The global cargo lift market is experiencing sustained growth, driven by rising industrial automation, expanding warehouse infrastructure, and increasing demand for efficient material handling solutions across logistics, manufacturing, and e-commerce sectors. According to a report by Mordor Intelligence, the global material handling equipment market—of which cargo lifts are a critical component—is projected to grow at a CAGR of over 6% from 2023 to 2028. Similarly, Grand View Research estimates that the global industrial lift market was valued at USD 4.5 billion in 2022 and is expected to expand at a CAGR of 5.8% through 2030. With safety regulations tightening and operational efficiency becoming a key performance metric, businesses are increasingly investing in advanced cargo lifting systems. Against this backdrop, a select group of manufacturers has emerged as industry leaders, combining innovation, reliability, and scalability to meet evolving market demands.

Top 9 Cargo Lift Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

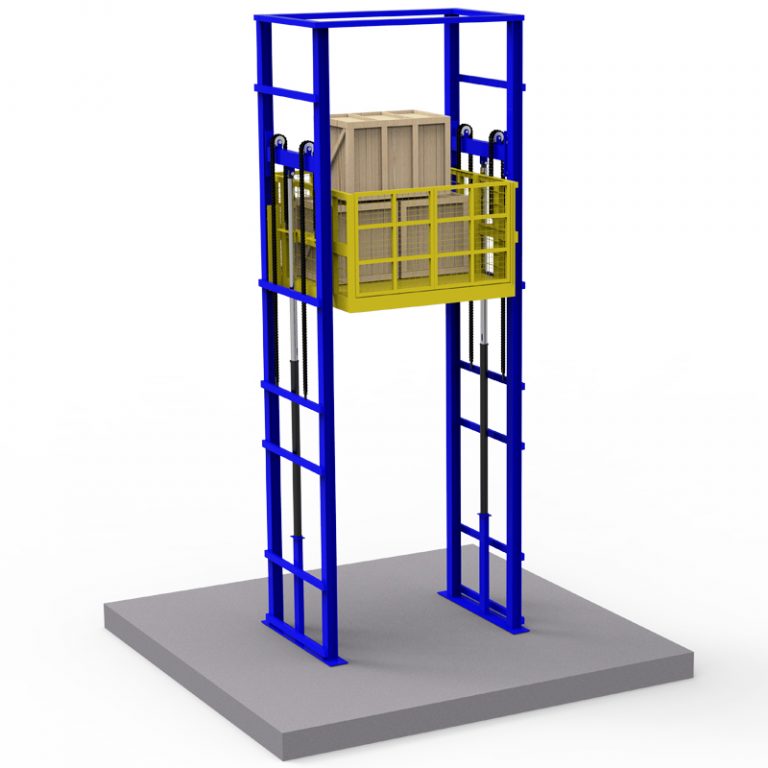

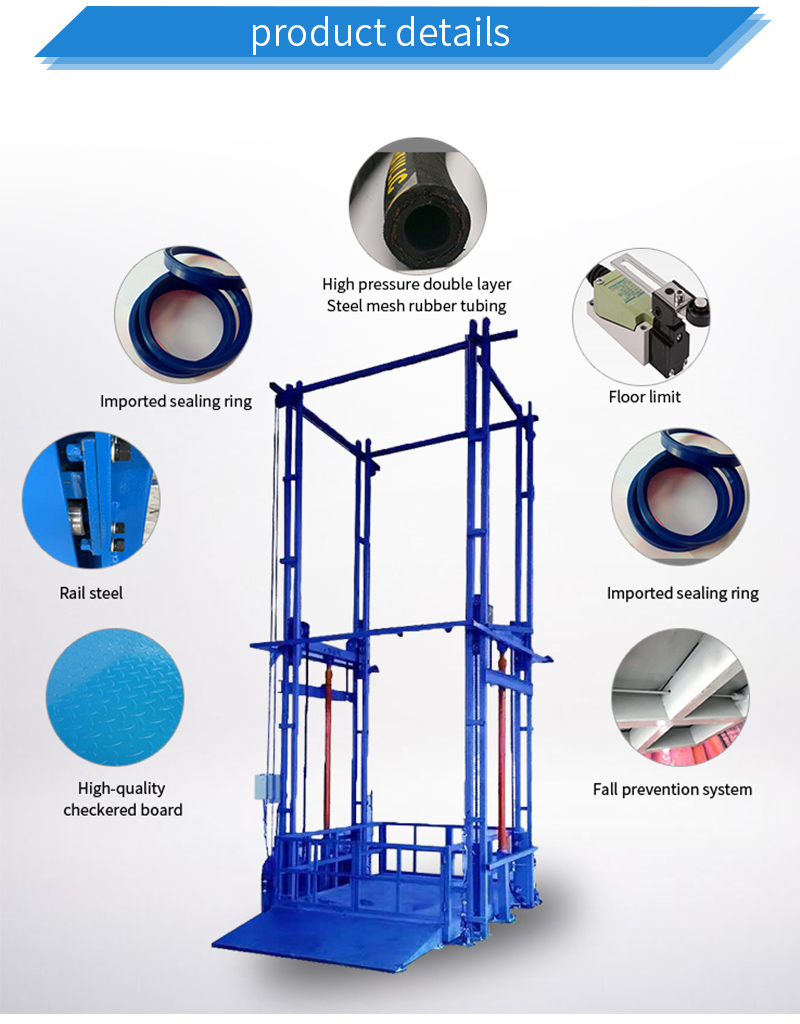

#1 OEM Cargo Lift For Manufacturer and Supplier, Exporter Factory

Domain Est. 2014

Website: srh-elevator.com

Key Highlights: Cargo Lift For Home Manufacturers, Factory, Suppliers From China, Our main objectives are to provide our customers worldwide with good quality, ……

#2 Elevators, Escalators, Lifts & Moving Walks

Domain Est. 1994

Website: otis.com

Key Highlights: Otis is a leading manufacturer and maintainer of Elevators, Escalators, Moving Walkways with world class modernization tools & service packages for ……

#3 Cargo Lift, Lift Table & Aerial Lift Manufacturer

Domain Est. 2011

Website: mornlift.com

Key Highlights: We provide cargo lifts, scissor Lift tables, car lifts, and aerial lifts with standard & bespoke models. Reliable and durable. Gea t free quote now….

#4 Freight elevators for goods & special requirements

Domain Est. 1993

Website: schindler.com

Key Highlights: From cargo freight elevators to custom applications, see how Schindler can solve complex transportation requirements with durable, cost-effective products….

#5 Nationwide Lifts Elevators. and Commercial Elevators for Sale

Domain Est. 1998

Website: elevators.com

Key Highlights: Buy a lift or elevator from Nationwide Lifts to get top-quality products and service that other elevator companies just can’t match….

#6 Freight Elevators – TK Elevator

Domain Est. 2001

Website: tkelevator.com

Key Highlights: Transport heavy equipment, large shipments of goods, and raw materials efficiently with TK Elevator’s highly durable, custom-engineered freight elevators….

#7 Galaxy Lifts

Domain Est. 2014

Website: galaxylifts.com

Key Highlights: Galaxy Lifts manufactures the #1 cargo lifts for homes and businesses. Affordable and made in the USA. Get your quote today!…

#8 Cargo Lift USA, LLC

Domain Est. 2018

Website: cargoliftusa.com

Key Highlights: Cargo Lift USA is an industry leader in the production and supply of cargo lifting, towing, moving, and lashing equipment….

#9 Cargo Lift Elevators

Domain Est. 2023

Website: cargoliftpros.com

Key Highlights: Residential cargo lifts from Cargo Lift Pros. Protect belongings from water damage & move heavy items with ease. Safe, durable, and reliable….

Expert Sourcing Insights for Cargo Lift

H2 2026 Market Trends Analysis for Cargo Lift Equipment

The global cargo lift market is poised for significant transformation in H2 2026, driven by technological innovation, evolving supply chain demands, sustainability mandates, and regional economic shifts. This analysis outlines key trends shaping the cargo lift sector—encompassing forklifts, pallet jacks, aerial lifts, and warehouse lifting systems—during the latter half of 2026.

1. Acceleration of Electrification and Zero-Emission Adoption

The transition from internal combustion (IC) to electric-powered cargo lifts will reach a tipping point in H2 2026. Driven by tightening emissions regulations (e.g., EU’s Fit for 55, U.S. EPA standards), rising fuel costs, and corporate ESG commitments, warehouse and logistics operators are prioritizing electric forklifts and electric pallet trucks.

– Lithium-ion Dominance: Lithium-ion battery technology will become the standard, offering faster charging, longer lifespan, and lower total cost of ownership (TCO) compared to lead-acid.

– Charging Infrastructure Growth: Warehouses will invest in smart charging stations and opportunity charging systems, enabling 24/7 operations without battery swapping.

– Hydrogen Fuel Cells: Limited but growing adoption in heavy-duty outdoor applications (e.g., port container handlers), particularly in Europe and Japan.

2. Integration of AI and Automation in Warehouse Logistics

Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) equipped with lifting capabilities will see expanded deployment. In H2 2026, AI-driven fleet management systems will optimize cargo lift routing, maintenance scheduling, and load balancing.

– Smart Lift Trucks: Integration with Warehouse Management Systems (WMS) and IoT sensors enables predictive maintenance and real-time asset tracking.

– Human-Machine Collaboration: Semi-autonomous forklifts with collision avoidance and adaptive pathfinding will enhance safety in mixed human-robot environments.

– Demand Surge in E-Commerce Hubs: High-throughput fulfillment centers will drive adoption of automated vertical lift modules (VLMs) and robotic palletizers.

3. Rise of Rental and Subscription-Based Models

Economic uncertainty and capital conservation strategies will fuel growth in Equipment-as-a-Service (EaaS) and short-term rental models.

– Flexibility and Scalability: Companies will prefer leasing cargo lifts to adapt quickly to seasonal demand fluctuations.

– Full-Service Packages: Rental agreements will increasingly include maintenance, telematics, and operator training, reducing operational burdens.

– Growth in Emerging Markets: Rental fleets will expand in Southeast Asia and Latin America, where upfront costs remain a barrier.

4. Supply Chain Resilience and Regionalization

Geopolitical tensions and trade volatility will push companies toward nearshoring and regional distribution hubs, increasing demand for cargo lifts in secondary logistics centers.

– Modular and Mobile Lift Solutions: Demand will rise for compact, reconfigurable lifts suitable for flexible warehouse layouts.

– Localization of Manufacturing: Equipment suppliers will expand regional production (e.g., in India, Mexico) to reduce lead times and tariffs.

5. Labor Shortages Driving Technology Adoption

Persistent labor shortages in warehousing and material handling will accelerate investment in lift equipment that reduces reliance on skilled operators.

– Ease of Use and Training: Simplified controls and augmented reality (AR)-assisted training will shorten onboarding times.

– Operator Assist Systems: Features like load stability detection and ergonomic design will improve safety and efficiency.

6. Sustainability and Circular Economy Practices

End-of-life management and circular design will become competitive differentiators.

– Refurbished and Remanufactured Units: Second-life cargo lifts will gain market share, supported by OEM-certified programs.

– Recyclable Materials: Manufacturers will increase use of recycled steel and plastics in new models.

Regional Outlook (H2 2026)

- North America: Strong demand driven by e-commerce expansion and industrial automation; leadership in electric and smart lift adoption.

- Europe: Strict emissions standards will make it the most electrified market; Germany and the Netherlands lead in automation.

- Asia-Pacific: Fastest growth region, especially in India and Southeast Asia, due to manufacturing expansion and urban logistics development.

- Latin America & MEA: Gradual modernization of material handling infrastructure, with Brazil and Saudi Arabia emerging as key markets.

Conclusion

H2 2026 will be a pivotal period for the cargo lift market, characterized by a convergence of digitalization, decarbonization, and decentralized logistics. Companies investing in electric, intelligent, and flexible lifting solutions will gain a competitive edge. Success will depend on adaptability to dynamic supply chains, sustainability imperatives, and evolving labor landscapes.

Common Pitfalls When Sourcing Cargo Lifts: Quality and Intellectual Property (IP) Concerns

Sourcing cargo lifts—especially from international or unfamiliar suppliers—exposes buyers to significant risks related to both product quality and intellectual property. Overlooking these areas can lead to safety hazards, costly downtime, legal disputes, and reputational damage. Below are the most common pitfalls in these two critical areas.

Quality-Related Pitfalls

Inadequate Supplier Vetting

A frequent mistake is selecting vendors based solely on price without thoroughly evaluating their manufacturing standards, certifications, or track record. Suppliers may claim compliance with ISO or CE standards but lack valid certification or fail to consistently apply quality control processes. This can result in substandard materials, poor welds, or incorrect load-bearing designs that compromise safety.

Lack of Third-Party Testing and Certification

Some suppliers provide in-house test reports that are not independently verified. Without accredited third-party certification (e.g., from TÜV, UL, or Lloyd’s Register), there’s no assurance that the cargo lift meets safety and performance standards such as ASME B30.1 or EN 14492-1. This increases the risk of equipment failure under operational stress.

Inconsistent Manufacturing Quality

Even if a prototype or sample unit meets specifications, mass production may involve cost-cutting measures—such as using lower-grade steel or reducing component tolerances—leading to inconsistent quality across batches. Without ongoing quality audits or inspections during production, these issues often go undetected until after delivery.

Insufficient Documentation and Traceability

Poor documentation, including missing material test reports (MTRs), weld maps, or assembly instructions, hampers maintenance and regulatory compliance. Lack of traceability also complicates recalls or warranty claims if defects emerge post-installation.

Intellectual Property (IP) Pitfalls

Unintentional Use of Infringing Designs

Buyers may unknowingly source cargo lifts that copy patented features—such as unique hoisting mechanisms, control systems, or structural configurations—protected in their home or target markets. If the supplier doesn’t own or license the IP, the buyer could face legal action, import seizures, or be forced to decommission the equipment.

Supplier Misrepresentation of IP Ownership

Some suppliers falsely claim to have proprietary designs or original engineering when, in fact, they are replicating established models from other manufacturers. This becomes problematic when enforcement actions are taken, leaving the buyer exposed to liability despite having no direct involvement in the infringement.

Weak Contractual IP Protections

Procurement contracts often lack clear clauses assigning IP rights, requiring warranty of non-infringement, or stipulating indemnification for IP disputes. Without these, buyers have limited recourse if litigation arises due to the supplier’s use of protected technology.

Reverse Engineering Risks

In some sourcing markets, suppliers may reverse-engineer competitors’ lifts and market them as their own. While cost-effective, these products carry high IP risk, especially if exported to countries with strong enforcement of patent and design rights.

Mitigation Strategies

To avoid these pitfalls, buyers should conduct comprehensive due diligence—including factory audits, independent product testing, and IP clearance searches. Contracts must include robust quality assurance terms and explicit IP warranties. Engaging legal and technical experts during the sourcing process can significantly reduce exposure to both quality failures and intellectual property violations.

Logistics & Compliance Guide for Cargo Lift

Overview of Cargo Lift Operations

Cargo lift refers to the mechanical or operational process of raising and lowering freight using lifting equipment such as forklifts, cranes, hoists, or integrated vehicle lift systems. Efficient and compliant cargo lift operations are critical to warehouse logistics, transportation, and supply chain safety. This guide outlines key logistics considerations and compliance requirements to ensure safe, legal, and effective cargo lifting.

Equipment Standards and Certification

All lifting equipment must meet recognized safety standards such as those set by OSHA (Occupational Safety and Health Administration), ISO (International Organization for Standardization), or ANSI (American National Standards Institute). Equipment must be certified prior to use and undergo regular inspections. Documentation, including load capacity ratings and manufacturer specifications, must be maintained and readily accessible.

Operator Training and Certification

Only trained and certified personnel should operate cargo lifting equipment. Training programs must cover equipment operation, load handling procedures, emergency protocols, and hazard recognition. Employers are required to maintain training records and ensure refresher training is conducted periodically or following incidents.

Load Assessment and Weight Limits

Before any lift, the cargo’s weight, dimensions, and center of gravity must be assessed. The load must not exceed the equipment’s rated capacity under any operating conditions. Overloading can result in equipment failure, accidents, or structural damage. Use calibrated scales and load charts to verify compliance.

Pre-Use Inspection Procedures

Operators must conduct a pre-shift inspection of lifting equipment, checking for defects such as hydraulic leaks, worn cables, damaged forks, or malfunctioning controls. Any identified issues must be reported immediately, and the equipment must be taken out of service until repaired and re-inspected.

Safe Lifting Practices

Ensure clear lifting zones free of personnel and obstructions. Use proper rigging techniques and secure loads appropriately before lifting. Maintain a stable base, especially on uneven surfaces, and avoid abrupt movements. Always lift and lower loads smoothly and under control.

Workplace Safety and Signage

Designate and mark lifting zones with warning signs and floor markings. Implement traffic control measures to separate pedestrians from lift operations. Use alarms or warning lights on equipment where visibility is limited. Emergency stop mechanisms must be functional and accessible.

Regulatory Compliance

Comply with local, national, and international regulations governing cargo handling. In the U.S., OSHA regulation 29 CFR 1910.178 (Powered Industrial Trucks) and 1910.184 (Slings) are key references. For international operations, adhere to ILO (International Labour Organization) standards and regional directives such as EU Machinery Directive 2006/42/EC.

Maintenance and Recordkeeping

Establish a preventive maintenance schedule based on manufacturer recommendations and operational usage. Maintain detailed logs of inspections, repairs, certifications, and operator training. Records must be retained for the required statutory period and available for audit.

Incident Reporting and Investigation

All accidents, near-misses, or equipment malfunctions involving cargo lifts must be reported immediately. Conduct a thorough investigation to determine root causes and implement corrective actions to prevent recurrence. Reportable incidents may need to be filed with regulatory authorities as per legal requirements.

Environmental and Site Considerations

Ensure cargo lift operations account for environmental conditions such as weather (for outdoor lifts), floor load capacity, and overhead clearance. Use appropriate equipment for hazardous environments (e.g., explosion-proof for flammable atmospheres). Minimize noise and emissions in sensitive areas.

Documentation and Audit Preparedness

Maintain a comprehensive compliance file including equipment certifications, training records, inspection logs, maintenance history, and standard operating procedures (SOPs). Regular internal audits help ensure ongoing compliance and readiness for external inspections.

Conclusion

Effective cargo lift logistics require disciplined adherence to safety protocols and regulatory standards. By prioritizing equipment integrity, operator competence, and systematic compliance, organizations can reduce risk, enhance operational efficiency, and ensure the safety of personnel and cargo.

Conclusion for Sourcing Cargo Lift

In conclusion, sourcing a cargo lift requires a comprehensive evaluation of technical specifications, safety standards, budget considerations, and long-term operational needs. It is essential to select a reliable supplier who offers high-quality, durable equipment that complies with industry regulations and can be customized to suit specific site requirements. Factors such as load capacity, lifting height, power source, and maintenance support play a critical role in ensuring efficient and safe operations. By conducting thorough market research, comparing quotes, and considering lifecycle costs, organizations can make an informed decision that enhances productivity, ensures worker safety, and delivers a strong return on investment. A well-sourced cargo lift not only meets current logistical demands but also supports scalability and operational continuity in the future.