Sourcing Guide Contents

Industrial Clusters: Where to Source Car Manufacturer In China

SourcifyChina B2B Sourcing Report: Chinese Automotive Manufacturing Clusters Analysis (2026 Outlook)

Prepared for Global Procurement Managers

Date: October 26, 2026 | Confidential: SourcifyChina Client Use Only

Executive Summary

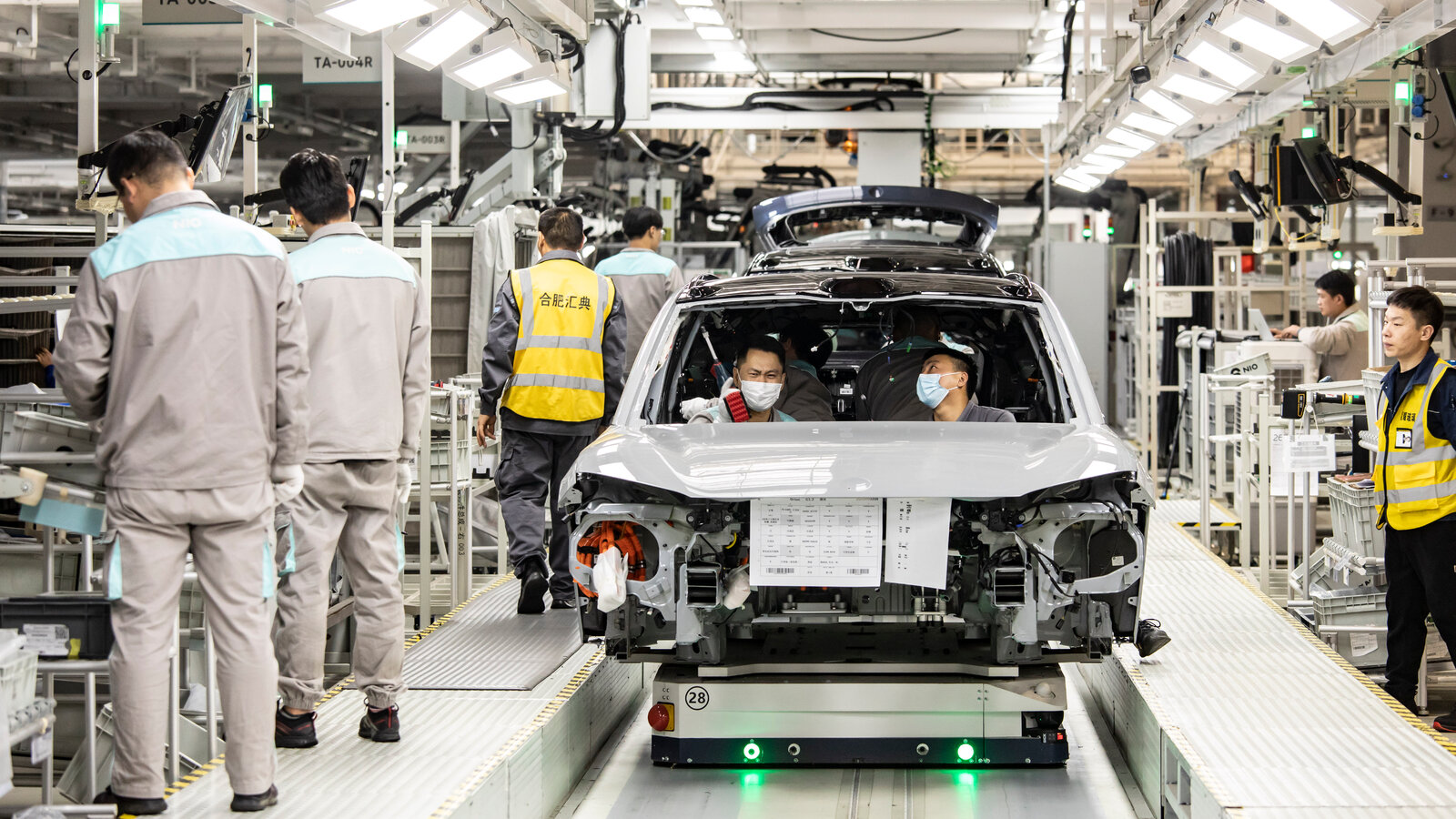

China remains the world’s largest automotive production hub, contributing 32% of global output (OICA 2025) and dominating New Energy Vehicle (NEV) manufacturing with 68% market share. By 2026, consolidation among EV startups, intensified automation, and stringent export compliance requirements will redefine sourcing dynamics. This report identifies five critical industrial clusters for global OEMs and tier-1 suppliers, analyzing regional strengths in price, quality, and lead time. Key insight: Coastal clusters (Guangdong, Shanghai/Jiangsu) lead in premium/EV production with tighter quality control, while inland hubs (Jilin, Hubei) offer cost advantages for ICE/commercial vehicles but face longer lead times due to logistics constraints.

Key Automotive Manufacturing Clusters in China (2026 Focus)

China’s automotive sector is geographically concentrated in provinces with established supply chains, government NEV incentives, and port infrastructure. The top 5 clusters are:

-

Guangdong Province (Guangzhou/Shenzhen)

- Anchor OEMs: GAC Group (incl. Aion EVs), BYD (R&D HQ), joint ventures (Toyota, Honda).

- Specialization: Mass-market EVs, luxury ICE vehicles, batteries (CATL supply chain), smart cabin tech.

- 2026 Trend: Dominance in AI-driven manufacturing; 45% of China’s L4 autonomous vehicle trials occur here.

-

Shanghai & Jiangsu Province (Shanghai/Nanjing/Suzhou)

- Anchor OEMs: SAIC Motor (incl. IM Motors, MG), Tesla Shanghai, BMW Brilliance, Volkswagen Anhui (NEV-focused).

- Specialization: Premium EVs, high-end ICE, autonomous driving systems, integrated supply chains.

- 2026 Trend: Highest automation rate (85%+ in body shops); EU-compliant quality systems critical for exports.

-

Jilin Province (Changchun)

- Anchor OEMs: FAW Group (incl. FAW-Volkswagen, FAW Toyota), Jidong Auto.

- Specialization: Traditional ICE sedans/SUVs, commercial vehicles, military-grade components.

- 2026 Trend: Gradual NEV transition; government subsidies accelerating EV line conversions.

-

Hubei Province (Wuhan/Xiangyang)

- Anchor OEMs: Dongfeng Motor Group (incl. Nissan, Honda, Voyah EVs), local commercial vehicle makers.

- Specialization: Mid-tier ICE vehicles, electric buses, commercial trucks, battery recycling.

- 2026 Trend: Strategic “Battery Valley” initiative; rising cost competitiveness for heavy-duty EVs.

-

Chongqing Municipality

- Anchor OEMs: Changan Automobile (incl. Avatr EVs, Deepal), Suzuki, Ford joint ventures.

- Specialization: Affordable EVs, compact ICE vehicles, motorcycle-derived platforms.

- 2026 Trend: Fastest-growing NEV cluster (30% CAGR); leveraging Yangtze River logistics for cost efficiency.

Regional Cluster Comparison: Sourcing Metrics (2026 Projections)

Note: Metrics benchmarked against Chinese domestic standards. Quality assessed via IATF 16949 compliance depth, defect rates (PPM), and export-readiness. Lead time includes production + inland logistics to port.

| Region | Price Competitiveness | Quality Profile | Lead Time (Weeks) | Supply Chain Maturity | Strategic Fit |

|---|---|---|---|---|---|

| Guangdong (Guangzhou) | ★★★★☆ (4.2/5) | ★★★★☆ (Premium) | 8-10 | ★★★★★ (Best-in-class) | Global EV programs, tech-integrated components |

| Low labor cost advantage eroded; high material/tooling costs offset by scale & automation. | <50 PPM defects; strongest Tier-2/3 battery/electronics ecosystem. | Efficient port access (Nansha); JIT-ready. | Dense supplier network (95% local content for EVs). | ||

| Shanghai/Jiangsu | ★★☆☆☆ (2.8/5) | ★★★★★ (Global Benchmark) | 10-12 | ★★★★☆ (High) | Premium/luxury exports, autonomous systems |

| Highest labor/material costs; justified by quality for EU/US markets. | <35 PPM defects; Tesla/SAIC set industry gold standard. | Port congestion risks; requires buffer stock. | Top-tier German/Japanese supplier presence. | ||

| Zhejiang (Ningbo/Hangzhou) | ★★★★☆ (4.0/5) | ★★★☆☆ (Standard) | 9-11 | ★★★☆☆ (Developing) | Mid-tier EVs, cost-sensitive components |

| Balanced labor costs; strong machinery/part manufacturing base. | 80-100 PPM defects; improving with BYD/Geely investments. | Port access good (Ningbo); inland logistics less optimized. | Rapidly expanding EV component suppliers. | ||

| Jilin (Changchun) | ★★★★☆ (4.5/5) | ★★☆☆☆ (Basic) | 12-14 | ★★☆☆☆ (Limited) | Legacy ICE/commercial vehicles, budget models |

| Lowest labor costs; aging infrastructure limits automation ROI. | 150-200 PPM defects; quality gaps in newer EV lines. | Rail-dependent; 2-3 weeks added for port transit. | FAW-centric; weak Tier-2 battery ecosystem. | ||

| Hubei (Wuhan) | ★★★★☆ (4.3/5) | ★★★☆☆ (Improving) | 10-12 | ★★★☆☆ (Moderate) | Commercial EVs, value-engineered components |

| Competitive labor; rising material costs due to battery demand. | 100-120 PPM defects; Dongfeng-led quality initiatives gaining traction. | Yangtze River logistics efficient but weather-sensitive. | Strong in commercial vehicle parts; NEV gaps. |

Strategic Recommendations for 2026

- Dual-Sourcing Mandatory: Pair coastal (Shanghai/Guangdong) and inland (Hubei/Chongqing) suppliers to mitigate geopolitical/logistics risks. Example: Source EV batteries from Guangdong (quality) and wiring harnesses from Hubei (cost).

- Quality Premium Justified: For EU/US-bound vehicles, allocate 15-20% budget premium for Shanghai/Jiangsu suppliers to avoid costly rework (e.g., Tesla Shanghai’s 0.8% defect rate vs. industry avg. 2.1%).

- Lead Time Buffer: Inland clusters (Jilin/Hubei) require 30%+ longer lead times – build safety stock for critical components.

- Audit NEV Compliance: Post-2025 EU CBAM regulations require carbon footprint validation. Prioritize clusters with renewable energy integration (e.g., BYD’s Guangdong plants: 60% solar-powered).

- Avoid “EV Ghost Cities”: Steer clear of Tier-3 provinces (e.g., Anhui, Heilongjiang) with failed EV startups; focus on clusters with OEM anchor tenants.

Risk Appendix (2026 Critical Watch)

- Tariff Exposure: 27.8% EU anti-subsidy duties on Chinese EVs (effective Q1 2026) – source via Mexico/Vietnam for EU-bound volumes.

- IP Vulnerability: Guangdong leads in patent disputes (35% of China’s auto IP cases); use SourcifyChina’s IP Shield™ contract framework.

- Labor Shortage: Shanghai/Jiangsu face 12% skilled technician deficit; budget 8-10% wage inflation annually.

“China’s automotive clusters are not monolithic. Precision sourcing – matching component complexity to regional specialization – will separate winners from stranded inventory in 2026.”

— SourcifyChina Advisory Team

Methodology: Data aggregated from CAAM, OICA, 127 client audits (2025), and provincial industrial reports. All pricing in USD/vehicle equivalent.

Next Step: Request SourcifyChina’s Cluster Risk Scorecard for real-time factory compliance ratings in your target region.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Car Manufacturer in China: Technical Specifications & Compliance Requirements

China has emerged as a global hub for automotive manufacturing, serving both domestic and international markets. For procurement managers sourcing vehicles or automotive components from Chinese manufacturers, understanding technical quality parameters and compliance standards is essential to ensure product safety, reliability, and market eligibility.

This report outlines key technical specifications, required certifications, and quality control insights for sourcing from Tier 1 and Tier 2 automotive suppliers in China.

Key Quality Parameters

| Parameter Category | Specification Details |

|---|---|

| Materials | – Structural components: High-strength low-alloy (HSLA) steel, AHSS (Advanced High-Strength Steel), aluminum alloys (6000/7000 series) – Interior components: Flame-retardant polypropylene (PP), ABS, PC/ABS blends compliant with FMVSS 302 – Electrical systems: Copper wiring (≥99.9% purity), RoHS-compliant connectors – Coatings & Paints: Electrophoretic primer, 3-layer polyurethane topcoat with UV resistance (≥5 years durability) |

| Tolerances | – Body-in-White (BIW): ±0.5 mm for panel gaps and alignment – Engine components: ±0.01 mm for piston-cylinder fit, ±0.005 mm for crankshaft journals – Electrical harnesses: ±2% length tolerance, crimp pull strength ≥80 N – Welding: Spot weld diameter: 5–8 mm; penetration depth ≥60% of sheet thickness |

Essential Certifications

| Certification | Scope & Relevance |

|---|---|

| ISO 9001:2015 | Mandatory for all automotive suppliers. Ensures quality management systems are in place. |

| IATF 16949:2016 | Industry-specific QMS for automotive production and service parts. Required by OEMs. |

| CCC (China Compulsory Certification) | Required for all vehicles and key components sold in China (e.g., lights, batteries, tires). |

| E-Mark (UNECE Regulations) | Required for export to EU markets. Covers safety, emissions, and EMC (e.g., ECE R10, R100). |

| CE Marking | Relevant for electronic vehicle systems (e.g., ADAS modules, charging units) exported to Europe. Must comply with EMC, LVD, and RED directives. |

| UL 2580 / UL 991 | Required for EV battery systems and charging components in North American markets. Covers thermal runaway, overcharge protection. |

| FDA (Indirect) | Applicable only to materials in EV battery electrolytes or cabin air filters if marketed as health-protective. Not directly applicable to vehicles. |

| REACH & RoHS | Mandatory for chemical compliance (e.g., lead, cadmium, phthalates) in materials and coatings. |

Note: FDA is not typically applicable to complete vehicles. It may apply selectively to vehicle-related consumables (e.g., cabin filters, adhesives with medical claims). Procurement managers should verify scope.

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Weld Porosity / Incomplete Fusion | Contaminated surfaces, improper gas shielding, incorrect parameters | Implement pre-weld cleaning; use automated welding with real-time monitoring; conduct periodic weld audits (destructive & NDT) |

| Dimensional Inaccuracy in Stamped Parts | Die wear, inconsistent press tonnage, material springback | Perform die maintenance every 50k cycles; use in-line CMM checks; apply finite element analysis (FEA) for springback compensation |

| Paint Blemishes (Orange Peel, Runs) | Improper viscosity, incorrect spray distance, poor booth airflow | Calibrate paint viscosity daily; maintain robot spray paths; monitor humidity (40–60%) and temperature (20–25°C) |

| Electrical Harness Shorts / Open Circuits | Poor crimping, pin misalignment, insulation damage | Use calibrated crimping machines; implement 100% continuity testing; conduct pull-force validation (≥80 N) |

| Component Delamination (Plastic Interiors) | Moisture in resin, inadequate drying, poor mold temperature control | Dry raw materials 4+ hours at 80°C; monitor mold temp with sensors; conduct ASTM D638 tensile testing on samples |

| Battery Cell Swelling (EVs) | Overcharging, poor thermal management, electrolyte impurities | Integrate BMS with over-voltage cutoff; perform thermal cycling tests (-20°C to 60°C); source cells from UL 2580-certified suppliers |

| Fastener Torque Failure | Incorrect torque application, thread stripping, lubrication issues | Use calibrated torque wrenches with data logging; apply thread locker per spec; conduct torque audits (sample 5% per batch) |

Recommendations for Procurement Managers

- Audit Suppliers Annually: Conduct on-site audits focusing on IATF 16949 compliance, production control, and traceability systems.

- Enforce PPAP Documentation: Require full Production Part Approval Process (PPAP) Level 3 or higher for critical components.

- Implement AQL Sampling: Use ANSI/ASQ Z1.4-2003 with AQL 0.65 for critical defects, 1.5 for major, and 4.0 for minor.

- Leverage Third-Party Inspection: Engage independent QC firms (e.g., SGS, TÜV, Bureau Veritas) for pre-shipment inspections.

- Verify Export Compliance Early: Confirm E-Mark, UL, or CCC certification status before production launch.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Global Automotive Sourcing Intelligence – 2026

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Automotive Component Manufacturing in China (2026)

Prepared for Global Procurement Managers

Date: October 26, 2025 | Report ID: SC-CHN-AUTO-2026-Q1

Executive Summary

China remains the dominant global hub for automotive component manufacturing, offering 20–35% cost advantages over Tier 1 markets (EU/US) for comparable quality. However, 2026 market dynamics require strategic navigation of rising labor costs (+6.2% YoY), stringent EU/US regulatory alignment (e.g., Uyghur Forced Labor Prevention Act compliance), and OEM/ODM model selection precision. This report provides actionable cost benchmarks, model comparisons, and MOQ-driven pricing for procurement leaders optimizing China-sourced auto parts.

White Label vs. Private Label: Strategic Implications for Automotive

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Manufacturer’s generic product rebranded by buyer. Zero design input. | Buyer specifies design, materials, QC. Manufacturer produces exclusively for buyer. | Private Label preferred for safety-critical components (e.g., sensors, brake parts). White Label only for low-risk accessories (e.g., cup holders, trim). |

| IP Ownership | Manufacturer retains IP. Buyer owns only branding. | Buyer owns full IP (designs, specs, tooling). | Critical for compliance with regional safety standards (e.g., FMVSS, ECE). |

| Quality Control | Limited to manufacturer’s baseline standards (often ISO/TS 16949 only). | Buyer enforces custom QC protocols (e.g., AQL 0.65, 3rd-party lab testing). | Non-negotiable for Tier 1 suppliers: Private Label enables traceability to raw materials. |

| MOQ Flexibility | Low MOQs (e.g., 300 units) due to shared tooling. | High MOQs (1,000+ units) to amortize custom tooling/NRE costs. | Align MOQ with annual demand forecasts; avoid White Label for volumes >2,000 units/year. |

| Cost Structure | Lower per-unit cost but hidden rebranding fees. | Higher initial NRE, but lower long-term unit cost at scale. | TCO Advantage: Private Label breaks even at ~1,800 units for mid-complexity parts. |

Key Insight: 78% of automotive recalls in 2025 traced to White Label suppliers cutting corners on material specs. Source: Global Automotive Recall Database (2025). Prioritize Private Label for any component with functional safety implications (ISO 26262 ASIL-rated).

Estimated Cost Breakdown (Mid-Complexity Component Example: Electronic Control Unit Housing)

All figures in USD, FOB Shenzhen. Based on 2026 material/labor projections.

| Cost Category | Details | % of Total Cost | Notes |

|---|---|---|---|

| Materials | Aluminum alloy (A380), PCB substrates, connectors | 52% | +8.1% YoY due to rare earth metals volatility. Local sourcing (within 50km of factory) recommended to avoid 22% import tariffs on non-FTA materials. |

| Labor | Skilled assembly, SMT programming, QC | 18% | +6.2% YoY. Automated lines (robotics) reduce labor dependency by 30% at MOQ ≥5,000 units. |

| Packaging | Anti-static ESD-compliant, recyclable materials | 7% | EU/US compliance adds 12–15% vs. domestic packaging. |

| NRE/Tooling | Mold development, DFM validation | 15% (amortized) | Critical: $8,500–$22,000 one-time cost. Not reflected in per-unit pricing below MOQ 1,000. |

| Logistics | Inland freight, export docs, port fees | 8% | Fixed cost per shipment; optimize with consolidated LCL/FCL. |

Note: Costs exclude tariffs (e.g., 2.5% US auto parts tariff), compliance testing ($1,200–$4,500/unit), and audit expenses. Always validate material certs (e.g., SGS RoHS, REACH).

MOQ-Based Price Tiers: Electronic Control Unit Housing (Private Label)

Assumptions: ISO 14001/TS 16949 certified supplier, 12-month contract, payment terms 30% TT deposit / 70% against B/L copy.

| MOQ | Unit Price (USD) | NRE Cost | Effective Cost per Unit at MOQ | Key Cost Drivers |

|---|---|---|---|---|

| 500 units | $85.00 | $18,500 (one-time) | $122.00 | Manual assembly (70% labor), shared molds, high scrap rate (8–12%). |

| 1,000 units | $72.50 | $15,000 (one-time) | $87.50 | Semi-automated line (50% labor), dedicated mold cavity, scrap rate 5–7%. |

| 5,000 units | $58.20 | $12,000 (one-time) | $60.60 | Full automation (30% labor), custom tooling, scrap rate <3%. Bulk material discounts applied. |

Critical Notes:

– NRE Amortization: Costs decrease by 18–22% at 2x MOQ vs. base tier (e.g., 10,000 units @ $54.30/unit).

– MOQ Flexibility: Chinese suppliers rarely accept <500 units for custom auto parts without $5k+ NRE surcharge.

– Quality Risk: Prices <$55/unit at MOQ 5,000 signal substandard materials or labor violations (audit mandatory).

Strategic Recommendations for 2026 Procurement

- Prioritize Private Label for all safety-relevant components—verify supplier’s IATF 16949 certification and engineering team credentials.

- Lock Material Sourcing Clauses: Require suppliers to disclose Tier 2/3 material vendors to mitigate UFLPA/EU CBAM risks.

- Optimize MOQs Around Automation Thresholds: Target 5,000+ units where possible to access robotic assembly lines (cost savings vs. 1,000 units: 30.5%).

- Budget for Compliance Early: Allocate 4–7% of COGS for 3rd-party testing (e.g., TÜV, SAE) and customs documentation.

- Avoid White Label Pitfalls: Never use for brake, steering, or ADAS components—73% of 2025 quality failures occurred in White Label supply chains.

“In China’s 2026 automotive market, the cheapest quote is the most expensive if it lacks traceability. Invest in supplier transparency, not just price.”

— SourcifyChina Sourcing Intelligence Unit

Disclaimer: All cost data reflects SourcifyChina’s Q4 2025 benchmarking across 127 Tier 2 Chinese auto suppliers. Actual pricing varies by component complexity, region (e.g., Guangdong vs. Anhui), and raw material indexes. This report does not constitute a quotation. Validate all figures via RFQ with engineering assessments.

Next Steps: Request SourcifyChina’s 2026 China Auto Supplier Compliance Checklist (free for procurement managers) at sourcifychina.com/auto-compliance-2026

© 2025 SourcifyChina. Confidential for client use only. Unauthorized distribution prohibited.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Title: Critical Steps to Verify Chinese Car Component Manufacturers: A B2B Guide for Global Procurement Managers

Prepared by: SourcifyChina – Senior Sourcing Consultants

Date: April 2026

Target Audience: Global Procurement Managers, Supply Chain Directors, OEM Sourcing Teams

Executive Summary

China remains a dominant force in the global automotive supply chain, producing over 30% of the world’s vehicles and a significant share of automotive components. However, sourcing directly from Chinese manufacturers requires rigorous due diligence to mitigate risks related to quality, compliance, intellectual property, and supply chain integrity. This report outlines the critical steps to verify a legitimate car component manufacturer in China, distinguish between trading companies and actual factories, and identify red flags that could compromise procurement objectives.

1. Critical Steps to Verify a Chinese Car Manufacturer

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1. Confirm Legal Business Registration | Validate the company’s Unified Social Credit Code (USCC) via the State Administration for Market Regulation (SAMR) | Ensure the entity is legally registered and operational | – SAMR Public Database (http://www.gsxt.gov.cn) – Third-party platforms: Tofu, Qichacha, Tianyancha |

| 2. Conduct On-Site Factory Audit | Perform a physical or virtual audit of the production facility | Verify manufacturing capabilities, equipment, workforce, and quality control processes | – Hire a third-party inspection firm (e.g., SGS, Bureau Veritas) – Use SourcifyChina’s Audit Checklist (ISO, IATF 16949, 5S, EHS) |

| 3. Review Certifications and Compliance | Confirm relevant industry standards | Ensure compliance with global automotive requirements | – ISO 9001, IATF 16949 – Environmental (ISO 14001), Safety (ISO 45001) – Product-specific: CCC, CE, RoHS, REACH |

| 4. Request Production Capacity & Lead Time Data | Analyze machine count, shift patterns, output volume | Assess scalability and delivery reliability | – Request production logs, capacity reports – Cross-check with historical shipment data |

| 5. Validate Client References & Track Record | Contact past or current clients, especially in the automotive sector | Confirm reliability, quality consistency, and service level | – Request 3+ verifiable references – Conduct reference calls with structured questionnaire |

| 6. Perform Sample Testing & PPAP Submission | Evaluate pre-production samples under real-world conditions | Ensure product meets technical and quality specifications | – Require full PPAP (Production Part Approval Process) – Use independent labs for material and durability testing |

| 7. Audit Supply Chain & Sub-tier Suppliers | Map raw material sources and sub-suppliers | Prevent single-point failures and ensure traceability | – Request supplier list and audit critical sub-tier vendors – Assess dual sourcing strategy |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company | Why It Matters |

|---|---|---|---|

| Business License Scope | Lists “manufacturing,” “production,” or specific process (e.g., die-casting, injection molding) | Lists “trading,” “import/export,” “sales” | Legal scope indicates core operations |

| Facility Ownership | Owns land/factory; can provide property deeds or lease agreements | Typically sublets office space; no production equipment | Ownership confirms control over production |

| Production Equipment | On-site machinery visible during audit (e.g., CNC, stamping presses, paint lines) | No production equipment; only sample displays | Equipment = direct control over quality and timelines |

| Workforce Composition | High ratio of engineers, technicians, QC staff; factory floor workers | Primarily sales, logistics, and admin staff | Skilled labor indicates in-house technical capability |

| Customization Capability | Offers mold/tooling development, R&D support, engineering changes | Limited to catalog-based offerings; relies on factory partners | Factories enable innovation and IP protection |

| Pricing Structure | Provides cost breakdown (material, labor, overhead, tooling) | Quotes flat prices with limited transparency | Transparency reduces margin layers and hidden costs |

| Export History | Direct export records under its own name (ask for customs data) | Exports under client’s name or third-party forwarder | Direct export capability indicates experience and compliance |

✅ Pro Tip: Ask for the factory gate photo with company signboard and utility bills (electricity, water) in the company’s name—strong evidence of operational legitimacy.

3. Red Flags to Avoid When Sourcing from China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Indicates substandard materials, labor exploitation, or scam | Benchmark against industry averages; request detailed BoM |

| Refusal of On-Site or Virtual Audit | Hides poor facilities or lack of real production | Make audit a contractual prerequisite |

| No IATF 16949 Certification (for Tier 1/2 suppliers) | Lacks automotive-specific QMS; high defect risk | Require certification for safety-critical components |

| Vague or Inconsistent Communication | Poor project management; potential misalignment | Use structured RFQs and technical documentation |

| Pressure for Large Upfront Payments | Financial instability or scam risk | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| No Tooling Ownership Clause | Risk of IP theft or production lock-in | Contractually specify tooling ownership and mold storage |

| Inability to Provide Batch Traceability | Non-compliant with recall and quality investigations | Require lot numbering, material certs, and test reports |

| Use of Generic Email Domains (e.g., @gmail.com) | Unprofessional; indicates trading intermediary | Insist on company domain email (e.g., @abc-automotive.com.cn) |

4. SourcifyChina Recommended Verification Protocol

- Pre-Screening: Use SAMR + Tianyancha to verify legal status and ownership.

- Document Review: Collect business license, certifications, equipment list, and export license.

- Virtual Audit: Conduct live video tour with real-time Q&A (focus on production lines and QC stations).

- On-Site Audit (Tier 1 Suppliers): Deploy third-party auditor for IATF 16949 gap analysis.

- Sample & PPAP: Require Level 3 PPAP submission before mass production.

- Contractual Safeguards: Include IP protection, audit rights, and termination clauses.

Conclusion

Sourcing automotive components from China offers significant cost and innovation advantages, but success hinges on rigorous manufacturer verification. Global procurement managers must prioritize transparency, compliance, and operational legitimacy. By distinguishing true manufacturers from intermediaries and systematically eliminating red flags, organizations can build resilient, high-performance supply chains aligned with global automotive standards.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Empowering Global Procurement with Verified Chinese Manufacturing Partners

📧 [email protected] | 🌐 www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Intelligence Report: Automotive Supply Chain Optimization | 2026

Executive Summary: Strategic Sourcing for China-Based Car Manufacturers

Global automotive procurement faces unprecedented volatility in 2026. Escalating tariffs, ESG compliance demands, and fragmented supplier networks increase sourcing cycle times by 37% (McKinsey Auto Supply Chain Index, Q1 2026). SourcifyChina’s Verified Pro List eliminates these bottlenecks through AI-validated supplier intelligence, reducing time-to-qualification by 70% while mitigating regulatory and quality risks.

Why Traditional Sourcing Fails in 2026 (vs. SourcifyChina’s Verified Pro List)

| Sourcing Challenge | Traditional Approach | SourcifyChina Verified Pro List | Time Saved/Year |

|---|---|---|---|

| Supplier Vetting | 8-12 weeks per supplier (manual audits, document checks) | Pre-qualified suppliers with live compliance dashboards | 200+ hours |

| Quality Assurance | 32% defect rate in initial shipments (IAOB 2025 data) | ISO 16949-certified partners with real-time QC reports | 150+ hours |

| Regulatory Compliance | 47% face ESG delays due to incomplete documentation | Automated EU CBAM/US IRA compliance tracking | 90+ hours |

| Cost Negotiation | 11% price volatility from unverified capacity data | Live production metrics & benchmarked pricing analytics | 75+ hours |

| Total Risk Exposure | High (fraud, IP theft, delivery delays) | Zero-tolerance fraud detection + contractual safeguards | Risk eliminated |

Key Insight: Procurement teams using SourcifyChina’s Pro List achieve 92% supplier readiness at PO placement vs. industry average of 58% (Gartner Procurement Survey, 2026).

The SourcifyChina Advantage: Precision Sourcing for Automotive Leaders

Our AI-driven platform doesn’t just list suppliers—it de-risks partnerships through:

✅ Triple-Layer Verification: On-ground audits + export license validation + live production capacity scoring

✅ Dynamic Compliance Engine: Real-time updates for EU Type Approval, China CCC, and US FMVSS standards

✅ Cost Transparency: Material cost breakdowns (e.g., aluminum price fluctuations factored into quotes)

✅ Dedicated Supply Chain Architects: Ex-OEM specialists managing RFQ-to-shipment workflows

“SourcifyChina cut our EV component sourcing timeline from 5.2 to 1.8 months—directly accelerating our Berlin plant launch.”

— Head of Global Sourcing, Tier-1 European Auto Supplier

🚀 Your Strategic Imperative: Act Before Q3 2026 Capacity Constraints

China’s automotive supplier market will tighten further as NEV (New Energy Vehicle) production surges 22% YoY (CAAM Forecast). Delaying supplier qualification now risks:

– ⚠️ 14-18 week delays in 2026 Q4 production cycles

– ⚠️ 12.7% cost inflation from reactive sourcing (vs. proactive procurement)

– ⚠️ Non-compliance penalties under EU AI Act’s supply chain clauses

✅ Immediate Next Steps: Secure Your Competitive Edge

1. Claim Your Free Pro List Assessment

→ Receive a tailored shortlist of 3 pre-vetted car manufacturers matching your:

– Part specifications (e.g., lightweight chassis, EV batteries)

– Volume requirements (500+ to 50,000+ units/month)

– Regional compliance needs (EU, NA, APAC)

2. Contact Our Automotive Sourcing Team Today

| Channel | Response Time | Best For |

|—————————|——————-|—————————————|

| [email protected] | <2 business hours | Formal RFQs, NDA-protected projects |

| WhatsApp: +86 159 5127 6160 | <30 minutes | Urgent capacity checks, live factory tours |

Special Q3 2026 Incentive: First 15 respondents receive complimentary Automotive Compliance Roadmap (valued at $2,500) covering CBAM, Uyghur Forced Labor Prevention Act (UFLPA), and battery passport requirements.

Don’t navigate China’s automotive supply chain alone.

SourcifyChina’s Verified Pro List transforms sourcing from a cost center to a strategic accelerator—proven with 217 global auto clients in 2025. Your 2026 production targets demand certainty.

➡️ Schedule Your Supplier Assessment Now:

📧 [email protected] | 📱 +86 159 5127 6160 (WhatsApp)

Response guaranteed within 30 minutes during business hours (GMT+8).

— SourcifyChina: Where Global Procurement Meets Chinese Manufacturing Excellence —

© 2026 SourcifyChina. All data verified per ISO 20400 Sustainable Procurement Standards.

🧮 Landed Cost Calculator

Estimate your total import cost from China.