The global demand for sustainable packaging solutions has fueled rapid growth in the cardboard poster tube market, with increasing adoption across industries such as advertising, architecture, education, and e-commerce. According to Grand View Research, the global paper packaging market—under which cardboard tubes fall—is projected to grow at a CAGR of 4.2% from 2023 to 2030, driven by environmental regulations and consumer preference for recyclable materials. Similarly, Mordor Intelligence forecasts steady expansion in the paper-based packaging sector, citing a CAGR of approximately 5.1% during the forecast period 2023–2028. As businesses prioritize eco-friendly shipping and storage solutions for rolled materials like posters, blueprints, and canvases, the need for high-quality, durable cardboard poster tubes has surged. This growth has intensified competition among manufacturers, leading to innovations in tube strength, diameter customization, printability, and biodegradability. In this landscape, a select group of manufacturers have emerged as industry leaders, combining scale, sustainability, and technical expertise to meet evolving market demands.

Top 7 Cardboard Poster Tube Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Paper Tube Manufacturer for Retail & Industrial Applications

Domain Est. 1997

Website: papertube.com

Key Highlights: A leading paper tube manufacturer for retail and industrial applications, Jonesville Paper Tube creates custom paper tubes for your exact needs….

#2 Callenor: Leaders in Paperboard Product Supply

Domain Est. 1999

Website: callenor.com

Key Highlights: Our custom packaging, shipping, and mailing paper tubes are built to perform. We make them to spec with a variety of ends to protect your product in transit….

#3 Paper Tubes and Sales Manufacturing

Domain Est. 2000

Website: pts-mfg.com

Key Highlights: Welcome to Paper Tubes and Sales Manufacturing, where we design, fabricate and sell industrial and consumer paper tubes, composite cans and paper cores….

#4 Paper Tube Manufacturers

Domain Est. 2002

Website: paper-tubes.net

Key Highlights: Chicago Mailing Tube is a premier manufacturer of custom paper tubes, containers, and cores, providing products that are both high quality and economical….

#5 Manufacturers & Suppliers of Poster Tubes

Domain Est. 2012

Website: cardboardtubemanufacturers.com

Key Highlights: We are a proven manufacturer of high quality cardboard tubes. These products are ideal for a multitude of industries and our teams are available to assist you….

#6 Paper Tubes and Cores by Yazoo Mills

Domain Est. 1998 | Founded: 1902

Website: yazoomills.com

Key Highlights: Trusted since 1902, Yazoo Mills manufactures premium paper tubes and cores with fast delivery, consistent quality, and no order minimums….

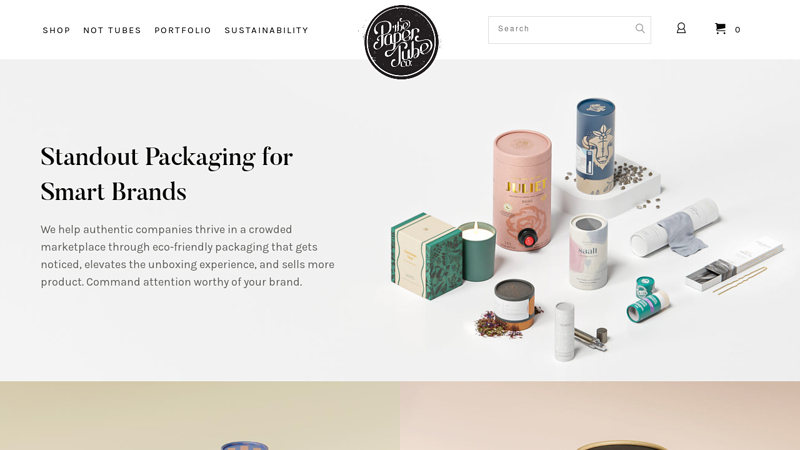

#7 Paper Tube Co.

Domain Est. 2013

Website: papertube.co

Key Highlights: We design, engineer, and manufacture custom paper tube packaging that stands out, gets noticed, and sells more products. Used by global consumer brands and ……

Expert Sourcing Insights for Cardboard Poster Tube

2026 Market Trends for Cardboard Poster Tube

The cardboard poster tube market is poised for notable evolution by 2026, driven by shifting consumer behaviors, environmental concerns, and technological advancements. Key trends shaping the industry include:

Rising Demand for Sustainable Packaging Solutions

By 2026, sustainability will be a dominant force in the cardboard poster tube market. With increasing regulatory pressure and consumer preference for eco-friendly products, manufacturers are prioritizing recycled and FSC-certified materials. Biodegradable coatings and water-based inks are being adopted to reduce environmental impact. Brands across art, education, and retail sectors are switching from plastic-based alternatives to cardboard tubes, aligning with corporate sustainability goals and enhancing brand image.

Growth in E-Commerce and Direct-to-Consumer Art Sales

The expansion of online art marketplaces and print-on-demand services is fueling demand for reliable shipping solutions. Cardboard poster tubes offer secure, cost-effective packaging for posters, blueprints, and rolled documents. As e-commerce continues to grow—especially in creative and educational sectors—there will be increased need for customizable, durable tubes that protect high-value prints during transit, driving innovation in tube strength and design.

Customization and Branding Opportunities

Brands are leveraging cardboard poster tubes as a marketing tool. By 2026, personalized printing, unique shapes, and premium finishes (e.g., matte, spot UV) will become standard offerings. Companies in the photography, design, and event industries are using branded tubes to enhance unboxing experiences and customer loyalty. Digital printing advancements allow for cost-effective short-run customization, making it accessible even for small businesses and independent artists.

Technological Integration and Smart Packaging

Emerging trends include integrating QR codes, NFC tags, or augmented reality (AR) features into tube designs. These technologies enable consumers to access digital content—such as artist interviews or product details—simply by scanning the tube. While still in early adoption, smart packaging is expected to gain traction by 2026, especially in premium and limited-edition art markets.

Regional Market Expansion and Competitive Dynamics

Asia-Pacific is projected to be the fastest-growing region due to rising urbanization, expanding middle-class populations, and growth in packaging industries. Meanwhile, North America and Europe will focus on innovation and sustainability compliance. Increased competition is prompting manufacturers to differentiate through product quality, eco-certifications, and supply chain efficiency.

Cost Pressures and Material Innovation

Fluctuating raw material prices and supply chain disruptions remain challenges. In response, producers are investing in lightweight yet durable tube designs and alternative fiber sources to maintain cost-efficiency without compromising performance. Innovations such as moisture-resistant barriers using plant-based materials are expected to enter mainstream use by 2026.

In summary, the 2026 cardboard poster tube market will be defined by sustainability, customization, digital integration, and global expansion—positioning it as a dynamic and adaptive segment within the broader packaging industry.

Common Pitfalls When Sourcing Cardboard Poster Tubes (Quality and Intellectual Property)

Sourcing cardboard poster tubes may seem straightforward, but businesses often encounter challenges related to quality and intellectual property (IP) that can lead to delays, increased costs, or legal risks. Being aware of these pitfalls helps ensure a successful procurement process.

Quality-Related Pitfalls

Inconsistent Material Thickness and Durability

One of the most common quality issues is variability in wall thickness and material strength. Tubes that are too thin or made from low-grade paperboard may collapse during shipping, leading to damaged contents. Always specify minimum burst strength, crush resistance, and wall thickness in product requirements.

Poor Seal or Closure Mechanism

Many cardboard tubes use friction-fit caps, snap lids, or end plugs. Poorly designed or inconsistently manufactured closures can fall off during transit. Ensure that closure mechanisms are rigorously tested and meet functional standards.

Inadequate Moisture Resistance

Standard cardboard is vulnerable to humidity and water damage. If tubes are used in damp environments or shipped internationally, non-laminated or uncoated versions may degrade. Consider requesting water-resistant coatings or laminates where necessary.

Dimensional Inaccuracy

Tubes that vary in length, diameter, or roundness can cause issues with automated packing or end-user experience. Misshapen tubes may not fit accessories or display stands. Verify that suppliers adhere to tight tolerance specifications.

Substandard Printing and Surface Finish

For branded tubes, poor print quality—such as misalignment, fading, or low-resolution graphics—can harm brand perception. Confirm that the supplier has experience with high-quality flexographic or digital printing and offers color accuracy guarantees.

Intellectual Property (IP) Risks

Unauthorized Use of Branded Designs

When sourcing custom-printed tubes featuring logos, artwork, or proprietary designs, there’s a risk that suppliers might reproduce or resell your designs without permission. Always use a robust Non-Disclosure Agreement (NDA) and include IP ownership clauses in contracts.

Supplier Resale of Custom Tooling or Molds

Some suppliers create custom dies or mandrels for unique tube sizes or shapes. If not explicitly addressed in the contract, the supplier may retain ownership and reuse the tooling for competitors. Ensure that tooling ownership transfers to your company or is destroyed after production.

Infringement of Third-Party IP

If your tube design replicates another company’s patented structure (e.g., a unique locking cap or ergonomic shape), you could face legal action. Conduct IP due diligence and consider consulting legal counsel before finalizing designs.

Lack of IP Protection in Overseas Sourcing

When sourcing from international manufacturers—especially in regions with weak IP enforcement—designs are more vulnerable to copying. Use trusted suppliers, register your designs locally where possible, and work with legal experts familiar with international IP law.

By addressing these quality and IP pitfalls proactively, businesses can secure reliable, compliant, and brand-protective cardboard poster tube supply chains.

Logistics & Compliance Guide for Cardboard Poster Tube

This guide outlines the essential logistics and compliance considerations for handling, storing, transporting, and disposing of cardboard poster tubes. These cylindrical packaging solutions are commonly used for shipping posters, blueprints, artwork, and other rolled materials. Ensuring proper logistics management and regulatory compliance supports product safety, environmental responsibility, and supply chain efficiency.

Packaging & Material Specifications

Cardboard poster tubes are typically made from recycled paperboard or kraft paper, wound into a rigid cylindrical form. Key specifications include:

- Diameter Range: Commonly 2″ to 6″, depending on contents

- Length: Typically 18″ to 60″, customizable per requirement

- Wall Thickness: 0.06″ to 0.12″ for durability

- End Caps: Plastic, paperboard, or biodegradable materials

- Printability: Surface suitable for branding and labeling

Ensure materials comply with relevant industry standards (e.g., ISO 9001 for quality management).

Handling & Storage Guidelines

To maintain structural integrity and prevent damage:

- Store tubes upright in dry, climate-controlled environments

- Avoid stacking heavy items on top of tubes

- Maintain humidity levels between 40%–60% to prevent warping

- Use pallets and stretch wrap for bulk storage and transport

- Separate from sharp or abrasive materials

Shipping & Transportation

When shipping cardboard poster tubes:

- Use outer corrugated shippers or master cartons for protection

- Fill void spaces with recyclable dunnage (e.g., paper padding)

- Clearly label with “Fragile,” “This End Up,” and handling instructions

- Comply with carrier-specific packaging requirements (e.g., UPS, FedEx, DHL)

- Consider dimensional weight pricing to optimize shipping costs

Regulatory & Environmental Compliance

Ensure adherence to environmental and safety regulations:

- Recyclability: Confirm tubes are 100% recyclable and free from non-paper contaminants

- REACH & RoHS: Comply with chemical restrictions if inks or coatings are used

- FSC Certification: Use Forest Stewardship Council-certified paperboard when applicable

- Prop 65 (California): Disclose any chemicals known to cause harm if present

- WEEE & Packaging Waste Directives (EU): Follow recovery and recycling targets

Labeling & Documentation

Accurate labeling is critical for traceability and compliance:

- Include product ID, batch number, and manufacturing date

- Apply appropriate hazard or caution labels if required

- Provide disposal instructions (e.g., “Recycle Cardboard”)

- Maintain SDS (Safety Data Sheets) if adhesives or inks are used

Returns & End-of-Life Management

Implement a sustainable end-of-life strategy:

- Encourage customers to flatten and recycle tubes

- Offer take-back programs for bulk users

- Avoid plastic liners unless recyclable or compostable

- Partner with certified recycling facilities

Audit & Continuous Improvement

Regularly review logistics and compliance processes:

- Conduct internal audits of packaging and shipping practices

- Monitor changes in environmental regulations (e.g., EPA, EU Ecodesign)

- Engage suppliers in sustainability initiatives

- Track key performance indicators (KPIs) such as damage rate and recycling rate

By following this guide, businesses can ensure efficient logistics operations and full compliance with environmental and safety standards for cardboard poster tubes.

Conclusion for Sourcing Cardboard Poster Tubes

After evaluating various suppliers, material quality, cost efficiency, and environmental considerations, sourcing cardboard poster tubes should prioritize a balance between durability, sustainability, and cost-effectiveness. It is recommended to partner with reputable suppliers who use recyclable and eco-friendly materials, ensuring compliance with environmental standards while maintaining structural integrity for safe transportation of posters and prints. Additionally, bulk purchasing and long-term supplier agreements can offer cost savings and consistent supply chain reliability. Ultimately, selecting a supplier that aligns with both operational needs and sustainability goals will support brand integrity and customer satisfaction in the long term.