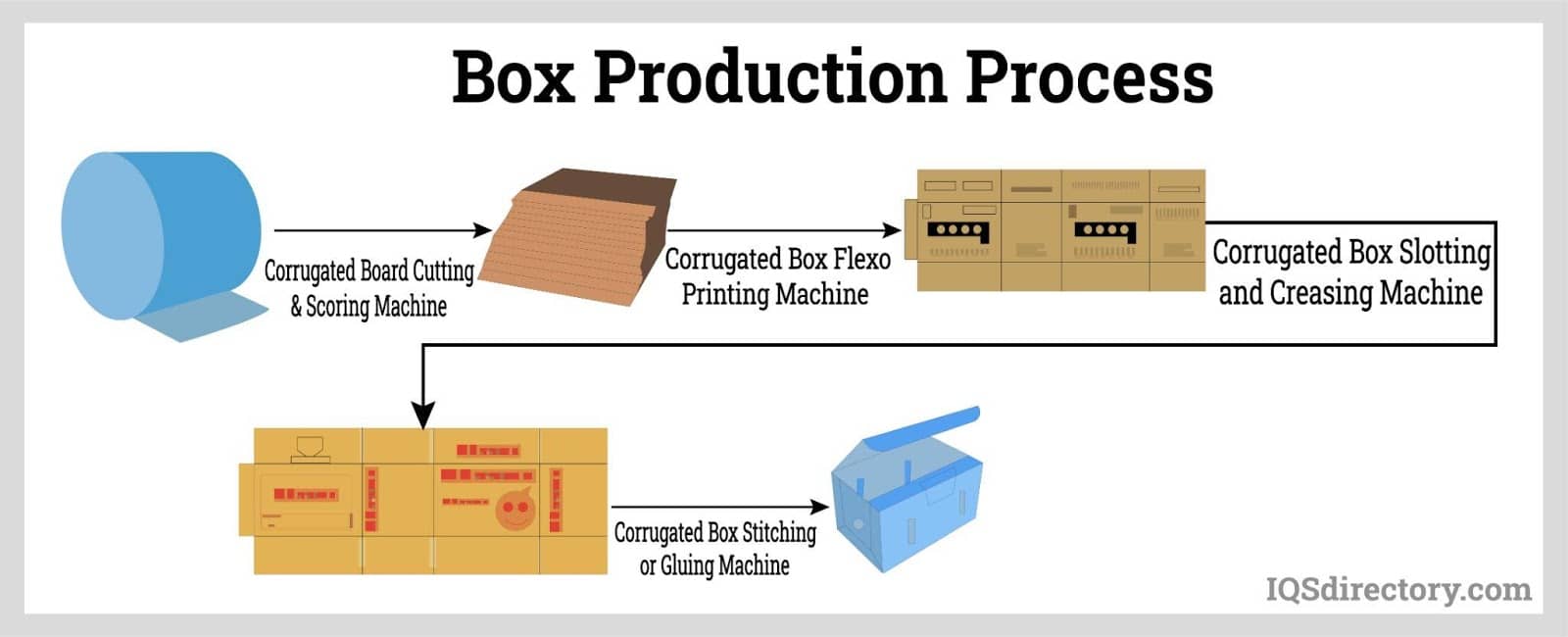

The global corrugated packaging market is experiencing robust growth, driven by rising e-commerce activity, increasing consumer demand for sustainable packaging, and advancements in packaging design. According to Grand View Research, the market was valued at USD 253.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.7% from 2023 to 2030. This surge is further amplified by the shift toward eco-friendly materials, with cardboard emerging as a preferred choice due to its recyclability and biodegradability. As brands prioritize both functionality and aesthetic appeal, the demand for innovative cardboard box packaging designs has intensified. In this competitive landscape, leading manufacturers are leveraging automation, digital printing, and sustainable sourcing to deliver customizable, high-impact packaging solutions. The following list highlights the top 10 cardboard box packaging design manufacturers shaping the industry through design excellence, scalability, and environmental stewardship.

Top 10 Cardboard Box Packaging Design Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cardbox Packaging

Domain Est. 2012

Website: cardbox-packaging.com

Key Highlights: Cardbox Packaging is an international producer of high quality and sophisticated carton packaging and paper cups focused primarily on FMCG market….

#2 Custom Cardboard Shipping Boxes from a Corrugated Box …

Domain Est. 2004

Website: expresspkg.com

Key Highlights: Express Packaging is a corrugated boxes manufacturer offering custom solutions to ensure complete satisfaction. As the oldest packaging manufacturer in ……

#3 Acme Corrugated Box

Domain Est. 1996

Website: acmebox.com

Key Highlights: We Think Inside and Outside the Box. Acme Corrugated Box offers packaging solutions you expect – and a few you won’t find anywhere else….

#4 BoxUp

Domain Est. 1998

Website: boxup.com

Key Highlights: Showcase your small business by adding your company logo and branding to any of BoxUp’s designs. Choose from custom mailers, gable boxes, or shipping boxes….

#5 Welch Packaging

Domain Est. 1999

Website: welchpkg.com

Key Highlights: Welch Packaging manufactures custom cardboard boxes, retail packaging, and e-commerce packaging. We offer design services, assembly, fulfilment, and delivery ……

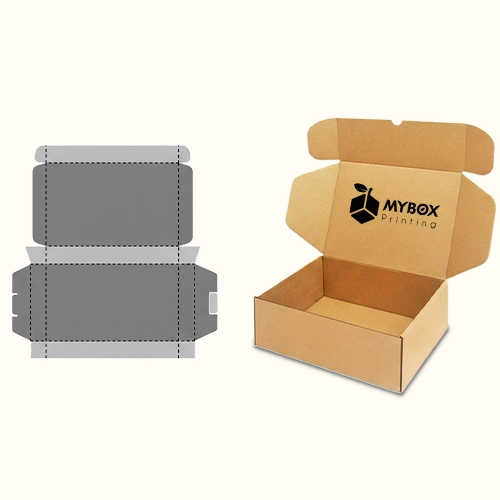

#6 Custom Die

Domain Est. 1999

Website: prempack.com

Key Highlights: Find the perfect packaging box for your products. Our custom corrugated shipping boxes are made with quality and durability in mind….

#7 Packwire

Domain Est. 2004

Website: packwire.com

Key Highlights: Design your custom boxes and packaging and place your order online in a few clicks. Packwire offers corrugated mailers, shipping boxes, retail folding boxes ……

#8 CompanyBox

Domain Est. 2006

Website: companybox.com

Key Highlights: CompanyBox helps customers build and strengthen their brands through custom-printed cardboard boxes, packaging, mailers, shippers, displays, and more….

#9 The Royal Group

Domain Est. 2016

Website: teamtrg.com

Key Highlights: Get wholesale packaging solutions with POP displays, supplies, and display solutions. Unlock custom, high-quality packaging to protect products….

#10 105 Packaging

Domain Est. 2024

Website: 105packaging.com

Key Highlights: Free delivery 14-day returnsWhere packaging meets personality. Design your packaging with our easy drag and drop design tool. Fast designer support and eco-friendly….

Expert Sourcing Insights for Cardboard Box Packaging Design

2026 Market Trends for Cardboard Box Packaging Design

As sustainability, e-commerce growth, and consumer experience continue to shape global packaging strategies, cardboard box packaging design is poised for significant evolution by 2026. This analysis explores the key trends influencing the industry, highlighting innovations, consumer demands, and technological advancements that will define the future of cardboard packaging.

Sustainability and Eco-Friendly Materials

Environmental responsibility remains a dominant driver in packaging design. By 2026, brands are expected to place even greater emphasis on fully recyclable, compostable, and biodegradable cardboard solutions. Consumers increasingly favor minimalistic packaging with reduced ink usage and avoidance of plastic coatings. Expect wider adoption of:

- Recycled and post-consumer waste (PCW) content in cardboard production.

- Water-based inks and natural dyes for printing.

- Plant-based barrier coatings replacing traditional plastic laminates to maintain durability while enhancing recyclability.

Regulatory pressures in North America, Europe, and parts of Asia will further accelerate the shift toward sustainable materials, pushing manufacturers to innovate in fiber sourcing and production processes.

E-Commerce Optimized Structural Design

With online retail continuing to expand, cardboard packaging in 2026 will be engineered primarily for e-commerce efficiency. Key developments include:

- Right-sized packaging to reduce material waste and shipping costs.

- Enhanced durability through double-wall corrugated board and reinforced corners to withstand multiple handling stages.

- Integrated tamper-evident features and easy-open mechanisms to improve unboxing experience and security.

Designers will increasingly use AI-driven simulation tools to prototype packaging that balances protection, cost, and sustainability for direct-to-consumer logistics.

Smart Packaging and Digital Integration

By 2026, smart technology will become more accessible and integrated into cardboard packaging. Trends include:

- QR codes and NFC tags embedded in box designs, enabling consumers to access product information, track sourcing, or engage with augmented reality (AR) content.

- Anti-counterfeiting solutions using digital watermarks and blockchain verification.

- Interactive unboxing experiences that connect physical packaging with digital brand storytelling or loyalty programs.

These features will help brands differentiate themselves while meeting consumer demand for transparency and engagement.

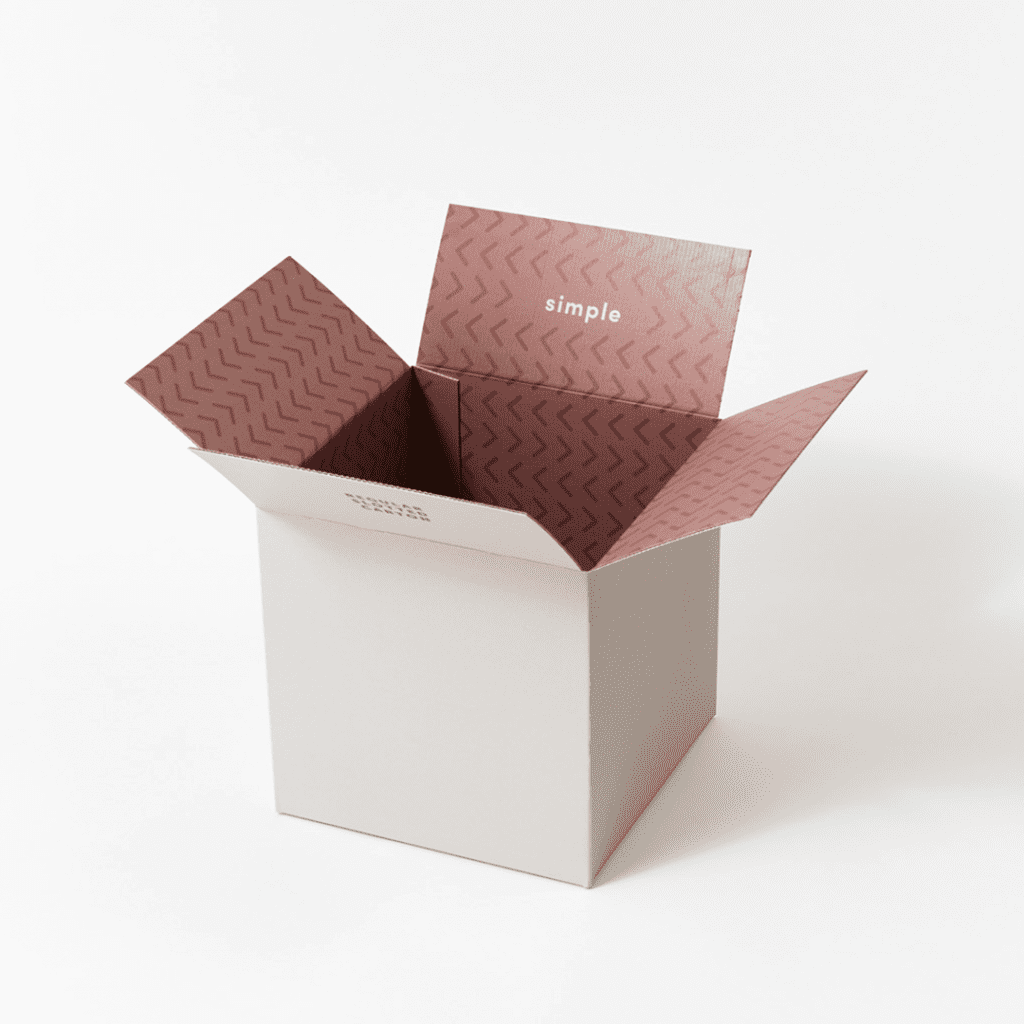

Minimalist and Brand-Centric Aesthetics

Visual design will lean toward clean, minimalist aesthetics that emphasize brand identity through typography, negative space, and subtle textures. In 2026, brands will use cardboard packaging not just as a container, but as a tactile extension of their values. Trends include:

- Uncoated kraft finishes that highlight the natural look of cardboard.

- Spot UV coatings and embossing for premium tactile appeal without sacrificing recyclability.

- Custom die-cut windows and modular designs that showcase products while maintaining structural integrity.

This shift reflects a growing desire for authenticity and transparency in branding.

Automation and Mass Customization

Advancements in digital printing and automated packaging lines will enable cost-effective on-demand and personalized packaging. By 2026, small and medium enterprises (SMEs) will gain access to scalable solutions for limited-run, customized cardboard boxes. This trend supports niche marketing, seasonal campaigns, and direct-to-consumer personalization, such as:

- Name or message printing on delivery boxes.

- Region-specific designs for localized branding.

Faster turnaround times and reduced setup costs will make custom cardboard packaging more accessible than ever.

Circular Economy and Reusable Packaging Models

The push toward a circular economy will inspire new reuse models. While single-use cardboard remains prevalent, 2026 will see increased experimentation with:

- Returnable and refillable cardboard packaging systems, especially in retail and subscription services.

- Consumer incentive programs encouraging box returns for recycling or repurposing.

- Design-for-disassembly principles, allowing boxes to be easily flattened, reused, or repurposed at home.

Brands aiming for net-zero goals will leverage these models to reduce lifecycle emissions and strengthen customer loyalty.

Conclusion

The cardboard box packaging design landscape in 2026 will be shaped by a convergence of sustainability, technology, and consumer-centric innovation. As environmental regulations tighten and digital integration becomes standard, designers and manufacturers must balance functionality, aesthetics, and ecological responsibility. Brands that embrace these trends early will not only reduce their environmental footprint but also enhance customer engagement and competitive advantage in an increasingly conscious marketplace.

Common Pitfalls in Sourcing Cardboard Box Packaging Design: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Cardboard Box Packaging Design

Designing effective cardboard box packaging requires a balance between functionality, cost-efficiency, and adherence to logistics and regulatory standards. This guide outlines key considerations to ensure your packaging supports smooth transportation, storage, and compliance with industry and legal requirements.

Structural Integrity and Stackability

Cardboard boxes must withstand stacking during storage and transit. Design with adequate compression strength by selecting the appropriate corrugated board grade (e.g., ECT or Mullen values) based on product weight and stacking height. Ensure consistent box dimensions that allow for tight, stable pallet configurations to prevent shifting and toppling.

Dimensional Optimization

Optimize box dimensions to reduce material usage and shipping costs. Avoid excessive void space; use dunnage or partitioning to secure contents. Design to standardized pallet and container dimensions (e.g., ISO pallets, shipping containers) to maximize space utilization and minimize freight charges based on dimensional weight.

Weight Considerations and Load Limits

Clearly label the gross weight of the packaged product. Ensure the box design supports the maximum load without failure. Respect carrier weight limits per package (e.g., most couriers cap at 70 lbs/31.8 kg) to avoid handling issues and additional fees.

Drop, Vibration, and Compression Testing

Validate packaging performance through standardized tests (e.g., ASTM D4169 or ISTA procedures). Simulate real-world hazards such as drops, vibrations, and compression forces during transport. Use test results to refine box design, flute selection, and internal protection methods.

Labeling and Barcoding Requirements

Include all mandatory labels: shipping address, return address, handling instructions (e.g., “This Side Up”), and barcodes (e.g., UPC, SSCC). Ensure barcodes are placed on flat, undamaged surfaces and comply with size, contrast, and placement standards (e.g., GS1 specifications) for reliable scanning.

Hazardous Materials & Special Handling

If packaging contains hazardous goods (e.g., chemicals, batteries), comply with relevant regulations such as DOT (U.S.), ADR (Europe), or IATA (air). Use UN-certified packaging where required, include proper hazard labels, and document contents accurately on shipping manifests.

Sustainability and Recyclability Compliance

Design for recyclability: avoid mixed materials, plastic laminates, or non-removable components. Use recycled content where possible and label with appropriate recycling symbols (e.g., Möbius loop). Comply with regional regulations such as the EU Packaging and Packaging Waste Directive or California’s SB 270.

International Shipping Regulations

For cross-border shipments, ensure packaging meets ISPM 15 standards for wood components (if used in crates or pallets). Avoid materials subject to phytosanitary restrictions. Include required customs documentation and ensure all labeling is in the destination country’s language if mandated.

Tamper-Evidence and Security Features

For consumer or regulated goods (e.g., pharmaceuticals, food), incorporate tamper-evident seals or designs. Use security tapes, destructible labels, or sealed flaps that show visible signs of interference to protect product integrity.

Documentation and Traceability

Maintain records of packaging specifications, testing results, and compliance certifications. Implement batch or lot tracking through labels or RFID where necessary for recalls or supply chain visibility.

By integrating these logistics and compliance principles into your cardboard box packaging design, you ensure product safety, reduce shipping risks, and support sustainable, legally compliant operations across global supply chains.

In conclusion, sourcing cardboard box packaging design involves a strategic balance between functionality, aesthetics, sustainability, and cost-efficiency. A well-designed cardboard packaging solution not only protects the product during transit but also serves as a powerful branding and marketing tool. By collaborating with reliable suppliers, leveraging innovative design techniques, and prioritizing eco-friendly materials, businesses can create packaging that resonates with consumers while minimizing environmental impact. Ultimately, investing in thoughtful cardboard box packaging design enhances customer experience, supports brand identity, and contributes to long-term business success in a competitive market.