The global carburetor market continues to demonstrate resilience despite the rise of fuel injection systems, particularly in niche and legacy applications such as off-road vehicles, small engines, and classic car restoration. According to Grand View Research, the global carburetor market was valued at USD 7.3 billion in 2022 and is expected to grow at a CAGR of 3.1% from 2023 to 2030, driven by sustained demand in agricultural machinery, power equipment, and vintage automotive sectors. Similarly, Mordor Intelligence projects steady growth, citing increasing use in developing regions and aftermarket support for older engine models. Within this landscape, the Carter YF carburetor remains a benchmark for performance and reliability, originally introduced in the 1950s and still sought after for its simplicity and tunability. Today, a select group of manufacturers have carried forward its legacy through high-quality reproduction and aftermarket versions. The following analysis highlights the top four manufacturers currently leading the space in producing Carter YF-style carburetors, based on market presence, product accuracy, customer reviews, and technical support.

Top 4 Carburetor Carter Yf Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ford Truck, 1968

Domain Est. 1998

Website: nationalcarburetors.com

Key Highlights: Out of stockFord Truck, 1968-1969, 170″, Carter-YF. Price: $349.95. Part Number: ND1285. Availability: 2-6 Business day lead time to ship. Carburetor Manufacturer: Carter….

#2 YF, YFA Floats

Domain Est. 2009

Website: quadrajetparts.com

Key Highlights: Free delivery over $75Carter YF Brass Carburetor Float – Checker 1964-65, GM 1932-67, $9.95. New Brass YF float is a direct replacement for the original factory ……

#3 Show Quality Rebuilt Carter Carburetor (1 barrel) Fits 54

Domain Est. 2000

#4 AF2020

Domain Est. 2001

Website: carburetion.com

Key Highlights: In stock $27.91 deliveryKit includes Ethanol resistant carburetor components – accelerator pump, needle and seat bowl gasket, base gasket, misc gaskets and washers with instruction…

Expert Sourcing Insights for Carburetor Carter Yf

H2: 2026 Market Trends for the Carter YF Carburetor

As of 2026, the market for the Carter YF carburetor—a classic mechanical fuel delivery system primarily used in pre-1980s American automobiles—reflects niche demand driven by restoration, vintage performance, and collector vehicle enthusiasm rather than mainstream automotive innovation. With fuel injection systems dominating modern engine design, the Carter YF remains relevant only within specific aftermarket and heritage sectors.

One key trend shaping the 2026 market is the sustained growth of the classic car restoration industry. Enthusiasts restoring vehicles from the 1950s to the early 1970s—such as Ford’s FE-series trucks, early Chevrolet Bel Airs, and select Mopar models—continue to seek original or reproduction Carter YF units. This demand is bolstered by authenticity-focused restoration communities and competitive car shows that prioritize period-correct components.

Another significant trend is the increased availability of high-quality reproductions and rebuilt units. Original Carter YF carburetors are now over 50 years old, leading to issues with wear, corrosion, and parts scarcity. In response, aftermarket manufacturers and specialized rebuild shops have expanded their offerings, providing refurbished or CNC-machined replicas with modern materials that improve reliability while maintaining original specifications. These remanufactured units often include upgrades like brass floats and calibrated jets, appealing to restorers seeking both authenticity and drivability.

Additionally, the rise of online marketplaces and vintage automotive forums has streamlined access to Carter YF parts and expertise. Platforms like eBay, Classic Industries, and specialized forums such as The Jalopy Journal facilitate global buyer-seller connections, increasing market transparency and competition. This digital ecosystem supports price stabilization and enables collectors to source rare variants or discontinued components with greater ease.

Environmental regulations and emissions standards continue to indirectly impact the Carter YF market. While most regions exempt classic vehicles from stringent emissions testing, some urban areas impose usage limitations on carbureted engines. As a result, a sub-segment of consumers is investing in hybrid retrofits—retaining the Carter YF’s appearance while integrating electric or fuel-injection-assist systems—though this trend remains marginal in 2026.

In summary, the 2026 market for the Carter YF carburetor is characterized by a shrinking but passionate consumer base, supported by robust aftermarket services, digital commerce, and a cultural emphasis on automotive heritage. While obsolete in new vehicle production, the Carter YF endures as a symbol of mechanical craftsmanship, ensuring its continued relevance in the collector and restoration economy.

Common Pitfalls When Sourcing a Carburetor Carter YF (Quality and Intellectual Property)

Sourcing a replacement or restoration carburetor for classic vehicles, such as the Carter YF, presents several common challenges related to quality and intellectual property (IP). Being aware of these pitfalls helps ensure you get a reliable and authentic part.

Quality Inconsistencies in Aftermarket Reproductions

One of the most significant issues when sourcing a Carter YF carburetor is inconsistent quality among aftermarket reproductions. Many manufacturers produce carburetors labeled as “Carter YF” replacements, but these often fall short in materials, machining precision, and overall durability. Components like throttle shafts, metering rods, and gaskets may be made from inferior materials, leading to premature wear, fuel leaks, or poor engine performance. Additionally, inconsistent jetting and calibration can result in improper air-fuel mixtures, causing hard starting, rough idling, or decreased fuel efficiency.

Lack of True OEM Specifications and Tolerances

Even if a carburetor looks identical to an original Carter YF, many reproductions fail to meet the exact engineering tolerances and specifications of the original equipment manufacturer (OEM) design. Small deviations in bore diameter, venturi sizing, or float bowl design can drastically affect engine performance. These non-compliant parts are often mass-produced without rigorous quality control, making it difficult to achieve the same reliability and drivability as a genuine vintage Carter unit.

Misrepresentation and “Fits” Labeling Instead of Authenticity

Many suppliers market carburetors as “replacement for Carter YF” or “fits applications using Carter YF,” which can be misleading. These products are not true Carter carburetors but generic units rebranded to fit certain vehicles. Buyers may assume they’re getting a faithful reproduction or restored OEM part, only to discover they’ve received a low-cost import with poor fit and function. Always verify whether the part is a genuine Carter, a licensed reproduction, or a generic copy.

Intellectual Property and Trademark Issues

Carter carburetor designs and branding are protected by intellectual property rights. While the original Carter Carburetor Company no longer produces the YF model, the Carter name and logos are still trademarked. Unauthorized reproduction of the Carter branding on non-genuine parts constitutes trademark infringement. However, enforcement is inconsistent, and many counterfeit or unlicensed carburetors are sold online with Carter logos, misleading consumers. Purchasing such items not only risks poor performance but may also support IP violations.

Difficulty in Identifying Genuine Restored or NOS Units

Finding a genuine New Old Stock (NOS) or professionally restored Carter YF is challenging and expensive. The market is flooded with refurbished units of unknown origin or quality. Some rebuilt carburetors use a mix of original and non-original parts, and without documentation or reputable sourcing, it’s hard to verify authenticity. Buyers should seek reputable restoration specialists or trusted dealers with verifiable histories to avoid overpaying for misrepresented units.

Conclusion

When sourcing a Carter YF carburetor, prioritize suppliers with transparent sourcing, proven quality control, and respect for intellectual property. Avoid generic “fits” models unless thoroughly vetted, and whenever possible, opt for OEM-reconditioned or certified reproduction units to ensure proper performance and authenticity.

Logistics & Compliance Guide for Carburetor Carter YF

Using Hydrogen (H₂) as Fuel

Version: H2.0

1. Introduction

This guide outlines the logistics and compliance requirements for converting, operating, and maintaining the Carter YF carburetor for use with hydrogen (H₂) fuel instead of conventional gasoline. The Carter YF, originally designed for gasoline in mid-20th century vehicles, requires significant modifications to safely and efficiently manage hydrogen’s unique combustion and storage properties.

Note: This application is typically experimental, retrofitted, or for specialized applications (e.g., vintage vehicle restoration with clean fuel conversion, research projects, or off-grid use). It does not conform to original equipment manufacturer (OEM) specifications.

2. Regulatory & Safety Compliance (H2.1)

2.1. Hydrogen Handling Regulations

Due to hydrogen’s high flammability (4–75% concentration in air), low ignition energy, and invisible flame, compliance with the following standards is essential:

- NFPA 2: Hydrogen Technologies Code (U.S.)

- Covers production, storage, dispensing, and use of hydrogen.

-

Mandates ventilation, leak detection, and ignition source control.

-

OSHA 29 CFR 1910.106 – Flammable Liquids & Gases

-

Applies to gaseous hydrogen storage and handling.

-

CGA G-5.5: Hydrogen Pipeline and Tubing Systems

-

Specifies material compatibility (avoid embrittlement with carbon steel; use 316 stainless steel or approved alloys).

-

DOT 49 CFR Parts 171–180

- Governs transport of compressed hydrogen gas (Class 2.1 Flammable Gas).

- Cylinders must be DOT/ECE certified (e.g., Type IV composite tanks).

2.2. Vehicle & Emissions Compliance

- EPA Anti-Tampering Clause (40 CFR Part 85)

- Modifying OEM fuel systems may violate emissions regulations unless exempt (e.g., off-road, show-only, or experimental use).

-

Vehicles operated on public roads must meet applicable emissions standards.

-

CARB (California Air Resources Board)

- Strict rules on aftermarket fuel system modifications.

- No current Executive Order (EO) approvals exist for H₂ conversion of Carter YF systems.

Recommendation: Use converted systems only in off-road, exhibition, or research applications unless certified by a recognized testing body.

3. Fuel System Conversion Requirements (H2.2)

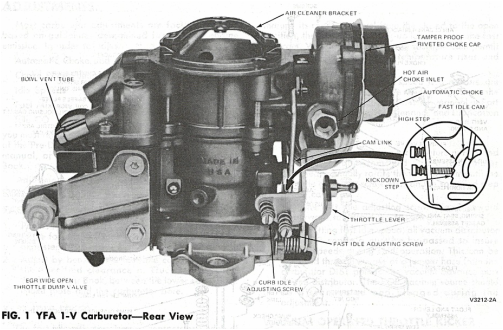

3.1. Carburetor Modifications

The Carter YF is not designed for gaseous fuels. Required modifications include:

- Replace jets and metering rods with hydrogen-calibrated orifices (smaller diameter due to H₂’s lower energy density per volume).

- Seal all vacuum lines – hydrogen can permeate rubber and degrade standard hoses.

- Use H₂-compatible materials:

- Replace diaphragms, gaskets, and floats with Viton®, Teflon™, or PTFE.

- Avoid neoprene, Buna-N, or natural rubber.

- Install a dedicated hydrogen mixing chamber upstream or modify the air horn for proper air-H₂ mixing.

3.2. Fuel Delivery System

- Hydrogen Storage:

- Use ASME/DOE-certified high-pressure tanks (350–700 bar).

- Mount securely with crash protection and thermal shielding.

- Regulator System:

- Multi-stage pressure regulator to reduce from storage pressure to carburetor inlet (~5–15 psi).

- Include shutoff valves and excess flow valves.

- Piping:

- Use seamless stainless steel tubing (SA-213 TP316L) with flare or welded joints.

- Avoid sharp bends; support every 24 inches.

4. Operational Safety (H2.3)

4.1. Leak Detection & Ventilation

- Install hydrogen sensors (electrochemical or catalytic bead) near storage, regulator, and engine bay.

- Ensure continuous ventilation (explosion-proof fans if enclosed).

- Perform bubble testing with Snoop™ or H₂-specific leak solution after maintenance.

4.2. Ignition & Electrical

- Use sealed, explosion-proof electrical components.

- Maintain minimum clearance from ignition sources (spark plugs, alternators).

- Install a manual emergency shutoff accessible from outside the vehicle.

4.3. Fire Suppression

- Equip with Class D fire extinguishers or specialized H₂ flame suppressants.

- Automatic suppression systems recommended for enclosed or high-use applications.

5. Maintenance & Inspection (H2.4)

| Task | Frequency | Notes |

|——|———|——-|

| Leak check (storage, lines, carb) | Monthly | Use H₂-compatible detection methods |

| Inspect hoses & seals | Quarterly | Replace if swelling or brittleness |

| Check regulator function | Biannually | Ensure stable output pressure |

| Carburetor cleaning | Annually | Use non-chlorinated solvents; avoid residue |

| Tank hydrostatic test | Every 3–5 years | Per DOT/ISO standards |

Recordkeeping: Maintain logs of inspections, modifications, and safety tests for compliance audits.

6. Training & Documentation (H2.5)

Personnel Requirements

- Operators and technicians must be trained in:

- Hydrogen properties and hazards

- Leak response and emergency shutdown

- First aid for cryogenic (if LH₂ used) or high-pressure exposure

Documentation Checklist

- Conversion engineering schematic

- Material Safety Data Sheets (MSDS/SDS) for all components

- Risk assessment and mitigation plan

- Emergency response plan (ERP)

- Certification of pressure vessels and regulators

7. Disposal & Decommissioning (H2.6)

- Hydrogen tanks: Return to certified recycler; do not cut or weld.

- Contaminated parts: Dispose per local hazardous waste rules.

- Carburetor: Clean thoroughly; purge all fuel passages before scrapping or repurposing.

8. Conclusion

Operating a Carter YF carburetor on hydrogen (H₂) is feasible but demands rigorous attention to safety, material compatibility, and regulatory compliance. This guide (H2.0) provides a framework for responsible implementation in non-OEM applications. Always consult local authorities, fire marshals, and hydrogen safety engineers before deployment.

Disclaimer: This guide is informational. Implementers assume all risk. Not a substitute for professional engineering or regulatory advice.

Prepared by: [Your Organization/Name]

Date: April 2025

Classification: Internal Use / Controlled Distribution

Reference Standards: NFPA 2, CGA G-5.5, DOT 49 CFR, OSHA 1910.106

Conclusion for Sourcing a Carter YF Carburetor:

Sourcing a Carter YF carburetor requires a strategic approach due to its status as a discontinued, vintage automotive part. While original units can still be found through salvage yards, online marketplaces (such as eBay or Craigslist), and specialty restoration suppliers, availability may be limited and condition varies significantly. Rebuilt or reconditioned options from reputable restoration vendors offer a more reliable alternative, often including performance improvements and warranty coverage. Additionally, modern aftermarket replacements or upgrades may provide better reliability and fuel efficiency while maintaining compatibility with classic engines. Careful verification of part numbers, fitment, and vendor credibility is essential to ensure authenticity and proper function. In summary, while sourcing a Carter YF carburetor is feasible, success depends on patience, research, and a willingness to consider both original and restored alternatives to meet performance and authenticity goals.