The global demand for sustainable and lightweight packaging solutions has propelled the cardboard mailing tubes market into a phase of steady expansion, with increasing adoption across industries such as textiles, posters and prints, industrial components, and consumer goods. According to a report by Mordor Intelligence, the global paper packaging market—which includes cardboard mailing tubes—is projected to grow at a CAGR of over 5.2% from 2024 to 2029, driven by rising e-commerce activity and the shift toward eco-friendly materials. Similarly, Grand View Research noted that the global corrugated packaging market reached a value of USD 305.1 billion in 2023 and is expected to expand at a CAGR of 5.7% through 2030, with rigid paperboard components like mailing tubes gaining traction due to their durability and recyclability. As brands prioritize low-carbon logistics and circular packaging models, manufacturers specializing in high-performance, customizable cardboard tubes are emerging as key contributors to sustainable supply chains. In this evolving landscape, the top eight cardboard mailing tubes manufacturers distinguish themselves through innovation, scale, and environmental stewardship.

Top 8 Cardboard Mailing Tubes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Callenor: Leaders in Paperboard Product Supply

Domain Est. 1999

Website: callenor.com

Key Highlights: Designed for strength and resilience, our cardboard shipping tubes are ideal for safeguarding a wide range of products, from fragile items to heavy-duty goods….

#2 Paper Tubes and Sales Manufacturing

Domain Est. 2000

Website: pts-mfg.com

Key Highlights: Welcome to Paper Tubes and Sales Manufacturing, where we design, fabricate and sell industrial and consumer paper tubes, composite cans and paper cores….

#3 Paper Tube Manufacturers

Domain Est. 2002

Website: paper-tubes.net

Key Highlights: Chicago Mailing Tube is a premier manufacturer of custom paper tubes, containers, and cores, providing products that are both high quality and economical….

#4 Leading Mailing Tube Manufacturers, Suppliers & Companies

Domain Est. 2012

Website: cardboardtubemanufacturers.com

Key Highlights: Here at Paper Tubes and Sales we are a proven manufacturer of high quality cardboard tubes. These products are ideal for a multitude of industries and our teams ……

#5 International Paper

Domain Est. 1997

Website: internationalpaper.com

Key Highlights: We transform renewable resources into innovative and sustainable packaging solutions, corrugated cardboard boxes, pulp and paper products, recycling solutions ……

#6 Paper Tubes and Cores by Yazoo Mills

Domain Est. 1998 | Founded: 1902

Website: yazoomills.com

Key Highlights: Trusted since 1902, Yazoo Mills manufactures premium paper tubes and cores with fast delivery, consistent quality, and no order minimums….

#7 Paper Tube Co.

Domain Est. 2013

Website: papertube.co

Key Highlights: We design, engineer, and manufacture custom paper tube packaging that stands out, gets noticed, and sells more products. Used by global consumer brands and ……

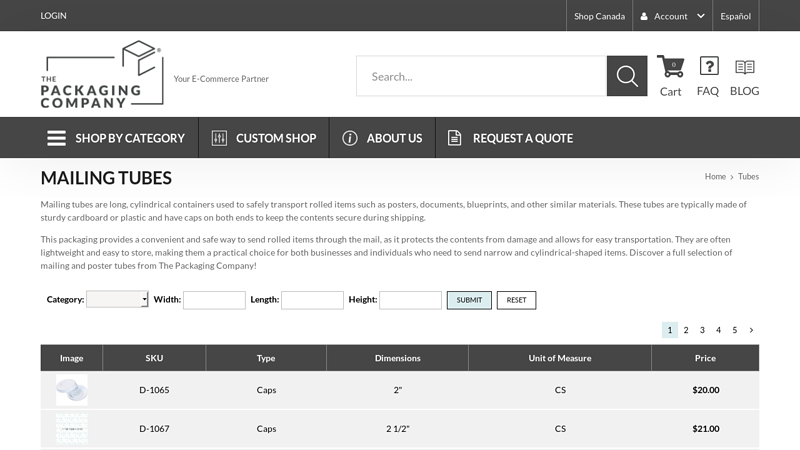

#8 Mailing Tubes

Domain Est. 2016

Expert Sourcing Insights for Cardboard Mailing Tubes

H2: 2026 Market Trends for Cardboard Mailing Tubes

The global market for cardboard mailing tubes is anticipated to experience steady growth and transformation by 2026, driven by sustainability trends, e-commerce expansion, and evolving packaging demands. Key market trends shaping the industry include:

-

Sustainability and Eco-Friendly Packaging Demand

As environmental awareness intensifies, businesses and consumers are increasingly favoring sustainable packaging solutions. Cardboard mailing tubes, being recyclable, biodegradable, and often made from post-consumer waste, align well with green initiatives. By 2026, regulatory pressures and corporate sustainability goals are expected to further boost demand for eco-conscious packaging, positioning cardboard tubes as a preferred alternative to plastic-based mailing solutions. -

Growth in E-Commerce and Direct-to-Consumer Shipping

The continued rise of e-commerce, especially in niche markets such as art, posters, textiles, and technical documents, is driving demand for protective and cost-effective shipping solutions. Cardboard mailing tubes offer a lightweight, durable option ideal for rolled materials. As brands adopt direct-to-consumer (DTC) models, customization and branding on tubes will increase, enhancing their appeal in premium and personalized packaging segments. -

Customization and Branding Opportunities

Advancements in digital printing technologies are enabling cost-effective customization of cardboard mailing tubes. By 2026, more businesses are expected to leverage printed tubes for branding, marketing, and unboxing experiences. Custom sizes, colors, and finishes will allow companies to differentiate themselves, particularly in competitive markets like fashion, art, and luxury goods. -

Innovation in Material and Design

Manufacturers are investing in improved moisture resistance, structural integrity, and tamper-evident features for cardboard tubes. Innovations such as water-based coatings and reinforced seams will enhance product protection during transit. Additionally, designs optimized for automated packing systems will support scalability in fulfillment centers. -

Regional Market Expansion

While North America and Europe remain dominant markets due to strong e-commerce infrastructure and environmental regulations, Asia-Pacific is expected to witness the fastest growth. Rising middle-class consumption, expanding logistics networks, and government support for sustainable packaging in countries like China, India, and Southeast Asian nations will fuel regional demand. -

Supply Chain Resilience and Localized Production

In response to global supply chain disruptions, companies are increasingly sourcing packaging materials locally. This trend is expected to encourage regional manufacturing of cardboard mailing tubes, reducing lead times and carbon footprints. By 2026, decentralized production models could become more prevalent, especially in emerging markets.

In summary, the 2026 outlook for cardboard mailing tubes is positive, supported by environmental imperatives, technological advancements, and shifting consumer behaviors. As brands prioritize sustainability and customer experience, cardboard mailing tubes are poised to play a strategic role in the future of protective packaging.

Common Pitfalls When Sourcing Cardboard Mailing Tubes (Quality and Intellectual Property)

Sourcing cardboard mailing tubes may seem straightforward, but overlooking key quality and intellectual property (IP) concerns can lead to costly issues, damaged brand reputation, and legal complications. Being aware of these common pitfalls helps ensure a reliable supply of effective and compliant packaging.

Poor Material Quality and Structural Integrity

One of the most frequent issues is receiving tubes made from substandard cardboard. Thin walls, low burst strength, or improper winding can result in tubes crushing during transit, leading to damaged contents and customer dissatisfaction. Always verify specifications like wall thickness, compression strength, and material grade (e.g., kraft vs. recycled content) with suppliers and request physical samples before bulk ordering.

Inconsistent Dimensions and Tolerances

Variability in diameter, length, or cap fit due to poor manufacturing control can disrupt automated packaging lines and affect branding. Tubes that don’t align with labeling or sealing equipment cause delays and waste. Clearly define dimensional tolerances in procurement contracts and conduct regular quality audits.

Inadequate Moisture and Water Resistance

Standard cardboard tubes may degrade in humid environments or if exposed to moisture, compromising product safety. Suppliers may overlook the need for moisture-resistant coatings or laminates. Confirm whether your application requires water-resistant treatments and verify performance with testing data.

Misrepresentation of Sustainability Claims

Many buyers prioritize eco-friendly packaging, but some suppliers make misleading claims about recyclability, biodegradability, or recycled content. Ensure certifications (e.g., FSC, SFI) are valid and backed by documentation. Greenwashing not only affects environmental goals but can also trigger regulatory scrutiny.

Overlooking Custom Design IP Rights

When sourcing custom-designed tubes—especially with unique graphics, shapes, or closures—failure to secure intellectual property rights is a major risk. Suppliers may retain design rights or reuse your custom molds and artwork for other clients. Always establish clear IP ownership in contracts, including rights to artwork, tooling, and proprietary designs.

Unauthorized Use of Branded or Patented Features

Some tube designs, such as twist caps, tamper-evident seals, or specific closure mechanisms, may be patented. Sourcing tubes that replicate these features without a license exposes your business to infringement claims. Conduct due diligence on design elements and ensure suppliers warrant their products don’t violate existing patents.

Lack of Compliance with International Shipping Standards

For global distribution, tubes must meet regulatory standards (e.g., ISTA, ISO) for durability and material safety. Non-compliant tubes can be rejected at customs or fail in transit. Confirm that your supplier adheres to relevant international standards and provides test reports when required.

Dependency on Sole or Unverified Suppliers

Relying on a single supplier—especially one without third-party audits—increases risk of supply chain disruption and quality inconsistency. Diversify sourcing and conduct supplier audits to verify production practices, quality control processes, and ethical standards.

By proactively addressing these pitfalls, businesses can secure high-quality, compliant, and IP-safe cardboard mailing tubes that protect products and strengthen brand trust.

Logistics & Compliance Guide for Cardboard Mailing Tubes

Cardboard mailing tubes are a popular packaging solution for shipping posters, blueprints, artwork, documents, and other rolled materials. To ensure efficient logistics and regulatory compliance, businesses must understand key considerations related to materials, labeling, transportation, and sustainability. This guide outlines best practices and requirements for using cardboard mailing tubes in domestic and international shipping.

Material Composition and Sourcing

Cardboard mailing tubes are typically made from recycled paperboard or kraft paper, wound into a cylindrical shape and bonded with adhesives. To meet environmental and compliance standards:

- Use tubes made from 100% recycled content where possible.

- Ensure adhesives are non-toxic and water-based to support recyclability.

- Verify that materials comply with Forest Stewardship Council (FSC) or Sustainable Forestry Initiative (SFI) certifications if promoting sustainable sourcing.

- Avoid coatings or laminates that hinder recyclability unless necessary (e.g., moisture-resistant barriers—clearly label as such).

Dimensional and Weight Guidelines

To optimize shipping efficiency and avoid dimensional weight charges:

- Confirm tube length and diameter comply with carrier size limits (e.g., UPS, FedEx, USPS).

- Keep total length + girth (diameter × π × 2) under 108 inches for standard ground services (check carrier-specific rules).

- Use lightweight materials to reduce overall package weight and shipping costs.

- Clearly mark internal dimensions on inventory systems to ensure correct product fit.

Labeling and Marking Requirements

Proper labeling ensures regulatory compliance and shipment integrity:

- Include sender and recipient addresses legibly on a label affixed to the side (not the cap).

- Use orientation arrows (“This End Up”) to prevent improper stacking.

- Apply fragile labels if contents are sensitive.

- For international shipments, include customs declarations, proper Harmonized System (HS) codes (e.g., 4819.20 for paper packaging), and country of origin.

- If recyclable, include the universal recycling symbol and “Recycle Cardboard” messaging.

Shipping and Carrier Regulations

Different carriers have specific rules for cylindrical packages:

- USPS: Accepts tubes up to 70 lbs; length + girth ≤ 108 inches for Priority Mail; longer tubes may require Parcel Select.

- UPS/FedEx: Charge based on dimensional weight if package density is low; tubes exceeding standard limits may incur oversize fees.

- IATA/ADR Regulations: For air or hazardous goods, ensure tubes do not contain restricted materials. Most mailing tubes are exempt unless used for dangerous goods.

- Automated Sorting: Avoid protruding caps or uneven ends that may jam sorting equipment.

Environmental and Regulatory Compliance

Cardboard mailing tubes must meet environmental and safety standards:

- Comply with EPA guidelines for recycled content and disposal.

- Adhere to European Packaging Waste Directive (94/62/EC) for shipments to the EU—ensure tubes are recoverable and meet heavy metal limits.

- In California, follow Proposition 65 requirements: disclose if adhesives contain listed chemicals.

- For food-contact applications (e.g., bakery tubes), comply with FDA 21 CFR regulations—standard mailing tubes are not suitable unless specifically certified.

Sustainability and End-of-Life

To support circular economy goals:

- Design tubes for easy disassembly (removable plastic or paper caps).

- Encourage consumers to recycle through clear instructions.

- Avoid mixed materials (e.g., plastic windows or metal closures) unless recyclable as a single stream.

- Consider compostable tubes for eco-conscious brands—ensure certifications like BPI or OK Compost if claiming compostability.

Best Practices Summary

- Source from suppliers with verifiable sustainability credentials.

- Test packaging with actual contents to ensure crush resistance and fit.

- Audit compliance annually, especially for international shipping.

- Train logistics staff on proper labeling and carrier-specific requirements.

By following this guide, businesses can ensure their use of cardboard mailing tubes is logistically efficient, cost-effective, and compliant with environmental and transportation regulations.

Conclusion for Sourcing Cardboard Mailing Tubes

After evaluating various suppliers, materials, and cost factors, sourcing cardboard mailing tubes presents a sustainable, cost-effective, and protective packaging solution for a wide range of products—particularly posters, blueprints, textiles, and other long, cylindrical, or fragile items. Key considerations such as tube diameter, length, wall thickness, and closure type (end caps, friction lids, etc.) must align with the specific shipping and branding needs of the business.

Opting for recyclable, FSC-certified, or biodegradable cardboard supports eco-friendly initiatives and meets growing consumer demand for sustainable packaging. Bulk purchasing from reputable manufacturers—domestically or internationally—can significantly reduce per-unit costs, though lead times, shipping logistics, and minimum order quantities should be weighed carefully.

In conclusion, partnering with reliable suppliers who offer quality assurance, customization options (such as printing or branded designs), and flexible order sizes ensures a resilient supply chain and enhances customer satisfaction. With proper sourcing strategy, cardboard mailing tubes serve as both a functional packaging choice and a reflection of brand values centered on sustainability and reliability.