation Sectors

The continued popularity of home improvement projects, fueled by remote work trends and rising real estate values, will drive demand for user-friendly carpet edging tapes. Products designed for easy self-installation—featuring stronger initial tack, clear application guides, and compatibility with various flooring types (including underlayment and hard surfaces)—will see robust growth. Retailers will expand their DIY-focused offerings, often bundling tape with transition strips or installation tools.

3. Innovation in Adhesive Technology and Performance

Advancements will focus on enhancing durability and versatility. High-performance, pressure-sensitive adhesives that bond effectively to diverse substrates (concrete, wood, tile) without residue upon removal will be in demand. Anti-slip and anti-fraying formulations will become standard, especially in high-traffic commercial spaces like offices, schools, and retail. Temperature-resistant and UV-stable tapes will gain traction in outdoor or sun-exposed applications.

4. Growth in Commercial and Institutional Applications

The commercial sector remains a key driver. With increased emphasis on safety and aesthetics in workplaces, healthcare facilities, and educational institutions, demand for reliable, code-compliant edging solutions will rise. Flame-retardant, low-VOC, and antimicrobial tapes will be particularly sought after in regulated environments, aligning with building safety and indoor air quality standards.

5. Regional Market Diversification and Supply Chain Localization

While North America and Europe maintain strong demand due to renovation cycles and stringent environmental regulations, growth in Asia-Pacific—especially in India, Southeast Asia, and China—will accelerate due to urbanization and expanding construction activity. Manufacturers are likely to respond by localizing production and distribution to reduce costs, improve delivery times, and navigate trade dynamics, potentially reshaping global supply chains.

6. Digital Integration and E-Commerce Expansion

Online sales channels will become increasingly critical. Detailed product information, augmented reality (AR) tools for visualizing installation, and integration with flooring design software will enhance the customer experience. B2B platforms will streamline procurement for contractors, while direct-to-consumer models will expand access to specialized or premium tape variants.

In summary, the 2026 carpet edging tape market will be defined by sustainability, performance innovation, and accessibility. Companies that invest in eco-conscious materials, intuitive design, and digital engagement will be best positioned to capture value in this evolving landscape.

Common Pitfalls When Sourcing Carpet Edging Tape (Quality and Intellectual Property)

Sourcing carpet edging tape may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to costly mistakes, product failures, and legal risks. Here are common pitfalls to avoid:

Inadequate Quality Standards and Material Verification

One of the most frequent issues is assuming that all carpet edging tapes are functionally identical. Buyers often fail to verify material specifications such as adhesive strength, UV resistance, temperature tolerance, and fabric durability. Low-quality tapes may use substandard adhesive that fails prematurely, especially in high-traffic or outdoor applications. Without proper testing or certification (e.g., ISO standards), the tape may degrade quickly, leading to peeling, fraying, or discoloration.

Lack of Customization Oversight

Many suppliers offer “custom” edging tapes but use generic base materials with minimal adaptation. Buyers may assume the product is tailored to their needs—such as specific widths, colors, or fire-retardant properties—without enforcing technical documentation or sample approvals. This can result in mismatches in performance or appearance, especially when integrating the tape into premium flooring systems.

Overlooking Intellectual Property Rights

A critical but often ignored risk is IP infringement. Some manufacturers, especially overseas suppliers, may reproduce patented tape designs, patterns, or adhesive technologies without authorization. Sourcing from such suppliers—even unknowingly—can expose your business to legal action, customs seizures, or forced product recalls. Always verify that the supplier owns or is licensed to produce the design or technology being offered.

Insufficient Due Diligence on Supplier Credentials

Relying solely on product samples or attractive pricing without auditing the supplier’s manufacturing processes, quality control systems, or IP compliance history is risky. Unverified suppliers may cut corners in production or source components from unauthorized third parties, increasing the likelihood of quality defects and IP violations.

Failure to Secure Proper Licensing or Documentation

When sourcing proprietary or branded edging tape solutions, failing to obtain written licensing agreements or material safety data sheets (MSDS) can lead to compliance issues. This is especially important in regulated environments like commercial aviation, healthcare, or public infrastructure, where traceability and certification are mandatory.

Conclusion

To mitigate these pitfalls, conduct thorough supplier vetting, request material certifications, perform independent quality testing, and ensure all IP rights are legally cleared before placing orders. Investing time upfront in due diligence protects your brand, ensures product reliability, and minimizes legal exposure.

Logistics & Compliance Guide for Carpet Edging Tape

Product Overview

Carpet edging tape, also known as carpet binding tape or seam tape, is a specialized adhesive or non-adhesive strip used to finish the edges of carpets, rugs, and flooring installations. It prevents fraying, enhances durability, and provides a clean, professional appearance. Common materials include cotton, polyester, nylon, or blends, often with heat-activated adhesive (for iron-on applications) or pressure-sensitive adhesive.

Shipping & Handling Requirements

Packaging

– Rolls of carpet edging tape should be wound tightly on sturdy cardboard cores to prevent deformation.

– Individual rolls must be wrapped in moisture-resistant plastic or polyethylene film to protect against humidity and contamination.

– Bulk packaging (e.g., cartons or master packs) should use corrugated cardboard with internal dividers to prevent crushing and abrasion.

– Clearly label packages with product type, width, length, color, and batch/lot number.

Storage Conditions

– Store in a dry, climate-controlled environment with temperatures between 15°C and 25°C (59°F to 77°F).

– Relative humidity should be maintained below 65% to prevent adhesive degradation or mildew.

– Keep away from direct sunlight, heat sources, and chemicals that may compromise adhesive properties.

– Store vertically (on end) to prevent flattening or edge damage.

Transportation

– Use enclosed, dry vehicles for all shipments; avoid open trucks or exposure to weather.

– Secure loads to prevent shifting, rolling, or compression during transit.

– Do not stack heavy items on top of carpet tape cartons.

– For international shipping, ensure compliance with IATA (air) or IMDG (sea) regulations if adhesives contain regulated substances.

Regulatory Compliance

International Trade & Customs

– HS Code: Typically classified under 5806.32 (narrow woven fabrics, of man-made fibers, other than goods of heading 5807) or 5806.39 (other narrow woven fabrics). Confirm with local customs authority based on material composition.

– Provide accurate commercial invoices, packing lists, and certificates of origin for exports.

– Check for import duties, anti-dumping measures, or textile quotas in destination countries (e.g., EU, USA, Canada).

Chemical & Environmental Regulations

– Ensure adhesive components comply with REACH (EU) and TSCA (USA) regulations.

– If adhesives contain volatile organic compounds (VOCs), comply with regional VOC emission standards (e.g., California Air Resources Board – CARB).

– Provide Safety Data Sheets (SDS) in the local language for adhesive-containing products.

– Adhesives must not contain restricted substances such as phthalates, heavy metals (e.g., lead, cadmium), or PFAS (where regulated).

Product Safety & Labeling

– Label all packaging with: product name, material content, dimensions, manufacturer/importer details, and country of origin.

– Include hazard warnings if applicable (e.g., “Keep away from heat” for heat-activated tapes).

– Comply with labeling laws such as FTC Care Labeling Rule (USA) for textile products, if applicable.

Sustainability & Disposal

– Follow WEEE, RoHS, or other e-waste directives only if tape includes electronic components (rare).

– Promote recyclability: advise end-users to separate tape from carpet for proper disposal.

– Consider voluntary certifications like OEKO-TEX® STANDARD 100 to demonstrate low harmful substance content.

Documentation & Traceability

- Maintain batch records and traceability logs for raw materials and finished goods.

- Retain SDS, compliance certificates, and test reports for a minimum of 5–10 years, depending on jurisdiction.

- For B2B distribution, provide conflict minerals reporting if applicable (e.g., under Dodd-Frank Act Section 1502).

Best Practices for Distributors & Installers

- Train staff on proper handling and storage to maintain product integrity.

- Rotate stock using FIFO (First In, First Out) to avoid aging or adhesive degradation.

- Advise installers to condition tape at room temperature before use, especially after cold storage.

- Recommend testing adhesion on sample materials before large-scale application.

Adhering to this guide ensures smooth logistics, minimizes compliance risks, and maintains product quality across the supply chain.

Conclusion for Sourcing Carpet Edging Tape:

After evaluating various suppliers, materials, and price points, sourcing carpet edging tape requires a balanced approach that considers quality, durability, cost-effectiveness, and compatibility with the specific application—whether for residential, commercial, or industrial use. Key factors such as adhesive strength, material composition (e.g., fabric, vinyl, or rubber), fire resistance, and color-matching options significantly influence performance and customer satisfaction.

Local suppliers offer quicker turnaround and the ability to inspect samples firsthand, while international vendors may provide competitive pricing—especially for bulk orders—but require careful vetting for quality control and shipping reliability. Building strong relationships with reliable suppliers, negotiating favorable terms, and maintaining a consistent quality standard are essential for long-term success.

Ultimately, the optimal sourcing strategy involves selecting a supplier that meets technical specifications, ensures timely delivery, and supports sustainability and compliance goals. Regularly reviewing supplier performance and staying informed about market innovations will help ensure that the chosen carpet edging tape enhances both the functionality and aesthetics of flooring installations.