The global car wrap film market is experiencing robust growth, driven by rising demand for vehicle customization, increased commercial fleet branding, and advancements in adhesive and vinyl technologies. According to a report by Mordor Intelligence, the vehicle wrap film market was valued at USD 4.2 billion in 2023 and is projected to reach USD 6.1 billion by 2029, growing at a CAGR of approximately 6.3% during the forecast period. Similarly, Grand View Research estimates the market to expand at a CAGR of over 6.5% from 2024 to 2030, fueled by urbanization, growth in the automotive aftermarket sector, and the rising popularity of temporary vehicle branding solutions. As demand escalates, manufacturers are investing heavily in R&D to improve conformability, durability, and ease of installation. This accelerating market momentum has given rise to a competitive landscape of innovative car wrap supplies manufacturers, each vying for market share through product differentiation, global distribution networks, and sustainable material development. The following list highlights the top 10 manufacturers shaping this dynamic industry.

Top 10 Car Wrap Supplies Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 HEXIS Manufacturer of Sign Vinyl, Digital Printing and Laminates …

Domain Est. 2010

Website: hexis-graphics.com

Key Highlights: HEXIS have been a major manufacturer of self-adhesive films for the sign industry, vehicle wrapping, fleet branding and textile decoration….

#2 3M Vehicle Wraps & Trims

Domain Est. 1988

Website: 3m.com

Key Highlights: Non-printable films used exclusively for covering or wrapping car surfaces….

#3 Discover Car Wraps and Graphics Solutions

Domain Est. 1993

Website: graphics.averydennison.com

Key Highlights: Learn how Avery Dennison can provide solutions for car and vehicle wraps using over 500 film colors in a cast and calendared series. Contact us today….

#4 World’s Largest Wrap Supply Company

Domain Est. 1994

Website: fellers.com

Key Highlights: Automotive Window Film & Tint. Protection Wrap Film. Overlaminates. Tapes. Architectural Films. Anti-Graffiti Films. Headlight & Taillight Vinyl….

#5 Kay Premium Marking Films

Domain Est. 1999

Website: kpmf.com

Key Highlights: Take a wander through our gallery where you will see an impressive and diverse selection of vehicle wraps completed using our products. Vehicle Wrap in Action….

#6 Metro Restyling

Domain Est. 2008

Website: metrorestyling.com

Key Highlights: Free delivery over $99 30-day returns…

#7 Quality car wraps, vinyl wraps, paint protection films & window films

Domain Est. 2012

#8 Wrapstock

Domain Est. 2012

Website: wrapstock.com

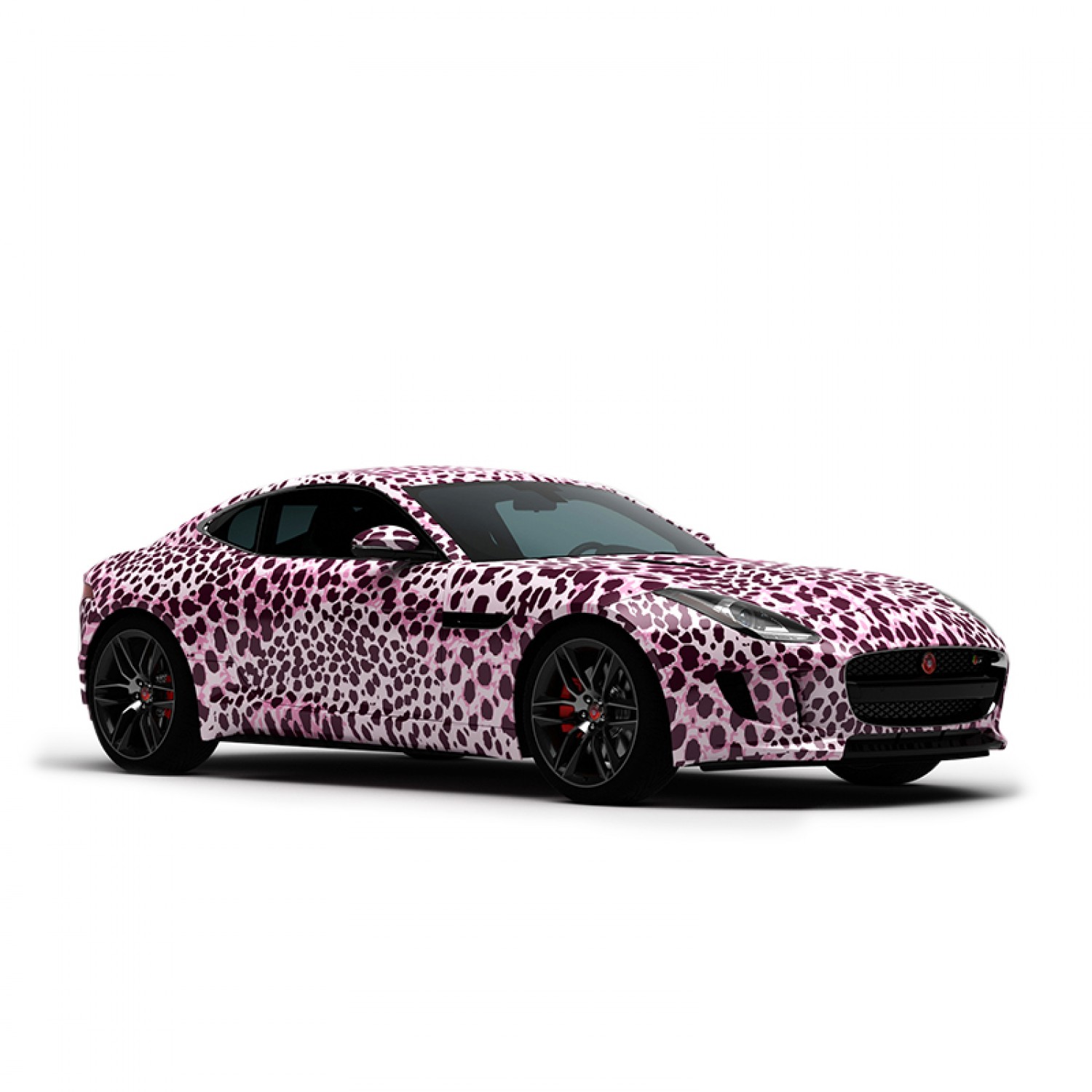

Key Highlights: Our designs, fit to any type of car, makes a smooth wrapping process. It’s quick and easy! Simply choose your design, download it, print it and wrap today! You ……

#9 Teckwrap USA

Domain Est. 2013

#10 CheetahWrap

Domain Est. 2014

Website: cheetahwrap.com

Key Highlights: CheetahWrap, supplier of easy-to-apply car wrap manufactured in the US. Automotive vinyl wrap designed for both professional and DIY wrap installers….

Expert Sourcing Insights for Car Wrap Supplies

2026 Market Trends for Car Wrap Supplies

The car wrap supplies market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and growing demand across both commercial and personal vehicle sectors. This analysis explores key trends shaping the industry and offers insights into future opportunities and challenges.

Growth Drivers and Market Expansion

By 2026, the global car wrap supplies market is projected to experience robust growth, with a compound annual growth rate (CAGR) estimated between 6% and 8%. This expansion is fueled by increased adoption of vehicle wraps for advertising, fleet branding, and aesthetic customization. Urbanization and the rise of influencer and rideshare economies are amplifying demand for personalized vehicle appearances. Additionally, the growing popularity of electric vehicles (EVs), which often feature minimalist designs, creates new opportunities for wraps as a means of individual expression.

Technological Innovation in Materials

A major trend in 2026 will be the widespread use of advanced vinyl materials with improved durability, conformability, and eco-friendliness. Suppliers are investing in self-healing films, matte and textured finishes, and color-shifting wraps that leverage nanotechnology. Pressure-sensitive adhesives with repositionable and residue-free properties will become industry standards, reducing installation time and increasing consumer appeal. Digital printing compatibility will also improve, supporting high-resolution custom designs with faster turnarounds.

Sustainability and Eco-Conscious Solutions

Environmental concerns are reshaping product development. By 2026, recyclable and biodegradable wrap films are expected to gain market share, driven by regulatory pressures and consumer demand for sustainable options. Leading manufacturers will emphasize low-VOC (volatile organic compound) adhesives and water-based inks. Additionally, reusable and removable wraps will appeal to environmentally conscious users and businesses seeking temporary branding solutions.

Expansion of E-Commerce and Direct-to-Consumer Models

The distribution landscape for car wrap supplies will continue shifting online. E-commerce platforms, social media marketplaces, and direct-to-consumer (DTC) sales channels will dominate, offering DIY enthusiasts and small installers easier access to premium materials. Augmented reality (AR) tools integrated into online stores will allow users to visualize wraps on their vehicles before purchase, enhancing customer confidence and reducing return rates.

Professionalization of Installation Services

As demand grows, so does the need for skilled installers. In 2026, certification programs and training platforms will expand, creating a more professionalized installation ecosystem. Partnerships between wrap supply manufacturers and training institutions will become common, ensuring product compatibility and quality control. Mobile installation services and subscription-based wrap programs for fleets are expected to emerge as niche growth areas.

Regional Market Dynamics

North America and Europe will remain dominant markets due to high vehicle ownership and strong branding cultures. However, the Asia-Pacific region, particularly China and India, will show the fastest growth, driven by expanding middle classes and urban vehicle use. Latin America and the Middle East will also see rising demand for cost-effective vehicle customization and advertising solutions.

Challenges and Competitive Landscape

Despite growth, the market faces challenges such as counterfeit products, price competition, and material supply chain volatility. Established brands will differentiate through innovation, customer support, and warranties. Consolidation among suppliers and distributors may occur to capture economies of scale and expand global reach.

Conclusion

By 2026, the car wrap supplies market will be characterized by innovation, sustainability, and digital transformation. Suppliers who adapt to evolving customer needs, invest in R&D, and embrace ethical production practices will lead the industry. As vehicles become more than transportation—serving as canvases for identity and branding—the car wrap industry will play a pivotal role in shaping automotive aesthetics and marketing strategies.

Common Pitfalls When Sourcing Car Wrap Supplies (Quality and Intellectual Property)

Sourcing car wrap supplies—such as vinyl films, laminates, and application tools—can be a minefield if not approached carefully. Two major areas where businesses often encounter problems are product quality inconsistencies and intellectual property (IP) infringement. Avoiding these pitfalls is essential for maintaining professional standards, protecting your brand, and ensuring customer satisfaction.

Poor Material Quality and Performance

One of the most common issues when sourcing car wrap supplies, especially from low-cost or unverified suppliers, is subpar material quality. Low-grade vinyl may exhibit poor adhesion, leading to bubbling, lifting edges, or premature peeling. Inferior films are also more prone to cracking, fading, or delaminating when exposed to UV light, extreme temperatures, or environmental contaminants. This not only results in costly rework but can also damage your reputation as a reliable installer.

Additionally, inconsistent thickness, stretchability, and air-release technology can make application difficult—even for experienced professionals. Sourcing from suppliers without proper technical specifications or testing data increases the risk of receiving materials that fail under real-world conditions.

Lack of Warranty and Technical Support

Many low-cost suppliers, particularly those operating online marketplaces or overseas, do not offer product warranties or technical support. Reputable manufacturers typically back their films with multi-year warranties covering issues like color fade, shrinkage, and adhesive failure. Without this protection, installers bear the full cost of material failure, including labor and customer goodwill.

Furthermore, the absence of reliable technical support means installers may struggle to resolve application issues, troubleshoot problems, or access recommended installation guidelines—leading to higher error rates and customer dissatisfaction.

Intellectual Property Infringement Risks

Sourcing counterfeit or imitation wrap materials poses serious intellectual property (IP) risks. Some suppliers offer “compatible” or “alternative” films that closely mimic the appearance and branding of well-known manufacturers like 3M, Avery Dennison, or HEXIS. These knock-offs often infringe on trademarks, patents, or proprietary designs, exposing your business to legal liability.

Using counterfeit materials can also void vehicle manufacturer warranties and lead to disputes with clients. Moreover, if your business is found to be knowingly distributing or installing IP-infringing products, you may face cease-and-desist orders, fines, or damage to your brand reputation.

Misrepresentation of Product Specifications

Another frequent pitfall is the misrepresentation of product specs. Some suppliers exaggerate performance claims—such as UV resistance, durability, or conformability—without third-party testing or certification. For instance, a film advertised as “10-year outdoor durability” may lack independent verification, leading to unexpected failures.

Always verify technical data sheets (TDS) and request samples before bulk purchasing. Cross-reference claims with industry standards and user reviews to avoid being misled by inflated marketing.

Supply Chain and Compliance Issues

Imported materials may not comply with regional safety or environmental regulations (e.g., REACH in Europe or CPSC standards in the U.S.). Non-compliant films could contain harmful phthalates or off-gas volatile organic compounds (VOCs), posing health risks and legal exposure. Additionally, unreliable supply chains can lead to inconsistent availability, long lead times, or shipment delays—disrupting your operations.

To mitigate these risks, vet suppliers thoroughly, request certifications, and consider working with distributors authorized by major brands. Prioritizing quality and legitimacy over short-term cost savings protects your business in the long run.

Logistics & Compliance Guide for Car Wrap Supplies

Navigating the logistics and compliance requirements for car wrap supplies is essential for smooth operations, cost efficiency, and legal adherence. This guide covers key considerations for the transportation, storage, and regulatory compliance of vinyl wraps, tools, and related materials.

Transportation & Shipping

Ensure car wrap supplies are shipped under proper conditions to prevent damage. Rolls of vinyl, laminate, and specialty films are sensitive to temperature extremes, moisture, and physical stress. Use climate-controlled transport when possible and always ship in protective packaging with end caps and stretch wrap. Clearly label packages as fragile and oriented to prevent rolling. Work with carriers experienced in handling wide-format materials to reduce the risk of kinking or crushing during transit.

Storage & Inventory Management

Store car wrap films and tools in a clean, dry, temperature-controlled environment between 60°F and 77°F (15°C to 25°C), away from direct sunlight and UV exposure. Unroll and re-roll materials periodically if stored long-term to prevent creasing or adhesive migration. Keep rolls stored vertically whenever possible to maintain roll integrity. Implement a first-in, first-out (FIFO) inventory system to minimize degradation of older stock and ensure material freshness.

Regulatory Compliance – Material Safety

Adhere to safety data sheet (SDS) requirements for all chemical-based products such as application solutions, primers, and cleaners. Maintain accessible SDS documentation in compliance with OSHA’s Hazard Communication Standard (HCS) in the U.S. or equivalent regulations (e.g., REACH in the EU). Ensure employees are trained on safe handling, storage, and disposal of hazardous substances.

International Shipping & Customs

For cross-border logistics, classify car wrap supplies under the correct Harmonized System (HS) codes—typically under 3919 (self-adhesive plates, sheets, film, foil, tape) for vinyl films. Provide accurate product descriptions, values, and country of origin on commercial invoices. Be aware of import restrictions or duties that may apply, especially for PVC-based materials subject to environmental regulations in certain regions (e.g., EU REACH or RoHS compliance).

Environmental & Disposal Regulations

Dispose of used vinyl scraps, solvents, and packaging in accordance with local environmental regulations. Many vinyl films contain PVC or polyurethane components that may require special handling or recycling programs. Partner with certified waste management providers and explore manufacturer take-back programs where available. Document disposal procedures to maintain compliance with EPA or equivalent environmental authorities.

Product Labeling & Certification

Ensure all car wrap products meet regional certification standards. For example, in the U.S., look for compliance with ASTM D3359 (adhesion testing) and FMVSS 108 for wraps on vehicle lighting areas. In the EU, verify CE marking and adherence to EN standards where applicable. Accurate labeling—including batch numbers, expiration dates, and installation instructions—supports traceability and customer compliance.

Insurance & Liability

Carry appropriate cargo and liability insurance for transported and stored materials. Given the high value of specialty wraps (e.g., chrome, matte, or color-shifting films), ensure coverage includes damage, theft, and errors in handling. Maintain records of shipments, inspections, and storage conditions to support claims if necessary.

By following these logistics and compliance guidelines, businesses can protect product integrity, meet legal requirements, and deliver reliable service in the competitive car wrap industry.

In conclusion, sourcing car wrap supplies requires careful consideration of quality, durability, compatibility, and cost-effectiveness. Establishing relationships with reputable suppliers—whether manufacturers, distributors, or online platforms—ensures access to premium materials such as vinyl wraps, laminates, application tools, and cleaning products. Evaluating factors like material performance, warranty, customer support, and shipping logistics contributes to long-term success in vehicle customization and wrapping services. By prioritizing trusted brands and staying informed on industry advancements, businesses can maintain high standards, increase customer satisfaction, and remain competitive in the growing automotive aftermarket sector.