The global capacitor market, a critical enabler of performance and efficiency in air conditioning (AC) units, is experiencing robust growth driven by rising demand for energy-efficient HVAC systems and expanding cooling needs across residential and commercial sectors. According to a 2023 report by Mordor Intelligence, the global capacitor market was valued at USD 3.5 billion in 2022 and is projected to grow at a CAGR of over 6.8% from 2023 to 2028. This growth is further supported by Grand View Research, which attributes increased capacitor demand to the proliferation of inverter-based AC units that rely heavily on high-quality, durable capacitors for motor start and run functions. As manufacturers scale production to meet rising global AC demand—especially in emerging markets across Asia-Pacific and the Middle East—price competitiveness, supply chain resilience, and technical innovation have become key differentiators. In this evolving landscape, the top six capacitor manufacturers for AC units are leveraging economies of scale, regional production capabilities, and technological advancements to offer cost-effective and reliable components, shaping the dynamics of pricing and market access.

Top 6 Capacitor Prices Ac Units Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Motor Run Capacitors

Domain Est. 1994

Website: grainger.com

Key Highlights: Run capacitors are typically used with medium-to-high torque applications required for air conditioners, auger drives, compressors, and conveyors. Provide ……

#2 AC Capacitor

Domain Est. 1995

Website: carrier.com

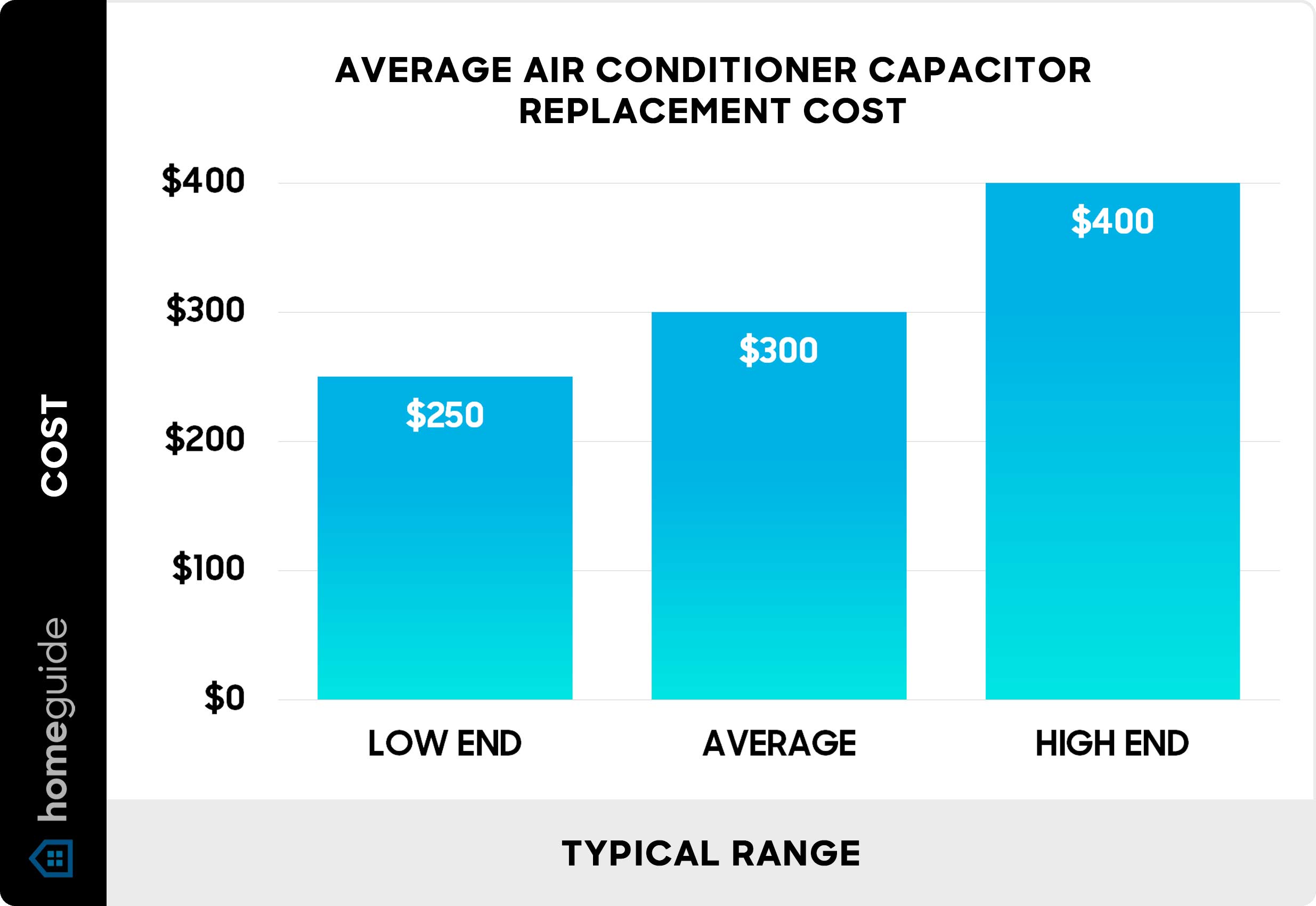

Key Highlights: The cost of replacing an HVAC capacitor typically ranges from $100 to $400, depending on the type of capacitor and the complexity of the replacement. Smaller, ……

#3 Capacitors

Domain Est. 1995

Website: parts.rheem.com

Key Highlights: Free delivery over $25 30-day returnsCapacitors are one of the most common parts that need to be replaced on residential air conditioning systems. Your system could have one or mor…

#4 Capacitors

Domain Est. 1995

Website: parts.ruud.com

Key Highlights: 30-day returnsUse the search bar above to find: Search by Part Number; Search by Description; Search by HVAC Model Number Search by HVAC Model or Serial Number; Search by WH ……

#5 AC Capacitors & Capacitors

Domain Est. 1995

Website: acehardware.com

Key Highlights: Tackle HVAC repairs yourself with capacitors. Explore a diverse assortment of air conditioner capacitor parts for your repairs online at Ace….

#6 Capacitors

Domain Est. 2000

Expert Sourcing Insights for Capacitor Prices Ac Units

H2: Projected 2026 Market Trends for Capacitor Prices in AC Units

The global market for capacitors used in air conditioning (AC) units is expected to undergo significant shifts by 2026, driven by technological advancements, supply chain dynamics, regulatory pressures, and growing demand for energy-efficient HVAC systems. Here’s an analysis of key trends likely to influence capacitor pricing in AC units over the coming years:

-

Rising Demand for Energy-Efficient and Smart AC Systems

The global push toward energy efficiency and sustainability is accelerating the adoption of inverter-based and smart AC units, which rely heavily on high-performance capacitors—particularly film and electrolytic types. As governments in regions like the EU, North America, and parts of Asia enforce stricter energy efficiency standards (e.g., SEER2, MEPS), manufacturers are investing more in advanced components. This increased demand is expected to exert upward pressure on capacitor prices, especially for premium-grade, long-life capacitors. -

Supply Chain Constraints and Raw Material Costs

Capacitor production depends on materials such as aluminum, tantalum, copper, and specialized polymers. Geopolitical tensions, mining restrictions, and logistics bottlenecks may continue to disrupt raw material supplies through 2026. For instance, China’s dominance in rare earth and aluminum production poses risks to cost stability. Any sustained increases in material input costs are likely to be passed on to AC manufacturers, contributing to higher capacitor prices. -

Technological Innovation and Miniaturization

Advancements in capacitor technology—such as the development of metalized film capacitors with improved thermal stability and longer lifespans—are enabling smaller, more reliable components. While these innovations enhance AC unit performance and durability, they come at a higher production cost. By 2026, the shift toward these high-reliability capacitors in premium and commercial AC systems will support premium pricing, especially in markets with high maintenance and downtime costs. -

Regional Manufacturing Shifts and Localization

In response to trade uncertainties and pandemic-era supply chain disruptions, AC and capacitor manufacturers are investing in regional production hubs in Southeast Asia, India, and Mexico. While this localization aims to reduce logistics costs and lead times, initial setup investments and labor adjustments may keep prices elevated in the short to medium term. However, by 2026, increased local production could stabilize or even reduce capacitor costs in certain markets, particularly in emerging economies. -

Impact of EV and Renewable Energy Sectors

The booming electric vehicle (EV) and renewable energy sectors are competing for the same high-performance capacitors used in AC units. As these industries prioritize capacitors for inverters and power management systems, availability for HVAC applications may tighten. This cross-sectoral demand competition could lead to supply constraints and price hikes, especially for DC-link and AC filter capacitors. -

Regulatory and Environmental Compliance

Environmental regulations such as RoHS (Restriction of Hazardous Substances) and REACH are pushing manufacturers to adopt greener materials and production processes. Capacitors free of harmful substances or designed for easier recycling may require more expensive manufacturing methods, influencing final pricing. Additionally, carbon tariffs and green certification requirements could add compliance-related costs. -

Price Forecast Outlook for 2026

Overall, capacitor prices for AC units are projected to experience moderate inflation through 2026: - Low-margin, standard capacitors: Prices may increase by 3–5% annually due to material and labor costs.

- High-performance and smart system capacitors: Prices could rise by 6–8% annually, driven by technology premiums and limited supply.

- Regional variation: Prices in North America and Europe may remain higher due to compliance and logistics, while Asia-Pacific could see more competitive pricing due to local production scale.

Conclusion

By 2026, capacitor prices in the AC unit market will be shaped by a complex interplay of technological innovation, regulatory demands, and supply chain resilience. While cost pressures are expected to persist, ongoing advancements and regional manufacturing growth may help moderate long-term price increases. AC manufacturers should prepare for tighter margins or invest in strategic sourcing and component optimization to remain competitive.

Common Pitfalls When Sourcing Capacitor Prices for AC Units (Quality and IP)

Sourcing capacitors for air conditioning units involves more than just finding the lowest price. Overlooking critical factors related to quality and IP (Ingress Protection) ratings can lead to system failures, safety hazards, and increased long-term costs. Here are the most common pitfalls to avoid:

Prioritizing Low Cost Over Quality

Choosing capacitors solely based on the lowest price often results in substandard components. Cheap capacitors may use inferior dielectric materials, thinner foils, or poor sealing, leading to premature failure, reduced efficiency, and frequent replacements. This increases downtime and maintenance costs over time.

Ignoring Capacitor Specifications and Compatibility

Not verifying technical specifications such as voltage rating, capacitance value (µF), tolerance, and temperature range can result in mismatched components. Using a capacitor with incorrect specs can damage the motor, reduce AC performance, or create fire hazards.

Overlooking IP (Ingress Protection) Ratings

Capacitors used in outdoor or harsh environments must have appropriate IP ratings to resist dust and moisture. Sourcing capacitors without sufficient IP protection (e.g., IP54 or higher for outdoor units) can lead to corrosion, short circuits, and early failure due to environmental exposure.

Failing to Verify Certifications and Standards

Reputable capacitors should comply with international standards such as UL, CE, RoHS, or IEC. Sourcing from suppliers who cannot provide certification documentation increases the risk of receiving counterfeit or non-compliant parts that may not meet safety or performance requirements.

Relying on Unverified Suppliers or Distributors

Purchasing from unknown or unverified suppliers—especially on open marketplaces—can expose buyers to counterfeit or reconditioned capacitors. These components often underperform and pose safety risks. Always source from authorized distributors or trusted manufacturers.

Not Considering Temperature and Environmental Conditions

AC capacitors operate under high thermal stress. Selecting capacitors without adequate temperature ratings (e.g., 85°C or 105°C) for the application can lead to reduced lifespan and thermal runaway. Environmental factors like humidity, vibration, and direct sunlight must also influence the choice.

Skipping Long-Term Reliability and Warranty Evaluation

Low-priced capacitors often come with limited or no warranty. Failing to assess the manufacturer’s warranty terms and reliability track record can result in unexpected costs when capacitors fail prematurely in the field.

Assuming All Capacitors Are Interchangeable

Even if two capacitors have the same capacitance and voltage, differences in construction, ESR (Equivalent Series Resistance), and ripple current handling can affect performance. Blindly substituting without full technical validation risks reduced efficiency and equipment damage.

Avoiding these pitfalls ensures you source capacitors that offer reliable performance, safety, and cost-effectiveness over the lifespan of the AC unit.

Logistics & Compliance Guide for Capacitor Prices in AC Units

When dealing with capacitors used in air conditioning (AC) units, understanding both logistics and compliance is essential for manufacturers, distributors, and HVAC service providers. Capacitors play a critical role in starting and running compressor and fan motors, and their pricing can be influenced by global supply chains, regulatory standards, and transportation requirements. This guide outlines key considerations to ensure efficient logistics and compliance adherence.

Supply Chain and Sourcing Logistics

Sourcing capacitors for AC units involves coordination between suppliers, manufacturers, and end users. Key logistics factors include:

- Supplier Location and Lead Times: Most capacitors are manufactured in Asia (e.g., China, Taiwan, South Korea). Shipping times via sea freight typically range from 30 to 45 days, while air freight reduces delivery to 5–10 days but increases costs significantly.

- Pricing Volatility: Capacitor prices are affected by raw material costs (e.g., aluminum, dielectric films) and global electronic component demand. Price fluctuations should be monitored through supply contracts with price adjustment clauses.

- Inventory Management: Given lead times, maintaining strategic safety stock is recommended, especially for high-demand models (e.g., dual-run capacitors in 35–50 µF range).

- Bulk vs. Drop Shipping: Distributors often benefit from bulk purchasing to reduce per-unit costs, while service companies may prefer drop shipping for just-in-time delivery.

Transportation and Handling Requirements

Capacitors are sensitive to physical and environmental conditions during transport:

- Packaging Standards: Use anti-static and shock-absorbent packaging to prevent damage. Moisture barriers are essential for long sea voyages.

- Storage Conditions: Store capacitors in dry, temperature-controlled environments (10–30°C, <60% relative humidity) to avoid degradation.

- Hazard Classification: While most AC capacitors are non-hazardous, certain types (e.g., those with PCBs or oil-filled designs) may be classified under hazardous materials regulations (e.g., DOT, IATA). Always verify material safety data sheets (MSDS).

- Import/Export Documentation: Ensure proper commercial invoices, packing lists, and certificates of origin are provided. Harmonized System (HS) code 8532.24.00 applies to fixed capacitors used in AC applications.

Regulatory and Compliance Standards

Capacitors in AC units must meet strict safety and environmental regulations:

- Safety Certifications: Look for certifications such as UL (Underwriters Laboratories), CE (Conformité Européenne), and ETL. In North America, UL 810 is the standard for motor capacitors.

- RoHS and REACH Compliance: Capacitors must comply with the Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) directives in the EU. This affects material selection and labeling.

- Energy Efficiency Standards: In regions like the U.S. (DOE) and EU (ErP Directive), capacitors contribute to overall AC unit efficiency. Using high-efficiency capacitors can help meet minimum performance thresholds.

- WEEE Compliance: In Europe, capacitors fall under the Waste Electrical and Electronic Equipment (WEEE) directive, requiring proper end-of-life recycling and disposal protocols.

Customs and Tariff Considerations

Importing capacitors may incur duties and require compliance with trade regulations:

- Tariff Rates: Duty rates vary by country. In the U.S., capacitors typically face low or zero tariffs under HTS 8532.24.00, but verify current rates via the USITC database.

- Trade Agreements: Capacitors sourced from countries with free trade agreements (e.g., USMCA) may qualify for reduced or eliminated tariffs.

- Customs Valuation: Accurately declare capacitor prices to avoid delays or penalties. Transfer pricing rules apply for intercompany transactions.

Quality Assurance and Documentation

To maintain compliance and avoid disruptions:

- Certificates of Conformity (CoC): Require suppliers to provide CoCs for each batch, confirming compliance with international standards.

- Traceability: Maintain lot tracking for capacitors to support recalls or warranty claims.

- Testing and Inspection: Conduct periodic sampling tests for capacitance, voltage tolerance, and insulation resistance per IEC 60252-1 standards.

Conclusion

Effective logistics and compliance management for capacitors in AC units directly impact pricing, availability, and product reliability. By understanding global supply dynamics, adhering to environmental and safety regulations, and ensuring proper documentation, stakeholders can mitigate risks and optimize costs. Regular audits and supplier evaluations are recommended to sustain a resilient and compliant supply chain.

Conclusion: Sourcing Capacitor Prices for AC Units

Sourcing capacitor prices for air conditioning units requires a strategic approach that balances cost, quality, and reliability. After evaluating various suppliers, including OEMs, wholesale distributors, and online marketplaces, it is evident that prices can vary significantly based on brand, capacitance value, voltage rating, and whether the capacitor is start or run type. Bulk purchasing and establishing relationships with trusted suppliers can lead to substantial cost savings, especially for HVAC service companies or contractors managing multiple units. However, prioritizing quality is essential—low-cost capacitors from unverified sources may compromise system performance and longevity, leading to increased maintenance costs and customer dissatisfaction. Additionally, considering factors such as warranty, availability, and shipping time ensures consistent operations and customer satisfaction. Ultimately, a well-informed procurement strategy that combines competitive pricing with reliable product standards will optimize both operational efficiency and cost-effectiveness in maintaining and repairing AC units.