The global automotive aftermarket is witnessing steady expansion, driven by rising vehicle ownership and the increasing need for reliable vehicle maintenance components. According to Mordor Intelligence, the automotive aftermarket parts market was valued at USD 652.77 billion in 2023 and is projected to grow at a CAGR of over 5.8% through 2029. Within this sector, demand for protective components such as car battery terminal covers has gained traction due to their role in enhancing battery longevity and ensuring electrical safety. With advancements in automotive design and a growing focus on corrosion prevention, manufacturers specializing in battery terminal solutions are positioning themselves strategically in the supply chain. This growth trajectory, supported by both OEM and replacement market demand, underscores the importance of reliable, high-quality terminal cover suppliers. Below, we spotlight the top six manufacturers shaping this niche yet essential segment of the automotive components industry.

Top 6 Car Battery Terminal Cover Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Lifeline Batteries

Domain Est. 1998

Website: lifelinebatteries.com

Key Highlights: Lifeline batteries manufacture deep cycle AGM batteries for consumers built to military specifications. AGM batteries made in the USA….

#2 2020

Domain Est. 2007

Website: parts.moparonlineparts.com

Key Highlights: In stock Rating 5.0 1 MSRP: $11.10 ; Discount: $3.11 (28% off) ; Manufacturer Warranty Minimum of 12 Months ; Guaranteed Fitment Requires VIN entry at checkout ; In-House Experts…

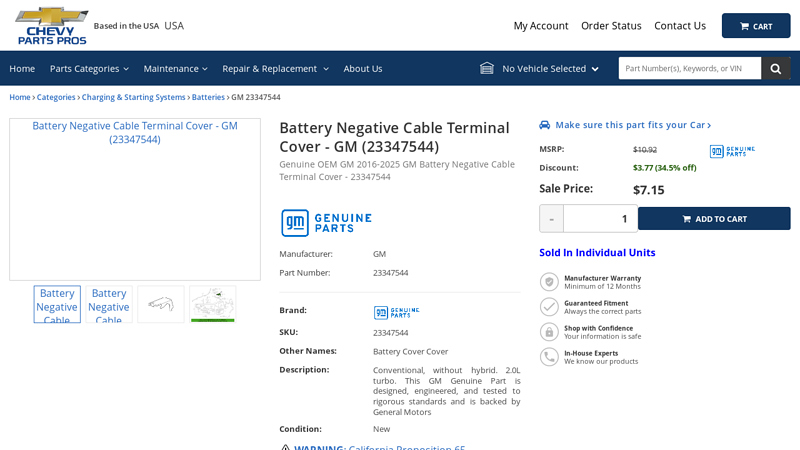

#3 2016

Domain Est. 2022

Website: parts.chevypartspros.com

Key Highlights: In stock $10.25 deliveryBattery Negative Cable Terminal Cover – GM ( 23347544). Manufacturer: GM. Part Number: 23347544. Guaranteed fit and 12-mo./ Unlimited-Mile Warranty….

#4 Interstate Batteries

Domain Est. 1996

Website: interstatebatteries.com

Key Highlights: The Interstate MTX car battery line offers premium performance and long life and includes both the AGM battery or EFB battery you need for your start-stop ……

#5 32418

Domain Est. 2007

Website: hondapartsnow.com

Key Highlights: In stock 1–4 day deliveryHondaPartsNow.com offers the great deal for genuine Honda parts, 32418PLA300. Cover, Battery Terminal for $12.04. All parts are backed by the Honda’s ……

#6 Battery terminal covers

Domain Est. 2009

Website: ft86club.com

Key Highlights: It would provide useful information you need to know about your new car. Also battery covers are red and are on the positive side of the battery ……

Expert Sourcing Insights for Car Battery Terminal Cover

2026 Market Trends for Car Battery Terminal Cover

Rising Demand Driven by Automotive Industry Growth

The global car battery terminal cover market is projected to experience steady growth by 2026, primarily fueled by the expansion of the automotive industry. With increasing vehicle production—especially in emerging economies such as India, Southeast Asia, and parts of Africa—demand for replacement and original equipment manufacturer (OEM) battery components, including terminal covers, continues to rise. Additionally, the growing adoption of internal combustion engine (ICE) vehicles in developing regions ensures sustained demand for traditional battery accessories.

Shift Toward Enhanced Safety and Durability Standards

Safety regulations and consumer awareness are pushing manufacturers to adopt higher-performance materials in car battery terminal covers. By 2026, there is an expected shift toward flame-retardant, UV-resistant, and high-temperature thermoplastics such as nylon and polypropylene. These materials reduce the risk of short circuits, corrosion, and acid leaks, aligning with global automotive safety standards. Regulatory bodies in Europe and North America are likely to enforce stricter guidelines, influencing global supply chains and product specifications.

Electric Vehicle (EV) Integration Challenges and Opportunities

While the rise of electric vehicles (EVs) may reduce reliance on standard 12V lead-acid batteries in the long term, most EVs still utilize auxiliary lead-acid batteries for backup systems, necessitating terminal covers. Furthermore, hybrid vehicles continue to rely heavily on traditional battery systems. By 2026, terminal cover manufacturers are expected to innovate with compact, insulated, and smart-integrated designs tailored for hybrid and EV applications, creating new niche markets.

Aftermarket Expansion and E-Commerce Influence

The aftermarket segment for car battery terminal covers is anticipated to grow significantly by 2026, driven by increasing vehicle ownership and DIY maintenance trends. Online retail platforms such as Amazon, AutoZone, and regional e-commerce sites are making it easier for consumers to access replacement parts. Brands are investing in direct-to-consumer models and bundling terminal covers with battery maintenance kits to boost sales. This trend is especially prominent in North America and Europe.

Sustainability and Recycling Initiatives

Environmental concerns are shaping material choices and production practices. By 2026, manufacturers are expected to increase the use of recyclable and bio-based plastics in terminal cover production. Some companies are exploring closed-loop recycling programs, where used covers are collected and reprocessed. These initiatives align with broader automotive industry goals to reduce carbon footprints and meet circular economy standards in regions like the EU.

Regional Market Dynamics

Asia-Pacific is poised to dominate the car battery terminal cover market by 2026 due to high vehicle production and after-sales service volumes in countries like China, Japan, and India. Meanwhile, North America and Europe will focus on premium, high-specification products due to stringent safety norms and a mature automotive aftermarket. Latin America and the Middle East represent emerging opportunities, particularly in the replacement parts sector.

Technological Integration and Smart Features

Though still in early stages, some manufacturers are experimenting with smart battery terminal covers that integrate sensors to monitor voltage, temperature, and connection integrity. By 2026, such innovations may begin entering premium vehicle segments, offering predictive maintenance data through vehicle diagnostics or mobile apps. While not yet mainstream, this trend signals a potential convergence of traditional components with vehicle connectivity systems.

In summary, the 2026 car battery terminal cover market will be shaped by material innovation, regulatory changes, EV adaptation, and digital distribution. Companies that prioritize safety, sustainability, and regional customization are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Car Battery Terminal Covers (Quality & IP)

Sourcing car battery terminal covers may seem straightforward, but overlooking key quality and intellectual property (IP) aspects can lead to safety risks, compliance failures, and legal exposure. Here are common pitfalls to avoid:

Poor Material Quality and Durability

Many low-cost suppliers use substandard plastics that degrade quickly under underhood conditions. Covers made from non-UV-stabilized or low-temperature-resistant materials can crack, warp, or become brittle due to heat, vibration, and exposure to battery acid. This compromises electrical insulation and increases the risk of short circuits or fire.

Inadequate Ingress Protection (IP) Rating

Battery terminal covers must provide effective protection against dust and moisture. Sourcing components without a verified IP rating—typically IP67 or higher—leaves terminals vulnerable to contamination and electrolyte tracking. Some suppliers may claim high IP ratings without third-party testing, resulting in covers that fail in real-world conditions.

Lack of Flame Retardancy Certification

Underhood environments demand flame-retardant materials to prevent fire propagation. Covers not compliant with standards such as UL 94 V-0 can contribute to fire hazards. Always verify material certifications and request test reports to confirm flame resistance.

Non-Compliance with Automotive Standards

Using terminal covers that don’t meet automotive industry standards (e.g., SAE J557, ISO 6722) can lead to reliability issues and failed audits. Ensure components are tested and certified for use in automotive electrical systems, including resistance to acid, temperature cycling, and mechanical stress.

Intellectual Property (IP) Infringement Risks

Sourcing from unverified suppliers increases the risk of copying patented designs. Many established manufacturers hold IP rights on specific terminal cover geometries, locking mechanisms, or labeling. Using counterfeit or cloned parts can result in legal action, product recalls, or supply chain disruptions.

Inconsistent Dimensional Accuracy

Poorly manufactured covers may not fit specific battery terminal types (SAE, JIS, or DIN) or vehicle models. Inaccurate tolerances can lead to improper sealing, loose fitment, or difficulty during installation—compromising both safety and performance.

Missing Traceability and Documentation

Reputable suppliers provide full material traceability, compliance documentation (RoHS, REACH), and test reports. Sourcing without these documents makes it difficult to validate quality or respond to customer claims or regulatory inquiries.

Overlooking Supplier Qualification

Relying on suppliers without proper quality management systems (e.g., ISO/TS 16949 or IATF 16949) increases the risk of inconsistent batch quality. Always audit or verify supplier certifications before committing to large orders.

Avoiding these pitfalls requires due diligence in vetting suppliers, validating specifications, and ensuring both technical performance and legal compliance.

Logistics & Compliance Guide for Car Battery Terminal Cover

Product Classification & Regulatory Overview

Car battery terminal covers are typically classified as automotive electrical accessories. They serve to insulate battery terminals, preventing short circuits, corrosion, and accidental contact. While not as heavily regulated as the battery itself, these components are subject to certain logistics and compliance requirements depending on the region of distribution.

Material Safety & Environmental Compliance

Terminal covers are commonly made from thermoplastic materials such as polypropylene (PP) or polyethylene (PE). Ensure materials are free from restricted substances under regulations like:

– REACH (EU) – Registration, Evaluation, Authorisation and Restriction of Chemicals

– RoHS (EU) – Restriction of Hazardous Substances in Electrical and Electronic Equipment

– Proposition 65 (California, USA) – Warning requirements for chemicals known to cause cancer or reproductive harm

Suppliers must provide a Declaration of Conformity and, where applicable, a Safety Data Sheet (SDS) for the materials used.

Packaging & Shipping Requirements

Terminal covers are generally low-risk goods but require proper packaging to maintain quality:

– Use moisture-resistant packaging to prevent degradation during transit

– Individual or bulk packaging based on retail or wholesale distribution

– Label packages with product name, part number, quantity, and manufacturer information

– Ensure compliance with carrier-specific packaging standards (e.g., UPS, FedEx, DHL)

No special hazardous material labeling is required unless combined with battery shipments—see below.

Transport Regulations When Shipped with Batteries

If terminal covers are packed with lead-acid or lithium car batteries, transport rules change significantly:

– IATA (Air) – Batteries are classified as hazardous goods (Class 8 for lead-acid, Class 9 for lithium). Terminal covers must not interfere with ventilation or secure fastening.

– IMDG (Sea) – Battery shipments require proper UN-marked packaging, documentation (e.g., Dangerous Goods Declaration), and segregation.

– 49 CFR (USA Ground) – Governed by the U.S. Department of Transportation; batteries must be protected from short circuits and damage.

When shipped separately, terminal covers are non-hazardous and follow standard shipping protocols.

Import/Export Documentation

For international trade, ensure the following:

– Accurate HS (Harmonized System) code – typically 8548.90 (parts for electric storage batteries) or 3926.30 (plastic parts for vehicles), depending on design

– Commercial invoice, packing list, and bill of lading/air waybill

– Certificate of Origin (required by some countries for tariff determination)

– Import permits or conformity assessments if required by destination country (e.g., INMETRO in Brazil, KC Mark in South Korea)

Regional Compliance Standards

- EU: May require CE marking if part of a safety system; ensure compliance with Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) if electrically active

- USA: No federal certification required for passive terminal covers, but must meet general product safety standards under CPSC guidelines

- Canada: Comply with CSA safety standards for automotive components where applicable

- GCC (Gulf Cooperation Council): May require GCC Conformity Marking for sale in member states

Labeling & Traceability

Each unit or package should include:

– Manufacturer or brand name

– Part number and compatibility (e.g., “Fits Standard Group Size 24DC Batteries”)

– Batch or lot number for traceability

– Country of origin

– Recycling symbol if plastic (e.g., ♻️ with resin code)

Storage & Handling Guidelines

- Store in a dry, temperature-controlled environment (15–30°C / 59–86°F recommended)

- Keep away from direct sunlight to prevent UV degradation

- Stack pallets safely to avoid crushing lower layers

- Ensure warehouse staff are trained in proper handling to avoid damage

End-of-Life & Recycling Considerations

- Design for recyclability: Use mono-materials where possible

- Comply with WEEE (Waste Electrical and Electronic Equipment) in the EU if sold as part of an electrical system

- Provide disposal guidance on packaging or website (e.g., “Dispose of at designated plastic recycling centers”)

Summary

Car battery terminal covers are generally low-compliance-risk components, but attention to material safety, proper documentation, and shipping conditions—especially when bundled with batteries—is essential. Adherence to regional environmental and packaging regulations ensures smooth logistics and market access worldwide.

Conclusion for Sourcing Car Battery Terminal Covers

In conclusion, sourcing car battery terminal covers requires a strategic approach that balances quality, cost, compatibility, and supplier reliability. These seemingly small components play a crucial role in ensuring electrical safety, preventing short circuits, and protecting against environmental factors such as moisture, dust, and corrosion. When selecting suppliers, it is essential to consider material durability—typically PVC, rubber, or heat-resistant plastics—along with adherence to industry standards and specifications.

Sourcing from reputable manufacturers, whether domestic or international, can lead to long-term cost savings and improved product performance. Evaluating suppliers based on certifications, production capacity, and track record helps mitigate risks related to product failure or supply chain disruptions. Additionally, considering customization options and inventory availability ensures seamless integration into the manufacturing or distribution process.

Ultimately, effective sourcing of car battery terminal covers contributes to the overall reliability and safety of automotive electrical systems. A well-informed procurement strategy not only enhances product quality but also supports operational efficiency and customer satisfaction in the competitive automotive aftermarket and OEM sectors.