The global carbon fiber composites market is experiencing robust growth, driven by increasing demand for lightweight, high-strength materials across sports and recreation industries. According to a 2023 report by Mordor Intelligence, the market is projected to grow at a CAGR of 8.5% from 2023 to 2028, with the sports equipment segment emerging as a key contributor—particularly in performance-driven applications like lacrosse. As players at all levels prioritize equipment that enhances speed, agility, and power, carbon fiber lacrosse shafts have become the standard for elite and amateur athletes alike. This surge in demand has catalyzed innovation and competition among manufacturers, resulting in a diversified landscape of brands engineering shafts with advanced composite formulations, enhanced durability, and optimized stiffness-to-weight ratios. Below, we examine the top seven carbon fiber lacrosse shaft manufacturers leading product development and market share through engineering excellence and data-backed performance improvements.

Top 7 Carbon Fiber Lacrosse Shaft Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Carbon Fiber Shafts for Offensive Players & Middies

Domain Est. 1997

Website: stringking.com

Key Highlights: Carbon fiber lacrosse shafts built to perform. Designed for the elite player who wants an ultra-stiff lacrosse shaft with industry-leading impact resistance ……

#2 ECD Carbon Pro 3.0 Lacrosse Shaft

Domain Est. 1999

Website: lacrosseunlimited.com

Key Highlights: In stock Rating 5.0 (6) ECD Carbon Pro 3.0 Lacrosse Shaft – Attack · Speed (30 in): Updated shape featuring increased concavity paired with a new raised texture for enhanced cont…

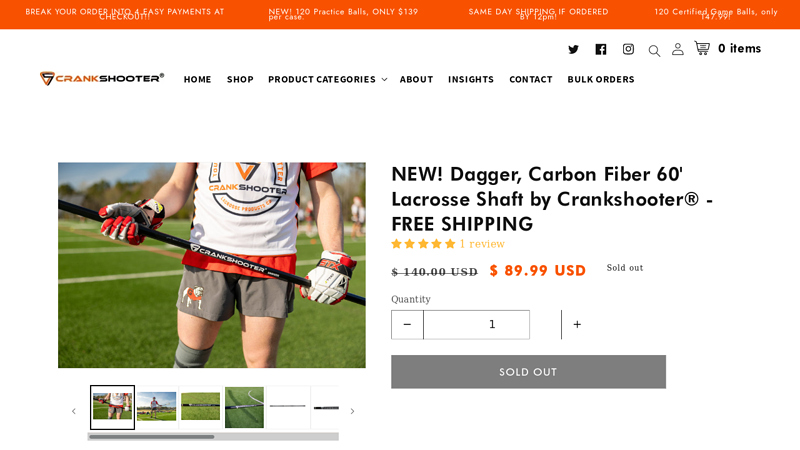

#3 NEW! Dagger, Carbon Fiber 60′ Lacrosse Shaft by Crankshooter

Domain Est. 2010

Website: crankshooter.com

Key Highlights: Out of stockPriced at just $89.99, the Dagger™ Carbon Fiber Shaft is a game-changer that will leave the competition feeling the heat (and not in your wallet). Enjoy the ……

#4 Epoch Lacrosse®

Domain Est. 2010

Website: epochlacrosse.com

Key Highlights: A LEGACY OF INNOVATION. Our Dragonfly shafts are revolutionizing the game. Engineered with carbon fiber, they deliver optimal flex and enhanced performance….

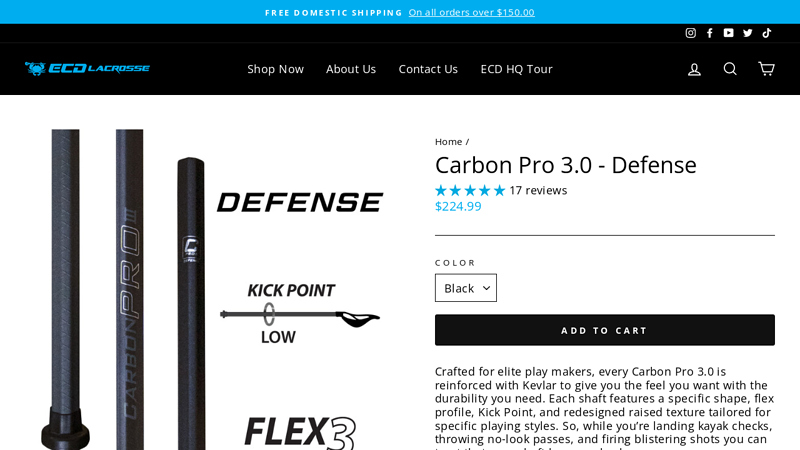

#5 Carbon Pro 3.0

Domain Est. 2015

#6 The Player Pro – 60″ Defensive Lacrosse Shafts for Men

Domain Est. 2015

Website: signaturelacrosse.com

Key Highlights: In stock Rating 5.0 (6) A shaft designed for elite players seeking maximum performance and reliability. Crafted from thermal-set carbon fiber reinforced polymer….

#7 Carbon Fiber Lacrosse Shafts

Domain Est. 2006

Website: universallacrosse.com

Key Highlights: 2–3 day deliveryFind all of the best Carbon Fiber Lacrosse Shafts at Universal Lacrosse! These are the shafts of the future as Carbon Fiber shafts have become a more and ……

Expert Sourcing Insights for Carbon Fiber Lacrosse Shaft

2026 Market Trends for Carbon Fiber Lacrosse Shafts

Rising Demand for Lightweight Performance Gear

By 2026, consumer preference for high-performance, lightweight lacrosse equipment is expected to drive significant growth in the carbon fiber shaft market. Players at both elite and amateur levels are increasingly prioritizing shafts that enhance speed, agility, and shot velocity. Carbon fiber, with its superior strength-to-weight ratio compared to traditional aluminum or composite blends, aligns perfectly with this trend. Manufacturers are responding by introducing advanced weave patterns and hybrid resin systems to further reduce weight without sacrificing durability, appealing to a new generation of fast-paced, skill-oriented athletes.

Technological Innovation and Material Advancements

Ongoing advancements in composite engineering are set to redefine carbon fiber shaft capabilities by 2026. Innovations such as nano-reinforced resins, 3D-woven carbon structures, and AI-driven design optimization are allowing brands to create shafts with improved impact resistance, vibration dampening, and torsional stiffness. These enhancements not only prolong product lifespan but also improve on-field feel and control. As R&D investments increase, expect to see more customizable shafts tailored to specific player positions—offensive shafts optimized for whip and quick release, defensive models built for impact absorption.

Expansion into Youth and Recreational Markets

While carbon fiber shafts have traditionally been premium products targeted at collegiate and professional players, 2026 will likely see broader market penetration into youth and recreational segments. As production costs decrease due to scaling and improved manufacturing techniques like automated layup processes, mid-tier carbon fiber options are becoming more accessible. Brands are launching entry-level carbon lines and subscription-based upgrade programs to attract younger athletes, positioning carbon fiber not just as a luxury but as a long-term investment in performance development.

Sustainability and Brand Differentiation

Environmental consciousness is emerging as a key differentiator in the sports equipment sector. By 2026, leading manufacturers are anticipated to emphasize sustainable practices in carbon fiber production—such as using recycled carbon fiber, bio-based resins, and energy-efficient curing methods—to appeal to eco-aware consumers. Companies marketing transparent, low-impact supply chains are likely to gain competitive advantage, particularly among schools, leagues, and retailers adopting green procurement policies. This shift could accelerate industry-wide adoption of circular economy models, including take-back and recycling programs for end-of-life shafts.

Competitive Landscape and Market Consolidation

The carbon fiber lacrosse shaft market is expected to experience increased competition and potential consolidation by 2026. As performance expectations rise, smaller brands may struggle to keep pace with the R&D and marketing demands, leading to acquisitions by larger sportswear conglomerates. Simultaneously, major players like STX, Warrior, and StringKing are likely to expand their carbon-specific product lines and deepen partnerships with material science firms. This consolidation could drive innovation but may also reduce price elasticity, keeping premium carbon shafts at the higher end of the market unless disruptive entrants emerge.

Common Pitfalls Sourcing Carbon Fiber Lacrosse Shafts

Quality Inconsistencies

One of the most prevalent issues when sourcing carbon fiber lacrosse shafts is inconsistent product quality. Many manufacturers, particularly those overseas, may use lower-grade carbon fiber or improper resin ratios, leading to shafts that are either too brittle or too flexible. This can result in premature cracking, warping, or failure during gameplay. Additionally, poor layup techniques and inadequate curing processes can compromise structural integrity, reducing performance and safety. Buyers should verify material specifications, request physical samples, and conduct third-party strength testing to ensure consistency and durability.

Intellectual Property (IP) Risks

Sourcing carbon fiber lacrosse shafts—especially from regions with lax enforcement of intellectual property laws—poses significant IP risks. Many designs, including proprietary weave patterns, ergonomic geometries, and patented manufacturing methods, are often copied without authorization. Counterfeit or knockoff shafts may infringe on existing patents or trademarks held by major sports equipment brands. To mitigate these risks, importers should conduct thorough due diligence on suppliers, require IP compliance documentation, and consider working with legal counsel to ensure designs do not violate existing patents. Using original design manufacturing (ODM) agreements with clear IP ownership clauses is also recommended.

Logistics & Compliance Guide for Carbon Fiber Lacrosse Shaft

Product Classification & Regulatory Overview

Carbon fiber lacrosse shafts are generally classified as sports equipment and are subject to regulations related to materials, safety, and international trade. While not typically regulated as hazardous goods, compliance with customs, safety standards, and material-specific rules is essential, especially due to the composite nature of carbon fiber.

International Shipping & Customs Documentation

When shipping carbon fiber lacrosse shafts internationally, ensure accurate Harmonized System (HS) code classification. A common code is 9506.62.00 (Lacrosse sticks and other equipment for sports, not elsewhere specified). Provide detailed commercial invoices listing product description, value, country of origin, and weight. Exporters must comply with destination country import regulations, including potential duties and taxes.

Material Safety & Handling Considerations

Carbon fiber is non-toxic in its finished form but can release fine particulates if cut or damaged. While intact shafts pose minimal risk, handlers should avoid grinding or machining without proper ventilation and personal protective equipment (PPE). Finished products do not require hazardous material labeling under IATA, IMDG, or DOT regulations when shipped as consumer goods.

Compliance with Sports Equipment Standards

Ensure lacrosse shafts meet performance and safety standards set by governing bodies such as US Lacrosse or World Lacrosse. Shaft specifications including diameter, weight, and structural integrity must comply with official rules to be tournament-legal. Manufacturers should conduct quality control testing and maintain documentation for certification purposes.

Environmental & Disposal Regulations

Carbon fiber is not biodegradable and recycling options are limited. Inform end-users about proper disposal methods in accordance with local waste regulations. Some regions classify composite materials under extended producer responsibility (EPR) programs, so consider take-back or recycling initiatives to support sustainability compliance.

Import Restrictions & Country-Specific Requirements

Verify destination country rules—some may impose restrictions on composite materials or require product certification (e.g., CE marking in the EU, UKCA in the UK). Canada may require labeling in English and French. Always confirm current import policies through official customs portals or trade advisors before shipment.

Packaging & Transportation Best Practices

Use durable packaging to prevent damage during transit, especially to the shaft’s structural integrity. Avoid compressing multiple shafts tightly, as pressure may cause microfractures. Label packages with “Fragile” and “This Way Up” indicators. Air freight is acceptable as carbon fiber is not classified as dangerous goods when in solid, manufactured form.

Recordkeeping & Traceability

Maintain records of material sourcing, manufacturing dates, compliance testing, and shipping documentation for a minimum of five years. Traceability supports recall management and demonstrates regulatory compliance during audits or customs inspections.

Summary

Carbon fiber lacrosse shafts require careful attention to classification, documentation, and adherence to sports and environmental standards. While not hazardous, their composite composition and international distribution demand proactive compliance planning to ensure smooth logistics and market access.

In conclusion, sourcing carbon fiber for lacrosse shafts offers a compelling combination of strength, lightweight performance, and durability that aligns perfectly with the demands of competitive play. When selecting a supplier or manufacturing partner, it is essential to prioritize high-quality, aerospace-grade carbon fiber materials and proven production techniques such as unidirectional layup or resin infusion to ensure optimal stiffness-to-weight ratio and impact resistance. Additionally, considerations such as cost-efficiency, scalability, and sustainability in sourcing practices—such as using recycled carbon fiber or minimizing waste—can enhance long-term viability. By partnering with reputable suppliers and investing in innovative design and quality control, manufacturers can produce high-performance lacrosse shafts that meet the evolving needs of athletes while maintaining a competitive edge in the sports equipment market.