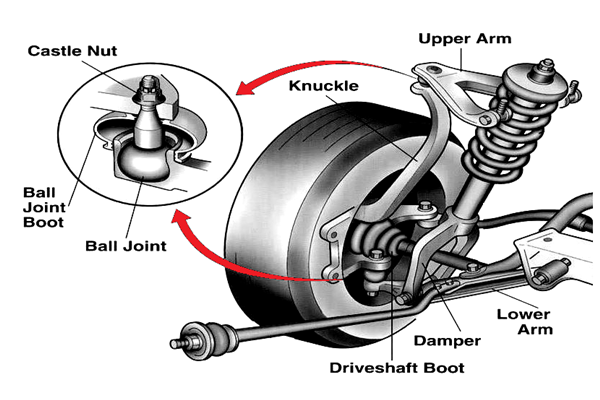

The global automotive suspension components market, driven by rising vehicle production and increasing demand for enhanced ride comfort and safety, is experiencing steady growth. According to Mordor Intelligence, the automotive suspension market was valued at USD 35.2 billion in 2023 and is projected to reach USD 46.7 billion by 2029, growing at a CAGR of approximately 4.8% over the forecast period. A critical component of this ecosystem, the car suspension ball joint, plays a pivotal role in steering precision and load-bearing performance. With the rise in electric vehicle (EV) adoption and the need for advanced suspension systems tailored to heavier battery platforms, demand for high-quality, durable ball joints is intensifying. Ball joints must now meet stricter OEM standards for longevity and performance under varying road conditions, prompting increased innovation among manufacturers. As competition heats up, a select group of suppliers have emerged as leaders through technological advancement, global reach, and compliance with stringent regulatory frameworks. Here are the top 10 car suspension ball joint manufacturers shaping the future of automotive mobility.

Top 10 Car Suspension Ball Joint Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

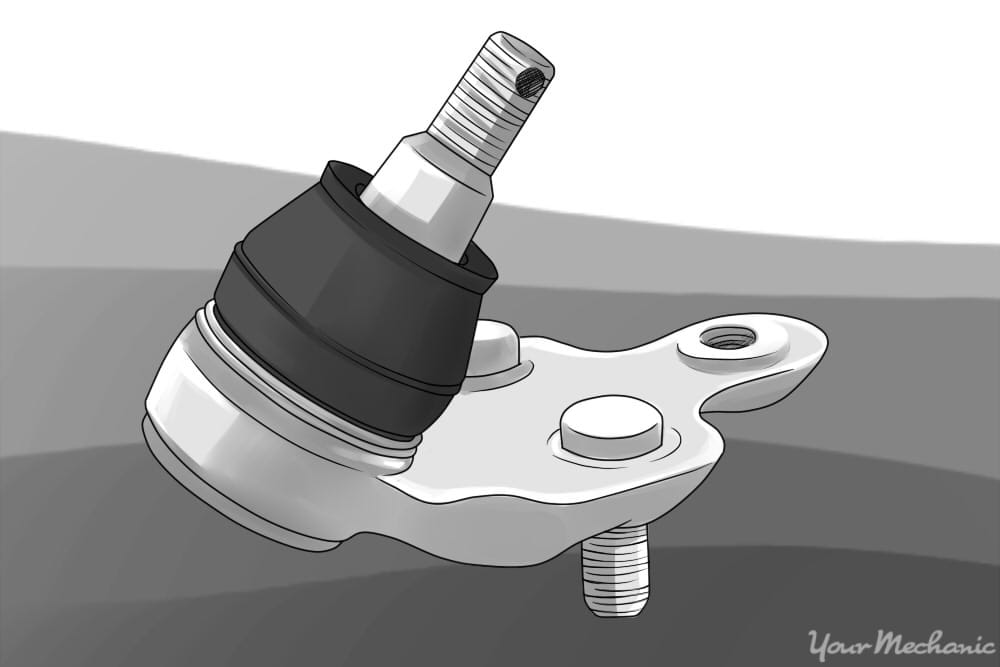

#1 Suspension Ball Joints

Domain Est. 2017

Website: thk-rhythm-auto.com

Key Highlights: THK develop and produce a wide range of various high-quality SBJs in conjunction with customer requirements. All technical feasible joining methods are applied …Missing: car man…

#2 Original Equipment Quality Ball Joints

Domain Est. 1995

Website: monroe.com

Key Highlights: Each Monroe ball joint is manufactured exclusively from premium-grade steel formulated and tested to ensure outstanding strength and durability. Ball joints are ……

#3 The Indispensable Ball Joint for Vehicle Suspension Systems

Domain Est. 1995

Website: thk.com

Key Highlights: THK, known best for its linear motion guides, also develops, manufactures, and sells ball joint products used in various automotive applications….

#4 LEMFÖRDER

Domain Est. 1996

Website: aftermarket.zf.com

Key Highlights: Only LEMFÖRDER can provide ball joints of such low elasticity that vehicles respond with greater agility, stability, driving dynamics and, above all, safety….

#5 Steering & Suspension

Domain Est. 1997

Website: febi.com

Key Highlights: The main task of the ball joint is to support the steering knuckle and to hold the widely-used McPherson strut in position at the base….

#6 Mevotech

Domain Est. 1997

Website: mevotech.com

Key Highlights: Designed for the Ride. Professional Technicians trust Mevotech’s driveline, steering and suspension parts to perform stronger, and last longer….

#7 Suspension Parts & Components

Domain Est. 2005

Website: moogparts.com

Key Highlights: BALL JOINTS. Featuring problem-solving innovations for longer life, increased durability and safer handling. View Ball Joints. Selection of MOOG bushings ……

#8

Domain Est. 2007

Website: spcalignment.com

Key Highlights: Designed, engineered, tested, and assembled in Colorado, SPC Performance adjustable upper control arms are loaded… Learn More. 15220 CARTRIDGE BALL JOINT EA….

#9 Ball Joints

Domain Est. 2012

Website: delphiautoparts.com

Key Highlights: We provide a range of sealed ball joints, that are lubed for life with a high-specification grease, to minimize maintenance requirements….

#10 Product Information

Website: sankei-555.co.jp

Key Highlights: Sankei Industry has focused on manufacturing quality aftermarket automotive parts (suspension and steering-related parts in particular)….

Expert Sourcing Insights for Car Suspension Ball Joint

2026 Market Trends for Car Suspension Ball Joint

The global car suspension ball joint market is poised for significant transformation by 2026, driven by evolving automotive technologies, increasing vehicle electrification, and a growing emphasis on safety and ride comfort. As a critical component in vehicle suspension systems, ball joints play a vital role in enabling smooth steering and shock absorption. This analysis explores the key market trends expected to shape the car suspension ball joint industry in 2026.

Rising Demand for Electric Vehicles (EVs)

One of the most influential trends shaping the 2026 ball joint market is the accelerated adoption of electric vehicles. EVs often feature heavier chassis due to battery packs, placing increased stress on suspension components. This necessitates the development of high-strength, durable ball joints designed to handle greater loads while maintaining precise control and longevity. Manufacturers are responding by investing in advanced materials such as forged steel and composite polymers to enhance performance and durability under EV-specific conditions.

Technological Advancements and Smart Suspension Systems

By 2026, smart and adaptive suspension systems are expected to gain mainstream traction, especially in premium and autonomous vehicles. These systems rely on real-time data and sensors to adjust ride height and stiffness, requiring ball joints that integrate with electronic control units. Innovations such as condition-monitoring ball joints—equipped with embedded sensors to detect wear and predict failure—are emerging. These “smart” components support predictive maintenance, enhancing vehicle safety and reducing downtime, particularly in commercial and fleet applications.

Lightweighting and Material Innovation

Automakers are under continuous pressure to reduce vehicle weight and improve fuel efficiency (or extend EV range). In response, ball joint manufacturers are shifting toward lightweight materials such as aluminum alloys and high-performance plastics without compromising strength. The integration of advanced coatings and surface treatments also enhances corrosion resistance and reduces friction, contributing to longer service life and improved efficiency.

Growth in Aftermarket Demand

The global aftermarket for suspension components, including ball joints, is projected to expand significantly by 2026. Aging vehicle fleets, especially in North America and Europe, are driving demand for replacement parts. Increased vehicle longevity and maintenance awareness among consumers are boosting sales through online and retail channels. OEMs and third-party suppliers are enhancing their aftermarket presence with improved product availability, warranties, and digital support tools.

Regional Market Dynamics

Asia-Pacific, particularly China and India, is expected to dominate the ball joint market by 2026 due to high vehicle production volumes and rising consumer demand. Meanwhile, stringent safety and emission regulations in Europe and North America are pushing automakers to adopt higher-quality suspension systems, favoring premium ball joint solutions. Localized manufacturing and supply chain resilience will also influence regional market strategies, especially in the wake of recent global disruptions.

Sustainability and Circular Economy

Sustainability is becoming a key consideration across the automotive supply chain. By 2026, ball joint manufacturers are anticipated to adopt greener production methods, including energy-efficient manufacturing and recyclable materials. Some companies are exploring remanufactured or reconditioned ball joints as eco-friendly alternatives, aligning with circular economy principles and reducing waste.

In conclusion, the 2026 car suspension ball joint market will be shaped by electrification, digital integration, material innovation, and sustainability. Companies that invest in R&D, adapt to regional demands, and align with evolving vehicle technologies will be best positioned to capture growth in this dynamic segment.

Common Pitfalls Sourcing Car Suspension Ball Joints (Quality, IP)

Sourcing car suspension ball joints requires careful attention to both quality and intellectual property (IP) concerns. Overlooking these aspects can lead to safety risks, legal issues, and reputational damage. Below are key pitfalls to avoid:

Poor Quality Control and Material Standards

Many suppliers, especially from low-cost regions, may cut corners on raw materials and manufacturing processes. Substandard steel, inadequate heat treatment, or poor sealing mechanisms result in premature wear, joint failure, and potential safety hazards. Always verify compliance with industry standards such as ISO/TS 16949, SAE J490, or OEM specifications. Request third-party test reports and conduct sample durability testing before scaling up orders.

Inconsistent Tolerances and Fitment Issues

Ball joints must meet precise dimensional tolerances to ensure proper fit and function across different vehicle models. Inconsistent production can lead to misalignment, excessive play, or installation difficulties. Confirm that suppliers use precision tooling and conduct regular in-process inspections. Request first-article inspection (FAI) reports and validate fitment with physical prototypes on target vehicle platforms.

Misrepresentation of OEM Equivalency

Some suppliers falsely claim their products are direct OEM equivalents or “OEM quality” without proper validation. This misleading marketing can result in performance gaps and liability exposure. Require documented cross-reference data and, if possible, conduct side-by-side testing with genuine OEM parts. Avoid suppliers who cannot provide traceable quality certifications or production records.

Intellectual Property (IP) Infringement Risks

Manufacturing or sourcing ball joints that replicate patented designs—such as unique housing geometries, boot seals, or internal bearing configurations—can expose buyers to IP litigation. Even if a supplier operates in a jurisdiction with lax IP enforcement, importing infringing parts into regions like the EU or the US may lead to customs seizures and legal penalties. Conduct IP due diligence: request design freedom-to-operate opinions and ensure designs are sufficiently differentiated from protected OEM solutions.

Lack of Traceability and Documentation

Reputable suppliers provide full traceability, including material certifications, batch numbers, and production dates. Without this, diagnosing field failures or managing recalls becomes nearly impossible. Insist on a documented quality management system (QMS) and ensure all components are marked or coded for traceability. Avoid suppliers unable to provide comprehensive documentation upon request.

Overlooking Aftermarket Certification Requirements

In regulated markets, ball joints may need to comply with certifications like E-Mark (Europe), DOT (USA), or ADR (Australia). Assuming that all parts meet these standards without verification is a common error. Confirm that the supplier has obtained and can provide valid certifications for the target market to avoid import or sales restrictions.

Logistics & Compliance Guide for Car Suspension Ball Joints

Product Overview and Classification

Car suspension ball joints are critical automotive components that connect control arms to steering knuckles, enabling smooth wheel movement and articulation. Proper handling, storage, and compliance with international standards are essential due to their safety-critical nature.

Harmonized System (HS) Code

The recommended HS Code for car suspension ball joints is 8708.80.00, which covers “Parts and accessories of the motor vehicles of headings 8701 to 8705: Other parts and accessories of bodies (including cabs), chassis (including axles, springs, steering wheels and steering columns), and suspension systems.” Always verify with local customs authorities, as classification may vary by country.

Packaging and Labeling Requirements

Ball joints must be packaged to prevent mechanical damage, corrosion, and contamination during transit. Use moisture-resistant materials and cushioning (e.g., foam inserts). Each package should be labeled with:

– Product name and part number

– Manufacturer or brand name

– HS Code

– Country of origin

– Net and gross weight

– Handling symbols (e.g., “Do Not Stack”, “Fragile”)

– Compliance marks (e.g., ISO, TS 16949 if applicable)

Transportation and Storage Conditions

- Temperature: Store and transport between 5°C and 40°C. Avoid extreme heat or freezing conditions.

- Humidity: Keep relative humidity below 70% to prevent rust. Use desiccants if necessary.

- Stacking: Limit stack height to avoid crushing lower layers. Use pallets for secure unit loads.

- Handling: Use appropriate lifting equipment; avoid dropping or impact.

Regulatory and Safety Compliance

Ball joints must meet relevant safety and quality standards:

– ISO 9001 / IATF 16949: Quality management systems for automotive production.

– SAE J490 / DIN 71125: Standards for mechanical strength and performance testing.

– REACH & RoHS: Compliance with chemical restrictions in the EU (e.g., lead, cadmium limits).

– DOT / FMVSS (USA): If sold as part of a safety system, ensure compatibility with Federal Motor Vehicle Safety Standards.

– E-Mark (UNECE): Required for sale in Europe; look for E-number on product or packaging.

Import and Export Documentation

Essential documents include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Material Safety Data Sheet (MSDS), if applicable

– Test Reports or Certificates of Conformity (e.g., ISO, SAE)

– Export License (if required by exporting country)

Country-Specific Requirements

- European Union: CE marking not required for individual ball joints, but must comply with vehicle type-approval frameworks. E-mark certification recommended.

- United States: No specific import license, but CBP may request proof of compliance with FMVSS.

- China: Requires CCC certification only if part of a complete vehicle system; otherwise, standard import procedures apply.

- Russia/Eurasian Union: May require EAC certification for automotive components.

Quality Assurance and Traceability

Maintain batch traceability through serial or lot numbering. Conduct regular quality audits and retain test records for at least five years. Implement a recall readiness plan in case of non-conformance.

Environmental and Disposal Considerations

Ball joints contain steel and lubricants. Dispose of damaged or obsolete units in accordance with local environmental regulations. Recycle metal components where possible. Avoid dumping lubricants into landfills or water sources.

Summary and Best Practices

To ensure smooth logistics and compliance:

1. Confirm correct HS code and country-specific certifications.

2. Use protective, labeled packaging.

3. Maintain proper storage conditions.

4. Keep complete documentation for customs and audits.

5. Stay updated on regulatory changes in target markets.

Consult with a customs broker or logistics expert when entering new markets to avoid delays or penalties.

In conclusion, sourcing car suspension ball joints requires careful consideration of several key factors to ensure safety, performance, and longevity. It is essential to prioritize product quality by selecting ball joints made from durable materials and meeting industry standards such as ISO, TS 16949, or OEM specifications. Working with reputable suppliers or manufacturers—whether local distributors or international partners—helps ensure reliability and consistency in supply. Additionally, evaluating factors like pricing, minimum order quantities, lead times, and after-sales support contributes to a successful sourcing strategy.

For optimal vehicle performance and passenger safety, OEM or OES-quality components are recommended, especially for critical suspension systems. Conducting due diligence through supplier audits, sample testing, and certification verification minimizes risks associated with counterfeit or substandard parts. Ultimately, an effective sourcing approach balances cost-efficiency with quality assurance, ensuring that the ball joints meet both technical requirements and safety standards across diverse vehicle applications.