The global chainsaw market is experiencing steady growth, driven by increasing demand in forestry, landscaping, and residential applications. According to Grand View Research, the global chainsaw market size was valued at USD 4.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. A significant portion of this market continues to rely on carburetor-based engines, particularly in regions with limited access to battery infrastructure and among users prioritizing cost-efficiency and power. As gasoline-powered chainsaws remain dominant in many professional and rural settings, carburetor technology plays a crucial role in engine performance, fuel efficiency, and emissions control. This sustained demand has fostered a competitive landscape of manufacturers specializing in durable, high-performance carburetor chainsaws. Based on production scale, technological innovation, and market reach, the following nine companies stand out as leading manufacturers shaping the current and future trajectory of the carburetor chainsaw industry.

Top 9 Carburetor Chainsaw Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Official Echo Chainsaw Carburetors

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: 1–2 day delivery 365-day returnsFind Carburetors to repair your Echo Chainsaw at eReplacementParts.com. Great prices on all factory–authorized Echo Carburetors….

#2 Farmertec

Domain Est. 2012

Website: farmertec.com

Key Highlights: 2.6 19 Farmertec.com is an online store by Farmertec Power Machinery, the purpose of the online store is to bring the best gas chainsaw and spare parts closer to you….

#3 Chainsaw cylinder parts and Chain brake manufacturer

Domain Est. 2013

Website: chainsawtooling.com

Key Highlights: NEW WEST Specializes in manufacture of chainsaw accessories. We supply high quality products including crankcase crankshaft, cylinder assembly, carburetor, and ……

#4 Chainsaw Carburetor Manufacturer

Domain Est. 2024

Website: stablecarb.com

Key Highlights: Shop high-quality Stable chainsaw carburetor online. Chainsaw carburetor is used in chainsaws STIHL MS170, MS180 and other model chainsaw….

#5 Parts & Service

Domain Est. 1994

Website: walbro.com

Key Highlights: Looking for a Carburetor or Parts? Available below is our: Catalog, where you can find carburetors and their associated kits; Online Store, where you can ……

#6 Carburetors (Lawn & Garden)

Domain Est. 1998

Website: tillotson.ie

Key Highlights: Our four main lines of diaphragm carburetors – HU, HE, HS and HL – cover the full range of engines, from smaller consumer engines to heavy-duty professional ……

#7 HUAYANG Carburetor

Domain Est. 2000

Website: huayang-china.com

Key Highlights: In China, we produces one of the most popular carburetor HUAYANG carburetor for a full line of gasoline outdoor power tools from Chainsaws, Brush Cutters, ……

#8 Parts & Service

Domain Est. 2011

Website: zamacorp.com

Key Highlights: Carburetor. $72.74. 1. Z011-120-0638-C, Carburetor. $64.40. 1. Z020-120-0613-A, Carburetor. CHECK AVAILABILITY WITH YOUR LOCAL DEALER OR DISTRIBUTOR. Z011-120- ……

#9 Carburetors

Expert Sourcing Insights for Carburetor Chainsaw

H2: 2026 Market Trends for Carburetor Chainsaws

As the global power tools and outdoor equipment market evolves, the carburetor chainsaw segment is expected to experience steady but transitional growth by 2026. Despite increasing competition from battery-powered and electric models, carburetor (gas-powered) chainsaws remain relevant in specific markets due to their power, durability, and cost-effectiveness for heavy-duty applications. The following key trends are anticipated to shape the carburetor chainsaw market in 2026:

-

Sustained Demand in Developing Regions

In emerging economies across Asia-Pacific, Latin America, and parts of Africa, carburetor chainsaws continue to dominate due to limited access to reliable electricity and lower upfront costs compared to battery-powered alternatives. Agricultural expansion, forestry operations, and rural infrastructure projects will drive consistent demand in these regions. -

Emission Regulations Influencing Design Innovation

Stricter environmental regulations—especially in North America and Europe—are pushing manufacturers to adopt low-emission two-stroke and advanced four-stroke engines. By 2026, most new carburetor chainsaws are expected to comply with EPA Tier 3 and Euro Stage V standards, incorporating improved carburetor tuning, catalytic converters, and fuel-efficient combustion technologies. -

Hybridization and Technological Upgrades

While fully electric models gain traction, some manufacturers are enhancing carburetor chainsaws with smart features such as auto-tuning carburetors, improved cold-start mechanisms, and diagnostic systems. These upgrades aim to extend the product lifecycle and bridge the performance gap with electric alternatives. -

Competition from Cordless Electric Chainsaws

The rise of high-capacity lithium-ion batteries is a major challenge for carburetor chainsaws. By 2026, cordless electric models are projected to capture a larger share of the consumer and light commercial markets due to quieter operation, lower maintenance, and eco-friendliness. However, carburetor chainsaws will retain dominance in professional logging and remote-area operations where runtime and refueling speed are critical. -

Focus on Aftermarket and Replacement Parts

The large installed base of existing gas-powered chainsaws ensures strong demand for replacement carburetors, filters, and maintenance kits. By 2026, the aftermarket segment is expected to grow, supported by third-party component manufacturers and DIY repair trends. -

Price Sensitivity and Value Positioning

Carburetor chainsaws will continue to hold a price advantage over premium electric models. This will make them attractive to budget-conscious users, small landowners, and contractors in price-sensitive markets. Manufacturers will likely emphasize total cost of ownership and ruggedness in marketing efforts. -

Regional Shifts in Production and Supply Chains

China remains a dominant manufacturer of carburetor chainsaws and components, but rising labor costs and trade considerations may lead to increased production in Southeast Asia and Eastern Europe by 2026. This could affect supply chain dynamics and influence pricing.

In summary, while the carburetor chainsaw market faces pressure from electrification and regulatory trends, it is expected to maintain a stable presence through 2026—particularly in professional, rural, and developing markets. Innovation, compliance, and strategic positioning will be critical for manufacturers aiming to sustain relevance in a transitioning landscape.

Common Pitfalls When Sourcing Carburetor Chainsaws (Quality and Intellectual Property)

Sourcing carburetor chainsaws, especially from international or third-party suppliers, involves significant risks related to both product quality and intellectual property (IP) rights. Avoiding these common pitfalls is crucial for protecting your brand, ensuring customer satisfaction, and maintaining legal compliance.

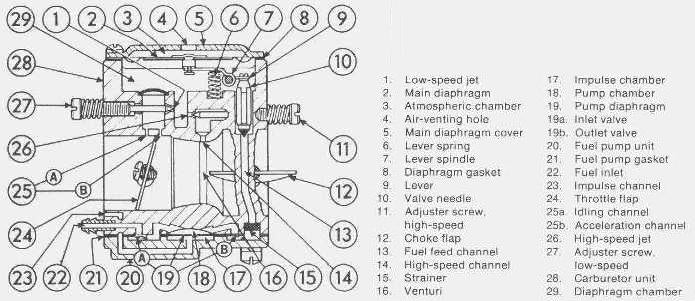

Poor Build Quality and Component Reliability

One of the most frequent issues when sourcing carburetor chainsaws is inconsistent or substandard build quality. Many low-cost manufacturers use inferior materials—such as low-grade aluminum, plastic components, or poorly machined carburetors—that degrade quickly under regular use. This results in frequent engine failures, fuel leaks, or performance issues like hard starting and stalling. Buyers often discover these flaws only after large shipments arrive, leading to costly returns, warranty claims, and reputational damage.

Lack of Compliance with Safety and Emissions Standards

Many sourced chainsaws—particularly those from unverified suppliers—fail to meet regional safety and emissions regulations (e.g., EPA, CARB, or EU CE standards). Using non-compliant carburetors can lead to excessive emissions, increased noise levels, or unsafe operation. Importing or selling such products can result in fines, shipment seizures, or legal liability in the event of user injury. Always require test certifications and ensure the product has been independently verified.

Inaccurate or Misrepresented Specifications

Suppliers may exaggerate engine power, fuel efficiency, or durability in product descriptions. For example, a chainsaw advertised as “52cc” might actually use an undersized or poorly tuned engine that performs more like a 45cc model. Similarly, carburetor types (e.g., diaphragm vs. float) may be misrepresented, affecting performance in different operating conditions. Always request third-party performance testing or conduct in-house evaluations before bulk ordering.

Intellectual Property Infringement

Sourcing carburetor chainsaws carries a high risk of IP violations. Many generic or OEM-style chainsaws copy the design, branding, or patented components (such as carburetor mounting systems or anti-vibration technology) of major brands like Stihl, Husqvarna, or Echo. Even if the supplier claims the product is “compatible,” using look-alike designs or logos can expose your business to cease-and-desist letters, lawsuits, or customs detentions. Always conduct IP clearance searches and avoid suppliers offering “replica” or “branded-style” products.

Inadequate After-Sales Support and Spare Parts

Low-cost suppliers often lack robust customer support or spare parts inventories. If a carburetor fails in the field, customers may be unable to get replacements or technical assistance, leading to negative reviews and loss of trust. Ensure your supplier offers a warranty, technical documentation, and readily available spare parts—especially for critical components like carburetors, which are prone to wear and adjustment.

Supply Chain and Consistency Issues

Batch-to-batch inconsistencies are common with mass-produced carburetor chainsaws. One shipment may perform well, while the next includes carburetors with incorrect jetting or poor fuel seals. Without strong quality control agreements and incoming inspection processes, businesses risk receiving non-uniform inventory that complicates servicing and support.

Conclusion

To mitigate these risks, conduct thorough due diligence on suppliers, insist on product certifications, perform independent quality audits, and consult legal experts on IP compliance. Investing in reliable sourcing practices upfront saves significant cost and liability down the line.

Logistics & Compliance Guide for Carburetor Chainsaw

This guide outlines the key logistics and compliance considerations for the transportation, handling, and regulatory approval of carburetor chainsaws. Adhering to these guidelines ensures safe, legal, and efficient operations across the supply chain.

Regulatory Compliance

Understanding and meeting regional and international regulations is essential for legal distribution and use of carburetor chainsaws.

Emissions and Environmental Standards

Carburetor chainsaws must comply with emissions regulations set by environmental agencies. In the United States, the Environmental Protection Agency (EPA) regulates small off-road engines (SORE) under 40 CFR Part 90, which limits hydrocarbon and nitrogen oxide (NOx) emissions. In the European Union, compliance with the EU Stage V emission standards under Regulation (EU) 2016/1628 is mandatory. Manufacturers must ensure certification and proper labeling (e.g., EPA or EU label) are affixed to each unit.

Noise Regulations

Chainsaws are subject to noise emission limits. The EU EN ISO 11681-1 standard specifies sound power level testing and maximum permissible noise levels. In the U.S., OSHA and EPA may impose workplace and product noise standards. Products must be tested and documented to meet these requirements.

Safety and Product Certification

Carburetor chainsaws must meet safety standards such as ANSI B175.1 (North America) and EN 13235 (Europe). These cover chain brake effectiveness, hand protection, throttle controls, and anti-vibration systems. Third-party certification from bodies like UL, CSA, or TÜV may be required for market access.

Packaging and Labeling Requirements

Proper packaging and labeling ensure product safety, regulatory adherence, and ease of handling during logistics.

Packaging Standards

Units should be packaged securely to prevent damage during transit. Use of corrugated cardboard, molded foam inserts, and protective wrapping is recommended. Packaging must withstand stacking and standard freight handling. Include desiccants in humid environments to prevent rust.

Labeling Compliance

Each package must display required regulatory labels, including:

– EPA or EU emissions compliance

– CE or UKCA marking (for European/UK markets)

– Manufacturer name and contact information

– Model and serial number

– Safety warnings and instructions (per local language requirements)

– Hazard symbols (e.g., fuel caution, moving parts)

Transportation and Shipping

Safe and compliant transport of chainsaws involves adherence to shipping regulations and proper handling procedures.

Domestic and International Shipping

Chainsaws containing residual fuel or lubricants may be classified as hazardous goods under IATA, IMDG, or ADR regulations. Even trace fuel can trigger classification under UN 3542 (Internal combustion engines). Always drain fuel completely before shipping unless approved as non-hazardous. Declare contents accurately and use appropriate shipping documentation.

Storage Conditions

Store chainsaws in a dry, temperature-controlled environment away from direct sunlight and flammable materials. Avoid high humidity to prevent corrosion. Palletized storage with proper load limits helps prevent damage.

Import and Export Documentation

Successful cross-border movement requires accurate documentation and customs compliance.

Required Documentation

– Commercial Invoice (with Harmonized System [HS] code – typically 8467.81 for chain saws)

– Packing List

– Certificate of Origin

– EPA or EU Conformity Declaration (for emissions)

– Test Reports (noise, safety, emissions)

– Bill of Lading or Air Waybill

Customs Clearance

Ensure HS code accuracy to avoid delays or incorrect duty assessments. Be prepared for customs inspections, especially for engines with emission controls. Use a licensed customs broker for complex shipments.

Aftermarket and Servicing Compliance

Post-sale compliance ensures ongoing regulatory adherence and customer safety.

Parts and Replacement Carburetors

Replacement carburetors must meet the same emissions and performance standards as original equipment. Distributors must provide EPA-certified or EU-equivalent parts. Tampering with emissions systems is prohibited under U.S. law.

User Instructions and Safety

Include multilingual user manuals with assembly, operation, maintenance, and safety instructions. Manuals must highlight refueling procedures, PPE requirements, and environmental precautions to remain compliant with consumer protection laws.

By following this guide, distributors, retailers, and logistics providers can ensure that carburetor chainsaws are handled safely, shipped legally, and meet all applicable regulatory standards worldwide.

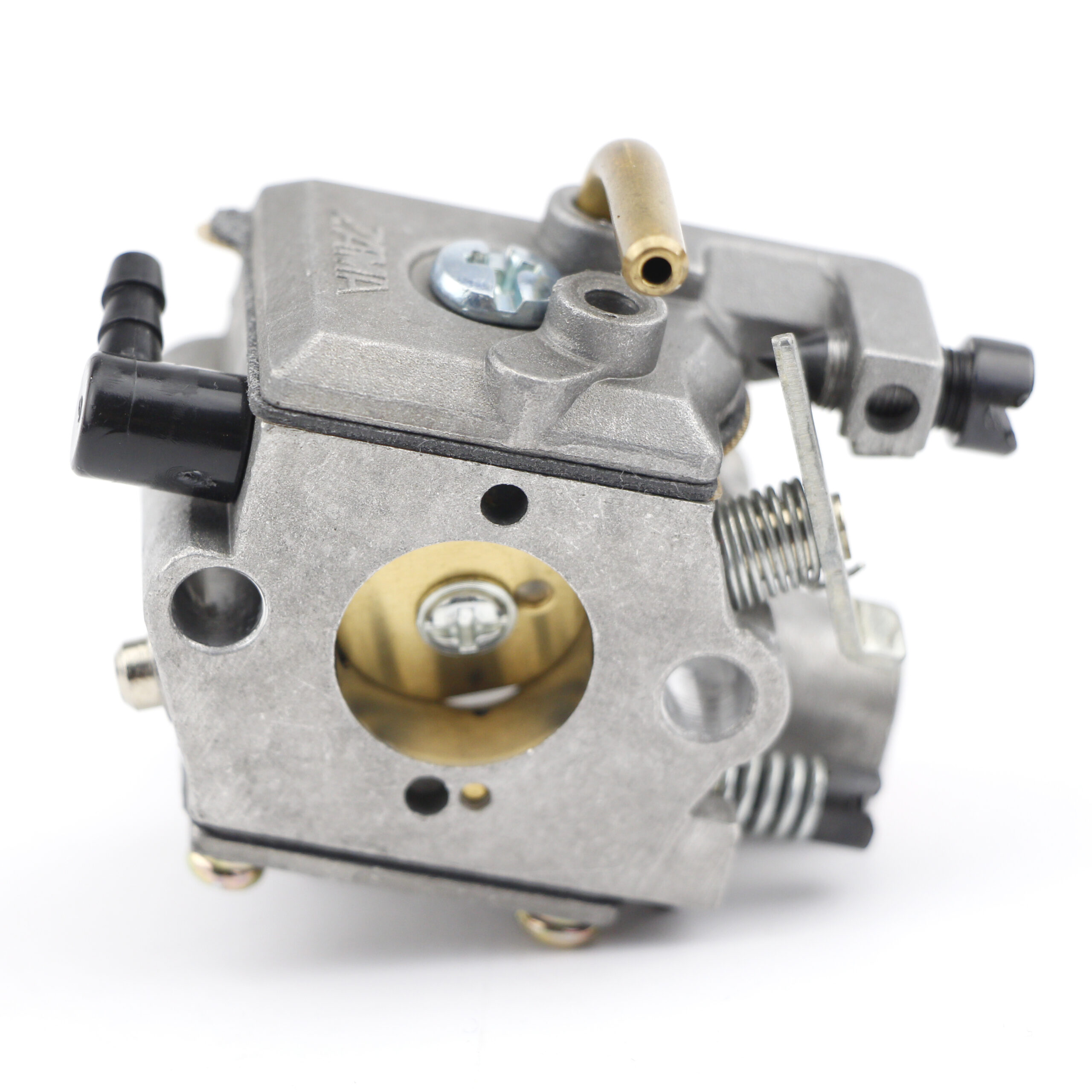

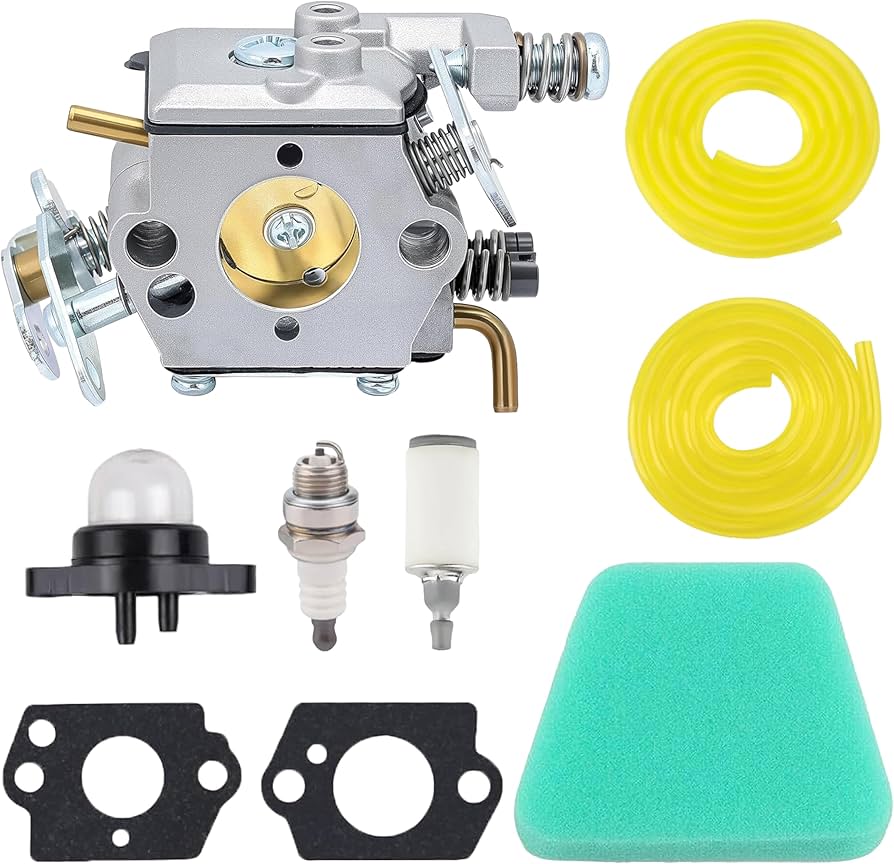

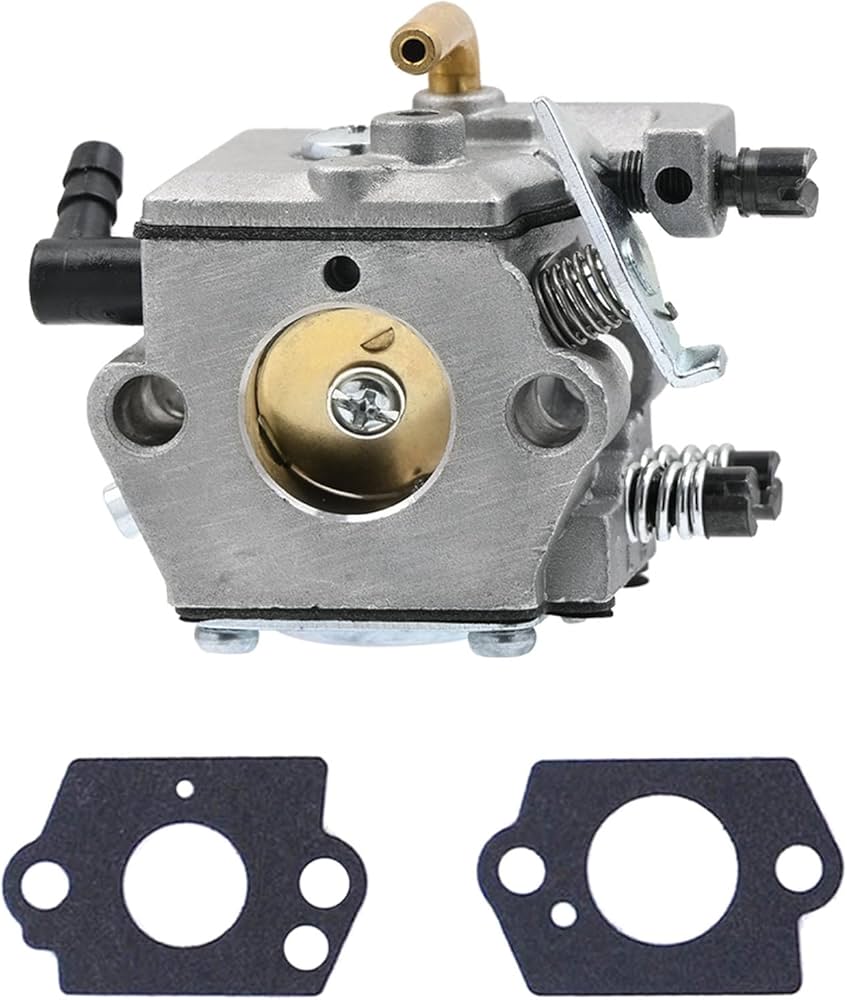

In conclusion, sourcing a carburetor for a chainsaw requires careful consideration of compatibility, quality, and reliability. It is essential to identify the correct model number and specifications of the chainsaw to ensure the carburetor fits and functions properly. Purchasing from reputable suppliers or OEM (Original Equipment Manufacturer) sources helps guarantee durability and optimal performance. While aftermarket options may offer cost savings, they should be evaluated for quality to avoid frequent replacements or operational issues. Additionally, considering availability, warranty, and customer support can further enhance the sourcing decision. Overall, a well-sourced carburetor not only restores efficient engine performance but also extends the lifespan of the chainsaw, making it a critical component in maintaining power tool reliability.