The global carbon brushes market is experiencing steady growth, driven by rising demand across industrial motors, automotive systems, and power generation applications. According to Grand View Research, the global carbon brushes market was valued at USD 1.79 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by increasing industrial automation, the expansion of renewable energy infrastructure—particularly wind turbines—and the ongoing need for efficient electric motor maintenance across manufacturing and transportation sectors. As motor performance heavily depends on reliable electrical contact, carbon brushes remain a critical component, with manufacturers increasingly segmenting their product lines by size to meet precise OEM specifications and application requirements. With demand shifting toward customized, high-performance solutions, the competitive landscape has seen a rise in innovation among leading carbon brush manufacturers. Based on market availability, application fit, and size-specific performance data, here are the top seven carbon brush manufacturers excelling in producing brushes by standardized and specialized dimensions.

Top 7 Carbon Brushes By Size Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Carbon Brushes Manufacturer, Carbon Brushes Exporter

Domain Est. 1999

Website: pelicancarbon.com

Key Highlights: We offer a wide range of Carbon Brushes including Bosch Industrial Carbon Brushes, Black Decker Carbon Brushes, Electrical Carbon Brushes, Industrial Black ……

#2 Carbon Brush Reference

Domain Est. 1996

Website: repcoinc.com

Key Highlights: Repco is the industry-leading source for replacement carbon brushes for industrial motors and generators. For more than 30 years Repco has built a solid ……

#3 Carbon Brush|Toyo Tanso Co., Ltd Products website

Domain Est. 2002

Website: toyotanso.com

Key Highlights: Introducing manufacturing process of mechanical carbon with excellent heat resistance, chemical resistance, self-lubrication and thermal shock resistance….

#4 Carbon Brush Finder

Domain Est. 1997

Website: helwigcarbon.com

Key Highlights: We’re proud to produce carbon brushes for many motors in a variety of industries. Use the carbon brush finder below to find the brush you’re looking for….

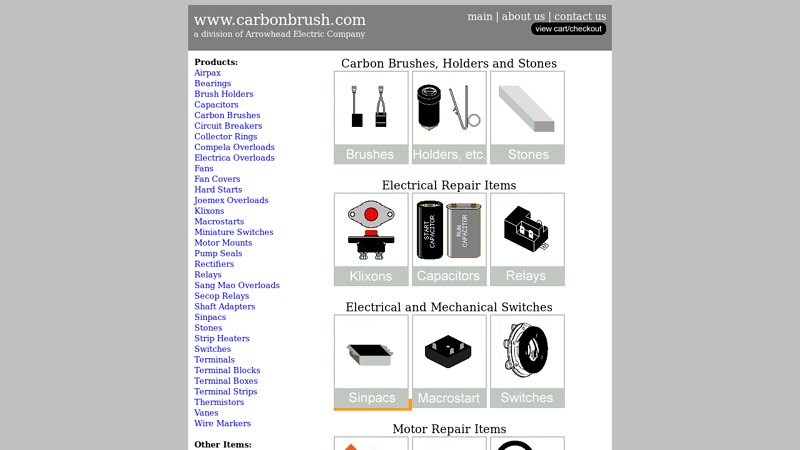

#5 www.carbonbrush.com/Arrowhead Electric Company Main Page

Domain Est. 1999

Website: carbonbrush.com

Key Highlights: Products: Airpax · Bearings · Brush Holders · Capacitors · Carbon Brushes · Circuit Breakers · Collector Rings · Compela Overloads · Electrica Overloads…

#6 Replacement Motor Brushes and their Specifications

Domain Est. 2002

Website: graphitestore.com

Key Highlights: 3–5 day delivery 30-day returnsWe offer fabricated and pressed-to-size carbon brushes designed to maximize brush life and performance for any given application….

#7 Carbon brushes range

Domain Est. 2006

Website: us.mersen.com

Key Highlights: Mersen offers a wide range of carbon brushes with various designs and grades for all types of motors ‐ from DC motors to asynchronous motors….

Expert Sourcing Insights for Carbon Brushes By Size

H2: 2026 Market Trends for Carbon Brushes by Size

The global carbon brushes market in 2026 is witnessing a nuanced evolution in demand across different sizes, driven by technological advancements, industry-specific requirements, and shifts in motor design. While overall market growth is sustained by demand from electric motors in industrial automation, automotive electrification, and renewable energy, the segmentation by size reveals distinct trends:

1. Growth in Medium and Large Carbon Brushes (Driven by Industrial and Energy Applications):

The medium (e.g., 12–25 mm cross-section) and large (e.g., >25 mm cross-section) carbon brush segments are projected to experience the most significant growth by 2026. This is primarily fueled by:

* Expansion of Wind Power: Large wind turbines rely heavily on high-current, robust carbon brushes in their generators and pitch/yaw systems. The global push for renewable energy ensures sustained demand for large-sized brushes capable of handling high loads and harsh conditions.

* Heavy Industrial Motor Demand: Sectors like mining, steel production, cement, and marine propulsion depend on massive DC and wound-rotor induction motors. These applications require large carbon brushes for durability and efficient current transfer under high voltage and amperage, supporting steady demand.

* Rail and Mass Transit Electrification: Electric locomotives and high-speed trains utilize motors requiring medium to large carbon brushes, and ongoing infrastructure investments globally bolster this segment.

2. Steady Demand for Small Carbon Brushes (Automotive and Consumer Electronics):

The small (e.g., <12 mm cross-section) carbon brush segment maintains stable demand, underpinned by:

* Automotive Ancillary Systems: Despite the rise of brushless motors in powertrains, numerous small brushed DC motors remain essential in vehicles (e.g., power windows, seats, wipers, fans, fuel pumps). The sheer volume of vehicle production ensures consistent need for small carbon brushes.

* Consumer and Power Tools: Corded and cordless power tools, household appliances, and power supplies still widely use small brushed motors due to their cost-effectiveness and simplicity. This segment provides a reliable baseline for small brush demand.

* Industrial Automation Components: Smaller servo motors and actuators in automated systems often utilize small carbon brushes, contributing to steady industrial demand.

3. Shift Towards High-Performance and Specialized Grades:

Across all sizes, there’s a growing preference for high-performance materials (electrographite, metal-graphite) over standard carbon grades. By 2026, buyers increasingly prioritize:

* Extended Lifespan: Reducing maintenance downtime in critical applications (e.g., wind turbines, industrial lines).

* Higher Current Density: Enabling more compact motor designs, particularly relevant for medium-sized brushes.

* Improved Commutation and Low Sparking: Essential for efficiency and reliability, especially in demanding environments.

* Customization: OEMs seek brushes tailored to specific size, shape, and performance requirements, driving innovation even within established size categories.

4. Regional Dynamics Influencing Size Demand:

Asia-Pacific: Dominates consumption due to massive manufacturing, automotive, and renewable energy sectors. Strong demand spans all sizes, with particularly high growth for large brushes in wind power (China, India) and small brushes in automotive/consumer goods.

* Europe & North America: Mature markets with focus on efficiency and sustainability. Demand is steady for large brushes in industrial retrofits and wind energy, and for small brushes in automotive service/replacement and specialized industrial equipment. Emphasis on premium, long-life grades is pronounced.

* Rest of World:* Emerging industrialization in regions like Latin America and Africa drives demand, primarily for medium and large brushes in mining, power generation, and infrastructure.

Conclusion:

By 2026, the carbon brushes market by size reflects a two-tiered trend: robust growth for medium and large sizes driven by renewable energy and heavy industry, and stable, volume-based demand for small sizes anchored in automotive and consumer applications. Success for manufacturers will depend on supplying high-performance, reliable, and increasingly customized products across all size segments, while navigating material costs and competition from brushless technologies in some applications.

Common Pitfalls Sourcing Carbon Brushes By Size (Quality, IP)

Sourcing carbon brushes by size alone—without considering quality and IP (Ingress Protection) ratings—can lead to significant operational and safety issues. While matching physical dimensions is essential, overlooking these critical factors often results in premature failure, equipment damage, or hazardous conditions. Below are key pitfalls to avoid:

Overlooking Material Quality and Composition

Selecting carbon brushes based solely on size may lead to using substandard materials. Low-quality carbon compounds can have inconsistent electrical conductivity, poor wear resistance, and excessive sparking. This results in shortened brush life, increased maintenance costs, and potential damage to commutators or slip rings. Always verify the brush grade (e.g., electrographitic, metal graphite) and ensure it matches the electrical and thermal demands of the application.

Ignoring IP Rating Compatibility

The IP rating of the brush holder or motor housing dictates the level of protection against dust and moisture. Sourcing brushes without considering the system’s IP rating may compromise the integrity of the entire enclosure. For example, using brushes that generate excessive dust in a high-IP environment can clog filters or lead to internal contamination. Ensure the brush design and housing assembly maintain the required IP protection to prevent environmental ingress.

Mismatched Electrical and Mechanical Specifications

Even if a brush fits dimensionally, it may not meet the required current density, operating voltage, or rotational speed. Brushes sourced without verifying these specs can overheat, arc, or fail under load. Additionally, incorrect spring pressure or shunt wiring can lead to uneven wear or poor contact, reducing efficiency and increasing downtime.

Lack of Traceability and Certification

Purchasing from uncertified or non-reputable suppliers increases the risk of counterfeit or non-compliant products. Without proper documentation, such as material test reports or ISO certification, it’s difficult to ensure batch consistency or compliance with industry standards (e.g., IEC, IEEE). Always source from suppliers with verifiable quality control processes.

Assuming Interchangeability Across Brands

While brushes may appear identical in size, differences in manufacturing tolerances, material blends, and performance characteristics can make them non-interchangeable. Assuming compatibility without testing can result in poor performance or accelerated wear. When replacing brushes, consult OEM specifications or conduct side-by-side performance evaluations.

Avoiding these pitfalls requires a holistic sourcing approach that balances size, material quality, environmental protection, and compliance—ensuring reliable and safe operation of electrical machinery.

Logistics & Compliance Guide for Carbon Brushes By Size

Overview

This guide outlines the logistics handling, packaging, shipping, and regulatory compliance considerations for carbon brushes categorized by physical dimensions (e.g., length, width, height, or metric equivalents). Proper management ensures product integrity, safety, and adherence to international and domestic regulations.

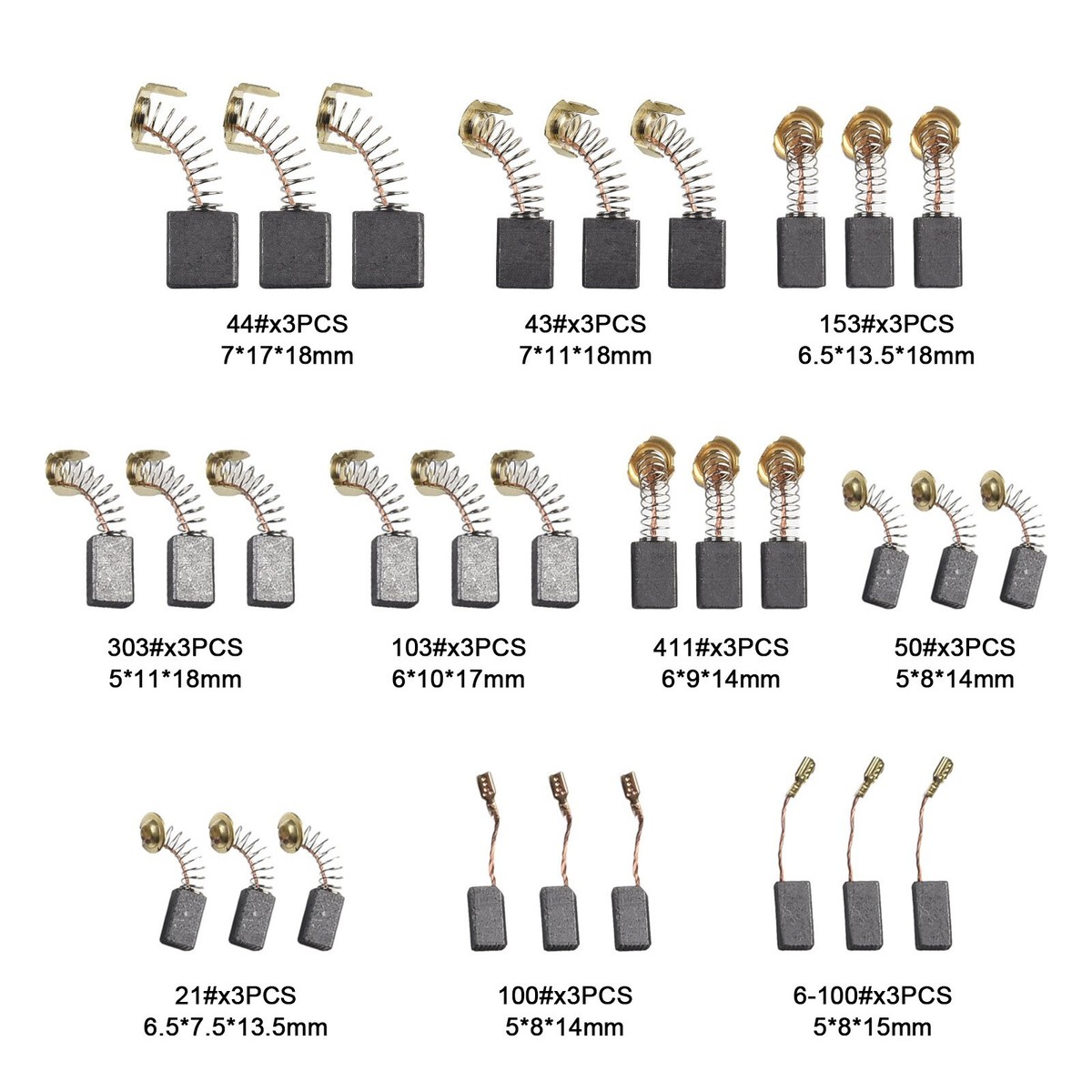

Classification by Size

Carbon brushes are commonly grouped by dimensional specifications to streamline inventory, shipping, and application compatibility. Standard size categories include:

– Miniature: < 10 mm in any dimension

– Small: 10–25 mm

– Medium: 26–50 mm

– Large: 51–100 mm

– Extra-Large: > 100 mm

Accurate size classification supports correct labeling, packaging, and handling protocols.

Packaging Requirements

- Material: Use anti-static, cushioned packaging (e.g., foam inserts, blister packs, or corrugated dividers) to prevent breakage and electrostatic damage.

- Labeling: Each package must be labeled with:

- Brush dimensions (L × W × H in mm or inches)

- Part/model number

- Net weight and gross weight

- Handling symbols (e.g., “Fragile,” “This Side Up”)

- Unitization: Group same-size brushes in sealed inner packs; consolidate into master cartons with weight limits ≤ 25 kg (55 lbs) for manual handling.

Storage Conditions

- Environment: Store in a dry, temperature-controlled area (15–25°C; 59–77°F) with < 60% relative humidity.

- Shelving: Use non-conductive shelving with adequate spacing to prevent contact damage.

- Segregation: Store by size category to reduce picking errors and streamline inventory audits.

Transportation & Shipping

- Domestic (e.g., US, EU):

- Use UN-certified packaging for quantities exceeding 5 kg per consignment.

- Label with proper shipping name: “Carbon Brushes, Non-Sparking” (not regulated as hazardous if non-conductive and non-flammable).

- International (Air & Sea):

- Comply with IATA (air) and IMDG (sea) guidelines. Carbon brushes are generally not classified as dangerous goods unless combined with lubricants or metallic components posing risks.

- Include HS Code: 8545.11.00 (Carbon Electrodes and Brushes) for customs clearance.

- Provide a commercial invoice with detailed size breakdown per item.

Regulatory Compliance

- REACH & RoHS (EU): Confirm brushes are free from restricted substances (e.g., cadmium, lead). Suppliers must provide compliance documentation.

- Proposition 65 (California, USA): Label if carbon dust contains listed chemicals (e.g., carbon black—known to cause cancer). Use:

“WARNING: This product can expose you to carbon black, which is known to the State of California to cause cancer.” - Customs Documentation: Include product specifications (including size), country of origin, and material composition on all export documents.

Handling & Safety

- Personnel Training: Staff must wear gloves and masks when handling loose carbon brushes to minimize dust inhalation.

- Static Control: Use grounded workstations and anti-static bags during packing in dry environments.

- Waste Disposal: Dispose of damaged brushes as industrial waste per local regulations. Carbon dust may require filtration and containment.

Quality Assurance & Traceability

- Maintain lot traceability by size batch.

- Conduct periodic audits of packaging integrity and labeling accuracy.

- Use barcode/QR codes on packaging linking to dimensional specs and compliance certificates.

Conclusion

Proper logistics and compliance management by carbon brush size ensures safe, efficient distribution and regulatory adherence. Consistent classification, labeling, and documentation are critical for global operations. Always consult the latest version of applicable regulations before shipment.

In conclusion, sourcing carbon brushes by size requires a systematic approach that balances precise dimensional specifications with application-specific performance requirements. Accurate measurement of length, width, thickness, and shunt wire configuration is critical to ensure proper fit and electrical compatibility. Standardized sizing facilitates interchangeability across manufacturers, but variations in material composition and grade mean that size alone is not sufficient—environmental conditions, load capacity, and operational speed must also be considered. Reliable suppliers, detailed product documentation, and adherence to industry standards (such as IEC or NEMA) further support successful sourcing. Ultimately, matching the correct carbon brush size to the motor or generator ensures optimal conductivity, minimizes wear, extends equipment lifespan, and reduces maintenance costs. Therefore, a comprehensive understanding of both physical dimensions and operational demands is essential for effective procurement.