The global cardboard shipping tube market is experiencing steady growth, driven by rising demand for sustainable packaging solutions across industries such as construction, textiles, printing, and e-commerce. According to Grand View Research, the global paper packaging market—of which cardboard tubes are a key segment—was valued at USD 388.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.6% from 2023 to 2030. Factors such as the shift away from plastic, increasing consumer preference for eco-friendly materials, and the expansion of online retail are accelerating this trend. Mordor Intelligence also projects strong growth for industrial paper tubes, citing heightened usage in protective packaging for high-value goods and durable shipments. As demand surges, manufacturers are innovating with stronger, lighter, and more customizable cardboard tubes, making it essential for buyers to partner with reliable, high-capacity producers. Here are the top 8 cardboard shipping tube manufacturers leading the charge in quality, sustainability, and global reach.

Top 8 Cardboard Shipping Tube Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Cardboard Tube Manufacturers and Suppliers

Domain Est. 2012

Website: cardboardtubemanufacturers.com

Key Highlights: Find cardboard tube manufacturers and suppliers that can design, engineer, and manufacture all kinds of industrial cardboard tubes….

#2 Cardboard Tubes, For Sale, Heavy Duty, Large, Small, Mailing, Buy …

Domain Est. 1996 | Founded: 1902

Website: mailing-tube.com

Key Highlights: Rating 2.8 (11) Manufacturer of custom large and small cardboard mailing tubes since 1902. Custom cardboard shipping tubes with no minimun order. Ships in 24 hrs….

#3 Paper Tubes and Sales Manufacturing

Domain Est. 2000

Website: pts-mfg.com

Key Highlights: Welcome to Paper Tubes and Sales Manufacturing, where we design, fabricate and sell industrial and consumer paper tubes, composite cans and paper cores….

#4 Paper Tube Manufacturers

Domain Est. 2002

Website: paper-tubes.net

Key Highlights: Chicago Mailing Tube is a premier manufacturer of custom paper tubes, containers, and cores, providing products that are both high quality and economical….

#5 Postal Tube Shop

Domain Est. 2011

Website: postaltubeshop.com

Key Highlights: Specialist postal tube manufacturer supplying a wide range of cheap cardboard postal tubes from stock. Cardboard cylinders, pipes, tubes, however you name it, ……

#6 Paper Tubes and Cores by Yazoo Mills

Domain Est. 1998 | Founded: 1902

Website: yazoomills.com

Key Highlights: Trusted since 1902, Yazoo Mills manufactures premium paper tubes and cores with fast delivery, consistent quality, and no order minimums….

#7 Paper Tube Co.

Domain Est. 2013

Website: papertube.co

Key Highlights: We design, engineer, and manufacture custom paper tube packaging that stands out, gets noticed, and sells more products. Used by global consumer brands and ……

#8 Mailing Tubes

Domain Est. 2016

Expert Sourcing Insights for Cardboard Shipping Tube

2026 Market Trends for Cardboard Shipping Tubes

The cardboard shipping tube market is poised for significant evolution by 2026, driven by sustainability mandates, e-commerce growth, and technological advancements in materials and manufacturing. Key trends shaping the industry include:

Rising Demand for Sustainable and Recyclable Packaging

Environmental concerns will continue to dominate packaging decisions. By 2026, businesses will increasingly adopt cardboard tubes due to their biodegradability, recyclability, and use of renewable resources. Regulations such as extended producer responsibility (EPR) and plastic reduction initiatives across North America and Europe will accelerate the shift from plastic and composite tubes to paper-based alternatives, boosting demand for eco-friendly cardboard solutions.

Growth Driven by E-Commerce and Art/Design Sectors

The continued expansion of e-commerce, particularly in art, photography, architectural plans, and posters, will fuel demand for protective yet lightweight shipping solutions. Cardboard tubes offer an ideal balance of durability and cost-efficiency for shipping fragile, rolled materials. Online marketplaces and direct-to-consumer brands will increasingly rely on customized tubes for premium unboxing experiences, further expanding market opportunities.

Innovation in Material Strength and Moisture Resistance

To meet performance requirements in diverse shipping environments, manufacturers will invest in enhancing cardboard tube properties. By 2026, expect wider adoption of water-resistant coatings, reinforced wall structures, and hybrid materials that improve crush resistance without compromising recyclability. These innovations will allow cardboard tubes to compete with less sustainable alternatives in more demanding applications.

Regional Market Expansion and Localization

While North America and Europe lead in sustainable packaging adoption, emerging markets in Asia-Pacific and Latin America will see accelerated growth due to rising industrialization and consumer awareness. Localized production facilities will emerge to reduce transportation emissions and comply with regional sustainability standards, reshaping global supply chains for cardboard tubes.

Digital Customization and Branding Integration

Brands will leverage cardboard tubes as a canvas for marketing and brand identity. Advances in digital printing will enable high-quality, full-color graphics and variable data printing at scale. By 2026, personalized tubes with QR codes, augmented reality features, and limited-edition designs will become common, especially in luxury, fashion, and promotional markets.

In summary, the 2026 cardboard shipping tube market will be defined by sustainability, innovation, and customization. Companies that invest in eco-conscious materials, advanced manufacturing, and value-added design will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Cardboard Shipping Tubes (Quality, IP)

Sourcing cardboard shipping tubes may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to damaged products, customer dissatisfaction, and legal risks. Here are common pitfalls to avoid:

Overlooking Material Quality and Specifications

Choosing tubes based solely on price often results in subpar materials that compromise product protection. Low-grade cardboard may lack sufficient burst strength, crush resistance, or moisture protection, leading to dents, collapses, or internal damage during transit. Always verify specifications such as wall thickness (e.g., single-wall vs. double-wall), burst strength (measured in lbs or kPa), and tube diameter tolerances to ensure the tube meets your shipping requirements.

Ignoring Dimensional Accuracy

Poorly manufactured tubes may have inconsistent diameters, uneven cuts, or warped ends. This can cause issues during automated packing lines or create gaps that allow products to shift. Ensure suppliers adhere to tight dimensional tolerances and conduct sample testing before scaling up orders.

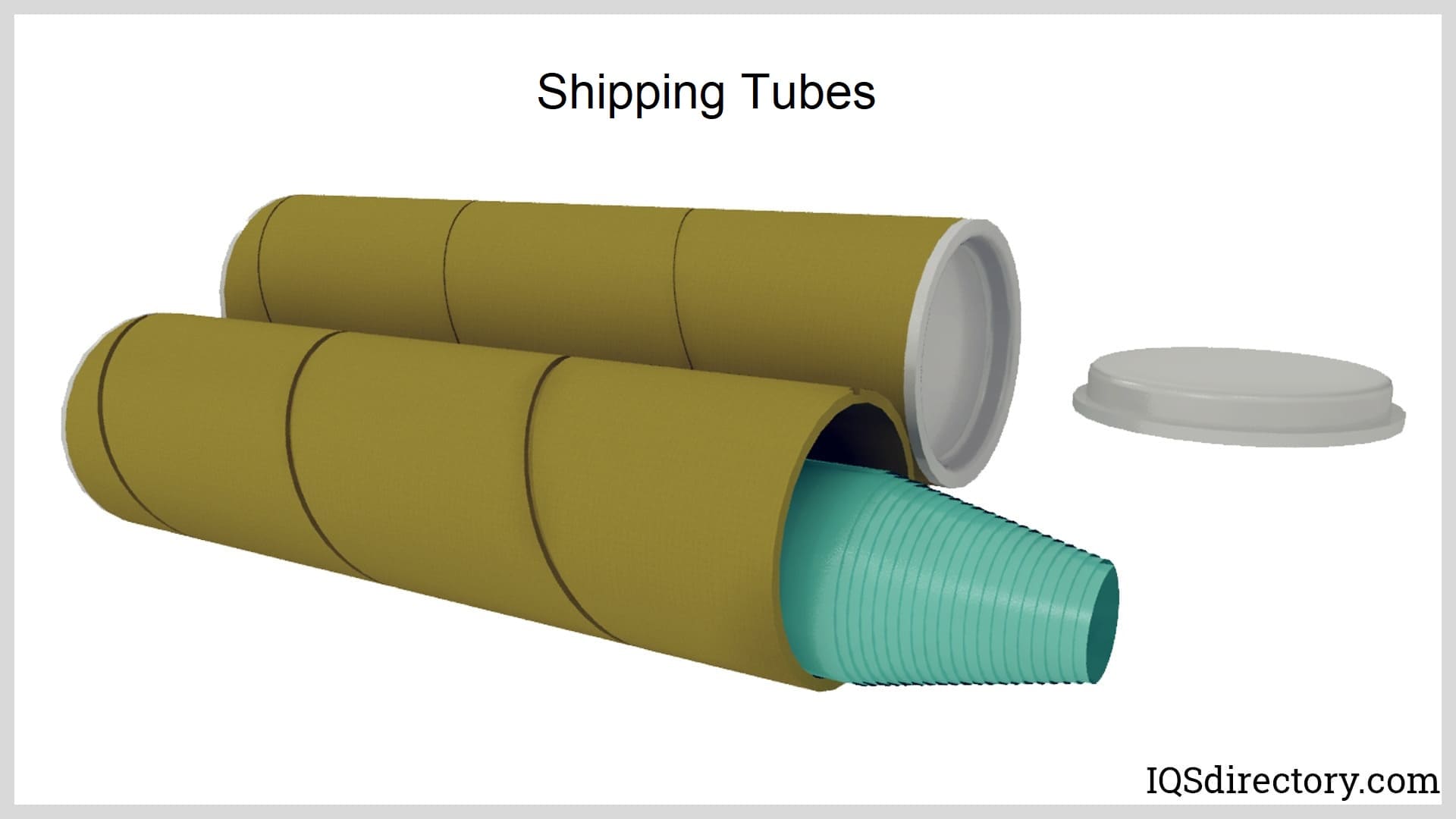

Insufficient End Cap or Closure Quality

Many cardboard tubes rely on plastic or cardboard end caps for security. Low-quality or poorly fitting caps can pop off during shipping, exposing contents to damage or tampering. Evaluate the compatibility and durability of end closures, especially for heavy or sensitive items.

Failing to Verify Custom Print and Branding Integrity

If branded tubes are required, poor print quality—such as misalignment, smudging, or color inaccuracies—can harm brand perception. Ensure the supplier uses high-quality printing methods (e.g., flexographic or digital) and provides print proofs. Additionally, confirm color matching standards (e.g., Pantone) are followed.

Overlooking Moisture and Environmental Resistance

Standard cardboard degrades when exposed to humidity or damp conditions. If shipping through variable climates, confirm whether the tubes have moisture-resistant coatings or liners. Failure to do so can result in weakened structural integrity and damaged contents.

Not Addressing Intellectual Property Risks

Using custom-designed tubes with proprietary shapes, logos, or printing patterns without proper IP safeguards is risky. Ensure your design is protected via trademarks or design patents, and include confidentiality and IP ownership clauses in supplier contracts to prevent unauthorized replication or resale.

Relying on Unverified Supplier Claims

Some suppliers may exaggerate material quality or compliance standards. Always request third-party test reports (e.g., for compression strength or recyclability) and conduct factory audits or sample testing before committing to large orders.

Neglecting Sustainability and Compliance Requirements

Environmental regulations and customer expectations are increasingly demanding sustainable packaging. Avoid suppliers who cannot provide documentation on recyclability, FSC certification, or the use of recycled content. Non-compliance can lead to reputational damage or supply chain disruptions.

By addressing these pitfalls proactively, businesses can ensure they source durable, reliable, and legally secure cardboard shipping tubes that protect products and uphold brand standards.

Logistics & Compliance Guide for Cardboard Shipping Tubes

Cardboard shipping tubes are widely used for transporting posters, blueprints, textiles, and other rolled materials. To ensure efficient logistics and regulatory compliance, businesses must follow best practices in packaging, handling, labeling, and environmental standards. This guide outlines key considerations for using cardboard shipping tubes across the supply chain.

Material & Construction Standards

Cardboard shipping tubes are typically made from kraft paper, corrugated fiberboard, or spiral-wound paperboard. To meet industry and regulatory requirements:

– Use FSC (Forest Stewardship Council) or SFI (Sustainable Forestry Initiative) certified materials to support sustainable sourcing.

– Ensure tubes meet minimum burst strength and crush resistance standards depending on contents (e.g., ASTM D642 for compressive strength).

– Confirm that inner liners or closures (plastic, paper, or cardboard caps) comply with relevant material safety standards if used.

Dimensional & Weight Specifications

Proper sizing ensures safe handling and cost-effective shipping:

– Follow carrier guidelines (e.g., USPS, FedEx, UPS) for maximum length, diameter, and weight. For example:

– UPS: Maximum length of 108 inches and combined length + girth (2 x diameter + 2 x length) not exceeding 165 inches.

– USPS: Standard Post: Max 70 lbs and 108 inches in length; Retail Ground: Up to 130 inches in combined length and girth.

– Clearly label tubes with external dimensions and gross weight for warehouse and carrier handling.

Packaging & Load Protection

Ensure contents are adequately protected during transit:

– Use internal inserts (e.g., foam, paper padding) to prevent shifting.

– Seal both ends securely with pressure-sensitive tape or manufacturer-end caps.

– Wrap fragile contents in protective paper or plastic sleeves before insertion.

– Indicate “Fragile,” “This End Up,” and “Do Not Bend” on external labels when applicable.

Labeling & Marking Requirements

Accurate labeling ensures compliance and efficient logistics:

– Include sender and recipient addresses with legible barcodes.

– Apply required shipping labels (e.g., carrier-specific barcodes, tracking numbers).

– Use GHS or OSHA-compliant labeling if shipping regulated items (e.g., technical drawings containing hazardous material references).

– For international shipments, provide a commercial invoice, country of origin, and Harmonized System (HS) code (e.g., 4823.90 for paper tubes).

Environmental & Recycling Compliance

Cardboard tubes are generally recyclable, but compliance depends on composition:

– Avoid non-recyclable plastic caps or laminates unless necessary; if used, label components for proper disposal.

– Comply with local regulations such as EU Packaging Waste Directive or U.S. FTC Green Guides for environmental claims.

– Label with recycling symbols (e.g., ♻️) and material type (e.g., “Made from 100% Recycled Paper”).

International Shipping Considerations

Cross-border shipments require additional compliance:

– Ensure tubes are free of soil, organic material, or wood components that could introduce pests (per ISPM 15, though tubes are generally exempt).

– Declare tube contents accurately to avoid customs delays.

– Verify that inks or adhesives used are REACH and RoHS compliant if shipping to the EU.

Carrier Acceptance & Handling

Work with carriers to ensure smooth processing:

– Confirm tube acceptance policies with carriers in advance.

– Avoid excessive length-to-diameter ratios that may lead to damage or refusal.

– Use protective outer sleeves or boxing for high-value shipments.

By adhering to these logistics and compliance guidelines, businesses can ensure safe, sustainable, and efficient transport of goods using cardboard shipping tubes while minimizing delays, fines, or environmental impact.

In conclusion, sourcing cardboard shipping tubes requires a strategic approach that balances cost, quality, sustainability, and supplier reliability. By identifying the specific requirements such as dimensions, strength, and volume needs, businesses can effectively evaluate potential suppliers and materials. Prioritizing eco-friendly, recyclable cardboard not only supports environmental goals but also enhances brand reputation. Additionally, building strong relationships with reputable manufacturers—whether local or international—can lead to long-term savings, consistent supply, and greater flexibility. Ultimately, a well-considered sourcing strategy ensures that cardboard shipping tubes meet both operational demands and customer expectations efficiently and sustainably.