The global fumed silica market, a segment in which Cabosil M5 is a leading product due to its high purity and performance in applications such as thickening agents, rheology control, and reinforcement in polymers, is experiencing steady growth. According to Grand View Research, the global fumed silica market size was valued at USD 1.47 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This growth is driven by increasing demand from end-use industries such as electronics, adhesives and sealants, coatings, and silicone rubber—sectors where high-performance grades like Cabosil M5 are critically utilized. As manufacturers continue to innovate and scale production to meet rising global demand, identifying the top producers of this essential specialty chemical becomes vital for procurement and supply chain strategy. Based on production capacity, global reach, product consistency, and market presence, the following eight manufacturers stand out as leaders in the production of Cabosil M5 and equivalent fumed silica products.

Top 8 Cabosil M5 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

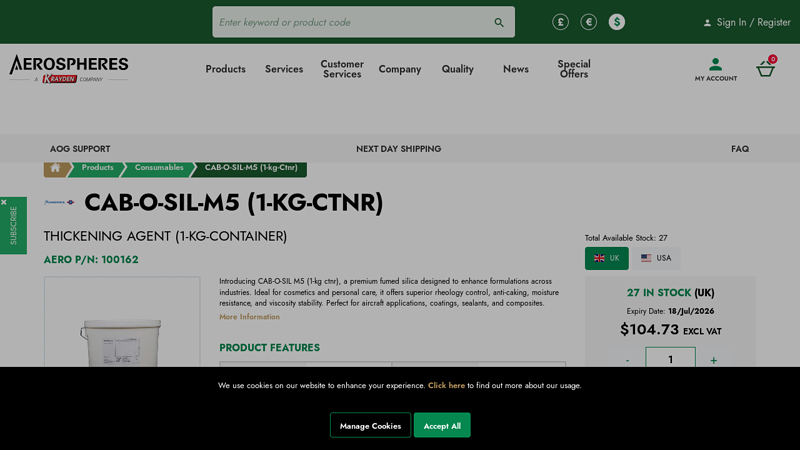

#1 Cab

Domain Est. 1997

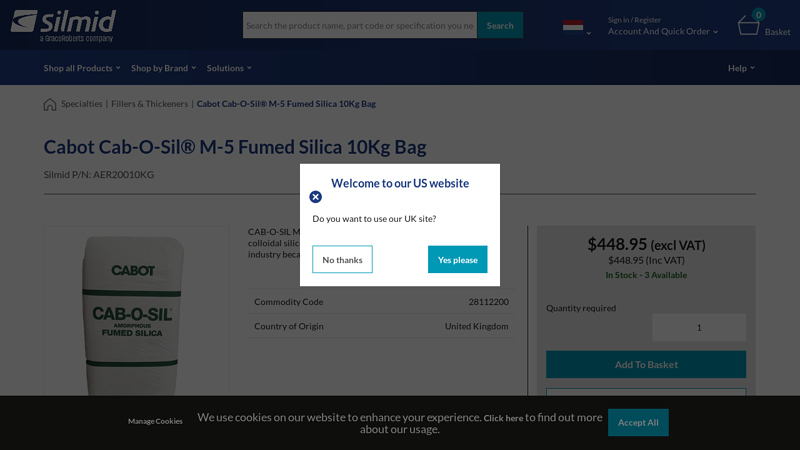

#2 Cabot Cab

Domain Est. 1999

Website: silmid.com

Key Highlights: Cabot CAB-O-SIL M-5 is untreated fumed silica. It is available to buy from Silmid online as a 10kg bag. Bulk discounts are available….

#3 “fumed” silica

Domain Est. 2000

#4 Cabot Cab

Domain Est. 2000

#5 CAB

Domain Est. 2000

#6 CAB

Domain Est. 2014

Website: ulprospector.com

Key Highlights: CAB-O-SIL® M-5 is a untreated medium surface fumed silica that provides thickening, thixotrophic, and anti-settling behavior in liquid systems….

#7 CAB

Domain Est. 2018

Website: univarsolutions.com

Key Highlights: In stock $1,075.40 deliveryCAB-O-SIL® M-5 fumed silica is a medium surface fumed silica which enables a significant increase in viscosity in liquid systems, free flow of powders an…

#8 Cabot Cab

Domain Est. 2019

Website: gracoroberts.com

Key Highlights: CAB-O-SIL M-5 untreated fumed silica is a synthetic, amorphous, colloidal silicon dioxide that is generally regarded as unique in industry….

Expert Sourcing Insights for Cabosil M5

H2 2026 Market Trends for Cabosil M5

As of the second half of 2026, the market for Cabosil M5, a fumed silica (pyrogenic silica) product manufactured by Cabot Corporation, is being shaped by several key industry dynamics, technological advancements, and macroeconomic factors. Cabosil M5 is widely used as a reinforcing agent, thickener, and anti-caking agent across industries such as paints and coatings, adhesives and sealants, personal care, pharmaceuticals, and specialty polymers. Below is an analysis of the prevailing market trends influencing its demand, pricing, and application landscape during H2 2026.

1. Increased Demand in High-Performance Coatings

The global push toward sustainable and durable infrastructure has driven growth in the high-performance coatings sector. In H2 2026, Cabosil M5 continues to be a preferred rheology modifier in solvent-based and powder coatings due to its ability to prevent pigment settling and improve scratch resistance. With rising construction and industrial maintenance activities in Asia-Pacific and the Middle East, demand for premium coatings has surged, directly boosting Cabosil M5 consumption.

2. Expansion in Electronics and Semiconductor Applications

Fumed silica is increasingly critical in encapsulants, thermal interface materials, and electronic adhesives. In H2 2026, the semiconductor and 5G infrastructure buildouts—particularly in Taiwan, South Korea, and the U.S.—have intensified the need for high-purity additives like Cabosil M5. Its role in enhancing thermal stability and reducing viscosity in electronic potting compounds has made it indispensable in advanced packaging technologies.

3. Sustainability Pressures and Green Manufacturing

Environmental regulations across Europe and North America are pushing formulators to reduce VOC emissions and improve recyclability. Cabosil M5 is gaining favor as a non-toxic, inorganic thickener that enables low-VOC formulations without sacrificing performance. In response, Cabot Corporation has introduced a “Green M5” variant—produced using lower-carbon energy sources—which is seeing adoption in eco-certified products, particularly in personal care and architectural coatings.

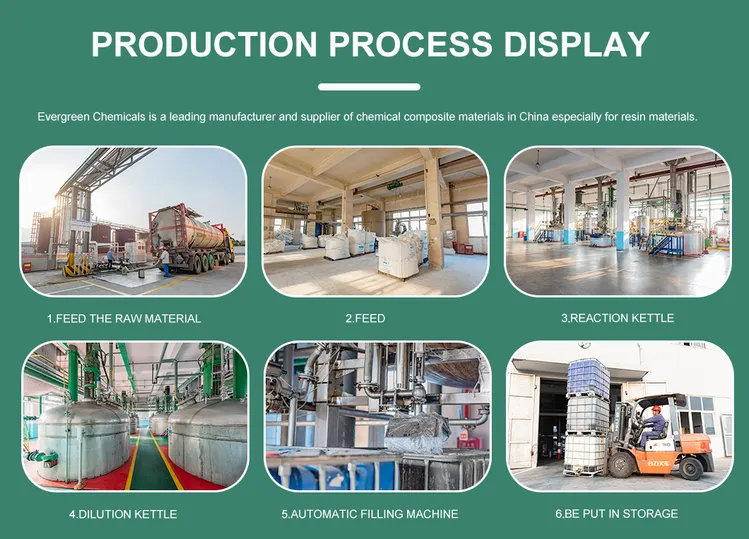

4. Supply Chain Resilience and Regional Production Shifts

Ongoing geopolitical tensions and supply chain reconfiguration efforts have prompted diversification of sourcing. In H2 2026, Cabot has expanded fumed silica production capacity at its facility in China to serve the Asia-Pacific market more efficiently, reducing reliance on trans-Pacific shipments. This localized production is helping stabilize supply and mitigate price volatility for Cabosil M5 in the region.

5. Competition from Alternative Silicas

Despite its performance advantages, Cabosil M5 faces growing competition from precipitated silica and silica gels, especially in cost-sensitive markets. However, in high-end applications where surface area, purity, and consistency are critical (e.g., pharmaceuticals and optical fibers), Cabosil M5 maintains a dominant position. Innovation in hybrid silica systems may challenge its market share over the long term, but for now, M5 remains the benchmark.

6. Pricing Trends and Raw Material Costs

Energy prices—particularly natural gas, a key input in the fumed silica production process—have remained elevated in H2 2026 due to constrained supplies in Europe and increased industrial demand in Asia. As a result, Cabot has implemented moderate price increases (3–5%) for Cabosil M5, passed through via contractual adjustments. Customers are absorbing these costs due to lack of viable substitutes in critical applications.

7. Digitalization and Customized Solutions

Cabot is leveraging digital tools to offer application-specific support, including rheology modeling and formulation optimization platforms. In H2 2026, customers in the adhesives and composites sectors are increasingly using Cabot’s online technical service portal to tailor Cabosil M5 usage for new product development, accelerating time-to-market.

Conclusion

In the second half of 2026, Cabosil M5 remains a high-value additive in performance-driven industries. While facing cost and competitive pressures, its unmatched technical properties ensure sustained demand. Strategic moves by Cabot—such as regional capacity expansion, sustainability initiatives, and digital customer engagement—are positioning Cabosil M5 for continued market leadership in the fumed silica segment. The outlook remains positive, with steady growth projected in electronics, advanced materials, and green chemistry applications.

Common Pitfalls When Sourcing Cab-O-Sil M5: Quality and Intellectual Property Concerns

When sourcing Cab-O-Sil M5, a high-purity fumed silica widely used in pharmaceuticals, cosmetics, electronics, and specialty chemicals, buyers often encounter critical challenges related to quality consistency and intellectual property (IP) protection. Being aware of these pitfalls is essential to maintaining product performance and regulatory compliance.

Quality-Related Pitfalls

1. Inconsistent Product Specifications

One of the most frequent issues is receiving material that does not meet the tight specifications expected of genuine Cab-O-Sil M5. Key parameters such as surface area (typically ~200 m²/g), pH (3.6–4.6), moisture content, and particle size distribution are critical for performance. Off-spec material from non-authorized suppliers can lead to formulation instability, poor dispersion, or failure in end-use applications.

2. Contamination and Impurity Risks

Fumed silica is highly sensitive to moisture and contamination. Unreliable suppliers may lack proper handling, packaging, or storage facilities, leading to compromised material (e.g., clumping, hydration, or metallic impurities). This is especially problematic in sensitive applications like parenteral drug formulations or semiconductor manufacturing.

3. Lack of Certifications and Traceability

Genuine Cab-O-Sil M5 from Cabot Corporation comes with full regulatory support, including Certificates of Analysis (CoA), compliance with USP/NF, EP, and JP standards (where applicable), and full batch traceability. Sourcing from third parties often means missing or falsified documentation, increasing regulatory risk during audits or inspections.

Intellectual Property and Sourcing Risks

1. Misrepresentation and Trademark Infringement

“Cab-O-Sil M5” is a registered trademark of Cabot Corporation. Unauthorized suppliers may sell generic fumed silica under this name, misleading buyers into believing they are purchasing the authentic product. This not only violates IP rights but also exposes the buyer to legal and supply chain liability.

2. Reverse Engineering and IP Exposure

When sourcing alternatives due to supply constraints, companies may inadvertently disclose sensitive formulation or process information to less reputable vendors. This increases the risk of reverse engineering or unauthorized use of proprietary knowledge, especially in emerging markets with weaker IP enforcement.

3. Supply Chain Transparency Gaps

Many distributors or brokers claiming to supply Cab-O-Sil M5 may not be authorized partners of Cabot Corporation. This lack of transparency makes it difficult to verify origin, increasing the risk of counterfeit or diverted goods entering the supply chain.

Best Practices to Avoid Pitfalls

- Purchase directly from Cabot Corporation or authorized distributors to ensure authenticity and traceability.

- Verify CoAs and regulatory documentation with Cabot’s customer service when in doubt.

- Conduct supplier audits and request evidence of authorization to distribute Cab-O-Sil products.

- Protect IP by limiting technical disclosures and using NDAs when evaluating alternative sources.

- Test incoming material using standardized methods (e.g., BET surface area, pH, loss on ignition) to confirm compliance.

By proactively addressing these quality and IP-related pitfalls, companies can safeguard their formulations, maintain regulatory compliance, and protect their intellectual property when sourcing Cab-O-Sil M5.

H2: Logistics & Compliance Guide for Cabosil M5

Cabosil M5, a fumed silica produced by Cabot Corporation, is widely used as a thickening agent, reinforcing filler, and free-flow agent in various industrial applications, including adhesives, coatings, cosmetics, and pharmaceuticals. Proper logistics handling and regulatory compliance are essential to ensure safety, maintain product quality, and meet legal requirements.

H2: Packaging and Storage

- Packaging Types:

Cabosil M5 is typically supplied in: - 10 kg multi-wall paper bags with inner polyethylene liner

- 750 kg or 800 kg super sacks (big bags)

-

100 kg fiber drums with liners (for specialty applications)

-

Storage Conditions:

- Store in a dry, cool, and well-ventilated area.

- Keep containers tightly closed when not in use to prevent moisture absorption.

- Avoid exposure to high humidity, as fumed silica is hygroscopic.

- Shelf life is typically 24 months from the date of manufacture when stored properly.

H2: Transportation and Handling

- Transport Classification:

- Not classified as hazardous under DOT, ADR, IATA, or IMDG regulations.

- UN number: Not applicable (non-hazardous for transport).

-

Proper shipping name: “Silica, fumed” or “Amorphous silica, fumed”

-

Handling Precautions:

- Use local exhaust ventilation or wear appropriate respiratory protection (e.g., N95 mask) when handling in poorly ventilated areas to avoid inhalation of fine dust.

- Minimize dust generation during transfer or pouring.

-

Use grounded equipment to prevent static discharge, which may disperse dust.

-

Loading and Unloading:

- Handle packages with care to avoid tearing or puncturing.

- Use appropriate material handling equipment (e.g., forklifts for big bags).

- Ensure loading areas are clean and dry to prevent contamination.

H2: Regulatory Compliance

- GHS Classification (Globally Harmonized System):

- Not classified as flammable, toxic, or reactive.

- May cause respiratory irritation (H335: May cause respiratory irritation).

- May cause eye irritation (H319: Causes serious eye irritation).

-

Label elements typically include:

- Pictograms: Exclamation mark

- Signal word: Warning

- Precautionary statements (e.g., P261: Avoid breathing dust/fume/gas/mist/vapors/spray)

-

REACH (EU Regulation):

- Registered under REACH (Registration, Evaluation, Authorization and Restriction of Chemicals).

-

No SVHC (Substances of Very High Concern) listed for Cabosil M5.

-

TSCA (USA):

-

Listed on the TSCA Inventory – compliant for commercial use in the United States.

-

FDA Compliance:

-

Certain grades of fumed silica (including M5) are FDA-compliant for use in food contact applications (21 CFR 175.300, 178.3725) and cosmetics.

-

RoHS & REACH SVHC:

- Complies with RoHS directives when applicable.

- No restricted substances above threshold levels.

H2: Safety and Personal Protection

- Personal Protective Equipment (PPE):

- Safety goggles or face shield

- Dust mask or respirator (NIOSH-approved)

- Protective gloves (nitrile or similar)

-

Long-sleeved clothing to minimize skin contact

-

First Aid Measures:

- Inhalation: Move to fresh air. If breathing is difficult, seek medical attention.

- Eye Contact: Rinse thoroughly with water for at least 15 minutes. Consult a physician.

- Skin Contact: Wash with soap and water.

- Ingestion: Rinse mouth. Do not induce vomiting. Seek medical advice if discomfort occurs.

H2: Environmental and Disposal Considerations

- Environmental Impact:

- Low toxicity to aquatic life.

-

Not classified as environmentally hazardous.

-

Disposal:

- Dispose of in accordance with local, regional, and national regulations.

- Can typically be landfilled as non-hazardous waste if uncontaminated.

- Avoid release into drains or waterways.

H2: Documentation and Traceability

- Required Documentation:

- Safety Data Sheet (SDS) – always available from supplier

- Certificate of Analysis (CoA) – upon request

-

Certificate of Compliance (CoC) – confirms adherence to specifications and regulations

-

Batch Traceability:

- Each batch is labeled with a unique lot number.

- Retain packaging labels and documentation for traceability.

H2: Supplier and Support Information

-

Primary Manufacturer:

Cabot Corporation

Website: www.cabotcorp.com

Contact: Regional customer service or technical support teams -

Regional Compliance Support:

Coordinate with local Cabot representatives for regulatory updates, SDS, and compliance verification in specific markets (e.g., EU, USA, Asia).

Adhering to this logistics and compliance guide ensures safe and legal handling, transport, and use of Cabosil M5 across global supply chains. Always refer to the latest Safety Data Sheet and consult with Cabot Corporation for application-specific guidance.

Conclusion for Sourcing Cab-O-Sil M5

After a comprehensive evaluation of the sourcing options for Cab-O-Sil M5 (fumed silica produced by Cabot Corporation), the following key points support the decision:

-

Consistent Quality and Performance: Cab-O-Sil M5 remains the industry benchmark for high-purity fumed silica, offering excellent thickening, anti-settling, and rheology control properties across various applications, including adhesives, coatings, cosmetics, and silicone rubber.

-

Supplier Reliability: Direct sourcing from Cabot Corporation or authorized distributors ensures product authenticity, technical support, batch traceability, and compliance with global quality standards.

-

Availability and Lead Times: While Cab-O-Sil M5 is widely available globally, securing long-term supply agreements can mitigate risks associated with market volatility, logistics delays, and raw material shortages.

-

Cost Consideration: Although Cab-O-Sil M5 is priced at a premium, its high performance and low usage levels often justify the investment compared to lower-cost alternatives that may compromise product quality.

-

Regulatory Compliance: Cab-O-Sil M5 meets key international standards (e.g., FDA, REACH, USP/NF), making it suitable for sensitive applications in pharmaceuticals and food contact materials.

-

Alternatives Assessment: While equivalent grades from other manufacturers (e.g., Aerosil 200) exist, switching requires extensive requalification and process validation, which may offset cost savings.

Final Recommendation: Proceed with sourcing Cab-O-Sil M5 from authorized channels to ensure product consistency, reliability, and regulatory compliance. Establish strategic inventory planning and maintain relationships with multiple approved suppliers to enhance supply chain resilience.