The global shielded twisted pair (STP) cable market is experiencing steady expansion, driven by increasing demand for high-speed data transmission, growing adoption in enterprise networks, and the proliferation of data centers. According to Mordor Intelligence, the global STP cable market was valued at approximately USD 9.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 6.2% from 2024 to 2029. This growth is fueled by the rising deployment of 5G networks, smart infrastructure, and industrial automation, all of which require reliable, interference-resistant cabling solutions. As organizations across sectors prioritize network performance and security, STP cables—offering superior electromagnetic interference (EMI) protection compared to UTP counterparts—have become a critical component in modern data infrastructure. With this demand surge, a select group of manufacturers are leading innovation, scalability, and quality in the STP cable space. Below, we highlight the top 8 cable STP manufacturers shaping the industry through technological advancement, global reach, and strong market presence.

Top 8 Cable Stp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ProX 300 Ft STP Cat 6 Cable W

Domain Est. 2013

Website: proxdirect.com

Key Highlights: ProX XC-CAT6-300 is a Shielded Twisted Pair (STP) Category 6 cable for touring sound and permanent installations, Audio/Video stage technology, and DMX systems….

#2 GlobalCable

Domain Est. 2021

Website: stpglobalcable.com

Key Highlights: STP Global Cable LLC is one of the largest producers of cable and electrical equipment products in the region. LLC operates within the STP Group of Companies….

#3 Simpson Strong

Domain Est. 1995

Website: strongtie.com

Key Highlights: Welcome to the Simpson Strong-Tie homepage showcasing our resources, products and services designed to help people build safer, stronger structures….

#4 Ethernet Cables Explained

Domain Est. 1996

Website: tripplite.eaton.com

Key Highlights: Network cables are divided into categories based mainly on bandwidth (measured in MHz), maximum data rate (measured in megabits per second) and shielding….

#5 Category 6 Cable

Domain Est. 1997

Website: belden.com

Key Highlights: Belden offers several Category 6 performance levels, including our REVConnect 3600 System cable with premium performance offering significant headroom….

#6 STI Firestop

Domain Est. 1997

Website: stifirestop.com

Key Highlights: STI is the global leader in developing perimeter fire barrier systems for sealing the void area between a fire-rated floor and non-rated exterior wall….

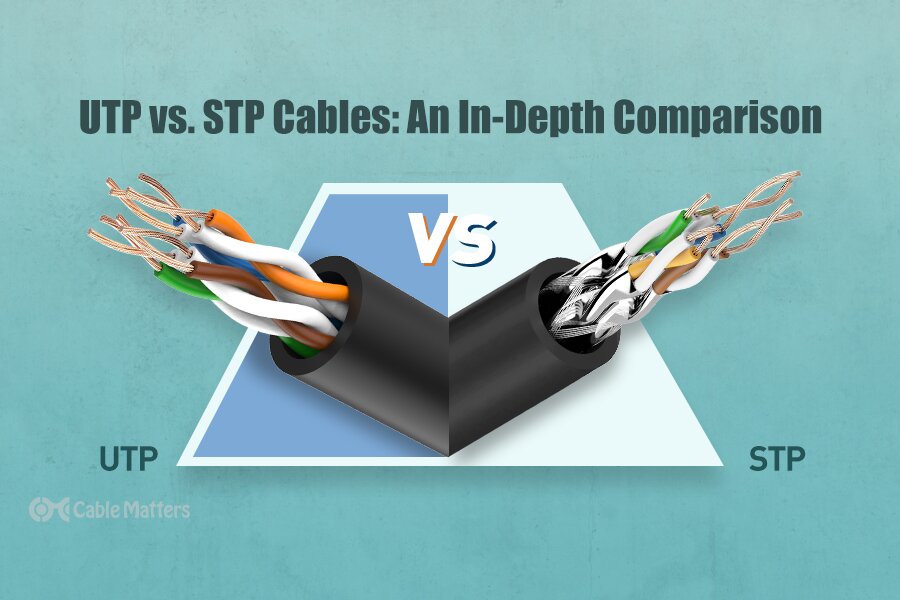

#7 What does UTP, S/UTP, FTP, STP and SFTP mean?

Domain Est. 2001

Website: universalnetworks.co.uk

Key Highlights: We’ve put together this handy guide to help you understand the meaning of some of the most common terms. The shielding inside your cable acts as a barrier to ……

#8 STP

Domain Est. 2019

Website: stp.mx

Key Highlights: Descubre cómo STP simplifica tus pagos y transferencias con tecnología avanzada y seguridad. Optimiza tus operaciones financieras hoy….

Expert Sourcing Insights for Cable Stp

H2 2026 Market Trends Analysis for Shielded Twisted Pair (STP) Cable

As we approach the second half of 2026, the global market for Shielded Twisted Pair (STP) cable is undergoing notable transformation, driven by technological advancements, evolving infrastructure demands, and shifting industry standards. Below is a detailed analysis of key trends shaping the STP cable market during this period.

-

Rising Demand in Industrial and Enterprise Environments

STP cables continue to gain traction in industrial automation, manufacturing, and high-performance enterprise networks due to their superior electromagnetic interference (EMI) protection compared to Unshielded Twisted Pair (UTP) cables. In H2 2026, industries such as automotive, aerospace, and energy are increasingly deploying STP cabling in control systems and data networks to ensure signal integrity in electrically noisy environments. -

Growth in Data Center Modernization

With data centers upgrading to support higher bandwidth applications (including AI workloads and real-time analytics), there is a renewed emphasis on reliable, low-latency connectivity. STP cables—particularly Category 6A, 7, and 8—are being adopted in structured cabling systems to support 10 Gbps to 40 Gbps transmission speeds. The demand is particularly strong in private and hybrid cloud infrastructures where security and performance are paramount. -

Expansion of Smart Buildings and IoT Integration

The proliferation of smart building technologies—such as integrated security systems, HVAC controls, and occupancy sensors—is driving the need for robust cabling solutions. STP cables are favored in these environments for their resilience to interference from wireless signals and power lines. H2 2026 sees increased deployment of STP in commercial real estate and smart campuses, especially in regions with stringent electromagnetic compatibility (EMC) regulations. -

Regional Market Shifts

Europe maintains a strong preference for STP cables due to strict EMC standards (e.g., EU EMC Directive). In contrast, North America is gradually increasing STP adoption, particularly in high-security government and financial institutions. Meanwhile, APAC markets like China, Japan, and South Korea are investing heavily in intelligent infrastructure, creating new growth opportunities for STP manufacturers. -

Material and Design Innovations

Manufacturers are responding to sustainability demands with eco-friendly STP cable designs—using low-smoke zero-halogen (LSZH) jackets and recyclable shielding materials. Additionally, miniaturized and flexible STP variants are emerging to support compact industrial devices and edge computing nodes. These innovations are expected to reduce total cost of ownership and improve installation efficiency. -

Competitive Pressure from Fiber Optics and Wireless

Despite its advantages, STP faces competition from fiber optic cabling in long-distance, high-bandwidth applications and from Wi-Fi 6E/7 in mobile and flexible office setups. However, STP remains cost-effective for short-range, high-interference environments, ensuring its relevance in hybrid network architectures. -

Supply Chain and Pricing Trends

In H2 2026, the STP market is experiencing stabilized raw material costs (especially copper and aluminum) following earlier volatility. Increased regional manufacturing in Southeast Asia and Eastern Europe is improving supply resilience and reducing lead times. Pricing remains competitive, with a shift toward value-added services such as pre-terminated solutions and certification support.

Conclusion

The STP cable market in H2 2026 is characterized by steady growth, driven by demand for reliable, secure, and high-performance connectivity in specialized environments. While alternative technologies continue to evolve, STP maintains a strategic position in industrial, enterprise, and smart infrastructure applications. Vendors who focus on innovation, compliance, and sustainability are best positioned to capitalize on these trends.

Common Pitfalls Sourcing Shielded Twisted Pair (STP) Cable

Sourcing high-quality Shielded Twisted Pair (STP) cable is critical for ensuring reliable, high-performance data transmission, especially in electrically noisy environments. However, several common pitfalls can compromise network integrity and lead to costly issues down the line. Being aware of these challenges helps in making informed procurement decisions.

Poor Cable Quality and Material Substitution

One of the most frequent issues when sourcing STP cable is receiving substandard products that do not meet specified performance standards. Some suppliers may use inferior materials, such as copper-clad aluminum (CCA) instead of pure copper conductors, which increases resistance and reduces signal integrity. Low-grade shielding materials (e.g., aluminum foil without a drain wire or inadequate braid coverage) can fail to provide effective electromagnetic interference (EMI) protection. Always verify compliance with recognized standards such as ISO/IEC 11801 or ANSI/TIA-568 and request test reports or certifications.

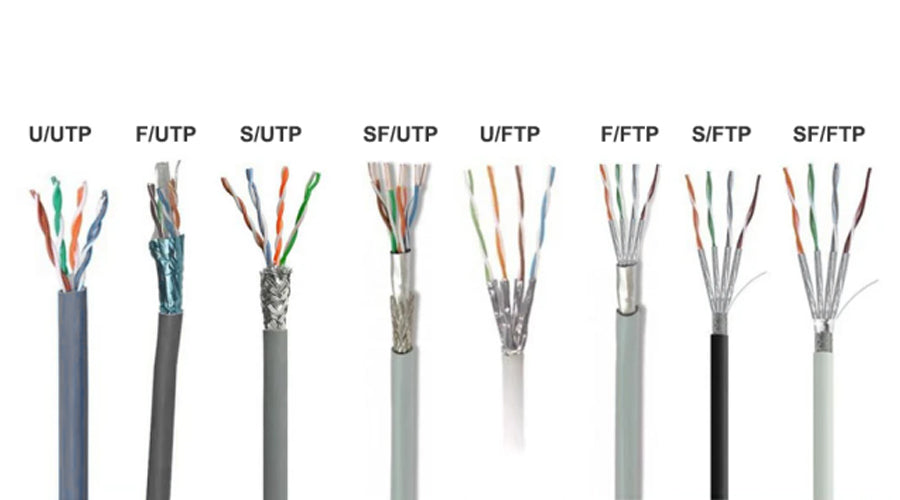

Inadequate or Misrepresented Shielding (Shielding Effectiveness)

STP cables rely on proper shielding to block EMI, but not all shielding is created equal. Pitfalls include cables advertised as “shielded” but actually using only foil (FTP) without braid, or offering inconsistent braid coverage (e.g., less than 85%). Poorly constructed shields can degrade performance, especially at higher frequencies. Ensure the cable type matches the environment—for example, use S/FTP (braided shield + foil per pair) in high-interference areas—and confirm shielding effectiveness through independent testing data.

Lack of IP (Ingress Protection) Rating for Outdoor or Harsh Environments

When deploying STP cables outdoors, in industrial settings, or in areas exposed to moisture and dust, an appropriate IP rating is crucial. A common mistake is sourcing standard STP cables without environmental protection, leading to water ingress, corrosion, and premature failure. Look for cables with suitable IP ratings (e.g., IP66 or IP67) and additional features like UV-resistant jackets, gel filling, or armored sheathing. Verify that both the cable and connectors maintain the IP rating when installed.

Non-Compliance with Industry Standards and Certification

Using STP cables that do not comply with relevant performance categories (e.g., Cat 6A, Cat 7, or Cat 8) can result in failed certification tests and unreliable network performance. Some low-cost suppliers may mislabel cables or provide counterfeit certifications. Always demand legitimate documentation such as UL listing, ETL verification, or third-party test reports. Ensure the cable supports the required bandwidth and transmission distance for your application.

Inconsistent Performance and Batch Variability

Lower-tier manufacturers may exhibit significant performance variation between production batches. This inconsistency can cause intermittent network issues that are difficult to diagnose. To avoid this, source from reputable manufacturers with strict quality control processes and consider performing batch sampling and testing before full deployment.

Poor Connector and Termination Compatibility

STP cables require proper grounding and termination to function correctly. A common oversight is using connectors or jacks not designed for shielded cables, which breaks the shield continuity and renders shielding ineffective. Ensure that patch panels, outlets, and plugs are specifically rated for STP and support proper grounding via connection to grounded racks or grounding buses.

Cost-Cutting Leading to Long-Term Expenses

While lower upfront costs may be tempting, sourcing substandard STP cable often leads to higher total cost of ownership due to network downtime, re-cabling, and troubleshooting. Investing in high-quality, certified STP cable from trusted suppliers pays off through improved reliability, compliance, and longevity.

Logistics & Compliance Guide for Cable STP

Overview of Shielded Twisted Pair (STP) Cable

Shielded Twisted Pair (STP) cable is a type of copper cabling used in data communication networks. It features individual wire pairs wrapped in metallic foil or braided shielding to reduce electromagnetic interference (EMI), making it ideal for environments with high electrical noise. Proper logistics and compliance management are essential to ensure product integrity, regulatory adherence, and efficient supply chain operations.

Packaging Requirements

Proper packaging is critical to prevent damage during transportation and storage. Follow these guidelines:

- Reels and Drums: STP cables must be shipped on manufacturer-approved reels or drums to avoid kinking, twisting, or crushing.

- Protective Wrapping: Use moisture-resistant, UV-protected outer wrapping when shipping in non-climate-controlled environments.

- Labeling: Clearly label packaging with product type, length, gauge, shielding type (e.g., foil + braid), and compliance markings (e.g., UL, ETL, RoHS).

- End Protection: Seal cable ends with protective caps to prevent moisture ingress and contamination.

Transportation Guidelines

Ensure safe and compliant transportation of STP cable products:

- Handling: Use mechanical handling equipment (e.g., forklifts, pallet jacks) for reels weighing over 25 kg (55 lbs). Never roll reels on their side unless designed for it.

- Loading: Secure reels vertically on pallets or horizontally with proper blocking to prevent rolling.

- Temperature Control: Avoid exposure to extreme temperatures. Store and transport between -10°C to 50°C (14°F to 122°F) unless otherwise specified by the manufacturer.

- Moisture Protection: Prevent exposure to rain or high humidity; use sealed containers or covered trucks.

Storage Conditions

Maintain optimal storage conditions to preserve cable performance:

- Environment: Store in a dry, well-ventilated, indoor area away from direct sunlight.

- Temperature: Ideal storage range: 0°C to 35°C (32°F to 95°F).

- Stacking: Do not stack reels more than two high unless designed for it. Use level, stable pallets.

- Shelf Life: Most STP cables have a shelf life of 5–10 years when stored properly. Check manufacturer specifications.

Regulatory Compliance

Ensure all STP cables meet relevant international and regional standards:

Safety Standards

- UL 444 / CSA CM/CMX: Required for plenum, riser, and general-purpose cables in North America.

- IEC 61156 Series: International standard for multicore and symmetrical pair/quad cables.

- EN 50575: EU regulation for cables in construction (CE marking required under CPR – Construction Products Regulation).

Environmental Compliance

- RoHS (EU Directive 2011/65/EU): Restricts use of hazardous substances (e.g., lead, mercury, cadmium).

- REACH (EC 1907/2006): Requires disclosure of Substances of Very High Concern (SVHC).

- Conflict Minerals (Dodd-Frank Act, Section 1502): Ensure sourcing of tin, tantalum, tungsten, and gold does not fund conflict zones.

Fire Safety Ratings

- Plenum (CMP): For air-handling spaces; low smoke and flame spread.

- Riser (CMR): For vertical shafts between floors.

- LSZH (Low Smoke Zero Halogen): Required in confined spaces (e.g., subways, tunnels); emits minimal smoke and no toxic halogens when burned.

Import/Export Documentation

Ensure full compliance with international trade regulations:

- Commercial Invoice: Include full product description, HS code (e.g., 8544.49 for insulated telecommunication cables), value, origin, and Incoterms.

- Certificate of Conformity (CoC): Required in many markets (e.g., GCC, Russia) to prove compliance with local standards.

- Bill of Lading/Air Waybill: Accurate shipment details, consignee, and routing.

- Customs Classification: Use correct Harmonized System (HS) codes to avoid delays and penalties.

Quality Assurance & Traceability

- Batch Tracking: Maintain lot numbers and manufacturing dates for traceability.

- Testing Records: Keep documentation of electrical performance tests (e.g., impedance, attenuation, crosstalk) and shield effectiveness.

- Certifications: Retain valid test reports from accredited laboratories (e.g., UL, TÜV, Intertek).

Disposal & Recycling

- Waste Electrical and Electronic Equipment (WEEE Directive 2012/19/EU): STP cables may fall under WEEE; ensure proper end-of-life disposal.

- Recycling Partners: Use certified e-waste recyclers to handle copper and insulation materials responsibly.

Summary

Effective logistics and compliance management for STP cables ensures product reliability, regulatory conformity, and supply chain efficiency. Adherence to packaging, handling, storage, and documentation standards—along with compliance with safety, environmental, and trade regulations—is essential for global distribution. Always consult manufacturer guidelines and local regulations to maintain full compliance.

Conclusion for Sourcing STP Cables

In conclusion, sourcing Shielded Twisted Pair (STP) cables requires a strategic approach that balances performance, cost, and long-term reliability. STP cables offer superior protection against electromagnetic interference (EMI) and crosstalk compared to UTP cables, making them ideal for industrial environments, data centers, and high-noise areas. When sourcing STP cables, it is essential to consider factors such as shielding type (e.g., F/UTP, S/FTP), cable category (e.g., Cat6a, Cat7), compliance with international standards (e.g., ISO/IEC, TIA/EIA), and the reputation of suppliers.

Partnering with certified and experienced manufacturers ensures product quality, consistent performance, and compliance with safety regulations. Additionally, evaluating total cost of ownership—not just upfront pricing—helps in making a sustainable investment. Proper installation and grounding practices must also be emphasized to fully realize the benefits of STP cabling.

Ultimately, a well-informed sourcing strategy for STP cables supports reliable, high-speed data transmission and future-proofs network infrastructure in demanding environments.