The global carbon fiber car wheel market is accelerating rapidly, driven by increasing demand for lightweight components that enhance vehicle performance, fuel efficiency, and sustainability. According to a 2023 report by Mordor Intelligence, the automotive carbon fiber components market is projected to grow at a CAGR of over 10.4% from 2023 to 2028, with carbon fiber wheels emerging as one of the fastest-growing segments due to their adoption in high-performance and electric vehicles. Grand View Research further supports this momentum, estimating that the global carbon fiber composites market in automotive applications will expand at a CAGR of 9.2% through 2030, fueled by advancements in manufacturing technologies and rising investments in EV platforms. As OEMs and aftermarket brands prioritize weight reduction without compromising strength, carbon fiber wheels have transitioned from exclusive motorsport components to premium offerings in consumer vehicles. This shift has catalyzed innovation among specialized manufacturers, resulting in a competitive landscape of technologically advanced players pushing the boundaries of design, durability, and scalability. The following nine companies represent the forefront of this evolution—leading in production capability, engineering expertise, and market influence in carbon fiber wheel manufacturing.

Top 9 Carbon Fiber Car Wheel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 HiPer Technology: Shop ATV Wheels

Domain Est. 1999

Website: hiper-technology.com

Key Highlights: Free delivery 30-day returnsHiPer Technology develops the best ATV wheels on the market, combining the latest carbon fiber composite and advanced aluminum alloy technologies….

#2 BST

Domain Est. 2001

Website: blackstonetek.com

Key Highlights: WELCOME TO BST. The world’s leading manufacturer of carbon fibre wheels. A wheel that’s lighter, faster, stronger, safer and sexier….

#3 Carbon Revolution

Domain Est. 2008

Website: carbonrev.com

Key Highlights: Carbon Revolution is a global technology company, which supplies lightweight carbon fibre wheels to the global automotive industry….

#4 Carbon Fibre Wheels for Cars and Supercars

Domain Est. 2020

Website: wheel.bucci-composites.com

Key Highlights: Discover the only Full Carbon Fibre Wheels. High performance, advanced technology, and carbon lightness for your supercar wheels….

#5 C

Domain Est. 2021

Website: c-inertia.com

Key Highlights: Our carbon wheels are the result of precision engineering and a proprietary manufacturing process designed for industrial-grade performance. Each wheel delivers ……

#6 Carbon+Forged Series

Domain Est. 1996

Website: forgeline.com

Key Highlights: Carbon+Forged wheels combine weight-optimized CNC-machined forged aluminum centers with revolutionary proprietary carbon fiber barrels….

#7 Lacks Carbon Fiber

Domain Est. 1997

Website: lacksenterprises.com

Key Highlights: To create the world’s most advanced carbon fiber wheel, we had to re-engineer the entire manufacturing process. Our design, fabrication, assembly, and ……

#8 Rotobox wheels

Domain Est. 2012

Website: rotobox-wheels.com

Key Highlights: World’s first SAE certified aftermarket carbon car wheels! We are proud to present you Rotobox car carbon wheels that are the first one aftermarket carbon ……

#9 custom forged 2

Domain Est. 2021

Website: rvrnwheel.com

Key Highlights: In stock Rating 5.0 (1) Custom forged concave carbon fiber wheel design, showcasing a sleek black finish and intricate detailing….

Expert Sourcing Insights for Carbon Fiber Car Wheel

H2: Market Trends for Carbon Fiber Car Wheels in 2026

By 2026, the market for carbon fiber car wheels is poised for significant transformation driven by advancements in materials science, increasing demand for high-performance and electric vehicles (EVs), and growing emphasis on lightweighting for improved efficiency and sustainability. Below is an analysis of key market trends shaping the carbon fiber car wheel industry in 2026.

1. Rising Demand from Electric Vehicle Manufacturers

Electric vehicles (EVs) are a primary growth driver for carbon fiber wheels. As automakers strive to extend battery range and improve acceleration and handling, reducing unsprung mass has become critical. Carbon fiber wheels—being up to 50% lighter than forged aluminum counterparts—directly contribute to energy efficiency. Major EV manufacturers such as Tesla, Lucid Motors, and Porsche are increasingly integrating carbon fiber wheels into high-end models, a trend expected to expand into mid-tier EVs by 2026 as production costs decline.

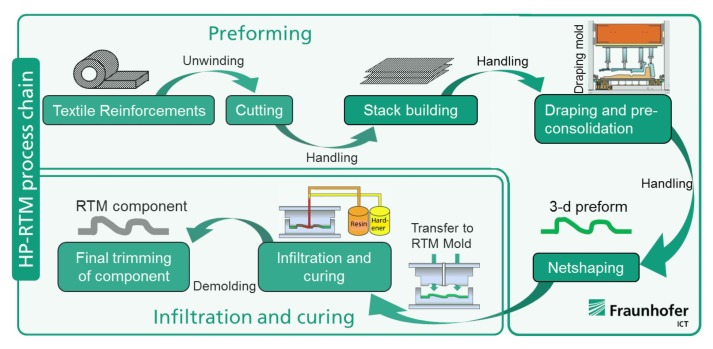

2. Cost Reduction through Advanced Manufacturing Techniques

Historically, the high cost of carbon fiber production has limited its use to supercars and luxury performance vehicles. However, innovations in automated layup, resin transfer molding (RTM), and out-of-autoclave (OOA) curing processes are reducing manufacturing times and material waste. By 2026, these advancements are expected to lower production costs by 20–30%, making carbon fiber wheels more accessible to premium mainstream automotive segments.

3. Sustainability and Recyclability Focus

Environmental regulations and consumer demand for sustainable products are pushing manufacturers to explore recyclable carbon fiber and bio-based resins. In 2026, several industry leaders are expected to launch closed-loop recycling programs for end-of-life carbon fiber wheels. Additionally, the European Union’s Circular Economy Action Plan is influencing design standards, encouraging modular and repairable wheel systems to extend product lifecycles.

4. Integration with Smart Wheel Technologies

Carbon fiber wheels are becoming platforms for integrating smart technologies, such as embedded sensors for tire pressure monitoring, temperature regulation, and impact detection. By 2026, the convergence of lightweight composites with IoT-enabled components is expected to create “smart carbon wheels” that enhance vehicle safety and performance data analytics, particularly in autonomous and connected vehicles.

5. Expansion of OEM and Aftermarket Adoption

Original Equipment Manufacturers (OEMs) are increasingly offering carbon fiber wheels as factory-installed options across performance and luxury lineups. Simultaneously, the aftermarket segment is growing rapidly, driven by enthusiasts and fleet operators seeking performance upgrades. Companies like BBS, Carbon Revolution, and Zyrus Engineering are expanding their product portfolios to meet this rising aftermarket demand.

6. Regional Market Growth

North America and Europe remain the largest markets due to high concentrations of luxury and performance vehicle consumers and supportive EV incentives. However, Asia-Pacific—particularly China and South Korea—is expected to see the fastest growth in 2026, fueled by domestic EV production and government investments in advanced materials research.

7. Supply Chain Maturation and Raw Material Innovation

The global supply chain for carbon fiber is becoming more resilient, with new production facilities coming online in the U.S. and Southeast Asia. Additionally, the development of high-strength, low-cost polyacrylonitrile (PAN)-based precursors and alternative carbon fiber types (e.g., lignin-based) is expected to stabilize raw material prices and reduce dependency on traditional suppliers.

Conclusion

In 2026, the carbon fiber car wheel market is transitioning from a niche, high-cost component to a strategically important element in automotive design—especially for EVs and performance vehicles. With falling production costs, technological integration, and sustainability initiatives, carbon fiber wheels are expected to gain broader market penetration, setting the stage for long-term industry growth.

Common Pitfalls When Sourcing Carbon Fiber Car Wheels

Quality Inconsistencies and Material Defects

One of the most significant challenges in sourcing carbon fiber car wheels is ensuring consistent quality. Carbon fiber components require precise manufacturing processes, including proper fiber alignment, resin content control, and curing cycles. Suppliers—especially lower-cost or less experienced ones—may cut corners, leading to voids, delamination, or weak resin bonds. These defects compromise structural integrity, increasing the risk of wheel failure under stress. Additionally, variations in carbon fiber weave patterns or ply layering can affect performance and durability. Without rigorous quality control and third-party testing, such as non-destructive testing (NDT) or load testing, buyers risk receiving substandard products unsuitable for high-performance automotive applications.

Intellectual Property and Design Infringement Risks

Sourcing carbon fiber wheels, particularly from overseas manufacturers, exposes buyers to intellectual property (IP) concerns. Many high-performance wheel designs are protected by patents, trademarks, or registered designs. Unscrupulous suppliers may produce counterfeit or knockoff versions of branded wheels, infringing on these rights. Purchasing such products—even unknowingly—can lead to legal liability, shipment seizures, or reputational damage. Furthermore, custom designs shared with suppliers during development may be replicated or sold to competitors if proper non-disclosure agreements (NDAs) and IP clauses are not in place. Due diligence in vetting suppliers, securing legal protections, and verifying design authenticity is essential to mitigate these risks.

Logistics & Compliance Guide for Carbon Fiber Car Wheels

Product Classification & Regulatory Overview

Carbon fiber car wheels are classified as automotive aftermarket parts and fall under specific international trade and safety regulations. They are typically categorized under HS Code 8708.70 (Wheels for motor vehicles) in most customs tariff schedules. Compliance with regional automotive safety standards is mandatory, including but not limited to DOT (U.S.), ECE (Europe), and ADR (Australia). Unlike standard OEM wheels, carbon fiber variants may require additional certification due to advanced composite materials and performance claims.

Packaging & Handling Requirements

Due to the high strength-to-weight ratio and susceptibility to impact damage, carbon fiber wheels require specialized packaging. Use rigid, shock-absorbing materials such as polyethylene foam inserts and double-walled cardboard or wooden crates. Each wheel must be individually wrapped in anti-static film to prevent surface scratches and electrostatic buildup. Clearly label packages with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. Avoid exposure to sharp objects and excessive pressure during handling and transport.

Transportation Modes & Considerations

Carbon fiber wheels can be shipped via air, sea, or ground freight, depending on volume, urgency, and destination. Air freight is recommended for high-value or time-sensitive shipments due to faster transit times and reduced risk of prolonged exposure to environmental hazards. Sea freight is cost-effective for bulk orders but requires additional protection against humidity and salt air. Regardless of mode, maintain stable temperature and humidity conditions—ideally between 15–25°C and 30–60% RH—to prevent resin degradation or delamination.

Import/Export Documentation

Ensure all shipments are accompanied by accurate documentation, including:

– Commercial Invoice (detailing product description, value, and HS code)

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Material Safety Data Sheet (MSDS) for carbon fiber composites (if required)

– Compliance Certificates (e.g., DOT, ECE, ISO 9001)

Export controls may apply if carbon fiber technology exceeds certain performance thresholds under dual-use regulations (e.g., Wassenaar Arrangement), particularly for military-grade materials.

Regional Compliance Standards

- United States: Wheels must comply with FMVSS No. 120 (for tire and wheel assemblies) and may require DOT certification. Aftermarket wheels must meet performance standards equivalent to OEM parts.

- European Union: Must adhere to ECE Regulation No. 124 for wheel approval, including dynamic fatigue, corrosion resistance, and impact testing. CE marking is required.

- Canada: Recognizes both DOT and ECE standards; Transport Canada may require third-party certification.

- China & Asia: CCC (China Compulsory Certification) may apply depending on import classification; verify with local customs.

- Australia: Requires ADR compliance and may need approval from the Department of Infrastructure, Transport, Regional Development, and Communications.

Environmental & Safety Regulations

Carbon fiber manufacturing and disposal are subject to environmental regulations due to resin emissions and non-biodegradable waste. Shippers must comply with IATA Dangerous Goods Regulations if resins or curing agents are included (rare for finished wheels). Proper disposal of packaging and damaged wheels should follow local recycling protocols for composite materials. Avoid incineration—carbon fiber dust is hazardous when inhaled.

Quality Assurance & Traceability

Implement a traceability system using serial numbers or QR codes on each wheel to track manufacturing batch, date, and compliance testing data. Maintain records for at least five years to support warranty claims and regulatory audits. Third-party testing reports from accredited labs (e.g., TÜV, SGS) should be available upon request.

Risk Mitigation & Insurance

Given the high value and fragility of carbon fiber wheels, secure comprehensive cargo insurance covering damage, theft, and delays. Specify coverage for composite materials and include clauses for “inherent vice” where applicable. Conduct regular audits of logistics partners to ensure adherence to handling and storage protocols.

After-Sales & Warranty Logistics

Establish a reverse logistics process for warranty claims, including return shipping instructions, damage assessment procedures, and repair/replacement protocols. Train customer service teams on carbon fiber-specific handling and safety warnings to avoid improper installation or misuse.

In conclusion, sourcing carbon fiber car wheels presents a compelling opportunity to enhance vehicle performance, aesthetics, and efficiency due to their exceptional strength-to-weight ratio, improved fuel economy, and superior handling characteristics. However, the sourcing process must carefully consider factors such as material quality, manufacturing techniques (e.g., autoclave curing vs. wet layup), supplier reliability, and cost implications. While carbon fiber wheels are significantly more expensive than traditional aluminum counterparts, their long-term benefits in high-performance and luxury automotive applications often justify the investment. To ensure optimal results, it is essential to partner with reputable manufacturers who adhere to strict quality control standards and provide verifiable performance data. As technology advances and production costs gradually decrease, carbon fiber wheels are poised to become more accessible, marking a transformative shift in the automotive industry’s pursuit of lightweight innovation.