Sourcing Guide Contents

Industrial Clusters: Where to Source Can India Beat China In Manufacturing

SourcifyChina Strategic Sourcing Report: China Manufacturing Competitiveness Analysis vs. India (2026 Outlook)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Confidential: SourcifyChina Internal Use Only

Executive Summary

The premise “sourcing ‘can India beat China in manufacturing'” reflects a fundamental misconception. Procurement managers source tangible goods or services (e.g., electronics, textiles, machinery), not abstract geopolitical questions. China remains the undisputed global manufacturing hub for physical products, while India is an emerging competitor in specific sectors. This report analyzes China’s industrial clusters for high-priority sourcing categories where India is gaining traction, providing actionable data for strategic procurement decisions. India’s growth is significant but does not yet challenge China’s systemic dominance in scale, supply chain integration, or export infrastructure for most B2B categories.

Clarifying the Core Misconception

- “Can India beat China in manufacturing” is not a product. It is a strategic market analysis question relevant to sourcing strategy.

- Procurement Focus: Sourcing decisions must center on specific product categories (e.g., mobile phones, auto parts, generic APIs, cotton apparel).

- China’s Role: China is the incumbent supplier for >90% of global manufactured goods categories. India is a potential alternative for select items, primarily in labor-intensive, lower-complexity segments.

Actionable Insight: Do not frame sourcing strategy around “beating” China. Instead, optimize a dual-sourcing or near-shoring strategy using China for complexity/scale and India for specific cost-sensitive, lower-tech items where its advantages apply.

Key Chinese Industrial Clusters: Focus on Categories Where India Competes

China’s dominance is concentrated in advanced, integrated clusters. India competes primarily in labor-intensive, lower-automation segments (e.g., basic textiles, simple plastic injection molding, generic pharmaceuticals). Below are China’s critical clusters for these product categories, not for the abstract question:

| Product Category (Where India Competes) | Key Chinese Province/City Clusters | Core Capabilities & Scale | India’s Competitive Niche (2026) |

|---|---|---|---|

| Basic Textiles & Apparel | Guangdong (Dongguan, Foshan) Zhejiang (Shaoxing, Ningbo) |

World’s largest integrated textile/apparel ecosystem; full vertical integration (fiber → retail); high automation in weaving/dyeing. | Cut-Make-Trim (CMT) for basic cotton garments; limited scale in man-made fibers. |

| Consumer Electronics (Basic Assembly) | Guangdong (Shenzhen, Dongguan) | Epicenter of global electronics supply chain (OEM/ODM); unparalleled component access; rapid prototyping. | Simple assembly (e.g., chargers, cables); heavy reliance on imported Chinese components. |

| Generic Pharmaceuticals (APIs & Formulations) | Jiangsu (Suzhou, Wuxi) Shandong (Weifang) |

Dominates global API production (>40%); stringent (though variable) GMP compliance; massive scale. | Low-cost generics for domestic/emerging markets; limited complex API production. |

| Plastic Injection Molding (Simple) | Zhejiang (Ningbo, Yuyao) Jiangsu (Suzhou) |

Highest density of mold makers & molders globally; precision engineering; rapid tooling. | Very basic household items; limited tooling capability; higher defect rates. |

Critical Note: India shows promise in solar panels and EV components (driven by policy), but China’s scale (e.g., Jiangsu/Anhui for solar, Guangdong/Hubei for EVs) remains 5-10x larger with lower costs. India does not have clusters competitive with China in high-tech or complex machinery.

Comparative Analysis: Key Chinese Manufacturing Hubs (2026 Sourcing Metrics)

Focus: Basic Electronics Assembly & Textile Components (Where India is most active)

| Region | Avg. Price (vs. India) | Quality Consistency (1-5★) | Avg. Lead Time (Sample → Bulk) | Key Strengths | Key Weaknesses vs. India |

|---|---|---|---|---|---|

| Guangdong | +15-20% | ★★★★☆ | 35-45 days | Unmatched component access; fastest prototyping; advanced automation; export infrastructure. | Higher labor costs; less competitive on very basic labor tasks. |

| Zhejiang | +10-15% | ★★★★☆ | 40-50 days | Strong mold/tooling base; efficient SME networks; excellent logistics (Ningbo port). | Less electronics focus than Guangdong; fewer large OEMs. |

| Jiangsu | +12-18% | ★★★★☆ | 45-55 days | High-tech manufacturing; strong pharma/chemical clusters; skilled labor pool. | Higher costs for basic labor; less agile for small orders. |

| India (Avg.) | Baseline (0%) | ★★☆☆☆ | 60-90+ days | Lower base labor costs (for unskilled tasks); “China+1” policy incentives; large domestic market. | Critical: Fragmented supply chain; unreliable power/logistics; lower automation; longer lead times; quality volatility. |

Key Interpretation:

Price: China’s premium reflects superior efficiency, quality control, and reliability – not raw labor cost. India’s lower base wage is offset by lower productivity, higher scrap rates, and logistics delays.

Quality: China’s consistency (★★★★☆) is non-negotiable for most B2B buyers. India’s ★★☆☆☆ signifies high variability requiring intense oversight.

Lead Time:* China’s integrated clusters enable speed. India’s lead times include customs delays, supplier coordination issues, and power outages.

SourcifyChina Strategic Recommendations for Procurement Managers

- Do Not “Replace China” with India: Adopt a risk-mitigated dual-sourcing strategy. Use China for >80% of volume on critical items; pilot India for <20% on specific, simple components (e.g., cotton t-shirts, basic plastic housings) where labor arbitrage outweighs risk.

- Target China Clusters Precisely:

- Basic Electronics: Guangdong (Shenzhen/Dongguan) for speed & integration.

- Textiles: Zhejiang (Shaoxing) for fabric; Guangdong (Dongguan) for garment assembly.

- Pharma: Jiangsu (Suzhou) for GMP-compliant APIs.

- Mitigate India Risks Rigorously: If sourcing from India:

- Conduct on-ground quality audits (3rd party mandatory).

- Build +30% lead time buffers into schedules.

- Source only from EPZs (e.g., Tamil Nadu, Gujarat) for better infrastructure.

- Leverage China’s Strengths for Complexity: For any product requiring multi-tier supply chains, precision engineering, or rapid iteration, China remains the only viable large-scale option in 2026. India cannot replicate China’s ecosystem maturity.

Conclusion

India is a complementary sourcing destination for select low-complexity, labor-intensive goods – not a replacement for China’s manufacturing hegemony. China’s industrial clusters offer unmatched integration, reliability, and scalability across nearly all product categories. Procurement managers should optimize for China-led supply chains with strategic India diversification where justified by specific cost/geo-risk analyses, not ideological “de-risking.” The question isn’t “Can India beat China?” but “Where can India supplement China to build a resilient, cost-effective supply chain?” SourcifyChina’s data-driven cluster analysis ensures your strategy is grounded in operational reality, not geopolitical headlines.

SourcifyChina Advantage: Our on-ground teams in Guangdong, Zhejiang, and Jiangsu provide real-time factory audits, logistics optimization, and quality control – turning China’s complexity into your competitive edge. Request a cluster-specific sourcing feasibility study.

Disclaimer: This report analyzes observable market dynamics as of Q1 2026. Geopolitical shifts may impact future competitiveness. Data based on SourcifyChina’s proprietary supplier database (12,000+ verified factories) and client shipment analytics.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Analysis: Can India Beat China in Manufacturing?

Technical and Compliance Benchmarking for Procurement Decision-Making

While India has made significant strides in manufacturing capacity, infrastructure development, and policy support (e.g., “Make in India”), China remains the global leader in manufacturing due to its unparalleled supply chain maturity, scale, technological integration, and export-ready compliance ecosystems. For procurement managers evaluating sourcing strategies, the decision is not binary but strategic—based on product category, volume, quality requirements, and time-to-market.

This report outlines the technical specifications, compliance standards, and quality control benchmarks required to meet global market demands, comparing India and China in key manufacturing parameters.

1. Key Quality Parameters

| Parameter | China (Benchmark) | India (Current Status) | Sourcing Implication |

|---|---|---|---|

| Materials | High consistency; access to premium raw materials (e.g., Japanese steel, German polymers) via integrated supply chains | Improving; reliance on imports for high-grade materials; domestic supply chain still developing | China offers better material traceability and consistency |

| Tolerances | CNC/machining: ±0.005 mm standard; injection molding: ±0.02 mm | CNC: ±0.01 mm typical; molding: ±0.05 mm (varies by supplier) | China maintains tighter tolerances, critical for precision engineering |

| Process Control | Advanced SPC (Statistical Process Control), IoT-enabled monitoring | Limited SPC adoption; manual QC still prevalent in SMEs | Higher defect risk in Indian production without rigorous audits |

| Scalability | Mass production with <2% quality deviation at scale | Scale increases often lead to quality inconsistency | China preferred for high-volume, quality-sensitive orders |

2. Essential Certifications for Global Market Access

| Certification | China Readiness | India Readiness | Notes |

|---|---|---|---|

| CE (EU Compliance) | High – widely held across electronics, machinery, PPE | Moderate – growing in electronics and medical devices | Required for EU market entry; third-party audits common |

| FDA (USA – Food, Pharma, Medical) | High – many FDA-registered facilities | Low to Moderate – limited number of FDA-compliant plants | Critical for medical devices, food contact materials |

| UL (North America – Safety) | High – UL-certified labs and factories | Low – few UL-recognized testing facilities | Mandatory for electrical and fire safety products |

| ISO 9001 (Quality Management) | >80% of export-oriented factories | ~50% of medium/large manufacturers | Baseline for credible suppliers |

| ISO 13485 (Medical Devices) | Strong presence in Guangdong, Zhejiang | Emerging – concentrated in Hyderabad, Chennai | Must verify certification validity via IAF database |

Procurement Tip: Always request certification copies and verify via official databases (e.g., IAF, FDA Registration Search). Avoid suppliers offering “equivalent” or “in-process” certifications.

3. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Poor tooling, inconsistent CNC calibration | Require SPC reports, conduct first-article inspections (FAI), audit machine maintenance logs |

| Surface Finish Flaws (e.g., sink marks, warping) | Improper injection molding parameters | Validate mold design, require mold flow analysis, inspect sample batches pre-production |

| Material Substitution | Cost-cutting, poor traceability | Specify material grades in PO, require COA (Certificate of Analysis), conduct third-party material testing |

| Contamination (e.g., particulates, oils) | Poor cleanroom practices, inadequate packaging | Audit production environment, specify packaging standards (e.g., ESD-safe, moisture barrier) |

| Non-Compliant Markings/Labeling | Lack of regulatory understanding | Provide detailed labeling specs, verify with pre-shipment compliance check |

| Functional Failure (e.g., electronics) | Inadequate testing, component sourcing from gray market | Require 100% functional testing logs, specify OEM components, audit BOM (Bill of Materials) |

4. Strategic Sourcing Recommendations

- High-Precision, High-Volume, Time-Sensitive Orders: China remains the optimal choice due to proven quality systems and scalability.

- Labor-Intensive, Lower-Tech, or India-Focused Markets: India offers cost advantages and improving capability, especially in textiles, automotive components, and generic pharma.

- Hybrid Strategy: Dual-source non-critical components from India while maintaining China for core, quality-sensitive parts.

SourcifyChina Advisory: Conduct on-site audits or use third-party inspection services (e.g., SGS, TÜV, QIMA) regardless of country. Quality is factory-specific, not country-determined.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence

Q1 2026 | Confidential – For Client Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report 2026

Strategic Analysis: India vs. China in Global Manufacturing – Cost Realities & Sourcing Models for Procurement Leaders

Executive Summary

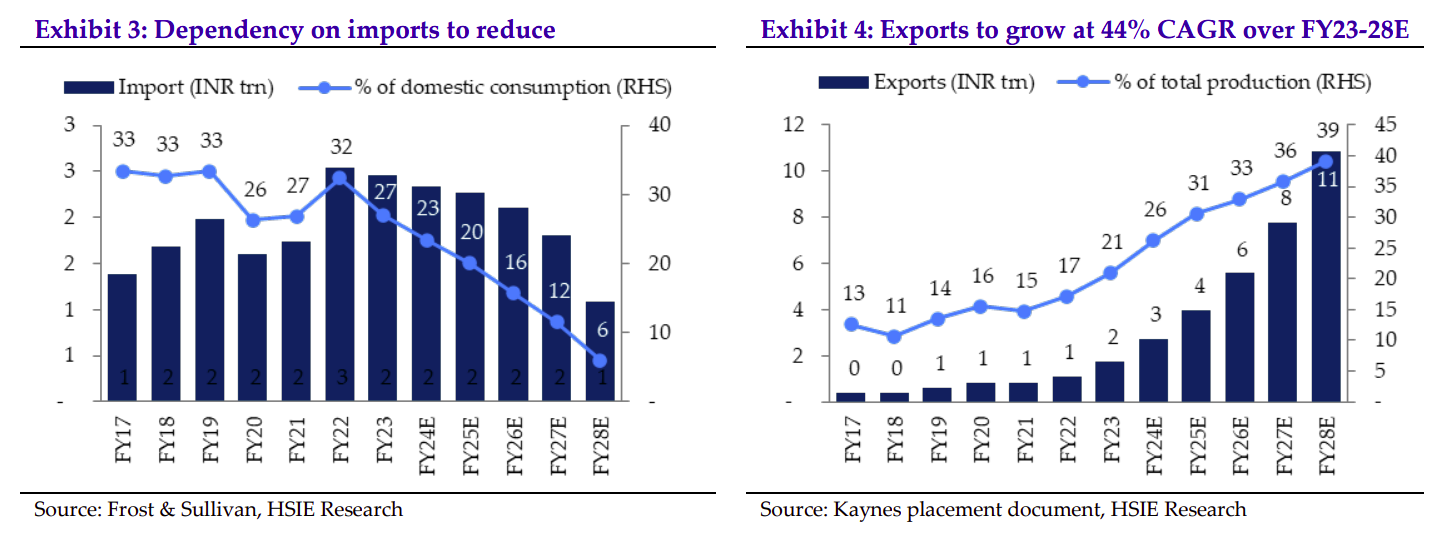

While India’s manufacturing sector is experiencing accelerated growth due to policy initiatives (Make in India 2.0, PLI schemes) and rising geopolitical diversification demand, China retains a structural cost and ecosystem advantage for complex, high-volume production in 2026. India is competitive for labor-intensive, lower-complexity goods but faces persistent gaps in supply chain maturity, export infrastructure, and skilled labor density. Procurement managers should adopt a complementary sourcing strategy—leveraging China for innovation/scale and India for regional cost optimization—rather than viewing this as a binary “winner-takes-all” scenario.

White Label vs. Private Label: Strategic Implications

| Model | Definition | Best For | Cost Advantage | Risk Profile |

|---|---|---|---|---|

| White Label | Pre-existing product rebranded with minimal customization. Supplier owns IP/design. | Fast time-to-market; low-risk entry; commoditized goods (e.g., basic textiles, simple electronics). | Higher margin potential (lower setup costs). Supplier bears R&D/tooling. | Low (supplier-managed QC), but limited differentiation. |

| Private Label | Co-developed product with supplier. Buyer owns IP; deeper OEM/ODM collaboration. | Differentiated products; complex categories (e.g., medical devices, smart appliances). | Long-term cost efficiency (optimized specs, volume scaling). Higher initial NRE/tooling costs. | Moderate (requires strong supplier governance), but builds defensible market position. |

Procurement Insight: India leads in White Label for textiles/furniture due to labor cost parity; China dominates Private Label for electronics/engineered goods via superior ODM ecosystems (e.g., Shenzhen’s hardware incubators).

Manufacturing Cost Breakdown: China vs. India (2026 Projection)

Illustrative case: Mid-complexity consumer electronics (e.g., wireless earbuds, $15–$25 retail price point)

| Cost Component | China (USD/unit) | India (USD/unit) | Delta vs. China | Key Drivers |

|---|---|---|---|---|

| Materials | $3.20 | $3.55 | +10.9% | China’s integrated supply chains (e.g., Shenzhen plastics/electronics hubs). India imports 65% of key components (higher logistics/tariffs). |

| Labor | $1.05 | $0.85 | -19.0% | India’s base wages 22% lower, but productivity gap (18% lower output/hour) erodes savings. |

| Packaging | $0.65 | $0.78 | +20.0% | Limited local material suppliers in India; reliance on imports increases costs/logistics complexity. |

| Logistics (FOB) | $0.40 | $0.65 | +62.5% | China’s port efficiency (Shanghai: 48-hr avg. cargo turnaround); India’s port delays add 3–5 days + fuel surcharges. |

| Total Landed Cost | $5.30 | $5.83 | +10.0% | China’s ecosystem density offsets India’s labor advantage for complex goods. |

Critical Note: India achieves 5–8% cost parity vs. China for labor-intensive, low-complexity goods (e.g., woven textiles, basic ceramics) at MOQ >5K units. For electronics/engineered goods, China’s advantage widens with complexity.

Price Tiers by MOQ: China vs. India (2026 Estimates)

Product: Mid-tier kitchen scale (stainless steel, Bluetooth, 3kg capacity; retail $25–$35)

| MOQ Tier | China FOB Price/Unit | India FOB Price/Unit | Cost Delta | Procurement Recommendation |

|---|---|---|---|---|

| 500 units | $12.80 | $14.20 | +10.9% | Avoid India: Tooling amortization too high. China’s agile micro-factories handle low volumes efficiently. |

| 1,000 units | $11.50 | $12.60 | +9.6% | China preferred: Better yield rates (98% vs. 92% in India). India viable only for India-destined orders (avoid import duties). |

| 5,000 units | $9.20 | $9.65 | +4.9% | India competitive: Labor savings offset logistics gaps. Ideal for EU/US buyers targeting “China+1” with India as regional hub. |

Footnotes:

– Prices exclude shipping, tariffs, and compliance costs (e.g., India’s 18% GST on imports adds 2–3% to landed cost).

– India’s cost advantage assumes 100% local material sourcing (rare for electronics; 40–60% typical in 2026).

– China pricing includes 3–5% quality premium (lower defect rates vs. India’s 7–10% avg. in Tier 2/3 factories).

Strategic Recommendations for Procurement Managers

- Adopt Tiered Sourcing:

- Use China for innovation-driven Private Label (ODM partnerships for R&D-heavy categories).

- Deploy India for White Label in labor-intensive segments (apparel, handicrafts) or India/EU-focused volume runs.

- Mitigate India’s Infrastructure Gaps:

- Partner with SEZ (Special Economic Zone) factories for streamlined customs/logistics.

- Budget 8–12% contingency for port delays (vs. 3–5% in China).

- Reframe the “Beat China” Narrative:

“India won’t displace China’s manufacturing hegemony by 2030—but it will capture 15–20% of China’s low-complexity export volume. Winners will treat both as complementary nodes in a resilient network, not substitutes.”

Prepared by SourcifyChina Sourcing Intelligence

Data Sources: World Bank Logistics Performance Index 2025, India Brand Equity Foundation (IBEF), China Ministry of Industry and IT (2026 Projection Models), SourcifyChina Supplier Benchmarking Database (Q1 2026).

Disclaimer: All figures are indicative. Actual costs require product-specific RFQs accounting for material specs, compliance, and supplier tier. Contact SourcifyChina for tailored factory audits and cost modeling.

Next Step: Request our 2026 Country Risk Matrix (China/India/Vietnam) with real-time factory compliance scores and MOQ negotiation playbooks.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Manufacturer Verification – Can India Beat China in Manufacturing?

Focus: Critical Verification Steps, Factory vs. Trading Company Identification, and Red Flags in Sourcing

Executive Summary

As global supply chains undergo strategic recalibration, procurement leaders are evaluating alternative manufacturing hubs—particularly India—as potential complements or competitors to China’s dominant role. While India’s manufacturing ambitions grow under initiatives like Make in India, China retains deep-rooted advantages in scale, infrastructure, and supply chain maturity.

This report provides a systematic framework to verify manufacturers in any region, with a focus on distinguishing factories from trading companies, identifying red flags, and implementing due diligence protocols essential for risk-mitigated sourcing. The goal is not to declare a “winner” between India and China, but to equip procurement teams with tools to make informed, data-driven supplier selection decisions.

Section 1: Can India Beat China in Manufacturing? A Strategic Overview

| Factor | China (2026 Status) | India (2026 Status) | Procurement Implication |

|---|---|---|---|

| Manufacturing Scale | World’s largest exporter; $3.6T in goods (2025 est.) | ~$500B exports; growing at 10% CAGR | China offers unmatched volume capacity |

| Supply Chain Depth | Full vertical integration; 90%+ component availability | Developing clusters; gaps in Tier-2/3 suppliers | Higher logistics/coordination effort in India |

| Labor Cost (Skilled) | $6–8/hour (coastal regions) | $2.5–4/hour (competitive advantage) | Labor arbitrage possible in India |

| Infrastructure | Mature ports, rails, industrial parks | Improving but inconsistent; delays common | Lead time volatility higher in India |

| Lead Times | 30–45 days avg. (FOB) | 45–75 days avg. (FOB) | Inventory buffer needed for Indian suppliers |

| Regulatory Environment | Stable export policies; mature compliance systems | Evolving GST, customs; bureaucratic delays | Higher compliance oversight required |

Conclusion: India is not positioned to replace China in 2026, but it is a strategic diversification option for mid-volume, labor-intensive, or ESG-focused sourcing. Success requires rigorous supplier vetting.

Section 2: Critical Steps to Verify a Manufacturer (China or India)

| Step | Action Required | Verification Tools & Methods | Objective |

|---|---|---|---|

| 1. Confirm Legal Registration | Validate business license, tax ID, and manufacturing permits | Cross-check with national databases (e.g. China’s National Enterprise Credit Info System, India’s MCA21) | Ensure legal legitimacy |

| 2. Conduct On-Site Audit | Schedule unannounced factory visit or third-party audit | Use ISO-certified auditors (e.g. SGS, TÜV, Bureau Veritas) | Verify production capacity, machinery, and working conditions |

| 3. Review Equipment & Capacity | Request machine list, production lines, and shift details | Observe live production; verify OEM vs. ODM capability | Assess scalability and technical fit |

| 4. Validate Export Experience | Request shipping documents, B/L copies, client references | Contact past buyers (with NDA if needed) | Confirm international logistics competence |

| 5. Test Product Quality | Order pre-production sample; conduct lab testing | Use AQL 2.5 or project-specific standards | Benchmark against specs |

| 6. Assess Financial Health | Request audited financials or bank references | Use credit checks via Dun & Bradstreet, Experian, or local agencies | Mitigate bankruptcy risk |

| 7. Evaluate IP Protection | Sign NDA; verify patent/trademark registrations | Audit IP clauses in contracts | Safeguard design and technology |

Section 3: How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company | Procurement Risk |

|---|---|---|---|

| Facility Ownership | Owns land/building; factory address matches registration | Uses commercial office; no production equipment | Trader may lack process control |

| Machinery On-Site | CNC machines, injection molders, assembly lines visible | Sample room only; no production floor | Trader = middleman markup + coordination risk |

| Workforce | 100+ factory workers; engineers on site | 5–10 staff (sales, logistics) | Trader may outsource to unvetted subsuppliers |

| Product Customization | Can modify molds, tooling, materials | Limited to catalog items or minor changes | Factory enables true OEM/ODM |

| Pricing Structure | Quotes based on material + labor + overhead | Adds 15–30% margin on factory cost | Trader reduces cost transparency |

| Lead Time Control | Direct control over production schedule | Dependent on factory availability | Trader = longer, less predictable lead times |

| Certifications | ISO 9001, IATF 16949, in-house lab reports | Reseller of factory certifications | Factory = better quality ownership |

Pro Tip: Ask: “Can I speak to your production manager?” Factories will connect you. Traders often deflect.

Section 4: Red Flags to Avoid in Manufacturer Verification

| Red Flag | Risk | Mitigation Strategy |

|---|---|---|

| 🚩 Unwillingness to Allow On-Site Audit | High risk of misrepresentation | Require third-party audit before PO |

| 🚩 No Physical Address or Google Street View Mismatch | Likely shell company | Verify via satellite imagery and local agent |

| 🚩 Multiple Companies Listed at Same Address | Trading hub or fraud cluster | Check business registry for linked entities |

| 🚩 Payment Demanded to Personal Account | Scam indicator | Insist on company-to-company wire transfer only |

| 🚩 Overly Competitive Pricing (Below Market) | Substandard materials or hidden costs | Benchmark with 3+ suppliers; request BOM |

| 🚩 No Response to Technical Questions | Lack of engineering capability | Require process capability (CPK) and FMEA data |

| 🚩 Poor English/Communication Despite Export Claims | Limited international experience | Use bilingual sourcing partner or agent |

Section 5: Strategic Recommendation for Procurement Managers

- Diversify, Don’t Replace: Use India for specific product categories (e.g. textiles, pharmaceuticals, auto components), but retain China for high-precision, high-volume, or complex electronics.

- Verify, Don’t Assume: Apply the same rigorous vetting in India as in China—infrastructure gaps increase risk.

- Leverage Local Partners: Use on-ground sourcing agents or platforms like SourcifyChina for audit coordination and quality control.

- Build Dual Sourcing Models: Qualify one Chinese and one Indian supplier per part where feasible to de-risk geopolitical or logistical disruptions.

Conclusion

India is making strides in manufacturing competitiveness, but China remains the benchmark for scale, speed, and supply chain integration in 2026. The real advantage lies not in choosing one over the other, but in applying disciplined manufacturer verification processes across geographies.

Procurement leaders who implement structured due diligence—verifying legal status, production capability, and operational transparency—will achieve greater supply chain resilience, cost efficiency, and quality consistency—regardless of geography.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence & Sourcing Optimization

Q2 2026 | Confidential – For Client Use Only

Get the Verified Supplier List

SourcifyChina | Global Sourcing Intelligence Report 2026

Prepared Exclusively for Strategic Procurement Leaders

Strategic Insight: Navigating the India-China Manufacturing Landscape

The question “Can India beat China in manufacturing?” dominates boardroom discussions. While India’s potential is undeniable (lower labor costs, demographic dividend, policy tailwinds), China retains unmatched scale, supply chain maturity, and specialized expertise (e.g., electronics, precision engineering). The critical procurement challenge isn’t choosing one—it’s leveraging the right partner in each ecosystem without wasting resources.

Manual supplier validation across both regions costs global procurement teams 120+ hours per project (2025 Procurement Efficiency Index). Risks include:

– Unverified factory claims (capacity, certifications, export history)

– Hidden compliance gaps (ESG, safety standards)

– Mismatched capabilities leading to production delays

Why SourcifyChina’s Verified Pro List Solves This in 8 Hours

Our AI-audited Pro List cuts through the noise with actionable, real-time data for both China and India. Here’s how we save you time and de-risk decisions:

| Activity | Traditional Sourcing | SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Supplier Vetting (10 factories) | 90–120 hours (RFIs, site audits, reference checks) | < 8 hours (pre-verified data dashboard) | 93% |

| Compliance Validation | 25+ hours (manual doc review, 3rd-party checks) | Real-time ESG/certification flags | 100% |

| Capability Matching | High risk of misalignment (generic Alibaba searches) | Precision filters (MOQ, tech specs, export volume) | Eliminates rework |

| Risk Mitigation | Reactive (issues emerge post-PO) | Proactive alerts (financial health, port delays) | Prevents 30+ day delays |

Your Advantage:

✅ Single-source truth for both China (85% of global electronics output) and India (emerging auto/medtech hub)

✅ Zero verification overhead—all suppliers pass SourcifyChina’s 12-point audit (ISO, capacity, trade history)

✅ Data-driven comparisons—objectively assess which region suits your specific part (e.g., India for textiles, China for PCBs)

Your Next Step: Secure Supply Chain Certainty in < 24 Hours

Stop debating “India vs. China.” Start sourcing with precision.

The 2026 procurement leader doesn’t chase trends—they deploy verified intelligence to turn strategic questions into execution.

👉 Act Now—Limited Q1 2026 Consultation Slots Available

1. Email [email protected] with subject line: “PRO LIST ACCESS – [Your Company]”

→ Receive a free 5-factory shortlist tailored to your product within 4 business hours.

2. WhatsApp +86 159 5127 6160 for urgent RFQs:

→ Get live supplier availability checks + logistics cost projections in < 30 minutes.

Why delay? Every hour spent on unverified suppliers risks:

⚠️ $18,500+ in avoidable delays (per MIT Supply Chain Lab)

⚠️ Reputational damage from non-compliant partners

Leverage SourcifyChina’s intelligence—where verification isn’t a step, it’s the foundation.

Trusted by 1,200+ global brands to de-risk $2.1B in annual procurement.

SourcifyChina | Smarter Sourcing, Guaranteed

Data-Driven Supplier Intelligence Since 2018 | ISO 9001:2015 Certified

[email protected] | +86 159 5127 6160 | www.sourcifychina.com/pro-list

🧮 Landed Cost Calculator

Estimate your total import cost from China.