The global confectionery equipment market, driven by rising demand for novelty foods and expanding foodservice sectors, is experiencing steady growth—with the candy floss machine segment benefiting significantly. According to Grand View Research, the global confectionery market was valued at USD 201.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.7% from 2023 to 2030. This expansion is fueled by increasing consumer preference for indulgent treats at events, amusement parks, and retail outlets, all of which rely on efficient, reliable candy floss machines. As demand surges, manufacturers are innovating to offer energy-efficient, high-capacity, and user-friendly models. Based on market presence, product range, technological advancement, and global distribution, we’ve identified the top 9 candy floss machine manufacturers shaping this growing industry.

Top 9 Candy Floss Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Homemade Candy Floss Machine Manufacturer and Supplier …

Domain Est. 2022

Website: gdbochuan.com

Key Highlights: Homemade Candy Floss Machine Manufacturers, Factory, Suppliers From China, We welcome clients, enterprise associations and friends from all components from ……

#2 Polyfloss Factory

Domain Est. 2012

Website: thepolyflossfactory.com

Key Highlights: We have invented a machine inspired by the principle of candy floss making, to recycle plastic waste locally ! Learn more. Our mission….

#3 Gold Medal Products Co.

Domain Est. 1996

Website: gmpopcorn.com

Key Highlights: 5-day delivery 60-day returnsChoose Gold Medal for all your concession equipment and supply needs, from popcorn and cotton candy machines to concession supplies, resources and more…

#4 Commercial Electric Candy Floss Machine

Domain Est. 1996

Website: twothousand.com

Key Highlights: The primary purpose of Electric Candy Floss Machines is to produce large quantities of cotton candy quickly and efficiently….

#5 Candy Floss Machines

Domain Est. 1998

#6 Candy Floss Machine

Domain Est. 1999

#7 Candy floss machine B5000

Domain Est. 2002

Website: bartscher.com

Key Highlights: This powerful model enables continuous candy floss production at a top professional level. €339.00. List price plus legal VAT….

#8 Cotton Candy Machines

Domain Est. 2018

Website: floatingcottoncandy.com

Key Highlights: A professional vertical production machine designed for the “Floss Art” professional! Controlled output with adjustable motor speed to control the floss ……

#9 Cotton Candy Making Machine

Domain Est. 2023

Website: asvrengineering.com

Key Highlights: Rating 4.5 (20) Explore top-quality Cotton Candy Making Machines, including automatic models, at great prices from ASVREngineering. Visit our website to find the perfect ……

Expert Sourcing Insights for Candy Floss Machine

H2: 2026 Market Trends for Candy Floss Machines

The global candy floss machine market is poised for notable transformation by 2026, driven by technological innovation, shifting consumer preferences, and expanding applications across diverse sectors. This analysis explores key trends expected to shape the market landscape in the coming years.

1. Rising Demand in Entertainment and Leisure Sectors

The entertainment and leisure industry remains a primary driver for candy floss machine adoption. With the post-pandemic revival of fairs, amusement parks, cinemas, and family entertainment centers, demand for nostalgic and visually appealing treats like cotton candy is growing. By 2026, operators are expected to increasingly invest in compact, energy-efficient, and easy-to-clean machines to enhance on-site production and improve customer experience.

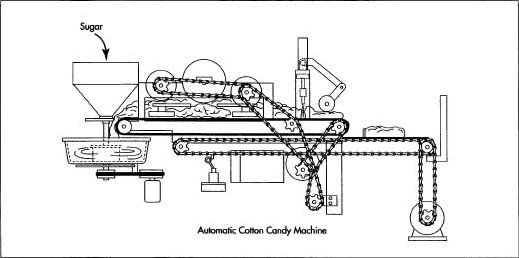

2. Technological Advancements and Automation

Innovation in machine design is a critical trend shaping the 2026 market. Manufacturers are integrating smart features such as digital temperature controls, automatic sugar feeding systems, and IoT connectivity for remote monitoring and maintenance. These advancements aim to reduce operator error, ensure consistent product quality, and lower operational costs—particularly appealing to commercial users and food truck operators.

3. Growth of Home-Use and Miniature Models

The consumer segment is witnessing a surge in demand for home-use candy floss machines, fueled by the do-it-yourself (DIY) food trend and social media-driven interest in unique party experiences. By 2026, compact, safe, and affordable countertop models are expected to gain significant market share. These machines often come with colorful designs, multiple flavor settings, and child-friendly safety features, expanding their appeal beyond traditional commercial settings.

4. Emphasis on Sustainability and Energy Efficiency

As environmental concerns grow, manufacturers are focusing on producing energy-efficient and eco-friendly candy floss machines. The shift toward recyclable materials, reduced power consumption, and longer product lifecycles is becoming a competitive differentiator. Regulatory pressures and corporate sustainability goals are expected to accelerate this trend by 2026, particularly in North America and Europe.

5. Expansion in Emerging Markets

Asia-Pacific, Latin America, and the Middle East are emerging as high-growth regions for candy floss machines. Urbanization, rising disposable incomes, and the proliferation of food festivals and street food culture are key factors. Localized marketing strategies and affordable machine pricing will be critical for market penetration in these regions by 2026.

6. Customization and Flavor Innovation

Consumers are increasingly seeking unique and customizable food experiences. Candy floss machines that support flavored sugar cartridges, natural colorings, and gourmet variants (e.g., matcha, sour apple, or edible glitter) are gaining popularity. Machine designs that allow for easy flavor switching and creative presentation will be in higher demand, especially in premium and specialty food segments.

7. Integration with Food Trucks and Mobile Vending

The mobile food industry continues to grow, and candy floss machines are becoming a staple in dessert-focused food trucks and pop-up events. Lightweight, portable, and quick-setup models are being developed to meet the needs of mobile vendors. By 2026, this segment is expected to see increased innovation in modular and multi-functional machines.

In conclusion, the candy floss machine market in 2026 will be shaped by innovation, consumer experience, and sustainability. Companies that adapt to these evolving trends—by offering smarter, greener, and more versatile products—will be best positioned to capture growth in both commercial and consumer markets.

Common Pitfalls When Sourcing Candy Floss Machines: Quality and Intellectual Property Concerns

Sourcing candy floss machines, especially from overseas manufacturers, can be a cost-effective way to enter or expand in the event, carnival, or retail food market. However, buyers often encounter significant challenges related to product quality and intellectual property (IP) rights. Being aware of these pitfalls can help mitigate risks and ensure a successful procurement process.

Quality-Related Pitfalls

Inconsistent Build Quality and Materials

One of the most common issues when sourcing candy floss machines is inconsistent build quality. Many suppliers, particularly in low-cost manufacturing regions, may use substandard materials such as cheap plastics, non-food-grade metals, or undersized motors. This can lead to frequent breakdowns, safety hazards, and a shortened product lifespan. Machines may not meet temperature control standards, leading to poor sugar melting and inconsistent floss production.

Lack of Safety Certifications

A major red flag is the absence of recognized safety certifications such as CE, UL, or ETL. Without these, the machine may not comply with electrical, thermal, or food safety regulations in your target market. Using uncertified equipment can lead to legal liability, product recalls, or bans at events and venues.

Poor After-Sales Support and Spare Parts Availability

Many suppliers offer low initial prices but fail to provide reliable after-sales support. This includes difficulty in obtaining replacement parts, lack of technical documentation, or unresponsive customer service. Without readily available spare parts—such as heating elements or spinning heads—downtime can significantly impact operations.

Inadequate Testing and Quality Control

Suppliers may skip rigorous quality control processes, shipping units that haven’t been properly tested. Buyers might receive machines that do not start, overheat quickly, or produce poor-quality cotton candy. Requesting pre-shipment inspection reports or arranging third-party QC checks can help avoid this.

Intellectual Property (IP) Risks

Infringement of Patented Designs

Some candy floss machines replicate patented technologies or design features owned by established brands. Sourcing a machine that infringes on existing IP can result in legal action, customs seizures, or forced product recalls. Always investigate whether the machine design overlaps with protected patents, especially in markets like the U.S. or EU.

Counterfeit or Branded Look-Alike Products

Suppliers may offer machines that mimic the appearance of well-known brands (e.g., resembling a popular commercial model) without authorization. While not always an outright counterfeit, this can still violate trademark or design rights. Buyers risk damaging their reputation and facing legal challenges if they unknowingly distribute imitation products.

Lack of IP Ownership Clarity

When working with OEM/ODM manufacturers, it’s crucial to clarify who owns the intellectual property of custom-designed machines. Without a formal agreement, the supplier may retain rights to the design, limiting your ability to make modifications or source from other manufacturers in the future.

No Documentation for IP Compliance

Reputable suppliers should be able to provide evidence of IP clearance, such as design freedom-to-operate opinions or patent disclaimers. If a supplier is unwilling or unable to provide such documentation, it may indicate potential IP vulnerabilities in the product.

How to Mitigate These Risks

- Request product samples and conduct performance testing before bulk ordering.

- Verify certifications and ensure compliance with local regulations.

- Use third-party inspection services to audit factory quality control processes.

- Conduct IP due diligence, including patent and trademark searches.

- Sign clear contracts that define quality standards, warranty terms, and IP ownership.

- Work with legally vetted suppliers through platforms or agents with proven track records.

By addressing these quality and IP pitfalls proactively, businesses can source reliable, compliant candy floss machines that support long-term success.

Logistics & Compliance Guide for Candy Floss Machine

Product Classification and HS Code

Candy floss machines are typically classified under Harmonized System (HS) Code 8516.79.00, which covers electric appliances for making food or drink. Accurate classification is essential for customs clearance, duty calculation, and import/export compliance. Confirm the specific subcategory with local customs authorities, as variations may exist by country.

Import and Export Regulations

Compliance with destination country regulations is mandatory. Key considerations include electrical safety standards (e.g., CE in the EU, UL in the U.S.), energy efficiency requirements, and labeling regulations. Exporters must ensure machines meet voltage and plug type requirements for the target market. Obtain necessary product certifications prior to shipping.

Packaging and Shipping Requirements

Package candy floss machines securely to prevent damage during transit. Use sturdy corrugated boxes with internal cushioning (foam inserts or bubble wrap). Clearly label packages with handling instructions—“Fragile,” “This Side Up,” and “Keep Dry.” Include product identification, model number, and country of origin on external packaging.

Electrical Safety and Certification

Candy floss machines must comply with electrical safety standards in the destination market. For the European Union, CE marking under the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive is required. In the U.S., UL certification (e.g., UL 197) may be necessary. Documentation proving compliance must accompany shipments.

Documentation for Customs Clearance

Prepare the following documents for smooth customs processing:

– Commercial Invoice (detailing product description, value, and terms of sale)

– Packing List (itemizing contents per package)

– Certificate of Origin (confirming manufacturing country)

– Safety and Compliance Certificates (CE, UL, etc.)

– Bill of Lading or Air Waybill

Ensure all documents are accurate and consistent to avoid delays.

Battery and Motor Compliance (if applicable)

If the machine includes a motor or rechargeable components, additional regulations may apply. Lithium batteries must comply with IATA Dangerous Goods Regulations for air transport. Declare any restricted components and provide appropriate safety data sheets (SDS) if required.

Environmental and Disposal Compliance

Adhere to environmental directives such as RoHS (Restriction of Hazardous Substances) in the EU, which limits the use of lead, mercury, and other hazardous materials in electrical equipment. Provide end-of-life disposal instructions to customers in accordance with local e-waste regulations.

Labeling and User Instructions

Include multilingual user manuals and safety warnings if exporting internationally. Labels on the machine must display:

– Manufacturer name and address

– Model and serial number

– Electrical specifications (voltage, frequency, power)

– Safety certification marks

– Warning symbols (e.g., hot surfaces)

Warranty and After-Sales Support

Establish a logistics plan for warranty claims and spare parts distribution. Clearly state warranty terms and service contact details in product packaging. Comply with consumer protection laws regarding repair, replacement, and return policies in the destination market.

Transport and Handling Best Practices

Use carriers experienced in handling electrical appliances. For international shipments, consider cargo insurance to protect against loss or damage. Monitor temperature and humidity during transit, especially for long sea voyages, to prevent condensation damage.

In conclusion, sourcing a candy floss machine requires careful consideration of several key factors including machine type (commercial vs. residential), build quality, ease of use and cleaning, energy efficiency, safety features, and after-sales support. Whether purchasing locally or from international suppliers, it’s essential to compare prices, warranties, and customer reviews to ensure reliability and value for money. Additionally, aligning the machine specifications with your intended usage—be it for a business, event catering, or personal enjoyment—will help in making a sound investment. By conducting thorough research and sourcing from reputable suppliers, you can acquire a durable and efficient candy floss machine that meets your needs and delivers consistent, high-quality results.