The global automotive air conditioning (A/C) market is experiencing steady growth, driven by rising vehicle production, increasing demand for passenger comfort, and advancements in climate control technologies. According to Mordor Intelligence, the automotive air conditioning market was valued at USD 33.5 billion in 2023 and is projected to reach USD 48.2 billion by 2029, growing at a CAGR of approximately 6.3% during the forecast period. A key challenge within this ecosystem—refrigerant leaks—has amplified demand for reliable, cost-effective solutions such as A/C leak sealers. As original equipment manufacturers (OEMs) and aftermarket service providers prioritize system efficiency and environmental compliance, especially under regulations targeting refrigerant emissions like HFCs, the need for high-performance sealants has surged. This growing demand has given rise to specialized manufacturers focusing on advanced chemical formulations capable of sealing micro-leaks without compromising system integrity. The following analysis highlights the top six car aircon leak sealer manufacturers leveraging innovation, distribution strength, and product reliability to capture value in this expanding niche.

Top 6 Car Aircon Leak Sealer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CPS Products

Domain Est. 1996

Website: cpsproducts.com

Key Highlights: CPS Products develops tools and equipment for HVAC/Refrigeration and Automotive systems. Find innovative solutions for professional service technicians….

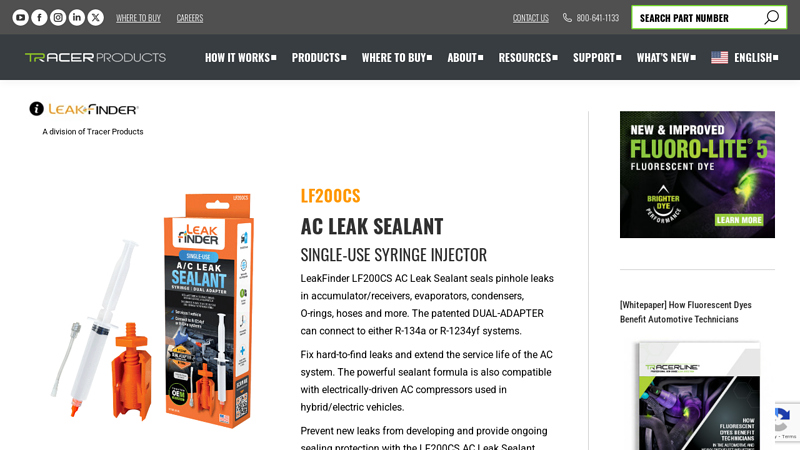

#2 LF200CS AC Leak Sealant

Domain Est. 1997

Website: tracerproducts.com

Key Highlights: LF200CS AC Leak Sealant seals any leaks in your car’s AC. The patented DUAL-ADAPTER can connect to either R-134a or R-1234yf systems….

#3 A/C Zero Leak, Permanent “Stop Leak” for A/C Systems, 4 Ounces

Domain Est. 2004

Website: comstarproducts.com

Key Highlights: In stock Rating 4.5 (25) ComStar’s A/C Zero Leak is specially formulated to stop small leaks in evaporators and condensers as well as around gaskets and seals….

#4 Tracer Products TP22000102CS

Domain Est. 2008

Website: autotoolworld.com

Key Highlights: In stock $9.89 deliveryTracer Products TP22000102CS | Cool Seal Ac Leak Sealer 2 Oz Bottle. The most economical way to add Cool Seal(TM) to an A/C system….

#5 AC sealant

Domain Est. 2011

Website: easyklima.com

Key Highlights: Our sealant allows for a safe and quick sealing of small leaks in the rubber parts of the A/C system ✓ Safe for the Car ⚡ Easy and Quice to Use ⭐ Safe ……

#6 Leak Saver® Air Conditioning Refrigerant Leak Sealants

Domain Est. 2017

Website: leaksavers.com

Key Highlights: Leak Saver® Direct Inject sealants permanently seal small refrigerant leaks in air conditioning, automotive, and refrigeration systems….

Expert Sourcing Insights for Car Aircon Leak Sealer

H2: 2026 Market Trends for Car Aircon Leak Sealer

The global market for car air conditioning (AC) leak sealers is expected to experience notable transformation by 2026, driven by evolving automotive technologies, environmental regulations, and shifting consumer behaviors. Below is an analysis of key trends shaping the car aircon leak sealer market in 2026:

-

Increased Demand for DIY Automotive Maintenance Solutions

The do-it-yourself (DIY) automotive care segment is expanding, with consumers showing a growing preference for cost-effective, easy-to-use repair products. Car aircon leak sealers—marketed as quick-fix solutions that require no professional tools—are gaining popularity among vehicle owners. By 2026, this trend is expected to boost market growth, particularly in regions with high car ownership and rising fuel and maintenance costs. -

Adoption of Environmentally Friendly Formulations

Regulatory bodies such as the Environmental Protection Agency (EPA) and the European Union are enforcing stricter guidelines on refrigerants and chemical emissions. As a result, manufacturers are reformulating leak sealers to be compatible with eco-friendly refrigerants like R-1234yf and to minimize environmental impact. By 2026, products labeled as non-ozone-depleting, biodegradable, or low-GWP (Global Warming Potential) are expected to dominate the market. -

Integration with Modern AC Systems and Electric Vehicles (EVs)

The rise of electric vehicles, which often use advanced thermal management systems, presents both challenges and opportunities. Traditional sealers may not be compatible with high-efficiency or electric AC compressors. In response, companies are developing specialized sealers designed for EVs and hybrid systems. By 2026, innovation in product compatibility with next-generation automotive platforms will be a key differentiator in the market. -

Growth in Emerging Markets

Regions such as Southeast Asia, Latin America, and Africa are witnessing increased vehicle ownership and aging vehicle fleets, which are more prone to AC system leaks. These markets represent significant growth potential for affordable maintenance solutions like leak sealers. Localized distribution networks and affordable pricing strategies are expected to drive market penetration by 2026. -

Technological Advancements in Sealant Chemistry

Next-generation sealers are incorporating nano-particle technology and reactive polymers that offer more durable and reliable sealing. These advanced formulations can withstand higher pressures and temperatures, reducing the risk of re-leakage. By 2026, smart sealants that react only at the leak site—avoiding clogs in other parts of the system—are expected to gain market share. -

E-Commerce and Digital Marketing Influence

Online retail platforms and social media marketing are playing a pivotal role in product visibility and consumer education. Brands are leveraging digital channels to demonstrate product efficacy through videos, customer reviews, and influencer endorsements. By 2026, a strong online presence will be essential for market competitiveness. -

Caution from OEMs and Service Providers

Despite rising consumer adoption, many Original Equipment Manufacturers (OEMs) and professional mechanics caution against the use of chemical sealers, citing risks of system clogs and compressor damage. This skepticism may limit market growth in professional repair channels. However, continued improvements in product safety and reliability could gradually shift expert opinions by 2026.

In conclusion, the car aircon leak sealer market in 2026 will be shaped by innovation, regulatory compliance, and consumer demand for convenience. While challenges remain, particularly regarding compatibility and professional acceptance, the overall outlook is positive, with opportunities for growth through technological advancement and market expansion.

Common Pitfalls When Sourcing Car Aircon Leak Sealer (Quality & IP)

Sourcing car aircon leak sealers—especially from global suppliers—can be fraught with issues related to product quality and intellectual property (IP). Being aware of these pitfalls helps mitigate risks and ensures you deliver a reliable, legally compliant product.

Poor Product Quality and Inconsistent Performance

Many low-cost suppliers offer aircon leak sealers that fail to meet technical specifications. Common quality issues include incorrect viscosity, unstable chemical composition, or inadequate sealing performance under real-world conditions. This can lead to ineffective repairs, system damage, or customer complaints, ultimately harming your brand reputation.

Misleading or Inaccurate Formulations

Some suppliers may claim their sealers are compatible with all refrigerants (e.g., R134a, R1234yf) or safe for compressors, but testing often reveals otherwise. Mislabeling or falsified safety data sheets (SDS) can result in product failure, potential liability, and non-compliance with automotive standards like SAE J2659.

Lack of Certification and Compliance

Reputable leak sealers should meet industry standards and carry certifications such as ISO 9001, REACH, or RoHS. However, many suppliers provide counterfeit or forged certificates. Without proper documentation, you risk regulatory penalties, import rejections, or legal action in target markets.

Intellectual Property Infringement

A significant risk lies in IP violations. Some manufacturers produce “copycat” versions of branded sealers, replicating packaging, formulas, or trademarks without authorization. Sourcing such products—even unknowingly—can expose your business to trademark infringement lawsuits, customs seizures, and forced product recalls.

Inadequate Packaging and Labeling

Poorly labeled or generic packaging not only affects brand perception but may also violate labeling regulations. Missing critical information like batch numbers, expiry dates, or hazard warnings can lead to compliance failures and safety concerns.

No Technical Support or Testing Data

Reliable suppliers should provide access to technical data sheets (TDS), compatibility charts, and support for troubleshooting. Many low-tier manufacturers lack in-house R&D and cannot offer performance data or assistance, leaving you vulnerable if issues arise post-purchase.

Hidden Minimum Order Quantities and Scalability Issues

Some suppliers advertise flexible terms but later impose high MOQs or struggle with consistent supply. This can disrupt your inventory planning and limit your ability to scale or respond to market demand.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: request samples, verify certifications, audit suppliers, and consult legal experts to ensure IP compliance. Partnering with reputable, transparent manufacturers is key to sourcing a high-quality, legally sound car aircon leak sealer.

Logistics & Compliance Guide for Car Aircon Leak Sealer

Product Classification and Regulatory Overview

Car Aircon Leak Sealers are typically classified as automotive chemical products and may contain sealants, lubricants, or refrigerant-compatible additives. Depending on formulation, they may fall under hazardous materials regulations during transport due to flammability, pressure, or chemical composition. Compliance with international, regional, and national regulations is essential for legal distribution.

Transportation and Shipping Requirements

These products often come in pressurized cans or liquid form, requiring adherence to dangerous goods regulations such as the UN Model Regulations (UN 1950 for aerosols) or ADR (for road transport in Europe). Proper UN-certified packaging, hazard labeling (e.g., Class 2: Flammable Gas), and transport documentation (e.g., Safety Data Sheet – SDS) are mandatory. Air and sea shipments may require additional IATA DGR or IMDG Code compliance.

Storage and Handling Guidelines

Store in a cool, dry, well-ventilated area away from heat, sparks, and direct sunlight. Keep containers upright and sealed to prevent leakage or pressure build-up. Ensure storage areas are equipped with fire suppression systems and spill containment measures. Personnel should use appropriate PPE (gloves, eye protection) when handling.

Labeling and Packaging Compliance

All packaging must comply with CLP (EU), GHS (globally), or equivalent local regulations, including hazard pictograms, signal words (e.g., “Danger”), hazard statements, and precautionary measures. Multilingual labeling may be required for cross-border distribution. Child-resistant packaging may be mandated in certain jurisdictions.

Safety Data Sheet (SDS) Requirements

A current, compliant SDS (in accordance with REACH, OSHA HazCom, or local standards) must be provided with every shipment. The SDS should include information on composition, first aid, fire-fighting measures, accidental release procedures, handling, and disposal.

Environmental and Disposal Regulations

Used or empty containers may still contain flammable residues and must not be incinerated or punctured. Follow local waste disposal regulations for hazardous chemical containers. Do not dispose of in drains or environment. Recycling programs for aerosol cans may be available regionally.

Import/Export Documentation and Restrictions

Verify country-specific import requirements, including customs codes (HS codes), product registration, and restrictions on refrigerant-related substances (e.g., substances impacting ozone layer or with high GWP under F-Gas Regulation). Some sealers may be restricted if they interfere with refrigerant recovery systems or violate environmental protocols.

Certification and Market-Specific Compliance

Ensure product meets regional standards such as CE marking (Europe), EPA SNAP program considerations (USA), or Transport Canada requirements. Third-party testing may be required for claims related to performance or safety. Avoid unsubstantiated marketing claims that could trigger regulatory scrutiny.

Incident Reporting and Recall Preparedness

Establish procedures for reporting accidents, leaks, or adverse events to relevant authorities (e.g., national chemical safety agency). Maintain a product traceability system and be prepared to initiate a recall if non-compliance or safety issues arise.

In conclusion, sourcing a reliable car air conditioning leak sealer requires careful consideration of product compatibility, leak size, system type, and quality standards. It is essential to select a reputable supplier or brand that offers a proven, non-clogging formula designed to effectively seal small leaks without harming the AC components. Whether opting for a DIY solution or a professional-grade product, ensuring technical specifications match the vehicle’s requirements will maximize efficiency and extend system longevity. Additionally, sourcing from trusted distributors or manufacturers with positive reviews and clear technical support enhances confidence in performance and safety. Ultimately, a well-researched sourcing decision can save time and repair costs while maintaining optimal cooling performance in automotive air conditioning systems.