The global can sealer machine market is experiencing robust growth, driven by rising demand for packaged food and beverages, increased automation in production lines, and stringent regulations around product safety and shelf life. According to a 2023 report by Mordor Intelligence, the market was valued at USD 1.85 billion in 2022 and is projected to grow at a CAGR of 5.2% through 2028. This expansion is further supported by Grand View Research, which highlights the growing adoption of advanced sealing technologies in pharmaceuticals and industrial packaging as key growth catalysts. With industries prioritizing efficiency, consistency, and compliance, the need for reliable, high-performance can sealer machines has never been greater. As competition intensifies, a select group of manufacturers stand out for their innovation, global reach, and technological prowess—shaping the future of hermetic sealing across sectors. Here’s a data-driven look at the top 10 can sealer machine manufacturers leading this evolution.

Top 10 Can Sealer Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Manual Can Sealer Manufacturer and Supplier, Factory

Domain Est. 2022

Website: gdbochuan.com

Key Highlights: Manual Can Sealer Manufacturers, Factory, Suppliers From China, We have been wanting forwards to creating long-term company interactions with around the ……

#2 Custom Can Sealer Machine Factory and Manufacturer, Supplier

Domain Est. 2022

Website: ctcanmachine.com

Key Highlights: Can Sealer Machine Manufacturers, Factory, Suppliers From China, Our merchandise are widely recognized and trusted by users and can meet up with ……

#3 Veeco

Domain Est. 1995

Website: veeco.com

Key Highlights: Veeco is a global designer and manufacturer of semiconductor process equipment for wet processing, laser annealing, ion beam, ALD, CVD, MBE, PVD, and more….

#4 Signode

Domain Est. 1996

Website: signode.com

Key Highlights: Signode is the leading worldwide manufacturer and distributor of protective packaging systems that apply plastic and steel strapping, and stretch film….

#5 Presto Appliances

Domain Est. 1999

Website: gopresto.com

Key Highlights: National Presto Industries, Inc. Makers of world famous Presto® Pressure Cookers, Canners, and Electric Appliances….

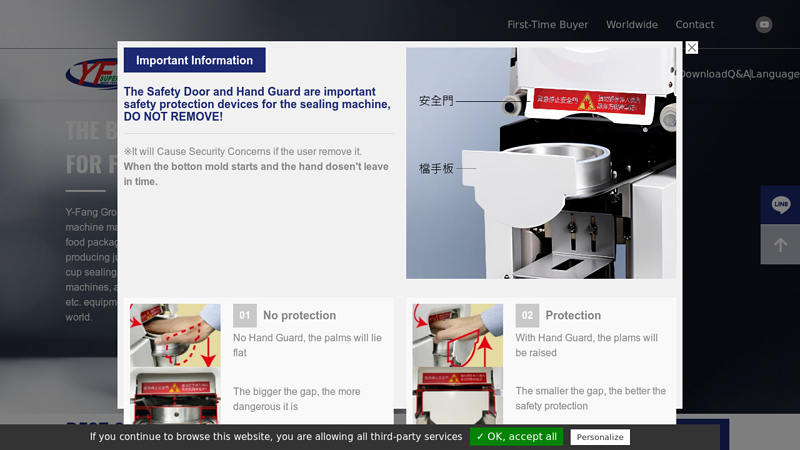

#6 Y

Domain Est. 2004

Website: yifunggroup.com

Key Highlights: Y-Fang group supplies automatic juice filling and seaming machines, vacuum packing, cup sealing machines, etc equipment and exports them all over the world….

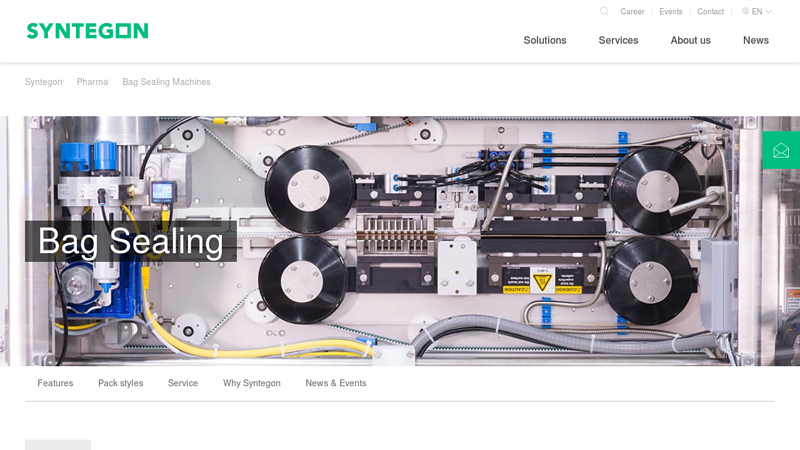

#7 Bag Sealing Machines

Domain Est. 2019

Website: syntegon.com

Key Highlights: Our bag sealing machine feature an advanced sealing technology to ensure bags are properly sealed, ideally suited for medical, food and non-food items….

#8 The Willamette Valley Company, LLC

Domain Est. 1997

Website: wilvaco.com

Key Highlights: We are leaders in providing a wide range of high-performance solutions, from coatings, fillers and adhesives to robotics, parts and engineering….

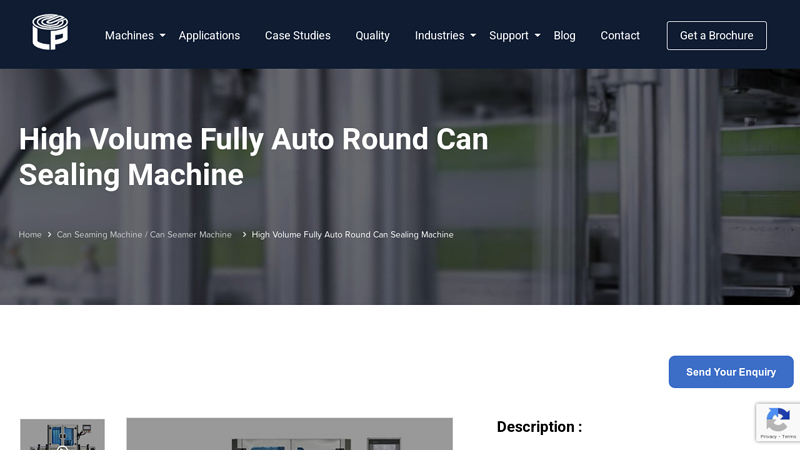

#9 High Volume Fully Auto Round Can Sealing Machine

Domain Est. 2018

Website: levapack.com

Key Highlights: High volume Fully-automatic single head seame. Adjustable production capacity,seam Up to 50 cans/minute. 4 rollers for consistent & leak-proof seam….

#10 DELLA

Website: della.ae

Key Highlights: Della Can Sealer Machine seals your cups to perfection on demand, eliminating the need for wrapping or taping the plastic cups and ultimately saving time….

Expert Sourcing Insights for Can Sealer Machine

H2: 2026 Market Trends for Can Sealer Machines

The global can sealer machine market is poised for significant transformation by 2026, driven by evolving consumer demands, technological innovation, and shifts in manufacturing practices across key industries such as food and beverage, pharmaceuticals, and household products. As automation and sustainability become central themes in industrial operations, can sealer machines are adapting to meet higher efficiency, precision, and eco-friendly standards.

One of the dominant trends shaping the 2026 landscape is the increasing adoption of smart and automated can seaming systems. Manufacturers are integrating Internet of Things (IoT) technology into sealer machines to enable real-time monitoring, predictive maintenance, and data analytics. This connectivity enhances operational efficiency, reduces downtime, and ensures consistent sealing quality—critical factors for maintaining product integrity and compliance in regulated industries.

Another emerging trend is the growing demand for flexible packaging solutions. With the rise of craft beverages, smaller batch production, and private-label products, there is a heightened need for can sealer machines that can handle variable can sizes and rapid changeovers. Modular and compact designs are gaining popularity, especially among small and medium-sized enterprises (SMEs) seeking cost-effective and scalable sealing solutions.

Sustainability is also influencing the market. By 2026, there is a stronger emphasis on energy-efficient machines and recyclable packaging materials. Can sealer manufacturers are responding by developing low-energy sealing processes and machines that support lightweight cans, reducing both material usage and carbon footprint across the supply chain.

Regionally, the Asia-Pacific market is expected to witness the fastest growth due to expanding food and beverage production, urbanization, and rising disposable incomes. Meanwhile, North America and Europe continue to lead in technological advancements, with a focus on high-speed, precision sealing equipment compliant with stringent safety regulations.

In conclusion, the 2026 can sealer machine market will be defined by smarter, more adaptable, and sustainable technologies. Companies investing in innovation, digital integration, and eco-conscious design will be best positioned to capture market share and meet the evolving needs of modern production environments.

Common Pitfalls When Sourcing a Can Sealer Machine: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Can Sealer Machine

This guide outlines key considerations for the logistics and compliance aspects of transporting and operating a Can Sealer Machine, ensuring safe delivery, regulatory adherence, and smooth integration into your production environment.

Packaging and Handling

Ensure the Can Sealer Machine is securely packaged in a robust wooden crate or heavy-duty pallet with corner protectors. Use anti-vibration materials (e.g., foam, air cushions) to protect sensitive components during transit. Clearly label the package with “Fragile,” “This Side Up,” and handling instructions. Avoid stacking heavy items on top. For machines with delicate sealing heads or control panels, additional internal bracing is recommended.

Domestic and International Shipping Requirements

For domestic shipments within regions like the U.S. or EU, standard freight procedures apply, including proper freight classification and carrier notification. For international shipping, ensure compliance with export regulations such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Export Controls, if applicable. Provide accurate HS (Harmonized System) codes—typically under 8422.40 (Machinery for cleaning, filling, sealing, capsuling, or labeling bottles or similar containers). Include a commercial invoice, packing list, and bill of lading or air waybill.

Import Documentation and Duties

Importers must prepare necessary documentation including a commercial invoice, packing list, bill of lading, certificate of origin, and import declaration. Verify if the Can Sealer Machine qualifies for duty-free entry under applicable trade agreements. Engage a licensed customs broker to manage tariff classification, assess import duties, and ensure compliance with local regulations. Some countries may require pre-shipment inspections or conformity assessments.

Electrical and Safety Compliance

Confirm the machine’s electrical specifications (voltage, phase, frequency) match the destination country’s standards (e.g., 110V/60Hz in North America, 230V/50Hz in Europe). The machine should carry relevant safety certifications such as CE (European Union), UKCA (United Kingdom), EAC (Eurasian Economic Union), or UL/CSA (North America). Ensure internal wiring complies with local electrical codes and includes protective grounding.

Machinery Directive and Conformity

In the European Economic Area, the Can Sealer Machine must comply with the EU Machinery Directive (2006/42/EC). This requires a Declaration of Conformity, CE marking, and technical file documentation demonstrating compliance with health, safety, and environmental protection standards. Include risk assessments, safety interlocks, emergency stop functions, and proper user instructions in the local language.

Environmental and Waste Compliance

Adhere to environmental regulations such as the EU’s RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives. Ensure the machine does not contain restricted substances (e.g., lead, mercury, cadmium) above permissible levels. Provide end-of-life disposal guidance and support recycling initiatives. In the U.S., comply with EPA guidelines related to industrial equipment and waste management.

Installation and Operational Compliance

Upon delivery, follow the manufacturer’s installation manual for proper setup, including anchoring, utility connections, and calibration. Conduct initial safety checks and operator training in accordance with OSHA (U.S.) or equivalent local workplace safety regulations. Maintain logs for maintenance, safety inspections, and operator certifications to demonstrate compliance during audits.

After-Sales Support and Documentation

Provide users with comprehensive documentation, including operation manuals, safety instructions, spare parts lists, and warranty information in the local language. Ensure traceability via a unique serial number and maintain records for compliance audits. Offer accessible technical support and spare parts supply to support long-term operational compliance.

Conclusion for Sourcing a Can Sealer Machine

Sourcing a can sealer machine is a critical decision that directly impacts production efficiency, product quality, and operational cost-effectiveness. After evaluating various options based on production volume, automation level, compatibility with can types and sizes, ease of maintenance, and regulatory compliance, it is clear that selecting the right machine requires a balance between initial investment and long-term operational benefits.

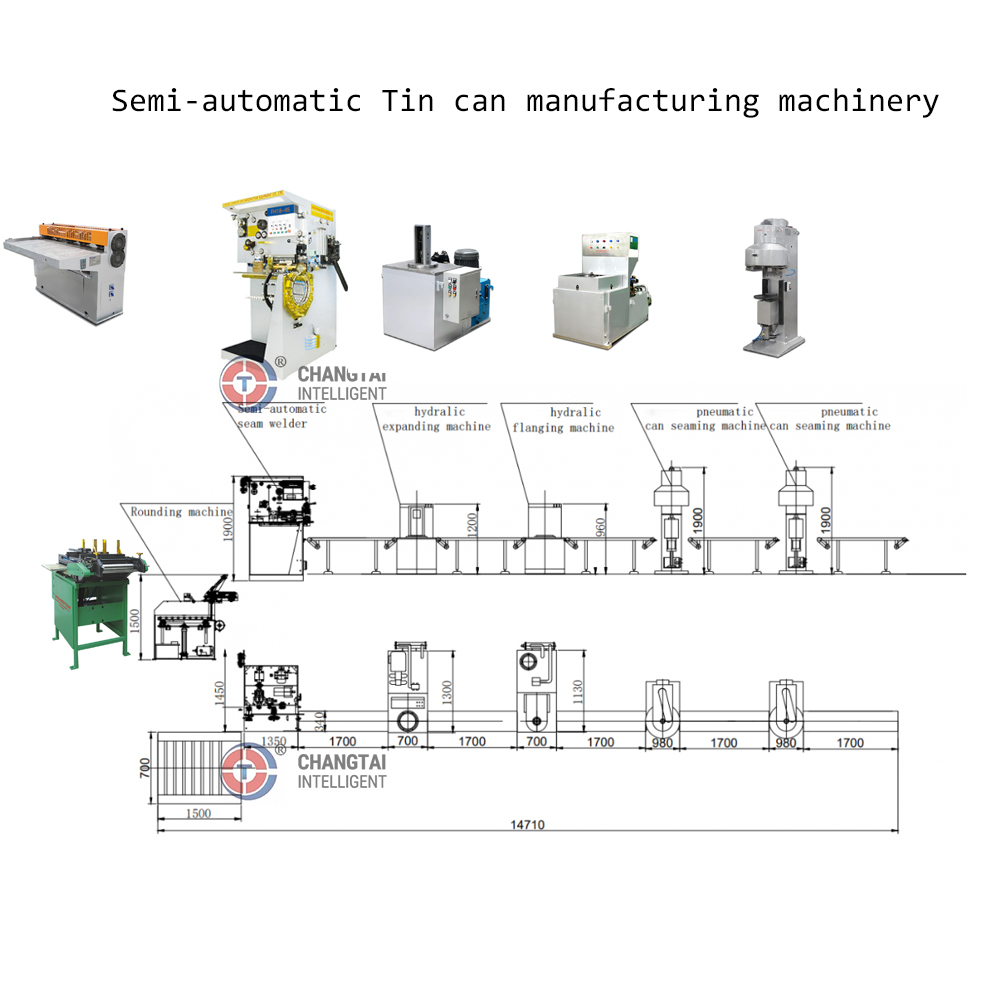

Automated can sealer machines offer higher throughput and consistency, making them ideal for large-scale operations, while semi-automatic or manual models may be more suitable for small to medium producers with limited budgets or lower output needs. Key considerations such as build quality, after-sales support, spare parts availability, and energy efficiency should not be overlooked.

Ultimately, partnering with a reputable supplier that provides technical expertise, training, and reliable service support ensures smooth integration into existing production lines and minimizes downtime. A well-chosen can sealer machine enhances product integrity, extends shelf life, and supports brand reputation, making it a valuable asset in the food and beverage, pharmaceutical, or chemical packaging industries.

In conclusion, thorough research, clear specification requirements, and due diligence in supplier selection are essential to sourcing a can sealer machine that meets both current needs and future scalability goals.