The global automotive coatings market is experiencing robust growth, driven by rising vehicle production, increasing consumer demand for aesthetically enhanced finishes, and advancements in coating technologies. According to a report by Mordor Intelligence, the automotive coatings market was valued at USD 34.21 billion in 2023 and is projected to grow at a CAGR of over 5.8% through 2029. A key segment within this space is specialty finishes, particularly metal flake pigments used in premium and custom car paint applications. These high-luster additives have gained traction not only among luxury automakers but also within the aftermarket and custom car industries, fueling demand for high-performance metal flake solutions. As consumer preferences shift toward personalized and eye-catching vehicle appearances, manufacturers specializing in car paint metal flakes are scaling production and investing in innovation. This list highlights the top seven manufacturers leading the charge in quality, consistency, and technological advancement in metal flake production for automotive paints.

Top 7 Car Paint Metal Flake Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Metalflake

Domain Est. 1998 | Founded: 1967

Website: metalflake.com

Key Highlights: 14-day returnsWelcome to Metalflake – the home of automotive & industrial refinishing supplies. Serving the trade and end user customers since 1967….

#2 Metal Flake for Automotive Paint, Chrome Silver, 4oz (4 Pack) 16oz Tot

Domain Est. 2004

Website: tcpglobal.com

Key Highlights: In stock Free deliveryProduct Features: (4 Pack) 4oz pouches, 1-pound total of automotive-grade large metal flake (.025″ / 625 micron); UV coated polyester glitter for paint with ….

#3 Roth Metal Flake

Domain Est. 2005

Website: rothmetalflake.com

Key Highlights: 30-day returnsFlake Bomber 2.5mm Tip. Regular price $119 ; Loose Cannon 3.0 Tip. Regular price $119 ; 1.4mm Color Kraft Spray Gun. Regular price $109 Sale price $79 ; Flake ……

#4 Metal Flake For Automotive Paint

Domain Est. 2009

Website: thecoatingstore.com

Key Highlights: Free delivery over $399.99 · 30-day returnsFireFlake is built from solvent resistant polymer metallized for reflective effect then coated with clear or transparent colored finishe…

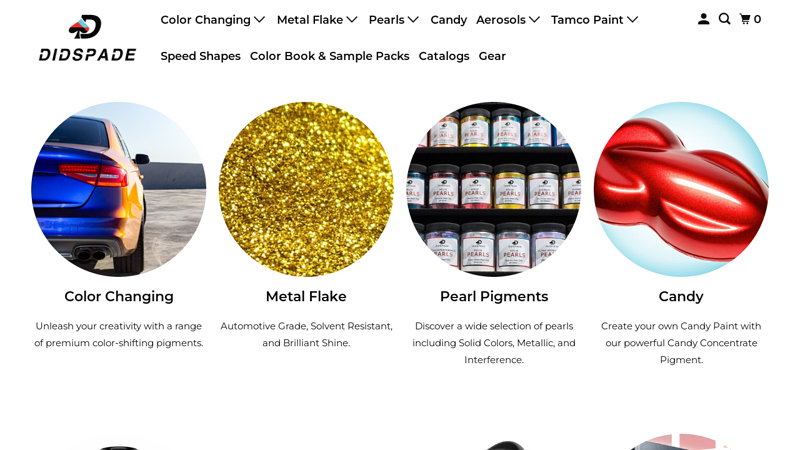

#5 Automotive Custom Pearl Pigments & Metal Flakes

Domain Est. 2013

#6 Black Onyx Metal Flake

Domain Est. 2016

#7 Flakes & Pigments

Domain Est. 2021

Website: limelinepaintsupply.com

Key Highlights: 6–9 day deliveryLiME LiNE 1 lb Metal Flake .008 – Automotive Grade for Custom Paint, Lowriders, Motorcycles, Hot Rods, and More. $59.99 $89.99….

Expert Sourcing Insights for Car Paint Metal Flake

H2: Projected Market Trends for Car Paint Metal Flake in 2026

Based on current industry dynamics, technological advancements, and consumer behavior, the car paint metal flake market in 2026 is expected to experience steady growth driven by customization, innovation, and evolving automotive aesthetics. Key trends shaping the market include:

1. Rising Demand for Customization and Aesthetic Differentiation:

By 2026, personalization will remain a dominant force in the automotive aftermarket. Metal flake paints—offering high-gloss, multidimensional finishes with dynamic sparkle under light—will continue to appeal to car enthusiasts, luxury vehicle owners, and custom builders. The desire for unique, head-turning appearances will sustain demand, particularly in markets with strong car culture like North America, Europe, and parts of Asia-Pacific.

2. Technological Advancements in Flake Uniformity and Application:

Manufacturers will increasingly adopt nano-engineered metal flakes and improved dispersion technologies to enhance consistency, reduce settling, and improve ease of application. Innovations such as hybrid flake-pigment systems and UV-resistant clear coats will extend durability and color retention, making metal flake finishes more viable for OEM and high-end aftermarket use.

3. Expansion in OEM and Premium Vehicle Adoption:

While historically limited to the aftermarket, select luxury and performance vehicle manufacturers are expected to integrate metal flake or flake-inspired finishes into special edition models by 2026. Brands like Porsche, BMW, and Lexus may offer premium paint options featuring fine metal flakes to differentiate limited-run vehicles, boosting market legitimacy and visibility.

4. Sustainability and Regulatory Pressures:

Environmental regulations regarding VOC (volatile organic compound) emissions will push suppliers toward water-based and low-VOC metal flake formulations. Research into bio-based resins and recyclable flake materials may gain traction, aligning with broader automotive industry sustainability goals. Compliance with regional standards (e.g., REACH in Europe, CARB in California) will be critical for market access.

5. Growth in Emerging Markets:

Regions such as India, Southeast Asia, and the Middle East will see increased adoption of custom paint finishes due to rising disposable income and growing car modification cultures. Local distributors and paint shops will expand access to metal flake products, supported by online retail and social media influence.

6. Integration with Digital Design and AR Tools:

By 2026, augmented reality (AR) apps and online configurators will allow consumers to visualize metal flake finishes on their vehicles in real time. This digital engagement will streamline decision-making and drive conversion in both retail and professional settings.

Conclusion:

The car paint metal flake market in 2026 will be characterized by innovation, increased customization, and broader market penetration. While challenges around cost, application complexity, and environmental compliance persist, strategic advancements and consumer demand will position metal flake finishes as a premium, high-growth segment within the automotive coatings industry.

Common Pitfalls When Sourcing Car Paint with Metal Flake (Quality and Intellectual Property)

Sourcing high-quality car paint with metal flake requires careful attention to both performance characteristics and legal considerations. Overlooking key aspects can lead to subpar finishes, project delays, or even legal disputes. Below are common pitfalls to avoid:

Poor Metal Flake Quality and Consistency

One of the most frequent issues is receiving paint with inconsistent or low-grade metal flake. Inferior flakes may be uneven in size, poorly cut, or made from substandard materials, leading to a mottled, dull, or patchy finish. Some suppliers use recycled or contaminated flake, which can oxidize over time, causing discoloration or reduced reflectivity. Always verify the flake source, cut type (e.g., precision-cut vs. irregular), and particle size distribution before purchase.

Inadequate Suspension and Settling Issues

Metal flake tends to settle in the paint can, especially if the suspension system is poorly formulated. Low-quality paints may require excessive stirring or mechanical agitation, and even then, flakes may not distribute evenly during application. This results in “flaking out” during spraying—where flakes clump or fail to align properly—ruining the desired effect. Ensure the paint uses a reliable rheology modifier and ask for technical data on shelf life and re-stirrability.

Color and Effect Mismatch

Custom or brand-specific color matches (e.g., OEM or show car finishes) often rely on proprietary flake blends and clear coat techniques. Sourcing from unauthorized or generic suppliers can result in noticeable differences in color shift, sparkle intensity, or flake orientation. Always request physical test panels (not just digital swatches) and conduct side-by-side comparisons under various lighting conditions before committing to large quantities.

Intellectual Property (IP) Violations

Using or sourcing paint that replicates trademarked or patented color effects (e.g., BMW Individual, BASF ChromaLusion®, or PPG Vibrance®) without proper licensing can lead to legal repercussions. Many high-end flake technologies are protected by patents covering flake shape, coating chemistry, or application methods. Sourcing counterfeit or reverse-engineered products—even unknowingly—exposes buyers and applicators to IP infringement claims. Always verify the supplier’s right to distribute and confirm whether the product is licensed or falls under legitimate reverse engineering exemptions.

Lack of Technical Support and Documentation

Reputable suppliers provide detailed technical data sheets (TDS), application guidelines, and safety data sheets (SDS). Generic or off-brand sources may lack this support, making it difficult to achieve optimal results or troubleshoot issues. Without proper cure schedules, recommended clear coat systems, or ambient condition guidance, even high-quality paint can underperform.

Supply Chain and Batch-to-Batch Variability

Inconsistent manufacturing processes can lead to noticeable differences between production batches. This is especially problematic for large or multi-phase projects where paint must be ordered at different times. Confirm with the supplier their quality control procedures and whether they guarantee batch-to-batch consistency—ideally with retain samples.

Avoiding these pitfalls requires due diligence: vet suppliers thoroughly, demand samples, verify IP status, and prioritize technical transparency over cost savings. Investing in reputable, legally compliant sources ensures a stunning, durable finish and protects against costly rework or legal exposure.

Logistics & Compliance Guide for Car Paint Metal Flake

Product Classification and Identification

Car paint containing metal flake components typically falls under hazardous materials due to flammable solvents and metallic particulates. Accurate identification is essential for regulatory compliance. The product must be classified according to the Globally Harmonized System (GHS) and assigned the appropriate UN number—commonly UN1263 (Flammable liquid, n.o.s.) for solvent-based formulations. Safety Data Sheets (SDS) must be up to date and include full ingredient disclosure, including metal flake composition (e.g., aluminum, bronze, or specialty alloys), and hazard statements related to flammability, respiratory risks, and environmental impact.

Packaging and Labeling Requirements

Metal flake car paint must be packaged in UN-certified containers designed for flammable liquids. Drums or pails must be tightly sealed to prevent leakage and vapor release. Each package must display GHS-compliant labels featuring pictograms (e.g., flame, health hazard), signal words (“Danger”), hazard statements (e.g., “Highly flammable liquid and vapor”), and precautionary statements. Proper marking with the UN number, proper shipping name, and shipper/consignee information is required. Outer packaging must also indicate orientation (e.g., “This Way Up”) and any accumulation or stacking limits.

Transportation Regulations (Air, Sea, and Ground)

Transportation of metal flake car paint is governed by international and national regulations:

– Ground (e.g., DOT 49 CFR in the U.S.): Requires placarding for flammable liquids when transporting large quantities. Vehicles must carry shipping papers, emergency response information, and spill kits.

– Air (IATA DGR): Strict volume limitations apply; quantities exceeding limits may be prohibited. Packages must pass drop and pressure tests and be labeled as “Forbidden” or “Limited Quantity” as applicable.

– Sea (IMDG Code): Requires detailed Dangerous Goods Declaration, stowage compliance, and segregation from incompatible materials (e.g., oxidizers). Vessels must have proper ventilation to prevent vapor accumulation.

Storage and Handling Procedures

Store metal flake car paint in a cool, dry, well-ventilated area away from ignition sources, direct sunlight, and incompatible substances. Use grounded, flame-proof storage cabinets rated for flammable liquids. Implement static control measures during handling to reduce fire risk. Employees must wear appropriate PPE (gloves, goggles, respirators) and be trained in spill response and safe transfer procedures. Avoid creating dust or aerosols when handling dry metal flake additives.

Regulatory Compliance and Documentation

Ensure compliance with all relevant regulations including OSHA (U.S.), REACH and CLP (EU), and local environmental laws. Maintain accessible SDS for all products, and verify that metal flake components do not contain restricted substances (e.g., certain heavy metals like lead or cadmium). Export shipments require customs documentation, including commercial invoices, packing lists, and Dangerous Goods Declarations where applicable. Regular audits and training ensure ongoing compliance.

Emergency Response and Spill Management

Develop and implement an emergency response plan specific to flammable paint spills. In case of spillage, eliminate ignition sources and contain with inert absorbents (e.g., vermiculite or sand). Do not allow runoff into drains or waterways. For large spills, evacuate area and contact emergency services. Fire response requires appropriate extinguishing agents (e.g., dry chemical, CO₂, or foam—never water jets). All personnel must be trained in spill control, evacuation, and first aid procedures.

Environmental and Disposal Considerations

Dispose of metal flake car paint and contaminated materials as hazardous waste in accordance with local, state, and federal regulations. Recycling metal content may be possible through licensed facilities. Never dispose of in regular trash or pour down drains. Track waste disposal via manifests and maintain records for regulatory inspections. Minimize environmental impact by using closed-loop transfer systems and spill prevention measures during operations.

Conclusion: Sourcing Car Paint with Metal Flake

Sourcing high-quality metal flake car paint requires careful consideration of several key factors, including color consistency, flake size and distribution, paint brand reputation, compatibility with base coats and clear coats, and supplier reliability. Whether for custom automotive finishes, restoration projects, or professional refinishing, selecting the right metal flake paint directly impacts the final aesthetic and durability of the vehicle’s finish.

OEM and aftermarket suppliers offer various options, from pre-mixed formulas to custom blends, allowing for unique and personalized results. It is essential to work with reputable suppliers that provide technical support, accurate color matching, and consistent product quality. Additionally, proper application techniques and safety precautions must be followed to ensure a flawless, long-lasting finish.

In conclusion, successfully sourcing metal flake car paint involves balancing performance, appearance, and reliability. By prioritizing quality materials, trusted vendors, and proper application methods, automotive professionals and enthusiasts can achieve stunning, show-worthy finishes that stand the test of time.