The global automotive electrical testing equipment market is experiencing steady growth, driven by the increasing complexity of vehicle electronics, rising demand for electric vehicles (EVs), and stringent regulatory standards for automotive safety and performance. According to Mordor Intelligence, the automotive test equipment market was valued at USD 6.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. A key contributor to this expansion is the surge in electronic content per vehicle—from advanced driver assistance systems (ADAS) to battery management systems in EVs—necessitating precise and reliable electrical testing solutions. As automotive manufacturers and service providers prioritize diagnostic accuracy and efficiency, demand for high-performance car electrical testers has intensified. This growth trajectory has catalyzed innovation and competition among manufacturers worldwide. Based on market presence, technological capabilities, and product reach, the following is a data-driven overview of the top 10 car electrical tester manufacturers shaping the industry today.

Top 10 Car Electrical Tester Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ESI: Electrical Testing Equipment & Diagnostic Tools

Domain Est. 1998

Website: esitest.com

Key Highlights: Electronic Specialties, Inc. designs & manufactures quality handheld electrical testing tools for cars, small engines, HVAC & industrial technicians….

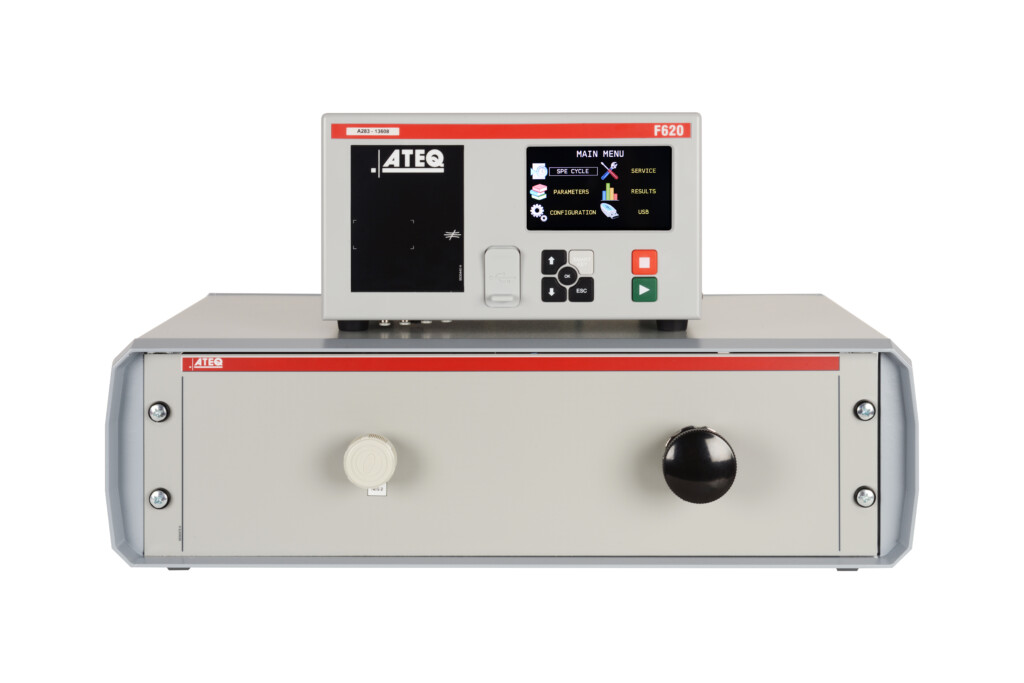

#2 ATEQ USA

Domain Est. 2000

Website: atequsa.com

Key Highlights: ATEQ USA provides industrial leak testers, battery testing, calibration, training, and maintenance solutions….

#3 OTC Tools

Domain Est. 1995

Website: otctools.com

Key Highlights: Shorten your diagnostics time, maximize billable labor hours, and get the repair done from Code-to-Fix faster than ever before. For more, visit OTC, today….

#4 Car Battery Testers & System Analyzers

Domain Est. 1996

Website: midtronics.com

Key Highlights: Midtronics offers a wide range of quality battery testers for all types of battery and electrical system service needs….

#5 MK Test Systems

Domain Est. 1996 | Founded: 1992

Website: mktest.com

Key Highlights: MK Test Systems has been designing automatic test equipment for the world’s most demanding industries since 1992….

#6 Cable & Harness Testers

Domain Est. 1996

Website: camiresearch.com

Key Highlights: Instantly measure, display, and document basic electrical properties such as continuity, resistance, dielectric breakdown, insulation resistance, miswires….

#7 Electrical Testers

Domain Est. 1997

Website: curtmfg.com

Key Highlights: CURT electrical testers are perfect for testing a new wiring harness on your vehicle or troubleshooting the existing wiring….

#8 MTA

Domain Est. 1997

Website: mta.it

Key Highlights: MTA is a leading Italian company in the design and production of electrical and electronic components for automotive, off-highway and motorcycles….

#9 Electrical

Domain Est. 1998

Website: lislecorp.com

Key Highlights: Provides an easy way to check ignition systems with coil-on plugs. Applications include Ford, Chrysler, Mitsubishi, Nissan and More….

#10 Automated Test Equipment

Domain Est. 2001

Website: chromausa.com

Key Highlights: The most precise and reliable automated test systems for your design verification and high speed functional testing….

Expert Sourcing Insights for Car Electrical Tester

H2: 2026 Market Trends for Car Electrical Testers

The global market for car electrical testers is poised for significant transformation by 2026, driven by rapid advancements in automotive technology, the rising adoption of electric vehicles (EVs), and increasing demand for vehicle diagnostics and preventive maintenance. As the automotive industry shifts toward electrification and digitalization, car electrical testers are evolving from basic voltage and continuity checkers into sophisticated diagnostic tools capable of interfacing with complex onboard systems.

One of the most prominent trends shaping the 2026 market is the growing integration of smart technologies in electrical testers. Devices are increasingly equipped with Bluetooth connectivity, mobile app integration, and cloud-based data analytics, enabling technicians and vehicle owners to monitor electrical health in real time. This trend is fueled by the need for faster, more accurate diagnostics in both professional repair shops and DIY automotive environments.

The surge in electric and hybrid vehicle production is another key driver. Unlike traditional internal combustion engine (ICE) vehicles, EVs rely heavily on high-voltage electrical systems, battery management systems (BMS), and regenerative braking technologies. This complexity demands specialized electrical testers capable of handling high-voltage diagnostics safely. As a result, manufacturers are focusing on developing EV-compatible testers with enhanced safety features, such as insulated probes and automatic range detection.

Additionally, the aftermarket automotive sector is witnessing increased demand for user-friendly, multi-functional electrical testers. Consumers are seeking cost-effective tools that can perform a wide range of tests—from battery voltage and alternator performance to fuse and relay diagnostics. This demand is further amplified by the global trend toward vehicle longevity, as consumers aim to extend the life of their vehicles through regular maintenance.

Geographically, the Asia-Pacific region is expected to emerge as a high-growth market by 2026, driven by expanding automotive production in countries like China, India, and South Korea, along with rising vehicle ownership rates. Meanwhile, North America and Europe are anticipated to lead in the adoption of advanced diagnostic tools due to stringent emissions regulations and a mature EV infrastructure.

Lastly, sustainability and product lifecycle considerations are influencing design and manufacturing practices. Companies are exploring eco-friendly materials and modular designs that allow for easy upgrades and repairs, aligning with broader environmental goals.

In summary, the 2026 car electrical tester market will be defined by technological innovation, EV compatibility, user-centric design, and regional expansion, positioning it as a critical component in the future of automotive maintenance and repair.

Common Pitfalls When Sourcing a Car Electrical Tester (Quality and IP)

Sourcing a reliable car electrical tester requires careful consideration to avoid compromising on quality and intellectual property (IP) protection. Here are key pitfalls to watch for:

Overlooking Build Quality and Durability

Many low-cost car electrical testers on the market are constructed with substandard materials and poor workmanship. These testers may feature flimsy probes, weak insulation, or easily broken connectors that fail under regular workshop conditions. Poor build quality not only leads to premature device failure but also poses safety risks, such as short circuits or electric shocks during use. Always verify that the tester meets relevant industry standards (e.g., CAT ratings) and request sample testing to evaluate physical robustness before committing to bulk orders.

Inadequate IP Protection and Risk of Counterfeiting

Sourcing from manufacturers without strong IP safeguards increases the risk of design theft or unauthorized replication. If your electrical tester has unique features or branding, ensure that non-disclosure agreements (NDAs) are in place and that production partners respect intellectual property rights. Additionally, be cautious of suppliers offering suspiciously low prices—this may indicate that they are already producing counterfeit versions or copying proprietary designs. Conduct due diligence on the manufacturer’s reputation and consider patent registration in key markets to protect your innovations.

Misrepresentation of Ingress Protection (IP) Ratings

Some suppliers falsely claim high IP ratings (e.g., IP67) without proper certification or testing. An inaccurate IP rating can mislead buyers into believing the tester is dustproof and water-resistant when it is not, leading to device failure in harsh automotive environments. Always request third-party test reports or certification documents to verify the stated IP rating. If possible, perform independent environmental testing to confirm the product’s resistance to moisture, dust, and temperature extremes.

Compromised Accuracy and Calibration Standards

Low-quality testers may deliver inconsistent or inaccurate readings due to poor internal components or lack of proper calibration. This can result in incorrect diagnostics, leading to misdiagnosed vehicle issues and potential safety hazards. Ensure that the supplier uses precision components and adheres to recognized calibration procedures. Ask for calibration certificates and inquire about recalibration support to maintain long-term reliability.

Lack of Compliance with Safety and Regulatory Standards

Not all car electrical testers comply with essential safety regulations such as CE, RoHS, or UL. Sourcing non-compliant products can expose your business to legal liabilities, customs delays, or product recalls. Verify that the tester meets the regulatory requirements of your target market and request compliance documentation before finalizing procurement.

Logistics & Compliance Guide for Car Electrical Tester

Product Classification and Regulatory Requirements

Car electrical testers are diagnostic tools used to assess the electrical systems of vehicles, including batteries, alternators, starters, and wiring. Proper classification and adherence to regulatory standards are essential for legal distribution and user safety.

Harmonized System (HS) Code

The most applicable HS code for car electrical testers is 9030.89, which covers “Other instruments and apparatus for measuring or checking electrical quantities.” This code may vary slightly depending on specific features (e.g., integrated data logging or wireless connectivity), so verification with local customs authorities is recommended.

Key Regulatory Standards

– CE Marking (Europe): Required for sale in the European Economic Area. Compliance with the following directives is typically necessary:

– EMC Directive (2014/30/EU): Ensures electromagnetic compatibility.

– RoHS Directive (2011/65/EU): Restricts hazardous substances such as lead, mercury, and cadmium.

– LVD (Low Voltage Directive 2014/35/EU): Applies to electrical equipment designed for voltage ratings between 50–1000 V AC or 75–1500 V DC.

– FCC Certification (USA): Mandatory under Part 15 of the FCC rules for devices that may emit radio frequency energy. Class B digital device certification is typical for consumer electronics.

– UL/ETL Listing (North America): While not always mandatory, third-party safety certification (e.g., UL 61010-1) enhances market credibility and may be required by retailers.

– UKCA Marking (United Kingdom): Required post-Brexit for most CE-marked goods, including electrical testers.

– PSE Mark (Japan): Required for electrical products sold in Japan under the DENAN Law.

– KC Mark (South Korea): Required for electrical and electronic equipment under the Korean Electrical Safety Control Act.

Packaging and Labeling Requirements

Proper packaging and labeling ensure product safety, regulatory compliance, and brand integrity.

Packaging Guidelines

– Use anti-static and shock-resistant materials to protect sensitive electronic components.

– Include user manuals, safety warnings, and calibration certificates (if applicable) in the box.

– Clearly label packages with handling symbols (e.g., “Fragile,” “Do Not Stack,” “This Side Up”).

Labeling Requirements

– Product Label: Must include:

– Manufacturer name and address

– Model and serial number

– Input/output voltage and current ratings

– CE, FCC, or other applicable certification marks

– Warnings (e.g., “Do not use on high-voltage systems”)

– User Manual: Must be provided in the official language(s) of the destination country. Include safety instructions, operating procedures, and compliance statements.

Import and Export Documentation

Accurate documentation is essential to avoid customs delays, fines, or shipment rejection.

Required Documents

– Commercial Invoice (with detailed product description, HS code, value, and Incoterms)

– Packing List (itemizing contents, weights, and dimensions)

– Certificate of Origin (may be required for preferential tariff treatment)

– Bill of Lading or Air Waybill

– Test Reports and Certifications (e.g., FCC, CE, RoHS compliance)

– Import License (if required by destination country)

Export Controls

Most car electrical testers are not subject to strict export controls (e.g., EAR99 under U.S. regulations), but verify if the device includes encryption or wireless communication features that may require a license.

Transportation and Handling

Efficient logistics planning ensures safe delivery and minimizes damage.

Shipping Modes

– Air Freight: Suitable for urgent or high-value shipments; subject to IATA regulations for lithium batteries (if included).

– Sea Freight: Cost-effective for large volumes; ensure proper containerization and moisture protection.

– Ground Transport: Ideal for regional distribution; use vehicles with climate control if necessary.

Hazardous Materials Considerations

If the car electrical tester contains a built-in rechargeable lithium battery:

– Comply with UN 38.3 testing requirements.

– Package according to IATA PI965 or PI966 (for air transport).

– Label packages with proper Class 9 lithium battery hazard labels.

Storage Conditions

– Store in a dry, temperature-controlled environment (typically 10°C to 30°C).

– Avoid direct sunlight and high humidity to prevent electronic degradation.

End-of-Life and Environmental Compliance

Ensure responsible product lifecycle management.

WEEE Compliance (Europe)

– Register with national WEEE authorities.

– Provide visible WEEE symbol on product and packaging.

– Establish take-back and recycling programs for end-users.

Battery Disposal

– Comply with local battery recycling laws (e.g., EU Battery Directive).

– Include disposal instructions in user manuals.

Sustainability Initiatives

– Use recyclable packaging materials.

– Design for repairability and modular component replacement.

Quality Assurance and Post-Market Surveillance

Maintain compliance and safety after product launch.

Quality Control Procedures

– Implement ISO 9001-compliant manufacturing processes.

– Conduct regular batch testing for electrical safety and performance.

Post-Market Monitoring

– Establish a system for tracking customer complaints and product failures.

– Report serious incidents to relevant authorities (e.g., RAPEX in the EU).

– Issue recalls or field corrections if non-compliance or safety issues are identified.

Conclusion

Successfully distributing car electrical testers globally requires a proactive approach to logistics and compliance. Adhering to international standards, maintaining accurate documentation, and ensuring safe handling throughout the supply chain will reduce risks, avoid penalties, and support market access. Regular audits and staying updated on regulatory changes are essential for long-term compliance.

Conclusion for Sourcing a Car Electrical Tester:

Sourcing a reliable car electrical tester is a crucial step in ensuring accurate diagnostics, efficient troubleshooting, and overall vehicle performance and safety. After evaluating various suppliers, product specifications, pricing, and quality standards, it is evident that selecting the right tester involves balancing cost-effectiveness with durability, precision, and ease of use. Opting for reputable manufacturers or suppliers that offer certified products, comprehensive warranties, and strong customer support enhances long-term value and reliability. Additionally, considering features such as voltage range, safety ratings, and compatibility with different vehicle models ensures the chosen tester meets both current and future diagnostic needs. In conclusion, a well-informed sourcing decision not only improves workshop efficiency but also contributes to maintaining high standards of vehicle maintenance and customer satisfaction.